Gas-dynamic metal spraying is performed with the aim of imparting the necessary properties to the surfaces of metal and non-metal products. This can be an increase in electrical and thermal conductivity, strength, protection from the effects of corrosion processes, restoration of geometric dimensions, etc. At the same time, depending on the specific task, depending on the metal of the product, the necessary equipment, consumables and spraying technology are selected. Most often, surfaces are subject to metallization, while the applied coating has high adhesion to the material on which it is applied, and the product is mechanically strong. Pure metal powders or mixtures can be sprayed, into which, in addition to the metal component, ceramic powder is introduced in certain quantities. This significantly reduces the cost of powder coating production technology and does not affect its properties.

The essence and purpose of gas dynamic spraying technology

The essence of the cold gas-dynamic spraying method is to apply and fix on the surface of a product or part solid particles of metal or a mixture of materials ranging in size from 0.01 to 50 microns, accelerated to the required speed in air, nitrogen or helium. This material is called powder. These are particles of aluminum, tin, nickel, babbitts of various brands, a mixture of aluminum powder and zinc. The medium used to move the material can be cold or heated to a temperature not exceeding 700 °C.

Upon contact with the surface of the product, a transformation of the plastic type occurs, and the energy of the kinematic type transforms into adhesive and thermal energy, which contributes to the production of a durable surface layer of the metal. The powder can be applied not only to metal surfaces, but also to those made of concrete, glass, ceramics, and stone, which significantly expands the scope of application of the method of creating surfaces with special properties.

Depending on the pressure, the following types of cold gas-dynamic spraying are distinguished:

- high;

- low.

In the first case, helium and nitrogen are used as a working medium that moves powder material ranging in size from 5 to 50 microns. Metal particles, if they move, have a pressure of more than 15 atm. In the second case, compressed air is used, which is supplied under a pressure not exceeding 10 atm. These types also differ in such indicators as heating power and working fluid consumption.

The spraying stages are as follows:

- preparing the surface of the product for spraying using a mechanical or abrasive method;

- heating the working medium (air, nitrogen, helium) to the temperature established in the technological process;

- supplying heated gas to the equipment nozzle along with powder under the required pressure.

As a result, the powder is accelerated in the flow to supersonic speeds and collides with the surface of the part or product. A layer of metal is sprayed with a thickness, the thickness of which depends on the heating temperature of the supplied gas and pressure.

The surface of the product is prepared using an abrasive method using the equipment itself for applying gas-dynamic spraying by simply changing the mode parameters.

The scope of application of this type of spraying is quite extensive. Using the method, they seal leaks in containers and pipelines, repair parts and castings made of light alloys, apply electrically conductive, anti-corrosion and anti-friction coatings, eliminate mechanical damage, and restore seats in bearings.

Impact of Particle Velocity on Coating Quality and Efficiency

- The coating particle has reached the minimum impact speed, which is necessary to excite the mechanism of interaction with the surface of the substrate (processed sample). This so-called “critical speed” affects the properties of the coating material.

- As the impact velocity is higher than the critical velocity, the deformation and quality of particle adhesion increase.

- If the impact velocity is too high (the "erosion rate"), more material is destroyed than added. No coating is formed.

- To form a dense and well-formed coating, the particle impact velocity must be between the critical velocity and the erosion rate.

The main advantages of the method

The advantages of the technology include:

- performing work under any climatic conditions (pressure, temperature, humidity);

- the possibility of using stationary and portable equipment, which in the latter case allows for work to be carried out at the location;

- possibility of applying coating to local areas (defective areas);

- the ability to create layers with different properties;

- the ability to create a layer of the required thickness or different thicknesses in multilayer coatings;

- the process does not affect the structure of the product being sprayed, which is an important advantage;

- safety;

- environmental friendliness.

The disadvantage of this type of spraying is only one fact. The layers can be applied to ductile metals such as copper, zinc, aluminum, nickel and alloys based on them.

Manufacturers from different countries produce stationary and portable equipment for manual and automated application of coatings of varying productivity on different metals.

Individual processing

Each individual material is processed individually.

Material processing requires individual adjustment of gas temperature and pressure. The combination of these two physical parameters determines the particle speed and the quality of the coating. The range of optimal spray velocity, limited by the critical velocity and the erosion rate, is called the deposition range. Within this range, the quality of coating application is influenced by parameters.

Candidates of physical and mathematical sciences O. KLYUEV and A. KASHIRIN.

When the first metal tools appeared, it turned out that, although hard and durable, they often deteriorated under the influence of moisture. As time passed, people created mechanisms and machines, and the more advanced they became, the more difficult conditions their metal parts had to work in. Vibrations and alternating loads, enormous temperatures, radioactive radiation, aggressive chemical environments - this is not a complete list of “tests” to which they are subjected. Over time, people have learned to protect metal from corrosion, wear and other phenomena that shorten the service life of parts. Essentially, there are two approaches to providing such protection: either alloying elements are added to the base metal, which give the alloy the desired properties, or a protective coating is applied to the surface. The operating conditions of machine parts dictate the properties that coatings must have. The technologies for applying them are varied: some are common and relatively uncomplicated, others are very subtle, allowing the creation of coatings with unique properties. And restless engineers continue to invent new coatings and come up with ways to obtain them. The fate of these inventions can be happy if the coating is much superior to its predecessors in useful properties or if the technology provides a significant economic effect. The development of physicists from Obninsk combined both of these conditions.

Metal particles flying at enormous speed upon collision with the substrate are welded to it, and ceramic particles compact the coating (a); stuck ceramic particles are visible on the thin section of the metal layer (b).

Diagram (above) and general view (below) of an apparatus for spraying metal coatings.

Using the device, you can apply coatings in any room and even in the field.

A negative pressure zone appears behind the critical section of the nozzle, and powder is sucked in here. Thanks to this phenomenon, it was possible to simplify the design of the feeder.

Defects in body parts (left) and the result of spraying (right): a - crack in an automatic transmission; b - cavity in the cylinder head.

Tools coated with a layer of copper or aluminum can be used in fire hazardous areas: when they hit metal objects, they do not create a spark.

TEMPERATURE PLUS SPEED

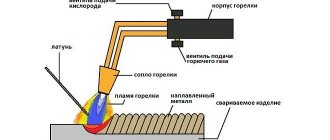

Of the methods for metallizing surfaces in modern technology, the most commonly used are galvanic deposition and immersion in a melt. Vacuum deposition, vapor deposition, etc. are used less frequently. The closest thing to the development of Obninsk physicists is gas-thermal metallization, when the applied metal is melted, sprayed into tiny droplets and transferred to a substrate with a gas stream.

Metal is melted with gas torches, electric arcs, low-temperature plasma, inductors and even explosives. Accordingly, metallization methods are called flame spraying, electric arc and high-frequency metallization, plasma and detonation gas spraying.

In the flame spraying process, a metal rod, wire or powder is melted and sprayed in the flame of a burner operating on a mixture of oxygen and flammable gas. In electric arc metallization, the material is melted by an electric arc. In both cases, metal droplets are moved to the sprayed substrate by air flow. In plasma spraying, a plasma jet generated by plasmatrons of various designs is used to heat and spray the material. Detonation gas spraying occurs as a result of an explosion that accelerates metal particles to enormous speeds.

In all cases, particles of the sprayed material receive two types of energy: thermal - from the heating source and kinetic - from the gas flow. Both of these types of energy are involved in the formation of the coating and determine its properties and structure. The kinetic energy of particles (with the exception of the detonation-gas method) is small compared to thermal energy, and the nature of their connection with the substrate and among themselves is determined by thermal processes: melting, crystallization, diffusion, phase transformations, etc. Coatings are usually characterized by good adhesive strength to the substrate (adhesion) and, unfortunately, low uniformity, since the spread of parameters across the cross section of the gas flow is large.

Coatings created using gas-thermal methods have a number of disadvantages. These include, first of all, high porosity, unless, of course, the goal is to specifically make the coating porous, as in some parts of radio tubes. In addition, due to the rapid cooling of the metal on the surface of the substrate, high internal stresses arise in the coating. The workpiece inevitably heats up, and if it has a complex shape, it can “lead.” Finally, the use of flammable gases and high temperatures in the work area complicate measures to ensure worker safety.

The detonation-gas method stands somewhat apart. During an explosion, the particle speed reaches 1000-2000 m/s. Therefore, the main factor determining the quality of the coating is their kinetic energy. Coatings are characterized by high adhesion and low porosity, but explosive processes are extremely difficult to control, and the stability of the result is almost impossible to guarantee.

SPEED PLUS TEMPERATURE

The desire to create more advanced technology has been around for a long time. The engineers had a goal - to preserve the advantages of traditional technologies and get rid of their shortcomings. The direction of the search was more or less obvious: firstly, coatings should be formed mainly due to the kinetic energy of metal particles (the particles should not be allowed to melt: this will prevent heating of the part and oxidation of the substrate and coating particles), and, secondly, the particles should acquire high speed not due to explosion energy, as in the detonation-gas method, but in a jet of compressed gas. This method was called gas-dynamic.

The first calculations and experiments showed that it is possible to create coatings with quite satisfactory characteristics in this way if helium is used as the working gas. This choice was explained by the fact that the gas flow speed in a supersonic nozzle is proportional to the speed of sound in the corresponding gas. In light gases (hydrogen was not considered due to its explosiveness) the speed of sound is much higher than in nitrogen or air. It is helium that would accelerate metal particles to high speeds, giving them kinetic energy sufficient to attach to the target. It was believed that the use of heavier gases, including air, was doomed to failure.

The work of experimental sputtering installations gave good results: particles from most industrially used metals, accelerated in a helium jet, adhered well to the substrate, forming dense coatings.

But the engineers were not completely satisfied. It was clear that equipment using light gases would inevitably be expensive and could only be used in enterprises that produce high-tech products (only there there are lines with compressed helium). And compressed air lines are available in almost every workshop, every car service center, and repair shops.

Numerous experiments with compressed air seemed to confirm the worst expectations of the developers. However, intensive search allowed us to find a solution. Coatings of satisfactory quality were obtained when the compressed air in the chamber in front of the nozzle was heated, and fine ceramics or hard metal powder was added to the metal powder.

The fact is that when heated, the air pressure in the chamber increases in accordance with Charles’s law, and therefore the flow rate from the nozzle also increases. Metal particles that have gained enormous speed in a gas stream are softened when they hit the substrate and welded to it. Ceramic particles play the role of microscopic sledgehammers - they transfer their kinetic energy to the underlying layers, compacting them, reducing the porosity of the coating.

Some ceramic particles get stuck in the coating, others bounce off it. True, this method produces coatings only from relatively ductile metals - copper, aluminum, zinc, nickel, etc. Subsequently, the part can be subjected to all known methods of mechanical processing: drilling, milling, sharpening, grinding, polishing.

THE MAIN CONDITION IS SIMPLICITY AND RELIABILITY

The efforts of technologists will be in vain if designers cannot create simple, reliable and economical equipment in which the process invented by technologists would be implemented. The basis of the apparatus for spraying metal powders is a supersonic nozzle and a small-sized electric compressed air heater capable of raising the flow temperature to 500-600 o C.

The use of ordinary air as a working gas made it possible to simultaneously solve another problem that faced the developers of light gas systems. We are talking about introducing sprayed powder into a gas stream. To maintain tightness, the feeders had to be installed up to the critical section of the nozzle, that is, the powder had to be fed into a high-pressure area. Purely technical difficulties were aggravated by the fact that, passing through the critical section, metal particles caused wear of the nozzle, worsened its aerodynamic characteristics, and did not allow stabilization of coating application modes. In the design of the apparatus with an air jet, engineers used the principle of a spray gun, known to everyone from school experiments in physics. When a gas passes through a channel of variable cross-section, its speed in a bottleneck increases, and the static pressure drops and may even be below atmospheric pressure. The channel through which the powder came from the feeder was located in just such a place, and the powder moved into the nozzle due to air suction.

As a result, a portable apparatus for applying metal coatings was born. It has a number of advantages that make it very useful in various industries:

to operate the device, you only need an electrical network and an air line or a compressor providing a compressed air pressure of 5-6 atm and a flow of 0.5 m 3 /min;

when applying coatings, the substrate temperature does not exceed 150 o C;

coatings have high adhesion (40-100 N/mm 2) and low porosity (1-3%);

the equipment does not emit harmful substances and radiation;

the dimensions of the device allow it to be used not only in the workshop, but also in the field;

Coatings of almost any thickness can be sprayed.

The installation includes a sprayer itself weighing 1.3 kg, which the operator holds in his hand or secures in a manipulator, an air heater, powder feeders, a unit for monitoring and controlling the operation of the sprayer and feeder. All this is mounted on a rack.

We also had to work hard to create consumables. Industrially produced powders have too large particle sizes (about 100 microns). A technology has been developed that makes it possible to obtain powders with grains of 20-50 microns in size.

FROM SPACE VEHICLES TO SEEDERS

The new method of spraying metal coatings can be used in a wide variety of industries. It is especially effective during repair work, when it is necessary to restore areas of products, for example, to repair a crack or a sink. Thanks to the low temperatures of the process, it is easy to restore thin-walled products that cannot be repaired in any other way, for example by surfacing.

Since the spraying zone has clear boundaries, the sprayed metal does not fall on defect-free areas, and this is very important when repairing parts of complex shapes, such as gearbox housings, engine cylinder blocks, etc.

Sputtering devices are already used in the aerospace and electrical industries, at nuclear power facilities and in agriculture, in auto repair plants and in foundries.

The method can be very useful in many cases. Here are just a few of them.

Restoration of worn or damaged surface areas.

Using spraying, parts of gearboxes, pumps, compressors, lost wax casting molds, and molds for the production of plastic packaging that are damaged during operation are restored. The new method has become a great help for workers at auto repair plants. Now, literally “on their knees,” they repair cracks in cylinder blocks, mufflers, etc. Without any problems, they eliminate defects (cavities, fistulas) in aluminum castings.

Elimination of leaks.

The low gas permeability of coatings makes it possible to eliminate leaks in pipelines and vessels when sealing compounds cannot be used. The technology is suitable for repairing containers operating under pressure or at high and low temperatures: heat exchangers, car radiators, air conditioners.

Application of electrically conductive coatings.

Sputtering makes it possible to apply copper and aluminum films to a metal or ceramic surface. In particular, the method is more cost-effective than traditional methods for copper plating of current-carrying busbars, galvanizing of contact pads on grounding elements, etc.

Anti-corrosion protection.

Films made of aluminum and zinc protect surfaces from corrosion better than paint and varnish and many other metal coatings. The low productivity of the installation does not allow processing large surfaces, but it is very convenient to protect such vulnerable elements as welds. By spraying zinc or aluminum, it is possible to stop corrosion in places where “bugs” appear on the painted surfaces of car bodies.

Restoration of plain bearings.

Babbitt liners are usually used in plain bearings. Over time, they wear out, the gap between the shaft and the bushing increases and the lubricant layer is damaged. Traditional repair technology requires either replacing the liner or welding defects. And spraying allows you to restore the liners. In this case, ceramics cannot be used to compact the layer of sprayed metal. Solid inclusions will cause the bearing to fail within a few minutes after the start of operation, and the surfaces of both the bushings and shaft will be damaged. I had to use a special design nozzle. It allows the coating of pure babbitt to be applied in the so-called thermokinetic mode. Powder particles immediately beyond the critical section of the nozzle are accelerated by a supersonic air flow, then the flow speed sharply decreases to transonic. As a result, the temperature rises sharply, and the particles are heated almost to the melting point. When they hit the surface, they are deformed, partially melt and adhere well to the underlying layer.

NOTE FOR SPECIALISTS

Literature

Kashirin A.I., Klyuev O.F., Buzdygar T.V. Device for gas-dynamic application of coatings from powder materials.

RF patent for invention No. 2100474. 1996, MKI6 S 23 S 4/00, publ. 12/27/97. Bulletin No. 36.

Kashirin A.I., Klyuev O.F., Shkodkin A.V. Method for producing coatings.

RF patent for invention No. 2183695. 2000, MKI7 C 23 C 24/04, publ. 06.20.02. Bull. No. 17.

The contact details of the developers and the conditions for purchasing their technologies or products can be found in the editorial office.

Purchase and sale of business equipment

- home

- Information articles

- Technologies

- “Defense Industry” shared a method for restoring metal products

By the way, Obninsk engineers have already developed several modifications of DIMET installations. Considering the wide demand for this equipment, both manual and automated cold gas dynamic spraying devices are now being mass-produced, which allows them to be used in industry, the oil and gas industry, as well as in small businesses for processing small parts. Moreover, there is nothing particularly complicated in the technology itself. To operate the complex (in addition to the material for spraying), only compressed air is required (supplied at a pressure of 0.6-1.0 MPa and a flow rate of 0.3-0.4 m3/min.) and a 220 V power supply.

Now let's talk about the advantages and disadvantages of the method. Metal spraying equipment from China? Firstly, unlike the gas-thermal method, CGN can be effectively used at normal pressure, in any temperature range and humidity level.

Secondly, it is absolutely environmentally safe. Thirdly, due to its high speed, it can also be used for abrasive cleaning of surfaces. Well, the only drawback of the technology is the ability to apply coatings only from relatively ductile metals, such as copper, aluminum, zinc, nickel, etc.

Equipment used

The apparatus for gas-dynamic metal spraying consists of the following main parts:

- powder containers;

- working fluid supply systems, including a compressed gas cylinder and all the necessary components for it;

- nozzles (as a rule, there are several of them, they are of different configurations and are used for different spraying modes);

- control panel.

In the Russian Federation, high-quality equipment for spraying using the gas-dynamic method is produced by the powder spraying center in Obninsk under the trademark “DIMET”.

It meets the requirements of domestic GOSTs, is certified and protected by patents in many countries, including Russia. The process of repairing a part using gas dynamic spraying is shown in the video:

We ask those who have worked with different types of gas-dynamic spraying equipment and different metals and types of powders to share their experience in the comments to the text and tell us how the surface was prepared and the spraying process itself.

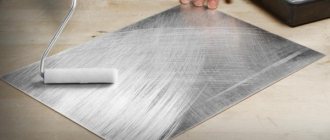

Powder coating

Powder coating of metals with polymer materials is the most effective way to obtain high-quality coatings with decorative or protective properties.

Spray powder is a mixture of rubber and colored pigment. It is applied to the surface using a special electrostatic gun. In this case, the powder acquires a charge, which facilitates effective coupling with the workpiece.

To obtain a high-quality coating, it is necessary to carefully prepare the surface. The essence of the procedure is to clean the workpiece from dirt and traces of corrosion, followed by degreasing.

To use the technology on an industrial scale, special automatic or manual painting lines are used.

Metal spraying is one of the most effective surface modification technologies. Processing allows you to obtain a coating with decorative or protective qualities that increase the performance properties of the product. What do you think about this technology? Which method do you think is the most promising? Write your opinion in the comments block.

Ultrasonic pressure treatment and ultrasonic hardening

The main technological parameters of ultrasonic hardening (USH) are the duration of exposure (t), ball diameter (dsh) or rounding radius of the working part of the tool (r), vibration amplitude (Ak), effective mass of the tool (Gin), longitudinal feed (s), number passes (i), the speed of movement of the part being hardened (v), the initial surface roughness (Ra) and the quality of the surface layer.

To improve the physical and mechanical properties of parts, finishing and strengthening treatment by surface plastic deformation (with a spherical or cylindrical tip) is used. In this case, the metal of the asperity protrusions moves in both directions from the point of contact with the deforming element. The height of the irregularities decreases, forming a new microrelief. To obtain the required surface roughness, it is necessary to apply the minimum necessary force to the deforming element, sufficient for plastic deformation to occur.

When rolling and rolling with roller and ball heads, mandrating, and pulling with smoothing broaches, the shape of non-rigid parts and parts of variable rigidity may be distorted. The application of ultrasonic vibrations (UV) to the deforming tool reduces the magnitude of the static load during plastic deformation of metals.

The installation diagram of the ultrasonic device (Fig. 1) includes an ultrasonic generator, a magnetostrictive transducer 5, a waveguide 3 and a deforming tip 2. The acoustic system is mounted in a movable housing 4, which can move along the axis of the fixed housing. The installation and regulation of the required radial force is carried out using a calibrated spring 7 and a screw 8. The tip 2 performs ultrasonic testing and with a small force P is pressed against the workpiece 1.

Rice. 1. Scheme of ultrasonic hardening with a spring-loaded ball or diamond tip

In practice, steel or carbide balls can be used as a tool, loosely or rigidly connected to the waveguide of the transducer, and in diamond burnishing, polished diamond crystals are used, sealed in steel holders. The radius of curvature of the working part of the diamond tip is 1. . . 4 mm and depends on the processing conditions, the material of the processed surface and the rigidity of the technological system. It has been established that under the influence of ultrasonic sound with an amplitude Ak = 10 μm, the rate of deformation of the surface layers increases 100 times and is accompanied by hardening. Serial equipment is used as equipment for performing ultrasonic hardening. The ultrasonic emitter is fixed in the tool holder (Fig. 2).

List of used literature

1. Borisov Yu.S. Gas thermal coatings from powder materials / Yu.S. Borisov, Yu.A. Kharlamov. – Kyiv: Naukova Dumka, 1987. – 210 p. 2. Vityaz P.A. Theory and practice of flame spraying / P.A. Vityaz, V.S. Ivashko, E.D. Manuilo. – Minsk: Science and technology, 1993. – 295 p. 3. Kudinov V.V. Plasma application of refractory coatings / V.V. Kudinov, V.M. Ivanov. – M.: Mechanical Engineering, 1981. – 192 p. 4. Rykalin N.N. Physical and chemical problems of joining dissimilar materials / N.N. Rykalin, M.X. Shorshorov, Yu.L. Krasulin. // Inorg. materials. – 1965. – T.1. – P. 29 – 36. 5. Terekhov D.Yu. Method of surface preparation before thermal spraying / D.Yu. Terekhov, B.M. Soloviev // Copyright certificate of the USSR No. 1638198 AI С23С 4/02 08/30/91 Bull. No. 32. – All-Union Scientific and Production Association for the Restoration of Parts “Remdetal”. 6. Nadolsky V.O. Method for preparing the surface of parts / V.O. Nadolsky, A.N. Navoznov // Copyright certificate of the USSR No. 1758082 AI S23S 4/02 08/30/92. Bull. No. 32. 7. Medvedev Yu.A. On the influence of roughness and the degree of hardening on the adhesion strength of plasma coatings / Yu.A. Medvedev, I.A. Morozov // Physics and chemistry of materials processing. – 1975. – No. 4. – pp. 27-30. 8. Popovkin B.A. Progressive technology and equipment for shot blasting metal / B.A. Popovkin // Technology, organization of production and management. – 1978. – No. 10. – pp. 31-35. 9. Ivashko V.S. Adhesion strength of coatings made of self-fluxing hard alloys / V.S. Ivashko // Mechanical Engineering. – 1979. – Issue. 2. – pp. 103-105. 10. Kudinov V.V. Production of coatings by high-temperature spraying / V.V. Kudinov., L.K. Druzhinin. – M.: MIR, 1973. – 85 p. 11. Kupriyanov I. L. Gas-thermal coatings with increased adhesion strength / I. L. Kupriyanov, M. A. Geller. – Minsk: Science and technology, 1990. – 176 p. 12. Masino M.A. Organization of restoration of automobile parts / M.A. Masino. – M.: Transport, 1981. – 176 p.