The Izhevsk Machine-Building Plant has produced many units, tools and equipment throughout its history. The IZH 250 lathe has become one of the most popular units, the demand for which continues to this day. Several modifications of this equipment have been produced, which are often used in both large and small enterprises.

With the IZH 250 you can perform many types of turning tasks in a collet, centers or chuck. The metal lathe IZH can produce metric, inch and modular threads.

Information about the manufacturer of the IZH-250P screw-cutting lathe

The manufacturer of the screw-cutting lathe model IZH-250P is Izhevsk Machine-Building , founded in 1807.

The history of machine tool building at the Izhevsk Machine-Building Plant begins on July 28, 1930, after the issuance of Order No. 181 on the creation of a machine tool department.

The first machine-tool production product at the plant was a lathe with an external transmission.

The most popular models of universal lathes produced at different times were “Udmurt”, “Udmurt-2” (161-AM), IZH-250, 1I611P, 1IS611V, 95TS, 250ITVM, 250ITVMF1 and the IT42 CNC lathe.

Machine tools produced by the Izhmash machine-building plant

- 1I611P

- high-precision universal screw-cutting lathe, Ø 270 - 1I611PMF3

- high-precision CNC lathe, Ø 320 - 1IS611V

- high-precision universal screw-cutting lathe, Ø 270 - 95-TV (95TV)

- screw-cutting lathe, Ø 250 - 95TS-1 (IS1-1)

- high-precision universal screw-cutting lathe, Ø 250 - 161-A, 161-AM (Udmurt-2)

- universal screw-cutting lathe, Ø 350 - 250-ITV (IZH 250-ITV)

- high-precision universal screw-cutting lathe, Ø 300 - 250-ITP (IZH 250-ITP)

- high-precision universal screw-cutting lathe, Ø 300 - 250ITVM (IZH 250ITVM)

- high-precision universal screw-cutting lathe, Ø 300 - 250ITVM.01, 250ITVM.03, 250ITVM F1

- high precision screw-cutting lathe, Ø 300 - 250ITVM F2

- high precision lathe with OSU operational control system, Ø 320 - 1711IFF3

- vertical milling machine with CNC and ASI, 300 x 230 - 1715IFF3

- horizontal milling machine with CNC and ASI, Ø 320 - 1336m

- turret lathe, Ø 420, Izhevsk, Kiev - IZH-T-400 (1623)

- universal screw-cutting lathe, Ø 400 - IZH-250

- universal screw-cutting lathe, Ø 250 - IZH-250P

- high-precision screw-cutting lathe, Ø 250 - IT-42

- CNC lathe, Ø 320 - TP500F3, TP1000F3

- lathe with inclined bed with CNC, Ø 250, Ø 500

Purpose of IZH 250

The metal lathe IZH 250 ensures high-quality execution of final operations. To perform turning, which does not require great precision and places significant loads on the machine, it is worth choosing another modification of the equipment - 250 ITP. To meet demand, Izhmash released several modernized versions of the IZH 250:

- IZH 250 ITVM.03 has a larger distance between centers, which makes it easy to process parts of non-standard shape.

- IZH 250 ITVMF1 is a unit with a digital indicator, which increases convenience, accuracy and efficiency.

- IZH 250 ITPM is used for low-precision turning operations.

IZH-250P High-precision screw-cutting lathe. Purpose, scope

IZH-250P high-precision screw-cutting lathe was created on the basis of the IZH-250 model, a machine of normal accuracy.

IZH-250P machine and the base model is the design of the spindle bearings: instead of roller spindle bearings, the machine is equipped with bronze split adjustable plain bearings.

Screw-cutting lathes, models IZH-250P, are designed for turning on centers, chucks or collets, as well as for cutting metric, modular and inch threads for use in large and small enterprises.

The machines can be used in tool and instrument manufacturing related to the precision processing of small-sized parts.

IZH-250PP machine has an increased accuracy class and is used to perform more precise work.

Design features of the screw-cutting lathe IZH-250P

The spindle of the IZH-250P screw-cutting lathe is mounted on bronze split adjustable plain bearings and has 22 rotation speeds: 12 revolutions from the gearbox through a V-belt drive and 10 speeds through the gearbox in the headstock.

The end of the spindle is threaded M68x6. A standard Ø200 mm cartridge is installed on an intermediate (adapter) flange, which is screwed onto the thread until it stops. The diameter of the hole in the spindle is Ø 33 mm for a rod Ø 30 mm. Morse taper 5.

The gearbox is installed in the left cabinet of the machine and is a four-axis gearbox, receiving movement from a flange electric motor. From the gearbox through a V-belt transmission, the movement is transmitted to the spindle. A friction plate clutch and brake are located on the drive shaft of the gearbox. The clutch provides on/off rotation of the spindle, and the brake reduces the spindle rotation time.

The feedbox receives movement through the guitar from the headstock gearbox.

The thread pitch and feed speed are selected using the handles on the front cover of the feed box.

support receives movement from the drive shaft connected to the output shaft of the feed box. When cutting threads, the movement of the caliper is ensured by the lead screw, and the lead shaft should not rotate.

The caliper apron converts the rotational movement of the lead shaft or lead screw into longitudinal and transverse movement of the caliper. The apron also provides manual longitudinal movement of the caliper from the flywheel.

Electrical equipment installed on the IZH-250P machine:

- The electric motor of the main movement drive is asynchronous, two-speed - 1420/2800 rpm, power - 2.6/3 kW, three-phase 380 V, type FT42-4/2.

- Electric motor for driving the lubrication oil pump is asynchronous with a squirrel-cage rotor - 1400 rpm, power - 0.18 kW, three-phase 380 V, type AOL12-4

- Cooling pump drive electric motor - 2800 rpm, power - 0.125 kW

- Irreversible magnetic starter with coil 380V, type PMI-1

- Reversible magnetic starter with a 380V coil for switching the direction of rotation of the main motion electric motor, type PMI-1R

- Two-pole thermal relay for protecting electric motors, type RT-1

Main technical characteristics of the screw-cutting lathe IZH-250P

Manufacturer: Izhevsk Machine-Building Plant Izhmash. Serial production began in 1963.

- The largest diameter of a Disk-type workpiece processed above the bed is Ø 250 mm

- The largest diameter of the Shaft type workpiece processed above the support is Ø 125 mm

- Distance between centers - 500 mm

- Height of centers - 150 mm

- Electric motor power - 2.6/3 kW

- Full machine weight - 1.5 t

Spindle of screw-cutting lathe IZH-250P

- Spindle end - threaded M68x6

- Internal (tool) spindle cone - Morse 5

- The diameter of the through hole in the spindle is Ø 33 mm

- The largest diameter of the processed rod is Ø 30 mm

- Limits of direct spindle revolutions per minute (22 steps) - 16..2000 rpm

Feeds and threads of screw-cutting lathe IZH-250P

- Limits of longitudinal feeds - 0.07..2.17 mm/rev

- Transverse feed limits - 0.01..1.08 mm/rev

- Limits of metric thread pitches - (24 pcs) 0.2..6 mm

- Limits of modular thread pitches - 0.2..6 modules

- Limits of inch thread pitches - 24..3.5 threads per inch

Design features of the device

The screw-cutting lathe of this model, due to some design features, has a number of special characteristics. Let us list these design features.

- The lead screw is automatically lubricated during threading operations.

- The feed and spindle speed parameters can be adjusted over a wide range.

- The IZH-250 apron is equipped with a special stopping mechanism, which allows turning on the machine against a hard stop and protects the box and feed mechanisms from possible overloads.

- The cutting head of the unit is fixed according to a backlash-free scheme, which ensures high accuracy and rigidity of its installation and position during processing.

- To select the spindle rotation speed, a preselective control system is used, which allows, when performing a certain technological operation, to prepare its subsequent switching on with the specified parameters in advance and carry it out when required.

- Due to the special design of the spindle unit, drive belts can be changed very quickly and easily; there is no need to disassemble it for this.

- Cutting various types of threads on the IZH-250 (metric, modular, inch) is carried out not by changing the gears in its guitar, but due to the versatility of the feed box.

- The IZH-250 bed is made of a special grade of cast iron - chromium-nickel, and the carefully polished guides on it are hardened using high-frequency currents.

Feed control on the machine of this model is implemented according to a mnemonic (facilitates memorization) principle and is carried out using a handle. According to this principle, the direction of movement of the handle coincides with the feed movement that the unit support with its cutting head will make.

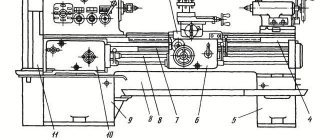

Kinematic diagram of IZH-250 (click to enlarge)

Principle of electrical machine (click to enlarge)

Dimensions of the working space of the IZH-250P lathe

Dimensions of the working space of the IZH-250P lathe

Spindle of lathe IZH-250P

Bed of lathe IZH-250P

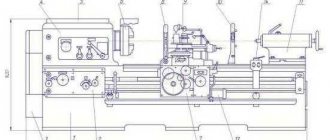

General view of the screw-cutting lathe IZH-250P

Photo of lathe IZH-250P

Photo of lathe IZH-250P

Photo of lathe IZH-250P

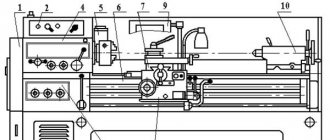

Location of controls for screw-cutting lathe IZH-250P

Location of controls for screw-cutting lathe IZH-250P

List of controls for the IZH-250P machine

- Gearbox clutch on/off handle

- Gearbox gear shift handle

- Gearbox gear shift handle

- Gear shift handle

- Gear shift handle

- Gear shift handle

- Gear shift handle

- Shift handle - screw / roller

- Switch on/off switch

- Flywheel for longitudinal movement of caliper manually

- Handle for turning on/off the longitudinal feed of the caliper

- Handle for turning on/off the cross feed of the caliper

- Feed reverse handle

- Lead screw on/off handle

- Manual caliper lateral movement flywheel

- Handle for moving the upper part of the support (cutting slide)

- Handle for turning and clamping the cutting head

- Tailstock quill movement flywheel

- Handle for moving the tailstock along the machine bed

- Tailstock quill clamp handle

- Turning on the lights

- Speed switch

- Back button

- Forward start button

- Stop button

- Connecting the machine to the network

- Turn on cooling

Lubrication diagram for a screw-cutting lathe IZH-250P

Specifics of the machine design

The largest diameter of a part that can be processed by the unit above the bed is 240 mm. The workpiece processed above the support can have a diameter of up to 168 mm. The longest workpiece length is 0.5 m.

The direct rotation frequency of the spindle has a wide range - from 63 to 3150 rpm. The spindle can be rotated in reverse at the same speed. Metric thread pitch ranges from 0.2 to 24 mm.

And also the screw-cutting lathe works with the following nuances:

- Automatic lubrication of the lead screw when cutting threads.

- Large range of adjustment of spindle speed and feed.

- The machine apron is equipped with a stop that can protect against overloads and, thanks to which turning can be carried out against a rigid stop.

- There are no gaps when attaching the cutter, which increases the rigidity and accuracy of its position during operation.

- The presence of preselective control, which allows you to select the spindle speed and prepare the machine for the next operation.

- The convenient structure of the spindle unit allows you to quickly and easily change drive belts, without disassembling the unit itself.

- The universal gearbox allows you to cut any type of thread without changing the gears on the guitar.

- The frame is made of cast iron with additions of chromium and nickel, the guides are very smooth and hardened with high frequency currents.

- The mnemonic principle of feed is carried out by a lever, the movement of which coincides with the direction of movement of the cutter.

Operation of the IZH 250 machine

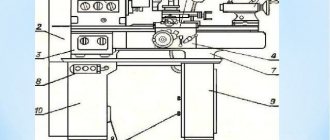

Design of the main components of the IZH-250P lathe

IZH-250P Headstock of lathe

Headstock of screw-cutting lathe IZH-250P

IZH-250P Friction clutch and brake of a lathe gearbox

Friction clutch and brake of the gearbox of the IZH-250P lathe

IZH-250P Feed box for lathe

Feed box for screw-cutting lathe IZH-250P

Technical characteristics of the screw-cutting lathe IZH-250P

| Parameter name | IZH-250 | IZH-250P | 1I611p | 250itvm |

| Main settings | ||||

| Accuracy class according to GOST 8-82 | N | P | P | IN |

| The largest diameter of the workpiece processed above the bed, mm | 250 | 250 | 250 | 240 |

| The largest diameter of the workpiece processed above the support, mm | 125 | 125 | 125 | 168 |

| Maximum workpiece length (RMC), mm | 500 | 500 | 500 | 500 |

| Height of the center axis above the flat guides of the frame, mm | 150 | 150 | 130 | 150 |

| Height from the cutting surface to the center line, mm | 20 | 20 | 16 | 16 |

| The greatest distance from the center axis to the edge of the tool holder, mm | 130 | 127 | ||

| Spindle | ||||

| Diameter of through hole in spindle, mm | 33 | 33 | 27 | 25 |

| The largest diameter of the rod passing through the hole in the spindle, mm | 30 | 30 | 24 | 24 |

| Number of stages of direct rotation of the spindle, rpm | 22 | 22 | 21 | 21 |

| Spindle direct rotation frequency, rpm | 16..2000 | 16..2000 | 20..2000 | 25..2500 |

| Size of the internal cone in the spindle, M | Morse 5 | Morse 5 | Morse 4 | Morse 4 |

| Spindle end according to GOST 12593-72 | threaded | threaded | 4 | 4 |

| Spindle braking | Eat | There is | There is | |

| Submissions | ||||

| Maximum stroke length of the caliper carriage, mm | 500 | 500 | 500 | 500 |

| Price for dividing the longitudinal movement dial of the caliper, mm | 0,1 | 0,1 | 0,1 | 0,1 |

| Longitudinal movement per one revolution of the dial, mm | 23,5 | 23,5 | 20 | 20 |

| Maximum lateral movement of the caliper, mm | 150 | 150 | 180 | 165 |

| Dividing value of the caliper transverse movement dial, mm | 0,05 | 0,05 | 0,02 | 0,05 |

| Transverse movement per one revolution of the dial, mm | 3 | 3 | 3 | 3 |

| Limits of longitudinal working feeds, mm/rev | 0,07..2,17 | 0,07..2,17 | 0,01..1,8 | 0,01..1,8 |

| Limits of working cross feeds, mm/rev | 0.01..1.08 (1/2 of cont.) | 0.01..1.08 (1/2 of cont.) | 0,005..0,9 | 0,005..0,9 |

| Speed of fast movements of the caliper, longitudinal, m/min | No | No | No | No |

| Speed of fast movements of the caliper, transverse, m/min | No | No | No | No |

| Limits of pitches of cut metric threads, mm | 0,2..6 | 0,2..6 | 0,2..48 | 0,2..48 |

| Limits of pitches of cut inch threads | 24..3,5 | 24..3,5 | 24..0,5 | 24..0,5 |

| Limits of pitches of cut modular threads | 0,2..6 | 0,2..6 | 0,2..30 | 0,2..12 |

| Switching longitudinal stops | There is | There is | There is | There is |

| Release cross stops | No | No | There is | There is |

| Fast movement of the caliper | No | No | No | No |

| Cutting slide | ||||

| Maximum movement of the upper slide of the caliper, mm | 120 | 120 | 120 | 120 |

| Dial division price, mm | 0,1 | 0,1 | 0,05 | 0,05 |

| Largest dimensions of the cutter holder, mm | 20 x 20 | 20 x 20 | 16 x 16 | 16 x 16 |

| Rotation scale division value, degrees | 1 | 1 | 1 | 1 |

| Tailstock | ||||

| The size of the internal cone of the tailstock quill according to GOST 25557-82 | Morse 3 | Morse 3 | Morse 3 | Morse 3 |

| Tailstock quill center according to GOST 13214-79 | Morse 3 | Morse 3 | Morse 3 | Morse 3 |

| Maximum movement of the tailstock quill, mm | 90 | 90 | 85 | 85 |

| Rule division price, quill movement, mm | 1 | 1 | 1 | 1 |

| Limb division price, quill movement, mm | 0,05 | 0,05 | ||

| Transverse displacement of the quill, mm | ±10 | ±10 | ±10 | ±10 |

| Electrical equipment | ||||

| Number of electric motors on the machine | 3 | 3 | 3 | 3 |

| Main drive electric motor, kW | 2,6/ 3 | 2,6/ 3 | 3 | 3 |

| Lubrication station electric motor, kW | 0,18 | 0,18 | 0,08 | 0,09 |

| Cooling pump electric motor, kW | 0,12 | 0,12 | 0,12 | 0,18 |

| Cooling pump (pump) | PA-22 | PA-22 | PA-22 | PA-22 |

| Overall dimensions and weight of the machine | ||||

| Machine dimensions (length width height), mm | 2030 x 875 x 1220 | 2030 x 875 x 1220 | 1770 x 970 x 1300 | 1790 x 810 x 1400 |

| Machine weight, kg | 1570 | 1570 | 1180 | 1180 |

- High precision screw-cutting lathe IZH250P. Manual for the machine, Izhmash, 1963

- Acherkan N.S. Metal-cutting machines, Volume 1, 1965

- Batov V.P. Lathes, 1978

- Beletsky D.G. Handbook of a universal turner, 1987

- Denezhny P.M., Stiskin G.M., Thor I.E. Turning, 1972. (1k62)

- Denezhny P.M., Stiskin G.M., Thor I.E. Turning, 1979. (16k20)

- Modzelevsky A. A., Muschinkin A. A., Kedrov S. S., Sobol A. M., Zavgorodniy Yu. P., Lathes, 1973

- Skhirtladze A.G., Novikov V.Yu. Technological equipment for machine-building industries, 1980

- Tepinkichiev V.K. Metal cutting machines, 1973

- Chernov N.N. Metal cutting machines, 1988

- Pikus M.Yu. A mechanic's guide to machine repair, 1987

Bibliography:

Related Links. Additional Information

- Classification and main characteristics of turning

- Selecting the right metalworking machine

- Multi-start thread. Methods for cutting multi-start threads on a lathe

- Graphic signs for lathes

- Friction clutch of a screw-cutting lathe

- Methodology for checking and testing screw-cutting lathes for accuracy

- Manufacturers of lathes

- Manufacturers of metal-cutting machines

- Directory of lathes

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Advantages of 250 ITVMF1

The 250 ITVMF1 is most in demand in modern conditions due to the additional digital indicator. It guarantees high productivity without loss of quality. The indicator allows you to speed up the measurement of the geometry of the workpiece and perform an approximate pass.

The dimensional accuracy ranges from 0.1 to 100 microns. And also, the operator does not need to remember the number of dial revolutions; independently, and sometimes manually, determine the characteristics and parameters. The machine automatically compensates for minor problems with the interaction of its own parts and wear of the cutting parts.

To count lateral movements with high accuracy – up to 0.005 mm/rev – the machine is equipped with a vernier mechanism. The lead screw connects directly to the guitar without the need for a gearbox.

ITV modifications comply with GOST 8-82 accuracy class B, ITP machines - P.

Structure of IZH 250ITVMF1