The ability to read the electrode markings will help a novice welder choose the right consumables. This skill is necessary for suppliers to select goods purchased for production. The quality of the seam and the cost of the product depend on the correct choice. Let's consider what each letter or number in the marking means, what types of electrodes are available and other details that will be useful in the selection.

- Types of electrodes

- Electrode brands

- Electrode diameter

- Purpose of electrodes

- Coating thickness coefficient

- Index group

- Coverage type

- Spatial position

- Welding current characteristics

Video description

Explanation of electrode designations.

Below we will talk about the classification of electrode elements, their purpose and properties.

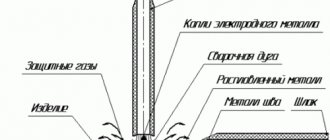

The purpose of the metal rod is to fuse the material being welded to a specific place where the workpiece is joined. The main part of the electrode serves to conduct current through itself. The end of the consumable melts under the influence of the elevated temperature of the welding arc. At the moment of melting of the end of the electrode, a complete product is formed together with the molten structure.

What does a consumable electrode consist of?

The welding electrode has a simple structure. Its main component is the rod; a special coating is made on the outside. The end that melts and comes into contact with the material being welded is made without coating.

Packing

The following can be used as packaging containers:

- plastic boxes;

- boxes made of metal alloys with a sealing function;

- carton boxes; to preserve the rods, this type of container is packaged in polyethylene or shrink film;

- boxes or packs of cardboard are also wrapped in packaging or sack moisture-resistant paper;

- For increased tightness, it is possible to pack materials in bundles wrapped in paper and then packed in polyethylene.

Packs and boxes have the following packaging forms: 1 kg; 5 kg. several packaging options for them

- boxes made of container or corrugated cardboard;

- fiberboard boxes;

- wooden boxes;

- reusable closed-type metal box pallets;

- large wooden boxes.

Each parameter of consumables affects the size of the package and its capacity. Also, all this also depends on the manufacturer, who independently shapes the container.

Important! When purchasing welding electrodes, it is necessary to accurately calculate the number of rods that will be needed to carry out a certain amount of work. If the required value is significantly exceeded, a certain number of electrodes will remain unclaimed. They will have to be stored for a long time and may absorb moisture. Then you will have to carry out calcination procedures; the number of calcinations is limited. Shelf life depends on storage conditions.

[ads-pc-4][ads-mob-4]

Type of rods and explanation of electrode markings

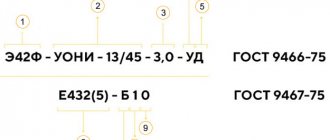

Any container in which welding rods are packaged has an alphanumeric coding, for example: E50A-UONI – 13/55 – 5.0 – UD / E514 (4) – B20

Marking of rods Source bsm21.ru

Electrodes, their markings

The first digits of the designation in our illustrative example indicate the type of rod. E50A - consumables that can be used for welding steel reinforced and non-reinforced metal. To make the abbreviation easier to understand, it is recommended to break it down into its components:

- E - rod is used for welding on an arc machine.

- 50 is the maximum value of the connection strength.

In our sample, this parameter is 50 kgf per 1 sq. mm.

- A – the joint has load toughness and good flexibility.

From this sample it is clear that it is possible to understand the decoding of the electrodes; it cannot be considered a difficult task. If you have an explanation at hand of what the digital and alphabetic signs mean, any beginner will understand.

What are they intended for, areas of application, for welding what steels

The material of welding wire Sv-08 MR electrodes with low carbon content limits the use of this filler material for manual arc welding of steels with a carbon content of no more than 0.25%. The mechanical characteristics of which, namely, the tensile strength of the structures being welded, should not exceed 46 kgf/sq. mm. Only such steels will have a high-quality weld when using MR grade electrodes.

The wide applicability of low-carbon and carbon steels in various fields of industry and construction contributes to the widespread use of MP grade electrodes . Their high arc stability and easy re-ignition make them popular among welding beginners. Professionals guarantee high-quality welds on critical structures and often use MR electrodes for tack welding followed by the use of electrodes with a basic coating.

Welding rods: types and characteristics

To work with reinforced products, you need rods coded “E” and hardness codes indicated by numbers: 38, 42, 46, 50, 55, 60, 70, 85, 100, 125, 150; 42A, 46A, 50A.

In the case when it is necessary to connect types of steel products that are resistant to thermal effects, consumables coded E-09 and E-10 are used. Many types of electrodes are suitable for welding high-alloy metal, their number is more than 40. The most commonly chosen electrodes are: E-12X13, E-06X13N, E-10X17T, E-12X11NMF, E-12X11NMF.

To connect materials with previously known characteristics, the following electrodes are used: E-10G2, E-12G4, E-10G3, E-16G2KhM, E-15G5, E-30G2KhM, the total number of types is 38.

Interpretation of welding electrodes

In an illustrative example, there is a UONI encoding - 13/55, which characterizes the brand of electrode. It is described in detail in the GOST section. Sometimes there is a designation patented by the manufacturer. Products of the OK group from the ESAB manufacturing brand are labeled in this way.

Electrode OK-46, d 3.0 ZAO ESAB-SVEL St. Petersburg Source molotok43.ru

Rod diameter

When deciphering the electrode markings, you can find digital symbols showing the cross-section of the consumable in mm. In the specified sample, this parameter is 5 mm. Based on this value, you need to know an important circumstance: the greater the thickness of the material being welded, the higher this parameter should be.

Purpose

In the representative sample, the letter “U”, placed almost at the end of the marking, indicates the choice of a consumable suitable for welding work with structures made of unreinforced steel raw materials, having a hardness limit of about 60 kgf per 1 mm2. When it is necessary to work with metal products with other parameters, then other symbols must be used, for example, “L”. Other letters:

- “B” is used for welding work on workpieces characterized by unusual qualities.

- "N" - for surfacing.

The letter "T" indicates that the rods are suitable for welding heat-resistant metal products.

Coating density parameter

The next letter after U is the letter code D, located in the representative sample, indicating how thick the coating layer is made. In our case, this layer is quite thick. In addition to D, the electrodes also have other letters: “M” - a slightly thick surface, closer to thin, “C” - medium size, “G” - impressive thickness.

Electrodes by thickness Source userdocs.ru

Rutile coating

The most common representatives of this type of electrodes are LEZ MR-3S, ANO-4, OZS-4. It is worth noting that this coating has more significant advantages.

The use of such consumables ensures a high-quality result even if the workpiece has various defective formations and corrosion spots. Also, the quality is not affected by humidity levels. Often the elements are used to work with 09GS steel and high-carbon materials.

There is one drawback associated with the silicon oxide content in the composition. Because of this, the formed seam has reduced impact strength and reduced flexibility. In the marking system, the coating is designated as follows:

- according to GOST 9466-75 and ISO “P” and R, respectively, according to the old GOST 9467-60

T (rutile).

In this case, the formed slag is easy to remove. This in turn further improves the quality of welding work.

Manufacturers of welding electrodes

The Russian consumables market offers a wide selection of electrodes produced by domestic manufacturers. The technological capacity of production allows us to meet the needs of individuals and enterprises in various fields of activity.

Russian electrode manufacturers are divided into 3 categories:

- Large production facilities that supply the bulk of customers with materials.

- .

- Small businesses that manufacture products to meet their own needs.

We list several manufacturing companies producing electrodes:

- SVEL - Altai welding electrode plant.

A modern facility producing a wide range of coated products.

- Belorechensky electrode.

Welding materials are produced in accordance with state standards, and the products are certified.

- "Electrode-Boron".

Manufactures universal welding electrodes.

The products of Russian manufacturers are in demand in various fields of activity and are actively purchased not only in stores in our country, but also abroad.

Types of welding materials

Electrodes used in manual arc welding are divided into:

- Non-melting.

They are made from different types of materials that differ in their refractoriness: tungsten, graphite, coal. Designed to ignite and maintain the welding arc. The joints between the workpieces are filled with additives created by manually applying a consumable that melts.

- Melting.

This type of electrode melts during welding operations on the surface of the structure. Made from steel, cast iron, copper or other metal. The specific type of raw material depends on the material. The rod performs the function of an additive and also plays the role of a cathode or anode. There are electrodes coated and uncoated.

Storage rules

Have you ever used a welding machine?

It happened! It didn’t happen

The main problem encountered during storage is high air humidity. The electrode coating quickly absorbs moisture, making it impossible to work with such filler material. The only way to correct the situation is to calcinate the welding electrodes.

For this, there are special ovens or portable canisters with heating elements. At home, it is recommended to store packages open (without polyethylene) at a temperature of 20-22 degrees, relative humidity 40-50%.

Wet electrodes can cause pores to appear on the surface and inside the seam, and an increase in metal spattering will also be observed.

To correctly select welding electrodes, you need to have a good understanding of what alloy you need to work with.

You should also carefully prepare the additive itself and the surfaces to be welded for the operation:

- Remove dirt and rust.

- Heat the electrodes.

- Set the welding current correctly.

If the technology is followed, you can count on obtaining seams with the characteristics specified by the electrode manufacturer.

According to welding current parameters

Rods with a cross section of 4 mm. are selected for welding on simple welding devices. They are also used on the most productive and powerful units.

The length of this consumable is 35 and 45 cm. Suitable for welding thin workpieces up to 1 cm. Operates at a current of 220A. Welding consumables with a cross section from 5 to 12 mm. used only in welding work in the presence of additional lighting created by powerful lighting installations.

Aluminum rod FoxWeld AL Мg 5 (ER-5356) 1.6 mm 5 kg Source yandex.ru

What is the difference, what is the difference between MR and ANO, USENI, OZS, OK

Electrodes of brands MR, ANO, OZS and have a rutile coating. This determines their similarity in the features of welding technology . However, some specific modifications for specific welding jobs may have minor differences from other brands of rutile-coated electrodes.

Electrode MR-3S

The UONI brand of electrodes has a basic coating, which makes the difference with MR brand electrodes very significant :

- the properties of rutile coating differ in their effect on the welding process from the main coating;

- unlike MR, which are used both on direct current and alternating current, UONI brand electrodes can only be welded on direct current of reverse polarity;

- MR requires much less preparation of the surface of the materials being welded than SSSI;

- SSSI is many times more sensitive to moisture than MR.

Which ones are better for the inverter and in other situations

The electrode brand does not play a decisive role in choosing an inverter or other welding equipment. It is important that the characteristics of the additive match the capabilities of the device. The main thing is to choose the right filler material for the materials being welded.