When it is necessary to smooth metal, wood, stone, plastic and other surfaces, a special tool is used - a grinding machine. It allows you to achieve a given degree of surface roughness, as well as remove used paint and varnish coatings. It is often used for finishing finishing of premises. Grinding machines have many varieties and differ significantly both in purpose and in performance, method of surface treatment, weight, and included equipment.

Types of sanders

There are six types of grinders, differing in the stroke of the grinding material and configuration:

- Circular;

- Longitudinal;

- Rotational, reciprocating.

Manufacturers produce tools that work both from the mains and with a battery.

Angle Grinder

An angle grinder, or popularly “grinder”, has an axis to which a cutting or grinding disc is attached, located at ninety degrees in relation to the electric drive rod.

- It is also used for grinding metal products, seams after welding, and removing the previous layer.

- For these purposes, a variety of attachments are used - felt sanding discs, flap brushes.

- Angler grinders are most often used for grinding metal, due to the high rotation speed of the electric motor (over ten thousand revolutions per minute).

It is possible to work with such indicators only by rough grinding of surfaces; it will not be possible to do better work at such speeds, especially on soft materials. The “grinder” has one significant disadvantage - the lack of proper dust removal.

Useful tips when working with a sander

If you need to sand a varnished surface, then you should set the tool to the lowest speed, since the varnished coating is sensitive to high temperatures. It is necessary to monitor the temperature conditions and regularly allow the surface to “cool” after each stage of grinding. To avoid creating unnecessary friction, you should use clean abrasives and do not press the tool with force. If you need to sand plastic, it is best to use an eccentric or vibration sander. Again, you need to set the minimum speed of the tool. The grain size of the sandpaper should be more than 240. Similar types of machines should be used if you need to sand a metal surface. However, the grain size should already be more than 600. To sand off the unevenness, you will have to use a grinder. If finer processing of the material is required, then you should think about using fiber or fan discs. The belt sander must first be turned on, and only then brought to the surface that needs to be processed. Otherwise, the tool may be thrown away from the workpiece at high speed (up to 25 km/h). When sanding, do not put too much pressure on the machine. Normal surface contact is sufficient for an effective grinding process. With strong pressure, the material will be removed in an increased volume, but this will affect the quality of grinding.

Photo: bosch-online.ru

When working with an angle grinder, be sure to use safety glasses. These sanders are the most dangerous. To ensure that the tool works reliably, regularly remove dust from the cavities of the angle grinder. This can be done by blowing and tapping the housing. Avoid overload. In this case, the service life of the tool will be maximum. The ends of the material being processed should not bite the cutting disc, otherwise its service life will not be long. To avoid this, it is necessary to ensure constant pressure on the grinder. At the same time, you should not make very deep cuts in one go, since this increases the load on the motor several times, which can cause damage even to a professional angle grinder.

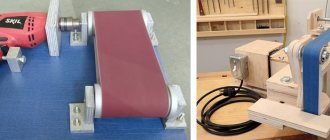

Belt sanding

The belt sander got its name from a solid abrasive sanding belt located on two shafts, one of which is the drive shaft.

This type of tool has a high belt speed and excellent productivity. Thanks to these qualities, the electric grinder is used for finishing work - fine grinding, before processing the product with paints and varnishes.

In addition, they are used during the construction stages to remove:

- Previous paint coating;

- Rusty coating;

- Excess on primed, plastered surfaces.

This type of sander is equipped with a closed dust extraction structure with the ability to connect a vacuum cleaner. In addition, on this model it is possible to install it upside down, so that the sanding belt can be aligned. To do this, the tool is secured using clamps included with the workbench. This function allows you to sharpen knives, bench tools, drills, using the grinder as a mini-grinder.

Stationary units

Stationary units include belt-plate grinding machines.

The stationary grinder is used mainly in small carpentry workshops or in small-scale production. The unit consists of a belt sander and a grinding wheel. Thanks to the installed table on the machine, you can round the corners of workpieces, grind the edges of parts, and also grind them at a certain angle.

Vibrating

Another name that many people know is a surface grinder. It received its second name thanks to a flat rectangular platform, which, with the assistance of an eccentric electric mechanism, makes reciprocating moves over the entire surface of the product.

Sanding attachments include rectangular sandpaper sheets attached to the surface of the sole using special clips or Velcro. Grinding machines are used for finishing work on various products.

However, the design of the tool does not allow access to corners and joints during grinding; in this case, a delta grinder is used, which is one of the varieties of this group.

Here the working surface resembles a triangle with an acute angle protruding forward. This design perfectly allows you to get into hard-to-reach places, while doing the job efficiently. Since the delta grinder is not used so often, only when necessary, these models are often produced with a battery.

Application

Designed for delicate processing of large flat surfaces. They occupy an intermediate place in terms of the cleanliness of processing parts between belt and eccentric ones. Using a surface grinder, finishing sanding of various surfaces is carried out: wood, plastic, stone.

Advantages: the ability to grind and polish internal corners, availability of consumables and moderate cost of the grinder itself.

Disadvantages: high noise relative to orbital ones.

Orbital (eccentric) electric sander

The working platform of an eccentric grinder is a circle that rotates and makes reciprocating movements. An eccentric device with two rollers allows this to be done (hence the second name of the tool).

The first is the axis of the grinder disk, shifted relative to the center by a couple of millimeters.

- Self-rotation is carried out through another roll passing through the middle of the circle in a circle around the shaft.

- Using this type of sander, you can achieve excellent grinding quality; in addition, you can polish the surface of the product coated with varnish.

- It is because of this that they are valuable in furniture, restoration, car repair shops and other enterprises where the quality of polishing and grinding of products is important.

Application

They are used for rough or fine grinding on large surfaces, for interlayer processing of materials and coatings, for polishing, processing large surfaces along and across the grain. Often machines of this type are used in carpentry and car painters. Using ESM, volumetric, profile and curved surfaces are processed. When working with an eccentric sander, it is unlikely to damage the workpiece: make abrasions, burn the material, or overdo it with the grinding depth. The noise and vibration levels are lower than other types of grinding machines.

Brush grinder

There are two types of brush grinding, which are similar in appearance to angle grinders and belt grinding. In the first type, the axis of rotation is also located at an angle of 90 degrees with respect to the electric drive, which is located in the elongated handle.

This model differs from an angle grinder in that the brush model has a much lower rotation speed. Also, the handle is on a completely different side.

- The second model is equipped with the same rectangular platform, only there will be only one roller, which acts as a drive.

- Its diameter is significantly larger than that of belt grinding.

- The scope of use of these models is the removal of oxidation, rusty layer, and previous coating from the surface of products before proceeding with finishing.

In addition, these products use round or cone-shaped pads to which sandpaper or felt is fixed. Thanks to this, you can grind or polish the surface.

Types of grinding machines

The main area of application of hand-held sanders is the processing of flat and curved surfaces of metal, wood, stone and plastic products with an abrasive tool. As a rule, such a grinding material is sandpaper based on fabric or paper, which moves at high speed along the surface being processed. Depending on what type of grinder it is, these movements can be longitudinal, circular, reciprocating and rotational. In addition to models connected to a 220 V network, many brands offer machines with autonomous battery power. The performance of such a grinding power tool depends on the power of the electric drive, as well as on the area of the abrasive in contact with the processing plane.

The standard speed of movement of the sandpaper depends on the type of material being sanded and in general follows a simple rule: the harder, the faster. Therefore, one of the most important technical characteristics of these devices, regardless of their type, is the ability to control the grinding speed. For this purpose, grinding machines are produced with adjustable motor speed, on which the linear speed of the sandpaper directly depends.

Another useful feature is the electronic stabilizer, which maintains a constant speed under load. Such options increase the price of the machine, but using them is much more convenient.

Corner

A manual angle grinder is popularly called a “grinder” or simply an angle grinder. This power tool has a spindle, on which cutting or grinding wheels are attached, located at an angle of 90º to the axis of the electric drive. In addition to cutting work, angle grinders are designed for rough grinding of metal, welds and removal of old coatings. Various flap wheels and brushes are available for this sanding machine, as well as felt and fiber sanding wheels. The main purpose of angle grinders is to work on metal, so they all have a high motor speed (usually more than 10,000 rpm). With such parameters, even if the speed is adjusted, it is impossible to qualitatively grind soft materials - only to strip and remove old coatings.

One of the main disadvantages of these sanders is the lack of a dust removal system.

Tape

This type of grinding machine gets its name from the tool used in them - a continuous abrasive sanding belt stretched over two rollers, one of which is the leading one.

The rollers have a small diameter, so the working part of the sanding belt is slightly less than half the length of its circumference. Belt grinders have a high linear speed of movement of the abrasive belt and high productivity. Therefore, they are most often used when preparing products for fine grinding or coating with paints and varnishes. In addition to processing metal and wood, such machines are used in construction work to remove old paint and rust, as well as leveling primed and putty surfaces. All belt sanders have an internal dust extraction system and the ability to connect an external vacuum cleaner.

One of the interesting features of this tool is the ability, provided by the design, to secure the machine on a workbench with the sanding belt facing upwards.

For this purpose, it is provided with protrusions or holes, and some manufacturers include special clamps in the delivery package. In this version, this grinder can be used as a mini-grinder for sharpening hand tools, drills and knives.

Vibrating

Vibratory sanders are also called surface sanders.

In this power tool, the working body is a flat rectangle (sole, platform), which, using an eccentric mechanism, makes reciprocating movements along the surface of the material being sanded. In this type of sander, rectangular sheets of sanding paper are used as a working tool, which are fixed to the elastic base of the sole using clamps or a sticky surface. The vibration frequency of the sole in such machines reaches 10–12 thousand per second, and the amplitude is 1–2 millimeters. Surface grinders are used for finishing grinding of various materials, and their performance directly depends on the area of the base, as well as the frequency and amplitude of its movements. The design feature of vibrating sanders does not allow them to process joints and corners, so for such purposes they use a variety of them - delta sanders. The working surface of this power grinding tool is made in the shape of a triangle with an acute angle extended forward, which makes it possible to process mating surfaces without dead zones. Delta sanders are mainly designed for working in hard-to-reach places after the main grinding, which is why many models are available in a cordless version.

Eccentric (orbital)

Orbital sanders have a round working base.

During grinding, it simultaneously rotates and performs reciprocating movements. This occurs due to the use of an orbital mechanism with two shafts in the machine drive. The first shaft is the axis of the sanding pad disk and is shifted relative to its geometric center by several millimeters (i.e., it is located eccentrically), therefore, turning around it, the disk makes circular reciprocating movements. And the rotation of the disk is transmitted through the second shaft, which passes through the geometric center of the circle and, in the process of movement, runs around the axial shaft in a circular orbit. Orbital sanders allow you to obtain the highest quality sanding and even polish paint coatings. Therefore, in furniture, restoration and auto repair shops, eccentric sanders are used for finishing and polishing, and other types are used for cleaning and pre-grinding. The performance and quality of surfaces during orbital grinding depends on the area of the base, the rotation speed and the amplitude of vibration of the disc. The lower the last indicator, the higher the quality and the lower the productivity. For most orbital sanders, it is fixed and ranges from two to five millimeters, but there are models with the ability to adjust this parameter.

Brush

There are two main layouts of brush sanders: similar to angular sanders and similar to belt sanders.

In the first case, the axis of rotation of the abrasive tool is also at right angles to the axis of the electric drive, and the electric motor is located in an elongated handle. The main difference between such a tool and an angle grinder is the low rotation speed and a different location of the guide handle. In the second case, the grinding machine has the same rectangular body, but only one roller, which is driven and has a larger diameter than a belt grinder. As a working tool, brush grinders use rollers with long metal or plastic bristles, as well as brushes with sandpaper lamellas. In this version, machines are used to clean surfaces from oxides, rust and old coatings before finishing. In addition, these machines use round or conical mandrels for abrasive cloth or felt, which can be used for grinding and polishing.

An exclusive area of application for brush sanders is the creation of texture on wood, which is done with special nylon brushes.

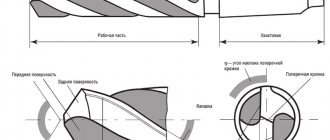

Straight (end)

Straight sanders are the simplest type of hand sanders. They are designed for trimming, deburring and sanding small surfaces. Structurally, such a tool is an elongated body with an electric motor with a diameter the size of a hand, on the shaft of which there is a spindle with a collet chuck with an internal diameter of 3 to 8 mm. Cylindrical, conical and spherical sanding stones of small diameter, as well as flap and cutting wheels are used as abrasive tools for straight grinders. Due to the ability to process sandpaper with the end, these machines are sometimes called end-cut machines.

Crosscut, straight model

They are the simplest of this category of tools. Used for minor work - trimming, stripping, sanding. In appearance it is an elongated body with an electric motor.

In this case, the working element is sanding attachments in the form of a cylinder, cone, or sphere of not very large shape. Both cutting and flap discs can also be used.

Delta sanders

Delta sanders are ideal for sanding corners.

If you decide to restore old furniture, window frames or blinds, then this machine will become your indispensable assistant. The operating principle of a delta grinder is similar to vibrating models of grinding machines, however, the special shape of their grinding plate makes it possible to process surfaces in narrow and hard-to-reach places. The power consumption of such a tool is only 100 - 300 W. Dust is removed into a special container. If you decide to choose a delta sander, please note that the sanding sheet is attached only with Velcro. To save money, some manufacturers have developed models that allow you to rotate the sanding sheet in the desired direction and use its surface to achieve maximum abrasion.

For delta sanders, you can purchase additional sanding or cleaning cloth to clean metal surfaces from rust, process hard-to-reach wooden parts, and matt varnish coatings. Polishing sheets will allow you to correctly carry out finishing, polishing and rubbing.

The supplied plate nozzles will allow the master to easily penetrate the narrowest crevices. If someone has once used a sanding plate with a flat or oval tongue, he will easily take on the processing of concave or rounded parts.

How does a household appliance differ from a professional one?

There are several main differences that are undoubtedly worth paying attention to when choosing a tool:

- Working hours. The household tool can be used without stopping for five to ten minutes, after which the machine should be allowed to cool for some time. A professional model can work from fifteen to twenty minutes, and she needs literally five minutes to rest.

- Terms of use, level of protection. It is immediately clear that a more serious instrument (professional) will look better in relation to the “amateur” one. It will better “swallow” dust and moisture, and “steadfastly” withstand wire breakdowns and long-term operation.

- Durability. For a household tool, it will be enough to work for two to three hours a day and that’s it, but a professional tool can withstand two full-fledged work shifts.

In addition, a professional tool has additional “bells and whistles,” but a household model may have them, but only a top-tier tool. It is clear that the manufacture of serious power tools requires high-quality materials and excellent fittings.

And they are several times more expensive compared to household ones. Most well-known manufacturers make it easier for their customers to choose by releasing instruments on store shelves where the body is made in different colors. For example, Bosh, blue is professional, green is amateur.

Choosing a manufacturer

High-quality sanders are produced by companies such as Interskol, Bosh , Hitachi , Makita, DeWalt . It’s no wonder that these brands are on everyone’s lips. The durability of the tools from these companies is combined with excellent performance, high efficiency and reliability of engines of various powers. The models are double insulated, and most also have a built-in dust removal system. For this purpose, the machines are equipped with a special dust collector. It is also possible to connect them to an industrial vacuum cleaner. And all this is combined with an affordable price. Another advantage of these tools is their excellent ergonomics. Among the imported manufacturers of grinding machines, it is worth highlighting Skil , Meister, Metabo , KRESS , and Black&Decker . High-quality Russian brands are Zubr and Interskol . Makita brand is the pride of Austria and Germany. The grinders of this company are a joint product of these countries. The main model range is represented by professional tools, but household models are also quite diverse. Convenience, reliability and quality/price ratio are the main features of the tools of this company. The largest assortment of Makita among drawing machines. Increased engine sealing is the difference between vibrating grinders from this company. Maximum performance is represented by grinders and eccentrics. The prices for the tools of this company are very diverse (this is due to the huge selection of models). For example, an eccentric sander from Makita can be bought for 3-12 thousand rubles. The price of vibrating grinders is 1.5-8 thousand, brush grinders - 12-16 thousand, belt grinders - 4-10 thousand, and the price of grinders is about 6 thousand. Cordless angle grinders are several thousand rubles more expensive. The most expensive are concrete grinders (from 20 thousand rubles). The Japanese brand Hitachi is a guarantor of durability and safety. The performance and reliability of grinders of this brand is no worse than that of Makita. The company specializes in premium instruments. The brand has existed for more than fifty years. During this time, the company managed to create and patent many developments and technologies. The range of sanders is rich both in the class of household tools and professional ones. A Hitachi belt sander can be bought for 4-8 thousand rubles, a vibrating one for 2.5-4 thousand, a polishing machine for 6-9 thousand, and an eccentric one for only 1 thousand rubles. Hitachi grinders are represented by a huge range of models, so the price range is from 2 to 10 thousand rubles. A cordless grinder can be bought for 14 thousand rubles. The German brand Bosch has been on everyone's lips for decades. Swiss and German production is represented by a range of professional tools. Poland and China manufacture household grinding machines from this company. The most popular are Bosch belt and random orbital sanders as they are the most highly efficient. The price of Bosch vibration grinders is 4-8 thousand rubles, eccentric - 3-6 thousand, concrete grinders - from 16 thousand, straight - 16-20 thousand, belt - 6-10 thousand rubles. Bosch grinders are also presented in a wide range and their price ranges from 2.5 to 8 thousand rubles. Meister company is a fairly fresh brand that is distinguished by its reasonable prices for high-quality goods. Meister grinders are made in Germany, they are convenient and easy to use when working. Such tools are suitable for both home and garden use, as well as for construction work.

What you should pay attention to

Before you go to the store to buy something, you should think again about where and what it will be used for.

After all, not only the price range will depend on this, but also the additional materials that will need to be purchased:

- If a sander is needed to remove old paint from a wooden floor in a country house, then in this case ordinary belt sanding will be sufficient. Moreover, its cost will not be very high, about several thousand, but it should have good reviews.

- If you are purchasing a tool for a home workshop, where carpentry work will be carried out on the manufacture of furniture and interior items, then you should think about buying a good orbital sander with excellent performance and speed.

However, no matter what tool you plan to purchase, it is worth considering the following indicators, which are relevant for all types of grinders:

- Speed of surface movement;

- Availability of speed control;

- How often will the abrasive material need to be changed?

- Availability of additional devices on the market;

- Equipped with spare batteries, handles;

- Possibility of connecting a vacuum cleaner, adapter;

- Noise level, vibration;

- Warranty, service.

In addition, you can find out how far the warranty workshops are from your place of residence, as well as how much the delivery of the purchased product will cost.

So you can choose any tool, the most important thing is that it works properly, is in demand, and is easy to maintain. You should not avoid reviews from real customers, as you can glean a lot of useful information from them that you would never get from the seller.

Application

Using a delta sander, fine grinding of protrusions, blind corners, edges, profiles, cleaning of exposed glue, processing of objects with small parts and complex surfaces are performed.

Delta grinder “iron” for 1,500 rubles using my link. Excellent reviews, fast delivery, quality product. View >>>

Particularly good in carpentry, furniture making, staircases, and automotive body work, used as a main tool or in addition to eccentric or orbital sanders.

USEFUL INFORMATION: Gypsum fiber sheets technical characteristics