Corrosion is the spontaneous destruction of metal surfaces under the influence of the interaction of the metal with the environment. Especially manifesting itself at increased mechanical and temperature stresses, corrosion processes cause great damage to steel structures. Correctly assessing the corrosion rate means increasing the durability of the product.

Definition of corrosion

Metal materials under chemical or electrochemical influence of the environment are subject to destruction, which is called corrosion.

Corrosion of metals is caused by redox reactions, as a result of which metals become oxidized and lose their properties, which renders metal materials unusable.

There are 3 signs that characterize corrosion:

- Corrosion is, from a chemical point of view, a redox process.

- Corrosion is a spontaneous process that occurs due to the instability of the thermodynamic system metal - environmental components.

- Corrosion is a process that develops mainly on the surface of the metal. However, it is possible that corrosion can penetrate deep into the metal.

Popular message topics

- Primitive Zoo

Hunting was the most important activity for primitive people. They hunted wild horses, goats, deer, cave bears, and mammoths. It also happened that the female became the prey, in which case people took the small cubs for themselves. - Celasia Flower

Definition of Celosia plant: Annual, up to 1 m tall, bare, branched stems, reddish in color. Petiolate leaf up to 3 cm long. The upper part is narrowed into a wedge shape. The inflorescence is dense and resembles a spikelet. - Zhaleika is a musical instrument

. Zhaleika is a wind musical instrument. It is common among Slavic peoples. At first it was an instrument used by shepherds to call cows and goats. Shepherds were very respected, and when he passed near the house,

Types of metal corrosion

The most common types of metal corrosion :

- Uniform – covers the entire surface evenly

- Uneven

- Electoral

- Local stains – individual areas of the surface are corroded

- Ulcerative (or pitting)

- Spot

- Intercrystalline - spreads along the boundaries of a metal crystal

- Cracking

- Subsurface

Main types of metal corrosion

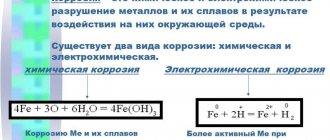

From the point of view of the mechanism of the corrosion process, two main types of corrosion can be distinguished: chemical and electrochemical.

Electrochemical corrosion of metals

Electrochemical corrosion of metals is the process of destruction of metals in the environment of various electrolytes, which is accompanied by the appearance of an electric current inside the system.

With this type of corrosion, an atom is removed from the crystal lattice as a result of two coupled processes :

- Anodic - metal in the form of ions goes into solution.

- Cathode – the electrons formed during the anodic process are bound by a depolarizer (the substance is an oxidizing agent).

The process of removing electrons from the cathode sites is called depolarization , and substances that promote removal are called depolarizers.

The most common corrosion of metals is with hydrogen and oxygen depolarization .

Hydrogen depolarization

Hydrogen depolarization is carried out at the cathode during electrochemical corrosion in an acidic environment :

2H++2e— = H2 discharge of hydrogen ions

2H3O++2e— = H2 + 2H2O

Oxygen depolarization

Oxygen depolarization is carried out at the cathode during electrochemical corrosion in a neutral environment :

O2 + 4H++4e— = H2O reduction of dissolved oxygen

O2 + 2H2O + 4e— = 4OH—

All metals, in their relation to electrochemical corrosion, can be divided into 4 groups, which are determined by the values of their standard electrode potentials:

- Active metals (high thermodynamic instability) are all metals in the range of alkali metals - cadmium (E0 = -0.4 V). Their corrosion is possible even in neutral aqueous environments in which there is no oxygen or other oxidizing agents.

- Metals of medium activity (thermodynamic instability) are located between cadmium and hydrogen (E0 = 0.0 V). In neutral environments, in the absence of oxygen, they do not corrode, but are subject to corrosion in acidic environments.

- Low-active metals (intermediate thermodynamic stability) - are located between hydrogen and rhodium (E0 = +0.8 V). They are resistant to corrosion in neutral and acidic environments in which there is no oxygen or other oxidizing agents.

- Noble metals (high thermodynamic stability) - gold, platinum, iridium, palladium. They can be subject to corrosion only in acidic environments in the presence of strong oxidizing agents.

Types of electrochemical corrosion

Electrochemical corrosion can occur in various environments. Depending on the nature of the environment, the following types of electrochemical corrosion are distinguished:

- Corrosion in electrolyte solutions - in solutions of acids, bases, salts, in natural water.

- Atmospheric corrosion - in atmospheric conditions and in any humid gas environment. This is the most common type of corrosion.

For example, when iron interacts with environmental components, some of its sections serve as the anode, where iron oxidation occurs, and others serve as the cathode, where oxygen reduction occurs:

A: Fe – 2e— = Fe2+

K: O2 + 4H+ + 4e— = 2H2O

The cathode is the surface where the oxygen flow is greater.

- Soil corrosion - depending on the composition of the soil, as well as its aeration, corrosion can occur more or less intensely. Acidic soils are the most aggressive, while sandy soils are the least.

- Aeration corrosion occurs when there is uneven access of air to different parts of the material.

- Marine corrosion - occurs in sea water due to the presence of dissolved salts, gases and organic substances in it .

- Biocorrosion - occurs as a result of the activity of bacteria and other organisms that produce gases such as CO2, H2S, etc., which contribute to metal corrosion.

- Electrocorrosion - occurs under the influence of stray currents in underground structures, as a result of the work of electric railways, tram lines and other units.

Mechanisms of occurrence and development of corrosion phenomena

Since most steel surfaces operate in an environment of certain humidity, as well as in water, aqueous solutions of salts, acids and alkalis, the predominant mechanism of rust formation is electrolytic. The only exception is furnace corrosion, which occurs in metal structures of heating devices: there, surface destruction occurs due to the formation of high-temperature rust - scale.

Electrolytic

During electrolytic corrosion in the presence of oxygen, a hydration reaction of steel iron occurs, the final product of which is iron oxide hydrate Fe(OH)2. This phenomenon is called anodic type corrosion. But the process does not end there. Iron oxide hydrate is an unstable substance and, in the presence of water (or water vapor), quite quickly decomposes into various iron oxides:

- at elevated temperatures, iron oxide FeO is formed predominantly,

- at room temperature or slightly higher – iron oxide Fe2O3,

- at intermediate temperatures (in the temperature range +250...+450°C) – magnetic iron oxide Fe3O4.

In any case, the surface of the steel rusts, only indicators of this phenomenon can be either reddish-brown or grayish-yellow.

Methods of protection against metal corrosion

The main method of protecting metal from corrosion is the creation of protective coatings - metallic, non-metallic or chemical.

Metal coatings

A metal coating is applied to the metal that needs to be protected from corrosion with a layer of another metal that is resistant to corrosion under the same conditions. If the metal coating is made of a metal with a more negative potential (more active) than the one being protected, then it is called an anodic coating . If the metal coating is made of a metal with a more positive potential (less active) than the one being protected, then it is called a cathodic coating .

For example, when applying a layer of zinc to iron, if the integrity of the coating is compromised, the zinc acts as an anode and will be destroyed, while the iron is protected until all the zinc is used up. The zinc coating in this case is anodic .

The cathode coating to protect the iron may, for example, be copper or nickel. If the integrity of such a coating is violated, the protected metal is destroyed.

Non-metallic coatings

Such coatings can be inorganic (cement mortar, glassy mass) and organic (high molecular weight compounds, varnishes, paints, bitumen).

Chemical coatings

In this case, the protected metal is subjected to chemical treatment in order to form a corrosion-resistant film of its compound on the surface. These include:

oxidation – production of stable oxide films (Al2O3, ZnO, etc.);

phosphating – obtaining a protective film of phosphates (Fe3(PO4)2, Mn3(PO4)2);

nitriding – the surface of the metal (steel) is saturated with nitrogen;

steel bluing - the metal surface interacts with organic substances;

carburization – obtaining on the surface of a metal its connection with carbon.

Changes in the composition of technical metal and corrosive environment

Changing the composition of the technical metal also helps to increase the metal's resistance to corrosion. In this case, compounds are introduced into the metal that increase its corrosion resistance.

Changing the composition of the corrosive environment (introducing corrosion inhibitors or removing impurities from the environment) is also a means of protecting the metal from corrosion.

Electrochemical protection

Electrochemical protection is based on connecting the protected structure to the cathode of an external direct current source, as a result of which it becomes the cathode. The anode is scrap metal, which, when destroyed, protects the structure from corrosion.

Protective protection - one of the types of electrochemical protection - is as follows.

Plates of a more active metal, called protector . The protector - a metal with a more negative potential - is the anode, and the protected structure is the cathode. The connection of the protector and the protected structure with a current conductor leads to the destruction of the protector.

Examples of problems with solutions for determining the protective properties of oxide films, determining the corrosion resistance of metals, as well as equations for reactions occurring during electrochemical corrosion of metals are given in the section Problems for the section Corrosion of metals

Categories Corrosion of metals, GENERAL CHEMISTRY

Conditions

Corrosion is the result of the interaction of a metal with oxidizing substances, which include oxygen, hydrogen, acids, and alkalis. The main characteristic of corrosion is the redox reaction. During corrosion, the metal oxidizes, restoring the oxidizing component of the environment.

Rice. 1. Corrosion.

Conditions for the formation of corrosion are:

- the presence of metal - a simple or complex substance (alloy);

- the presence of a corrosive environment - active substances located around the metal and affecting its surface;

- long period of time.

Rust - iron (III) oxide or hydroxide - forms on iron-containing products and has a red color. Objects made of copper acquire a greenish tint when corroded. This is a multi-layered patina, the top layer of which consists of copper (II) carbonate.

Rice. 2. Patina.