Wood, as one of the most popular and convenient finishing materials, does not cause any particular difficulties in processing.

But to achieve a perfectly smooth surface, for example, under varnish, ordinary carpentry tools will not work. A wood sander can speed up and facilitate leveling.

This multifunctional device is presented on the market in various modifications, differing in design and application features.

Types of sanders

There are six types of grinders, differing in the stroke of the grinding material and configuration:

- Circular;

- Longitudinal;

- Rotational, reciprocating.

Manufacturers produce tools that work both from the mains and with a battery.

Angle Grinder

An angle grinder, or popularly “grinder”, has an axis to which a cutting or grinding disc is attached, located at ninety degrees in relation to the electric drive rod.

- It is also used for grinding metal products, seams after welding, and removing the previous layer.

- For these purposes, a variety of attachments are used - felt sanding discs, flap brushes.

- Angler grinders are most often used for grinding metal, due to the high rotation speed of the electric motor (over ten thousand revolutions per minute).

It is possible to work with such indicators only by rough grinding of surfaces; it will not be possible to do better work at such speeds, especially on soft materials. The “grinder” has one significant disadvantage - the lack of proper dust removal.

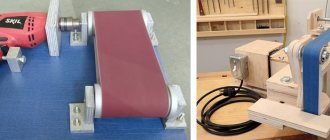

Belt sanding

The belt sander got its name from a solid abrasive sanding belt located on two shafts, one of which is the drive shaft.

This type of tool has a high belt speed and excellent productivity. Thanks to these qualities, the electric grinder is used for finishing work - fine grinding, before processing the product with paints and varnishes.

In addition, they are used during the construction stages to remove:

- Previous paint coating;

- Rusty coating;

- Excess on primed, plastered surfaces.

This type of sander is equipped with a closed dust extraction structure with the ability to connect a vacuum cleaner. In addition, on this model it is possible to install it upside down, so that the sanding belt can be aligned. To do this, the tool is secured using clamps included with the workbench. This function allows you to sharpen knives, bench tools, drills, using the grinder as a mini-grinder.

Tips for caring for power tools

In order for grinding machines to serve for a long time, you need not only to be able to handle them skillfully, but also to provide the necessary care. In addition, do not overload and operate the grinders as normal. If the tool manufacturer has specified a period of continuous operation, it should not be exceeded. Give your equipment a break in a timely manner. When working an angle grinder, do not neglect the protective casing. It not only ensures safety for a person during work, but also protects the electric motor from dust and metal particles entering it and the bearings.

When working with the tool, do not use consumables that do not correspond to the specific model. After finishing work, wipe the surface of the sander with a clean cloth to remove dirt and traces of grease. If you wind the sander cord around the tool, do not pull it too tightly, otherwise it will break after some time.

It is also necessary to carry out preventive maintenance of the tool. The frequency of this depends on how often you use the grinder. If it is used for domestic purposes and occasionally, then maintenance carried out once or twice a year is sufficient. But if you work with a tool intensively, at a professional level, then you need to make sure that it is always in working condition. To do this, you need to monitor the wear of parts and their timely replacement. In this case, prevention should be carried out once every 3 months, or even more often. During preventative maintenance, the instrument must be thoroughly cleaned both externally and internally. It is recommended to wash grinders with special compounds and check moving parts for wear. All nuts, screws and bolts must also be tightened. If equipment needs lubrication, it must be carried out in a timely manner, as well as faulty parts or worn-out components must be replaced with new ones.

Vibrating

Another name that many people know is a surface grinder. It received its second name thanks to a flat rectangular platform, which, with the assistance of an eccentric electric mechanism, makes reciprocating moves over the entire surface of the product.

Sanding attachments include rectangular sandpaper sheets attached to the surface of the sole using special clips or Velcro. Grinding machines are used for finishing work on various products.

However, the design of the tool does not allow access to corners and joints during grinding; in this case, a delta grinder is used, which is one of the varieties of this group.

Here the working surface resembles a triangle with an acute angle protruding forward. This design perfectly allows you to get into hard-to-reach places, while doing the job efficiently. Since the delta grinder is not used so often, only when necessary, these models are often produced with a battery.

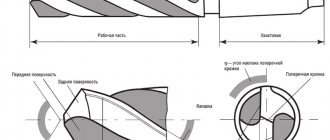

Angle grinder capabilities, discs for it

A grinder (angle grinder) can also be used for sanding wood. It can be used for rough processing.

This tool allows you to quickly clean wooden surfaces, in particular sand floors and walls. This universal device is capable of performing a variety of operations, with appropriate wheels for each: cutting, grinding and roughing (grinding).

A grinder can cut metal, stone, and wood. But it is not advisable to saw boards and other wood, otherwise the tool will overheat greatly. Wood saw blades for grinders resemble modern saw models, but different alloys are used for their manufacture. The only drawback of an angle grinder is the presence of various irregularities after work, which then take a long time to level out.

For grinding work, special red wheels are used. A good option is to use petal or disc wheels with a grain size suitable for each case.

Considering that the working plane is located under the protective casing, performing specific actions does not pose a danger to humans, which makes it possible to move the tool in any direction. The main thing is to be careful when working with surfaces that have protruding heads of screws and nails.

Note! To make it easier and faster to replace sandpaper, it is recommended to install an attachment with a sticky surface on the grinder.

Draw machine

In a belt sander for wood, the working element is represented by a belt fixed around two rollers. During their movement, the tape attached to the sole is brought into working condition and rotates at the required speed. It is the speed that is considered an important indicator of the operation of this device and it depends on the power, which can be in the range of 500-1200 W. There are tools equipped with an additional speed regulator, which allows you to select the most optimal option for each type of surface.

Belt sizes vary depending on the modification of the sanding machine. This indicator is the highest for the most functional device. At the same time, the weight and dimensions of the structure will also be significant. When choosing a power tool, special attention should be paid to the grain size of the tape used. For ease of work, it is necessary to have several types of tapes with different grain sizes. One type of belt sander for wood is a brush device that performs the roughest processing.

Orbital (eccentric) sander

According to the principle of operation, this device for processing wooden surfaces is similar to a VShM. The main distinguishing indicator is the higher productivity of the vibratory sander. In addition, processing is carried out more accurately and delicately thanks to the complex trajectory of the grinding element. The grinding is carried out with discs with a diameter of 15 cm. Abrasive circles of suitable grain size are molded onto them.

The disadvantage of an eccentric machine is the formation of excessive amounts of dust. But manufacturers supply models equipped with effective dust collectors, which allow work to be carried out in enclosed spaces.

Vibrating sander

The sole of a vibration-type technique can be triangular (iron) or rectangular. During processing, she performs circular movements with a small amplitude. The machine is used for those cases when it is necessary to obtain a high-quality surface, for example, to restore furniture before applying stain or varnish. Sanding is required especially carefully, since all flaws will be clearly visible through the transparent layer of the finishing coat. At the same time, the device has low performance.

Note! It is better to choose a rectangular sole for finishing large areas, and for corners and hard-to-reach places it is advisable to use a triangular shape.

When working with a vibrating grinder, it is imperative to remove debris, any solid substances, and grains of sand so that small circles - marks - do not form on the surface. To remove such defects, you will need an abrasive wheel with the finest grain size. The surface of the wood to be treated must be thoroughly cleaned with a vacuum cleaner.

Oscillating wood sander

This electric tool is a multi-functional resurfacer that is also capable of sanding wood surfaces. It differs from other tools in its budget price and very low power consumption. With its help you can process sharp corners and places near vertical walls. To carry out this manipulation, a special triangular platform is installed on the grinding machine, to which a grinding wheel on a self-adhesive base is attached. In addition, the device makes it possible to effectively clean the floor from glued linoleum and tiles, create slots, and cut communication lines.

During operation, the sole moves in a horizontal plane with minimal amplitude, the tops of the platform deviate by an average of 2.5 mm (1.7 degrees). Due to these movements, surface treatment is carried out. This device can be used for grinding corners and other hard-to-reach areas. The machine does an excellent job not only of removing wood, but also of smeared or dried glue. In general, the oscillating machine is used for finishing in places where other machines cannot cope due to their low productivity or sanding spot.

Orbital (eccentric) electric sander

The working platform of an eccentric grinder is a circle that rotates and makes reciprocating movements. An eccentric device with two rollers allows this to be done (hence the second name of the tool).

The first is the axis of the grinder disk, shifted relative to the center by a couple of millimeters.

- Self-rotation is carried out through another roll passing through the middle of the circle in a circle around the shaft.

- Using this type of sander, you can achieve excellent grinding quality; in addition, you can polish the surface of the product coated with varnish.

- It is because of this that they are valuable in furniture, restoration, car repair shops and other enterprises where the quality of polishing and grinding of products is important.

Brush grinder

There are two types of brush grinding, which are similar in appearance to angle grinders and belt grinding. In the first type, the axis of rotation is also located at an angle of 90 degrees with respect to the electric drive, which is located in the elongated handle.

This model differs from an angle grinder in that the brush model has a much lower rotation speed. Also, the handle is on a completely different side.

- The second model is equipped with the same rectangular platform, only there will be only one roller, which acts as a drive.

- Its diameter is significantly larger than that of belt grinding.

- The scope of use of these models is the removal of oxidation, rusty layer, and previous coating from the surface of products before proceeding with finishing.

In addition, these products use round or cone-shaped pads to which sandpaper or felt is fixed. Thanks to this, you can grind or polish the surface.

Types of grinders by application

According to their purpose, grinders are divided into angle, straight, belt, brush, eccentric, vibrating, delta grinders, polishing and oscillating.

Angle Grinder

An angle grinder, or grinder, is used for processing metal, stone, ceramic and concrete surfaces. The working shaft of such a machine is located at an angle to the plane of the electric motor. Using abrasive discs, angle grinders can be used to remove rust, cut ceramic tiles into pieces, and grind welds. Additional special attachments expand the scope of use of the grinder. When choosing such a tool, pay special attention to the length of the spindle and the weight of the unit.

Cutting wheel BOSCH for stone 115x22x2.5

Straight grinder

A grinding machine of this type is also called an engraver. An engraver is a multifunctional tool that can be used to perform work that requires high precision. A straight grinder consists of a housing, an electric motor, a gearbox with a spindle. Using such a machine, you can perform grinding, drilling, cutting, sanding, engraving and other types of work. The machine may come with various types of brushes, cutting wheels, grinding stones, etc. Direct type grinders have a compact size, which allows them to be used even in cramped conditions when work space is very limited.

Belt sander

This tool is used when rough grinding, surface roughing is required, or when it is necessary to remove a thick layer of a particular material. This type of machine is used in carpentry, carpentry, and construction. It is used to process materials such as plastic, wood, metal, etc. Grinding is carried out by moving the sanding belt along guide rollers. This tool is characterized by a particularly low center of gravity, which means that minimal effort is required when working with the draw frame. If you need a tool to level small surfaces, it is better to purchase a machine with a short belt.

Brush grinder

The peculiarity of this tool is that instead of sandpaper, a metal brush is used. Thanks to it, machines of this type make it possible to effectively process various surfaces: wood, metal, and glass. With this tool you can sand parquet and wooden floors, remove old paintwork, make the surface smooth, and structure wood.

Random orbital sander

Also called orbital. Its design includes an eccentric, which makes it possible to simultaneously perform both reciprocating and circular movements. Using an eccentric machine you can clean, grind and polish volumetric, profile and curved objects. Equipped with sheets of different grain sizes, orbital machines can work with a variety of surfaces, including plastic, wood and metal.

Orbital sanders come in two types: those equipped with a classic handle and those equipped with a single-palm handle. The former are designed for processing large surface areas, while the latter are used when delicate work is required.

Random sander BLACK&DECKER KA198-QS, 260 W, 125 mm

Vibration sander

A vibrating or surface grinding machine is also used for grinding wood, plastic, metal, stone, and composite materials. This tool is actively used in woodworking, body repair, and also in furniture repair. The vibrating grinder is driven by an electric motor, which transmits oscillatory motion to the sole through an eccentric connecting rod. Abrasive sheets are attached to the sole with clips or Velcro.

Orbital sander MATRIX EM-OS 180, 180 W, 90×187 mm

Delta sander

This is a type of sander similar to an oscillating sander. It differs in a different shape of the working element; in delta sanders it has the shape of a triangle. They use a delta sander to process the surface in hard-to-reach places: in recesses, on convexities, etc. The delta sander is easy to use, it is compact in size and has a low weight.

Polishing machine

This is the name of another type of grinder. The device is equipped with a D-shaped handle attached to the body. A distinctive feature of the device is that it operates at low speeds, which can be adjusted. This machine comes complete with several wheels: abrasive, felt, foam and fur. This machine is used for surface cleaning, sanding and polishing. It can be used where particularly delicate grinding is required.

Oscillating machines

The peculiarity of such machines is the triangular sole, moving with a small amplitude - from 1 to 3 mm. The sole has holes for removing dust. Abrasive sheets are attached to it using Velcro. This machine is intended for cutting, polishing and cleaning various surfaces, as well as making holes in chipboard and gypsum board.

Crosscut, straight model

They are the simplest of this category of tools. Used for minor work - trimming, stripping, sanding. In appearance it is an elongated body with an electric motor.

In this case, the working element is sanding attachments in the form of a cylinder, cone, or sphere of not very large shape. Both cutting and flap discs can also be used.

How does a household appliance differ from a professional one?

There are several main differences that are undoubtedly worth paying attention to when choosing a tool:

- Working hours. The household tool can be used without stopping for five to ten minutes, after which the machine should be allowed to cool for some time. A professional model can work from fifteen to twenty minutes, and she needs literally five minutes to rest.

- Terms of use, level of protection. It is immediately clear that a more serious instrument (professional) will look better in relation to the “amateur” one. It will better “swallow” dust and moisture, and “steadfastly” withstand wire breakdowns and long-term operation.

- Durability. For a household tool, it will be enough to work for two to three hours a day and that’s it, but a professional tool can withstand two full-fledged work shifts.

In addition, a professional tool has additional “bells and whistles,” but a household model may have them, but only a top-tier tool. It is clear that the manufacture of serious power tools requires high-quality materials and excellent fittings.

And they are several times more expensive compared to household ones. Most well-known manufacturers make it easier for their customers to choose by releasing instruments on store shelves where the body is made in different colors. For example, Bosh, blue is professional, green is amateur.

Types of cars

There are several main types of sanders for household use on sale. Each grinding machine has its own design features and mechanism of action.

For carpentry, joinery, construction and repair work, the following types of power tools are chosen:

- a belt sander for wood (LSM) is designed to perform rough and aggressive processing of surfaces, including plastic and metal;

- Brush sanders allow you to highlight the texture of wood, removing more soft fibers, and remove layers of varnish and old paint. The working part is a roller on which a metal or abrasive nylon brush is mounted;

- An orbital grinder (VShM) is used for a softer finish. Gentle processing occurs due to circular movements and the small amplitude of the working tool. The sole has a rectangular shape, which makes cleaning corners easier;

- delta sander is a type of flat orbital sander with a triangular base. This device is suitable for processing hard-to-reach places and small areas, as well as recesses, corners, and irregularities;

- An eccentric sander is a power tool that allows you to bring the surface being treated to an ideal condition, including plywood. This task is accomplished through the rotational and oscillatory movements of the sanding pad. The device has a high degree of productivity, but cannot be used for cleaning internal corners and small surfaces.

A wood sander is an indispensable tool for processing walls, floors, interior items and other decorative elements. It can speed up the process of grinding and polishing surfaces made of natural materials several times.

What you should pay attention to

Before you go to the store to buy something, you should think again about where and what it will be used for.

After all, not only the price range will depend on this, but also the additional materials that will need to be purchased:

- If a sander is needed to remove old paint from a wooden floor in a country house, then in this case ordinary belt sanding will be sufficient. Moreover, its cost will not be very high, about several thousand, but it should have good reviews.

- If you are purchasing a tool for a home workshop, where carpentry work will be carried out on the manufacture of furniture and interior items, then you should think about buying a good orbital sander with excellent performance and speed.

However, no matter what tool you plan to purchase, it is worth considering the following indicators, which are relevant for all types of grinders:

- Speed of surface movement;

- Availability of speed control;

- How often will the abrasive material need to be changed?

- Availability of additional devices on the market;

- Equipped with spare batteries, handles;

- Possibility of connecting a vacuum cleaner, adapter;

- Noise level, vibration;

- Warranty, service.

In addition, you can find out how far the warranty workshops are from your place of residence, as well as how much the delivery of the purchased product will cost.

So you can choose any tool, the most important thing is that it works properly, is in demand, and is easy to maintain. You should not avoid reviews from real customers, as you can glean a lot of useful information from them that you would never get from the seller.

Criterias of choice

When purchasing a specific model of grinding equipment, you should take into account the tasks that the power tool must perform in the future. The choice of professional or household equipment depends on this.

Professional wood sanders are ideal for long, active and continuous work. They will cost much more than household tools. For use without significant loads and long-term work, you should give preference to simpler grinders. If the choice is between a professional device and a regular one, then it is better to purchase the first option, despite its high cost. If the second one was chosen, then when working with it it is recommended to subject the device to less heavy loads. You need to pause every 3 hours. Only following simple operating rules will extend the life of the tool.

It is also important to consider the type of work for which the grinder is selected. For processing smooth surfaces, the optimal solution would be to purchase a belt sander. If there is a need for sanding or polishing decorative wooden products, it is recommended to purchase eccentric models. The ratio of the cost of consumables and upcoming costs during operation of the device also needs to be taken into account.

If you intend to use the grinding machine indoors, then you should pay attention to equipment with a built-in dust collector or the ability to connect a vacuum cleaner. Considering that the process of sanding surfaces will generate a lot of dust, you need to prepare for it to appear everywhere. Cleaning a room manually takes a lot of effort and time.

The length of the cord plays a significant role when choosing a sander model. Since it is inconvenient to work with a device on a short cord, and it is not always possible to use an extension cord.

We sell battery-powered tools that are useful for work in the country and in houses where electricity has not yet been installed. The cost of such models is high.

When choosing a device, you should test the location of the handles, check whether it is convenient to switch modes, and how difficult it is to hold the machine in your hands.