The spindle of a lathe must impart torque to the part being processed on the machine. To do this, a clamping device that best matches the workpiece is attached to the end of the spindle. There are a large variety of clamping devices, but usually this is a three-jaw chuck - it ensures reliability and accuracy of clamping, ease of installation and removal of most symmetrical parts.

The design of the spindle end of a lathe must satisfy the following requirements:

- Ensure secure fastening of the lathe chuck

- Ensure accurate alignment of the chuck relative to the spindle axis

- Ensure installation and removal of the cartridge for replacement in a minimum amount of time

DIY lathe chuck

Even today, lathes play a huge role in the production of certain parts.

All components and all equipment on any machines change over time, as they are subject to wear. All these elements of equipment must be of high quality and durable, since the quality of the finished product depends entirely on the quality of the installed parts. So is the lathe chuck. It is without this element that the machine becomes useless. Below we will analyze everything related to this element of the lathe. Let's start by finding out what this part is.

General concepts

The chuck is one of the main elements of turning equipment. It is due to this that the future workpiece is fastened (installed). It is attached to the headstock with the gearbox. The chuck mechanism consists of a cam device.

Purpose

It is this part of the machine that has the most important mission in any workpiece processing. Due to the cam mechanism, which is located inside the chuck itself, the workpiece is clamped and centered. This happens due to the simultaneous narrowing of the cams around the plane of the workpiece. After clamping the workpiece, the workpiece is clamped with a quill located on the tailstock. When these actions are completed, the machine starts and the part rotates, which can be processed.

Variety

Nowadays, lathe chucks are distinguished by the presence of fastening elements (jams). There are only three of these types:

Double cam

Such cartridges are capable of securing complex, asymmetrical and shaped parts. In such cartridges it is possible to secure surfaces that are not subject to treatment. They are used in small production, as well as in serial production.

Three cam

This type of equipment is the most common and is used in all work. Allows you to process round and hexagonal parts. This type of chuck uses three different jaws. Regardless of this, the workpiece is centered together with the clamping of all three cams.

Four cam

This type is used for processing rectangular workpieces. Here, for each cam, there is a separate mechanical unit, which makes all cams independent.

Types of jaw chucks

But the types of cartridges do not end with three types. They are also divided according to the mechanism for fixing the workpiece:

Collet

They consist of a sleeve with slots in which the petals are located (various modifications include from 3 to 6 petals). These petals act as cams.

Wedge

This type of equipment is used mainly on machines with numerical control. secured using 3 cams, which are located on a flat spindle.

Lever

These cartridges contain sliders, with the help of which the cams move by lever force. This type is used for small-scale production, as well as for processing a single workpiece.

Membrane view

In this case, a pneumatic drive is used, with the help of which the membrane is compressed. This type is used only for fine processing, to remove a thin layer of chips.

Drilling

These chucks are similar in principle to chucks for hand drills. When the nut is tightened with a special wrench, the cams are smoothly squeezed out. Due to this action, the part or tool is clamped.

Thermal cartridge

This type of device is very inconvenient to use. This is due to the fact that when attaching the workpiece, thermal heating of the chuck itself is performed, and the same actions are performed when removing the tool.

Hydraulic chuck

The principle of operation is similar to that of a thermal cartridge. The part is clamped by a liquid that compresses the cams under pressure. Due to the liquid contents in the cartridge, additional damping of vibrations that occur during operation is performed.

Design

Design of jaw lathe chuck

Let's look at the structural elements that make up the lathe chuck itself:

Used to carry out clamping actions.

Spring

Allows you to use the key to perform certain actions to clamp the part and vice versa.

Sleeve

Produces free passage of the key.

Stopper

Prevents the part from unscrewing while the machine is running.

Gear

Transmits rotational motion to the spiral disk.

Flange

The part on which the entire structure is fixed.

Spiral disc

Due to the rotational movement of the gear, this disk drives the cams.

Reverse cam

Used for clamping the workpiece from the inside.

Cam straight

Used for clamping the workpiece from the outside.

Frame

An element of a part on which the cam mechanism is located.

Overhead cams

For clamping long and short parts with large diameters.

Each of the parts of the entire mechanism performs a specific function and is not superfluous.

Assembly according to drawings

Drawing of a three-jaw chuck

The jaw chuck for turning equipment is assembled according to diagrams that can be downloaded from the Internet and printed on a printer. As a rule, factory cartridges cost a lot of money and therefore many have learned to make such parts homemade . Their design is simple, but quite understandable. Before you begin assembling this fixture, you must fully understand the entire mechanism of the chuck and cam mechanism. If it is not possible to make such elements yourself, then they can be ordered from any turner. It won't cost much.

Assembly begins with a flange on which all the necessary holes for fastenings are located. Following this, all the parts of the mechanism are gradually installed, which are completed by covering with the case and bolting the entire cartridge

Classifications

Conventionally divided into two groups:

- Cam . Movable segments (cams) fix the part. They differ from each other in design and purpose.

- Collet . Depending on the working position of the collet chuck for a lathe, which secures the part in the desired position, lathe chucks of this type are distinguished:

- with retractable collet;

- fixed collet;

- retractable collet.

Double cam

Self-centering double-jaw chucks. All parts of the product are made of steel; moving parts are subjected to heat treatment, which increases their strength characteristics and wear resistance.

Provide self-centering and fixation of untreated surfaces of workpieces. The dimensions of the working diameter of the chuck are standardized and vary from 125 to 400 mm.

Mounting cartridge used:

- complex shaped parts;

- non-cylindrical and asymmetrical workpieces.

Three-jaw

The locking mechanism of the 3-jaw chuck is made:

- with rack and pinion mechanism;

- with spiral disc.

Rack and pinion

More precisely, a chuck with a spiral disk has a more powerful clamping of the workpiece. Can be used in small-scale or piece production.

Four-jaw

The four-jaw chuck is used when processing asymmetrical workpieces. Allows you to machine a part off-center or when boring holes along different axes.

The product is attached by two pairs of independent holders in mutually perpendicular planes and ensures complete alignment of the spindle axis with the surface being processed.

The cam can be solid or assembled. The chuck with a prefabricated jaw has a base and a mounted jaw. The assembly cam is placed in the groove of the main element and has free radial movement without loss of stability.

This ensures double keyed fastening. The advantage of the design is the rigidity of fixation and ease of use.

Six-jaw

The fixing force is distributed between six cams, which allows you to fasten a thin-walled part without fear of its destruction or deformation.

How to install a chuck on a lathe?

Installing a chuck on a lathe can be done using several methods, it all depends on the specific type of this element that you will be dealing with.

There are two types of chuck mounting on a lathe spindle:

Threaded fastening is used on small machines with light types of chucks, flanged on medium and heavy machines.

If it is light, it is quite easy to install on the machine without outside help, then heavy ones (more than 20 kg) are installed with the help of auxiliary lifting mechanisms, or in tandem with a partner. Let's consider the procedure for installing a heavy flange-mounted chuck on a lathe.

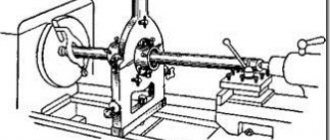

To install a heavy chuck, you need to prepare two mounting fixtures.

- mounting stand;

- guide

The mounting stand is made from a board approximately 50 mm thick. The width is equal to 1.5 times the width of the installed cartridge, the length of the stand L- corresponds to the width of the bed-B and the radius-D.

The blocks are attached to the bottom of the stand. Through vertical through holes, the stand is bolted to the movable rest of the machine support. The height of the stand is adjusted by the thickness of the bars.

Between the steady rest with the stand attached to it and the chuck still installed on the machine, the gap should be 1-3 mm.

The guide is a cylindrical shaft with a diameter of 25-40 mm, with a shank in the form of a Morse cone of at least number three. The length of the cylindrical part of the guide is equal to 1.5-2.0 times the width of the installed cartridge.

Installation procedure

Before installing it, you should carefully check the condition of the surfaces of the spindle and chuck. Surfaces should not have nicks, scratches, burrs or contaminated areas.

Identified defects are eliminated point by point with a file or scraper. You should check the runout of the end and cone of the spindle landing base, which should not exceed three microns.

Place a metal rod or pipe with a diameter of about 20 mm into it. clasp it with your fists. With a partner, grasp the rod on both sides, or using lifting mechanisms, through the mounting loop, move the cartridge onto the mounting stand fixed to the machine support.

Install the guide in the tailstock. The chuck should be shifted by rolling towards the spindle axis.

Using a longitudinal feed, move it to the spindle flange so that the chuck studs do not reach the mounting holes of about 10 mm. The machine should be set to neutral speed to allow the spindle to rotate freely.

Move the tailstock with the quill completely retracted forward towards the chuck so that the guide extends over the entire width of the cam prisms and fix the tailstock.

Clamp the jaws of the chuck to transfer the weight to the guide. Align the key on the spindle flange with the mounting hole. Set the rotary washer to the position of the open holes. Using the quill, push the cartridge forward until it stops.

After making sure that all the stud nuts are out of the back of the spindle flange, turn the rotary washer to the locked position. Tighten the top nut with enough force to transfer the weight of the chuck onto the spindle. Open the cams and move the tailstock back. Compress the nuts according to the rule crosswise, evenly distributing the force between the studs.

After installation is completed, the chuck should be checked for axial and axial runout. If the standards are exceeded, it should be removed and all mating parts of this assembly should be carefully inspected.

Video: installation of a lightweight cartridge on a threaded fastener.

Selecting the right product

The characteristics of the selected device directly affect the ability to work with the form, the accuracy of the geometry of the future product, and the quality of the surface. The lathe chuck also determines the production speed and the maximum number of parts produced per shift. An incorrectly selected design increases the number of defects and can lead to machine failure. According to GOST, the connection must be made taking into account the following parameters:

- Design load. A lathe chuck can work with parts of a certain internal and external diameter, shape and weight. If the maximum permissible dimensions are exceeded, the device will fail (especially when operating at high speeds);

- Type of product fixation on the spindle axis. For fastening, a centering belt or flange, a Camlock clamp or a rotary washer can be used;

- Dimensions of mounting holes and their position on the body;

- Frequency limits. Shows at what maximum speed the lathe chuck operates;

- The number of cams, their type (overhead or compound), hardness and fastening method used, type of movement - all this determines how convenient it will be to work with the clamp, and how much time it will take to readjust it;

- Cartridge accuracy.

In order not to make a mistake when choosing a product, it is recommended to first obtain professional advice. This can be done from our company employees by contact numbers. We will recommend suitable lathe chucks taking into account the specifics of your production.

DIY lathe chuck

Even today, lathes play a huge role in the production of certain parts. All components and all equipment on any machines change over time, as they are subject to wear.

All these elements of equipment must be of high quality and durable, since the quality of the finished product depends entirely on the quality of the installed parts. So is the lathe chuck. It is without this element that the machine becomes useless. Below we will analyze everything related to this element of the lathe. Let's start by finding out what this part is.

General concepts

The chuck is one of the main elements of turning equipment. It is due to this that the future workpiece is fastened (installed). It is attached to the headstock with the gearbox. The chuck mechanism consists of a cam device.

Purpose

It is this part of the machine that has the most important mission in any workpiece processing. Due to the cam mechanism, which is located inside the chuck itself, the workpiece is clamped and centered. This happens due to the simultaneous narrowing of the cams around the plane of the workpiece. After clamping the workpiece, the workpiece is clamped with a quill located on the tailstock. When these actions are completed, the machine starts and the part rotates, which can be processed.

Variety

Nowadays, lathe chucks are distinguished by the presence of fastening elements (jams). There are only three of these types:

Double cam

Such cartridges are capable of securing complex, asymmetrical and shaped parts. In such cartridges it is possible to secure surfaces that are not subject to treatment. They are used in small production, as well as in serial production.

Three cam

This type of equipment is the most common and is used in all work. Allows you to process round and hexagonal parts. This type of chuck uses three different jaws. Regardless of this, the workpiece is centered together with the clamping of all three cams.

Four cam

This type is used for processing rectangular workpieces. Here, for each cam, there is a separate mechanical unit, which makes all cams independent.

Types of jaw chucks

But the types of cartridges do not end with three types. They are also divided according to the mechanism for fixing the workpiece:

Collet

They consist of a sleeve with slots in which the petals are located (various modifications include from 3 to 6 petals). These petals act as cams.

Wedge

This type of equipment is used mainly on machines with numerical control. secured using 3 cams, which are located on a flat spindle.

Lever

These cartridges contain sliders, with the help of which the cams move by lever force. This type is used for small-scale production, as well as for processing a single workpiece.

Membrane view

In this case, a pneumatic drive is used, with the help of which the membrane is compressed. This type is used only for fine processing, to remove a thin layer of chips.

Drilling

These chucks are similar in principle to chucks for hand drills. When the nut is tightened with a special wrench, the cams are smoothly squeezed out. Due to this action, the part or tool is clamped.

Thermal cartridge

This type of device is very inconvenient to use. This is due to the fact that when attaching the workpiece, thermal heating of the chuck itself is performed, and the same actions are performed when removing the tool.

Hydraulic chuck

The principle of operation is similar to that of a thermal cartridge. The part is clamped by a liquid that compresses the cams under pressure. Due to the liquid contents in the cartridge, additional damping of vibrations that occur during operation is performed.

Design

Design of jaw lathe chuck

Let's look at the structural elements that make up the lathe chuck itself:

Used to carry out clamping actions.

Spring

Allows you to use the key to perform certain actions to clamp the part and vice versa.

Sleeve

Produces free passage of the key.

Stopper

Prevents the part from unscrewing while the machine is running.

Gear

Transmits rotational motion to the spiral disk.

Flange

The part on which the entire structure is fixed.

Spiral disc

Due to the rotational movement of the gear, this disk drives the cams.

Reverse cam

Used for clamping the workpiece from the inside.

Cam straight

Used for clamping the workpiece from the outside.

Frame

An element of a part on which the cam mechanism is located.

Overhead cams

For clamping long and short parts with large diameters.

Each of the parts of the entire mechanism performs a specific function and is not superfluous.

Assembly according to drawings

Drawing of a three-jaw chuck

The jaw chuck for turning equipment is assembled according to diagrams that can be downloaded from the Internet and printed on a printer. As a rule, factory cartridges cost a lot of money and therefore many have learned to make such parts homemade . Their design is simple, but quite understandable. Before you begin assembling this fixture, you must fully understand the entire mechanism of the chuck and cam mechanism. If it is not possible to make such elements yourself, then they can be ordered from any turner. It won't cost much.

Assembly begins with a flange on which all the necessary holes for fastenings are located. Following this, all the parts of the mechanism are gradually installed, which are completed by covering with the case and bolting the entire cartridge

Installation

Installing the jaw chuck

Installation is carried out as follows and in strict sequence:

Installation of the mandrel

First of all, this part is installed to ensure complete fitting of the cartridge.

Installing the chuck itself on the spindle

Using a frame, it is put on the spindle and secured with bolts.

Consolidation

The chuck is secured to the spindle with bolts. In this case, a simple open-end wrench will be a good helper.

Securing the workpiece

After installing the chuck, a part, workpiece or tool is fixed into it.

Three jaw chucks

The three-jaw chuck is most widely used. The reason for its high popularity is the speed of fastening parts, which is especially important in small-scale production, where workpieces are changed very often.

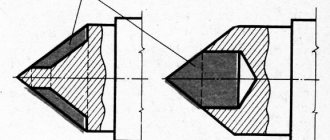

Unlike wedge-type chucks, this chuck does not require changeover time when installing a workpiece of a different size. Centering of the cartridge can be done with a cylindrical belt or a cone.

The cartridge is a massive faceplate in which radial grooves are cut. They move three cams driven by a bevel gear, which is mounted inside the faceplate. One of the rings is equipped with an end thread, called an Archimedes spiral, with which it can be rotated with a key. When this spiral rotates, all cams move simultaneously.

Varieties

To bore the jaws of a lathe chuck, it is necessary to choose the optimal method for a particular type. Several types of cams are produced, each of which has design features.

Direct

This type of cam is designed to clamp a workpiece with a shaft on the outside and for a workpiece with a hole on the inside. The cams are directly located on top and grip the part.

Reverse

Necessary for clamping the workpiece from the outside. Used for processing hollow blanks so that there is something to cling to.

Invoices

This is a composite version of the cartridge, which is made of non-ferrous metal or stainless steel. Used when working with large-scale projects. This variation is used when working with workpieces of large diameter, and it does not matter whether they are long or short.

Prefabricated

A metal cam in this type is mounted on a steel rail. Alloy steel is used, and the cam teeth are ground, hardened and carburized.

Clamping mechanism design

Another important classification of devices, affecting their design and application, concerns the assembly of the clamping mechanism. According to this parameter, chucks for lathes are divided into the following types:

- Drivers are the simplest, used for processing the center; if it is necessary to sharpen the side surfaces, gear and pin units are selected;

- Spiral self-centering - centering occurs simultaneously with fixation, which reduces the time required for preparation. The most popular lathe chucks are equipped with two, three or six holders;

- Lever - their feature is the presence of a rod with a coupling, driven by a hydraulic drive. Due to this, fastening occurs. In demand in small-scale production;

- Wedge rack - this lathe chuck is similar in characteristics to a lever chuck, but provides greater centering accuracy;

- Collet - capable of fixing only rod samples with a small diameter. Despite the low versatility, they are popular due to minimal radial runout, which improves the quality of work;

- Drilling - designed for connecting drills and other tools to the machine;

- Thermal chucks - used on the same machines as collet chucks, but they require a shrink fit to connect the tool;

- Hydraulic chucks are another alternative to collet devices. The lathe chuck clamps the tool due to the operating fluid pressure, which reduces the force required for reliable clamping.

Let's take a closer look at the design and capabilities of the most popular devices.

Lathe collet chucks

The key working element is a metal sleeve, divided into 3,4 or 6 petals. The maximum diameter of the fixed product depends on their number: metal plates capture the part inserted inside the sleeve and hold it during the entire working process. Structurally, collets are divided into two types: feeding and clamping. In the first, the hardened steel bushing has three incomplete cuts, forming petals with the ends pressed together. Feed collets use spring-type petals, and their number varies depending on the model. As the collet is pressed into the chuck, the slots become narrower and the grip between the collet and the workpiece increases.

Due to this, this type of cartridge is often used for secondary fastening of an already processed product: the petals hold it firmly, but do not damage the surface. If the profile of the part does not match the shape of the collet, special replaceable liners are used.

How to squish it correctly?

To properly bore the cartridge, you must follow the sequence of actions. Professional boring is carried out in several stages, each of which must be performed with high quality and in accordance with all technical requirements.

Dismantling

First of all, it is necessary to dismantle the cartridge. Otherwise, it will not be possible to get rid of the workpiece runout and accurately align all the necessary axes. If the chuck is not clamped, but is in a free state on the machine, the defects will remain. After dismantling, it is necessary to remove the cams and clean them. Then you need to check the runout.

Sandpaper treatment

If there is a slight degree of wear and scuffing, it is enough to treat the part first with coarse-grained and then fine-grained sandpaper. In order not to distort the cam profile when sanding, it is necessary that the sandpaper covers approximately half of the cam profile and at the same time have a slight tension. If the cam wear is significant, full boring is necessary.

How to sharpen?

To groove the cams, a certain order must be followed:

- Install them by aligning them with the hole in the lathe chuck.

- Clamp the ring so that it can move freely.

- You will need two cutters: one for boring grooves, and the second for developing planes.

- Starting from low speeds, you should find the optimal rotation mode.

- The cutter for disassembling the planes must be installed so that contact occurs along the entire plane of the fists.

This way, conical boring is carried out and the workpiece can be fastened securely and safely.

Grinding

This is the final stage of boring, which is carried out only if there is a real need. At the same stage, a test is carried out with a metal shaft. The shaft is fixed in the chuck of the lathe and with its help it is possible to determine whether there is any runout. If there is runout, additional grinding is required.

Basic dimensions and designations

The adopted system of standards provides detailed data for each type of lathe chuck. It shows the dimensions of each element. The tables show the main parameters: flange diameter, size and shape of the cams, diameter of the internal hole in the housing, hole size and method of fastening, permissible rotation speed. The lathe chuck is calculated based on the requirements specified in the technical specifications for the machine.

The main parameters can be determined by the accepted markings. It is established by a unified notation system. It includes eight digits. The designation ends with a lowercase letter. The numbers indicate the following dimensions:

- number of cams;

- outer diameter of the product;

- basic dimensions established by standards;

- method (type) of attachment to the spindle;

- the shape of the fists.

For example, marking 3-200.33.14 P allows you to set the following. The product has three cams. The outer diameter is 200 mm, the standard version is 33. It has modification number 14 and an increased accuracy class “P”.