A DIY sandblasting attachment used for installation on a standard Karcher machine will allow you to turn such equipment into a full-fledged sandblasting unit, useful in many situations. Most Karcher washing machines operate under high pressure, so their technical capabilities are quite sufficient to supply sand through such a nozzle. The difference between such a homemade device and a classic sandblaster will be that sand will be supplied through its nozzle along with water, but this is not critical for many situations.

Kärcher wet sandblasting kit

Sandblasting nozzle for a Karcher: do-it-yourself sandblasting from a sink

To quickly and efficiently clean surfaces from dirt, old paint and rust, it is best to use sandblasting.

This type of cleaning is carried out using special equipment - cameras, guns.

If you have a high-pressure washer, you can save on the purchase: the sandblasting nozzle on the Karcher will help in everyday life and repairs, and you can make it yourself.

Operating principle of the nozzle

Whatever the sandblasting machine, the principle of its operation is as follows: as a result of the operation of the compressor, the air flow is under high pressure, due to which abrasive (usually sand) enters the nozzle of the device. The latter is fed through the outlet hole in a thin but strong stream directly onto the object being processed, as a result of which the top layer is removed.

Sandblasting for Karcher is a device that can make a high-pressure washer suitable for work like a sandblasting gun.

This attachment will not replace professional equipment, but it is perfect for cleaning small surfaces.

Instead of air, the charge of kinetic energy will be given to each portion of sand by water, but otherwise the principle of operation of the device will remain the same:

- under the influence of the high pressure created by the compressor, water passes through the intake hole of the hose, the other end of which is placed in a container with sand;

- a vacuum is created in the intake hose, which helps the abrasive move into the main hose;

- After mixing sand and water, the flow is supplied through the outlet to the surface of the product.

To reduce sand consumption and increase processing efficiency, dispensers and taps can be introduced into the specified design. Typically, a sandblasting nozzle for Karcher consumes 30 kg of sand for every 0.8-1 square meter of surface.

Application areas of the nozzle

Due to the high power of the jet, using the Karcher nozzle you can process various surfaces:

- clean wood and concrete from plaster, old paint, varnishes, building mixtures;

- remove rust and scale from metal;

- clean various products before processing, applying protective and finishing coatings;

- get rid of stubborn stains;

- remove stains and drips of glue and polyurethane foam.

Making a homemade nozzle

A special nozzle for a high-pressure washer turns the latter into a good sandblasting unit; it is only important to purchase high-quality components. You will need:

- reliable hose with the ability to work under pressure;

- dispenser to save abrasive;

- nozzle for throwing sand and water;

- trigger hook;

- clamp and fitting.

The quality of the nozzle will determine the durability of the nozzle and the final result, so it is better not to skimp on it. Ceramic devices fail faster than those made from tungsten and cobalt alloys.

However, metal nozzles can be susceptible to rust due to the presence of water in the sink, so sooner or later any nozzle can deteriorate.

For more expensive devices, the trigger is included, otherwise you will have to buy it separately.

The nozzle on a Karcher for sandblasting must include a reinforced hose at least two meters long. You should not purchase hoses without additional reinforcement of the frame - they are not capable of operating under pressure of several atmospheres. A product of dubious quality will tear quite quickly.

Recommendations for safe use of the nozzle

In order not to harm yourself, it is necessary to work with the high-pressure washer and the nozzle in compliance with safety precautions, otherwise the water-sand mixture can cause injury. The advantage of such a device over a conventional sandblasting gun is the absence of dust settling in the lungs, so there is no need for a respirator. But you need to follow these tips:

- wear durable protective clothing;

- wear comfortable closed shoes;

- Clean products outdoors rather than indoors.

If you have a Karcher sink or its equivalent, it is not difficult to build a sandblasting unit yourself. This will save money and allow for high-quality surface treatment for every need that arises.

Precautionary measures

When working with a machine on which a sandblasting attachment is installed, certain precautions must be observed. A water-sand mixture can cause injury.

- When working with the device, wear special clothing, it will protect against injury;

- use closed and comfortable shoes;

- carry out cleaning work outdoors.

Since contaminated surfaces are processed and cleaned using sand and water, there is no need to use a respirator.

Sandblasting nozzle for Karcher: sandblasting from a high pressure washer

A DIY sandblasting attachment used for installation on a standard Karcher machine will allow you to turn such equipment into a full-fledged sandblasting unit, useful in many situations.

Most Karcher washing machines operate under high pressure, so their technical capabilities are quite sufficient to supply sand through such a nozzle.

The difference between such a homemade device and a classic sandblaster will be that sand will be supplied through its nozzle along with water, but this is not critical for many situations.

Kärcher wet sandblasting kit

Principle of operation

The operating principle of a sandblasting machine or device is to supply sand into a special nozzle.

The abrasive comes from a special container using high-pressure air .

To create such a powerful air flow, the sandblasting machine is equipped with a compressor, which imparts kinetic energy to the sand. For Karcher-type devices, equipment with pneumatics is typical.

It is a mistake to believe that such a sandblasting nozzle can fully replace a professional device. But it is quite capable of cleaning different surfaces Some recommendations should be taken into account when working:

- use distilled water - this will protect metal parts of the structure from corrosion;

- The abrasive must be fine-grained and sifted.

A part made independently will function according to the following principle:

- Water under the influence of high pressure created by a compressor will flow along the intake hole of the hose, which at the other end is placed in a special container with sand. This circuit is necessary to create a vacuum in the intake hose.

- The vacuum helps the abrasive move into the main hose, where the sand is mixed with the water flow. Thus, sand is supplied along with water.

For better functionality and productivity of the unit, you need to improve the design by adding dispensers and taps. These additions will reduce sand consumption. The best values would be thirty kilograms of abrasive per surface area of 0.8 meters to be cleaned.

Alternative manufacturing methods

The many options for homemade sandblasting are determined by the needs of the owners and the different materials available.

You can make your own effective installation using products intended for other work.

For example, a high-pressure washer unit will help you assemble a dust-free sandblasting machine with your own hands. Below are several working and effective options for homemade installations.

From a pressure washer

You can assemble a sandblaster from Karcher. This car wash creates high water pressure with low water flow. To obtain an efficiently operating dust-free installation, you just need to assemble a special nozzle for the outlet tube. Required:

- a self-made or store-bought ceramic nozzle;

- reinforced hose;

- mixing block, a tee with a suitable fit diameter is suitable;

- feed adjustment unit, cylindrical type dispenser;

- a tube for collecting abrasive, equipped with an air supply path into a closed container with sand or other material.

What else can a nozzle and gun be made from?

Making your own sandblasting gun is not difficult. For assembly, you can use a nozzle for a regular ball valve located at the end of the hose for discharging the air-sand mixture. The nozzle is a nut that clamps the outlet nozzle for the abrasive.

The nozzle, in turn, can be made on a lathe. But it is more rational to use a spark plug. The worn-out part is cut with a grinder, while the durable ceramic rod is separated from the metal parts of the structure, and its length is adjusted.

The process of cutting a candle requires appropriate skills. In addition, when cutting, a large amount of dust is generated, and a not very pleasant smell appears. If you don’t have a separate room and the skills to work with an angle grinder, it’s easier to purchase a suitable nozzle in a store.

DIY designs are often more effective than pistols, a wide range of which are commercially available. Therefore, if you have free time, it is wise to spend it on implementing your technical solution, and spend the saved money on other, no less important goals.

Making sandblasting yourself allows you to reduce the cost of purchasing a serially assembled machine by 3–5 times. Maximum savings can be achieved by using a homemade compressor, but it is very difficult to achieve sufficient power. The best option is do-it-yourself sandblasting in combination with a powerful factory compressor.

Main components of sandblasting machine

Homemade sandblasting is assembled on the basis of standard schemes, differing in the method of supplying sand to the contaminated part. Despite the existing design differences, the components for both options are the same:

- compressor - a device for pumping air mass;

- a receiver necessary to create the necessary air supply;

- abrasive tank;

- gun - the main device designed to supply an abrasive mixture to the surface to be cleaned;

- hoses.

In order to increase the duration of continuous operation and maintain the supply pressure, it is recommended to equip the sandblaster with a moisture separator. When using a plunger compressor, an oil filter system should be installed on the air intake duct.

The device, regardless of the assembly scheme, forms a combined output flow of air and abrasive. When assembled according to a pressure circuit, sand under the influence of pressure enters the outlet pipe, in which it is mixed with the air supplied from the compressor. To form a vacuum in the abrasive supply channel in ejector devices, the Bernoulli effect is used. Sand is fed into the mixing zone under the influence of only atmospheric pressure.

The existence of many options for sandblasting manufacturing schemes is explained by the possibility of creating it from materials at hand, which often seem unnecessary. To understand the essence of the process, it is enough to consider the general principles of assembly.

Do-it-yourself sandblasting attachment for a Karcher - Metalist's Handbook

A do-it-yourself sandblasting gun can be made using different methods, but the classic materials used for installation are:

- Compressor;

- Spray;

- Ball valve;

- Large plastic bottle;

- Fitting.

These elements that are needed to do sandblasting can be found in most home workshops. However, not everyone has a compressor and you need to purchase this missing element.

It is relatively expensive, but still cheaper than a whole sandblasting machine. So if you assemble a hydrosandblasting machine with your own hands, the benefits in terms of savings will be worthy.

However, you need to be more careful when choosing a pressure source - it must only be with a receiver. This chamber creates an air flow so that it is the same and the pressure does not fundamentally change throughout the cleaning process.

A homemade device depends on a constant supply, so you need to take care of this.

Possible options

Before you buy sand and start building a device, you need to study what the design of a sandblasting machine might be.

If the device is required for decorative events, processing glass or jewelry iron, then a homemade sandblasting chamber is better suited for this.

This device looks like a small chamber, the size of which is proportional to the size of the parts that need processing.

If you need large sandblasting to clean a car body or solid metal structures and prepare for priming and painting, then you don’t need a camera, but a hand-held sandblasting gun. In this case, you will need a separate room and protective clothing for work.

The design should also take into account how often the device will be used.

If you plan to sandblast with your own hands on a scale close to organizing a business, then the power of the assembled device will have to be given due attention.

The more often a working device is needed, the more power is needed. The main thing is that the homemade compressor for sandblasting is cooled correctly and promptly during operation.

Also, the operating principle of the sandblasting machine depends on what kind of processing is intended:

- Engineering. In this case, do-it-yourself sandblasting with water is used separately, in two arms, and mixing occurs only at the tip. Technically, such a device is easier to construct, but the elements of the device are small and difficult to handle;

- Pressure. In this case, sandblasting with your own hands delivers a stream of sand and air simultaneously. A pressure jet immediately flies out of the nozzle and the speed developed in such an apparatus is extremely high. In this case, it turns out that in a short time you can clean and sandblast a large surface.

Manufacturing of the device

It is better to do sandblasting with your own hands in the form of a spray gun, which looks like a small handle with two nozzles. Accordingly, sand is supplied from one, and air under high pressure from the other. It is better to buy a tip that emits a jet of abrasive from resistant metals:

High quality sandblasting nozzles

You can also make a nozzle for sandblasting yourself, but it’s still better to buy a ready-made one so as not to have to constantly redo it. Cast iron and ceramics wear out extremely quickly and the effect is mediocre. Some people recommend making a sandblasting nozzle from a spark plug, but this requires some skill.

It is impossible to make sandblasting without a gun, so the diameter of the handle and nozzle must be made the same size. A plastic bottle is attached to the top of the handle and serves to store abrasive, while water sandblasting is supplied from the bottom.

After the structure is assembled, you should connect the spray gun to a pressure source that supplies compressed air.

The principle of operation is clear - oxygen under pressure, which is created by the compressor, enters the internal cavity of a plastic bottle with sand and then exits into the double. After the air mixes with the sand it is pushed out.

For convenience, to make your own sandblasting machine more practical, you can install a tap here that could regulate the flow of sand. As you can see, making a sandblasting machine with your own hands is not as difficult as it seems at first glance.

Camera device

A do-it-yourself sandblasting machine is also made in the form of a chamber - a closed device, which is intended for finishing small-sized parts.

It looks like an oblong box, which you can make yourself from iron corners or buy it ready-made.

In any case, the steel sheet that serves as the walls in this structure must be at least two millimeters thick.

Also, the design of the chamber should include small windows so that you can visually monitor what is happening inside. To make a homemade sandblasting machine with your own hands effective, it is better to make a window on top, from there you can better see the process.

As you can see, the design assumes that manipulations with parts take place inside the case, so you need to make round holes on the side that are sized to fit gloves made of durable rubber. The strength of the gloves needs to be high, otherwise you will have to constantly change them.

In each case, both glass and gloves wear out over time due to constant contact with abrasives.

Therefore, just as a do-it-yourself sandblasting nozzle for a Karcher should be made of durable metal, it is advisable to provide glass in advance that is resistant to this kind of damage.

Inside the chamber you need to place a gun that will allow you to direct the sand stream in the desired direction. And below the container there is a tank that holds abrasive material, and a hose for collecting sand is placed through a hole in the floor.

The light inside is provided by protected lamps, but it is not needed if the room is already sufficiently illuminated.

This kind of sandblasting for Karcher is equipped with a special door, which is needed so that it is convenient to place the part inside for processing.

For long parts, provide end holes to allow the part to pass through the chamber.

Cover the doors with a tarpaulin; it will prevent sand from flying out of the structure when cleaning small parts.

Fire extinguisher

On the Internet, you can often find information on how to make a sandblasting device based on a fire extinguisher. You will need not so much a working fire extinguisher as the metal from it. A steel tube is mounted inside, which is attached to a thread at both ends.

Air moves through this tube, and at one end there is a groove for collecting sand. When the installation is completed, the housing is sealed back inside and abrasive material is poured inside. The lower end of the fire extinguisher is equipped with a pipe going to the gun, and the other end is connected to the compressor.

It turns out to be such a voluminous sandblasting nozzle for karcher with your own hands.

Under the created pressure, sand from inside the housing gets inside the tube and slides into the lower part. The air pressure forces the sand to be sucked in and fly out of the tip in the direction at speed.

Accordingly, an oxygen or gas cylinder can serve as such a small housing. Before using the cylinder, you just need to make sure that there are no remnants of gas that was previously there.

Consumables

So, we now know how and what is done, we made a compressor for sandblasting with our own hands and assembled the device, now we’ll figure out the consumable parts.

Sand collected from the street is not suitable for use in this type of apparatus, since it is not uniform in size and composition; the grains of sand vary.

This affects not only the operation of the installation, but also the resulting effect, that is, the processed part. Large grains of sand not only strip off paint and rust, but also leave grooves in the metal that are not needed there.

Therefore, it is better to purchase abrasive separately, rather than use whatever comes to hand. Construction stores sell a lot of abrasive mixtures of various consistencies, and their prices are moderate.

After you have purchased the abrasive and the device has been assembled, remember these important postulates:

- Use a wide nozzle. A narrow one will quickly deteriorate and become worn down by sand or abrasive material constantly flying through it. The principle here is this: the greater the power, the wider the nozzle;

- Gradually, wearing parts should be placed so that if something happens, they can be easily replaced with the same ones;

- Don't even think about using a sandblaster inside a living space, as the resulting waste will destroy the apartment. It is better to use a small chamber for this matter or a special separate room.

Upgrading a blow gun to sandblasting

Sandblasting, made from a blow gun, is small in size. The performance and efficiency of the device depends on the power of the compressor used.

To create a mini sandblasting machine you will need the following materials:

- blow gun;

- tee;

- ball valve designed to regulate the supply of abrasive;

- outlet nozzle with clamping nut.

You can use a small fire extinguisher or a regular PET bottle as an abrasive tank.

Do-it-yourself sandblasting on Karcher - manufacturing instructions

It is quite possible to do sandblasting with your own hands, especially if you have at least the minimum necessary materials. For example, if you already have a Karcher sink, then the nozzle made for it can become a full-fledged sandblasting machine. Since most washers of this type operate under high pressure, it is relatively easy to convert it into a full-fledged sandblaster.

In this case, the abrasive material is supplied together with water. Although in general the principle of operation is practically no different from classic sandblasting. Kärcher nozzle for sandblasting

The main difference is that instead of a compressor, pneumatic washing equipment is used.

Thus, the abrasive material (sand) is supplied under the influence of strong kinetic energy, due to which cleaning is carried out. Sand for sandblasting comes in different types, so you should pay attention to the properties of each material. A gun for pneumatic cleaning equipment can play the role of a nozzle.

You can either purchase it ready-to-use or assemble it yourself.

Sandblasting nozzle

In order to make an attachment for a Karcher sink with your own hands, you need to have the following elements:

- nozzle;

- trigger;

- reinforced hose;

- dispenser

Sandblasting nozzle for Karcher You should also purchase a special ceramic nozzle if you plan to use it constantly. Due to frequent use of abrasive material, a metal analogue can quickly become unusable. The ceramic option will last much longer.

Now, regarding the nozzle. This is, in fact, the basis of the nozzle for any type of sandblasting, not only when using a Karcher washing unit. Making a nozzle with your own hands is quite difficult, but still possible.

To do this, you need to select a metal rod with a diameter of at least 15 mm and saw it from the middle. But since this is quite problematic, it is better to just buy a good nozzle.

The operation of the entire nozzle depends on the quality of this component.

The hose must be at least 2 meters long and must be reinforced. This is due to the fact that the abrasive material, in this case sand, will quickly render an ordinary hose unusable.

As for the dispenser, it is needed for economical use of abrasive material. It should be noted that some nozzle models are sold with a trigger.

You can assemble the nozzle by following this algorithm:

- a ceramic or metal nozzle is attached to the nozzle via a thread;

- on the other side of the nozzle, a hose is installed using a clamp and fitting;

- A dispenser is attached to the end of the ceramic nozzle.

Please note that all joints between parts must be sealed. You can seal them using a special fum tape. Diagram of a sandblasting nozzle

To save sand, you can use a tank with a grate. To do this you will need a reinforced hose. Its beginning should be attached to a container with water and abrasive material. The end should go into a tray to collect waste sand. Thus, you can significantly save sand consumption.

The cleaning process is carried out using high water pressure. As a consequence of this, the sand is supplied under strong kinetic energy and simply “beats off” particles of dirt, paint, corrosion and other things.

With the help of such a simple device, you can thoroughly and quickly clean almost any surface, even after severe rust damage.

Nozzle for sandblasting machine

Safety precautions

Even despite the fact that sandblasting is done using a special nozzle, basic safety rules should be applied. Since the flow of abrasive material is supplied under fairly strong pressure, injury can occur if you are careless. To prevent this from happening, the following rules should be applied in practice:

- work only in closed protective clothing;

- shoes must be closed;

- It is better to clean outdoors.

As for face and respiratory protection, in this case they are optional. You can get by with overalls and closed shoes.

Safety precautions when working with sandblasting It is not difficult to build a sandblasting machine with your own hands if you approach this matter correctly. Moreover, this is easy to do if you already have special nozzles and a washer with good pressure.

In this case, you can save on buying a compressor.

If you don’t want to make such a device with your own hands, or for some reason it’s not possible, you can simply purchase a ready-made sandblasting nozzle or the device itself.

But it will be much more expensive than if you assemble it yourself.

Manufacturing method from a spray gun

Sandblasting can also be done using a spray gun. For assembly you need to prepare:

- a gun that functions as a mixing valve;

- handle with air supply device;

- a plastic bottle that acts as a tank for abrasive;

- tee;

- ball valve for regulating sand supply.

Using an airbrush instead of a spray gun will allow you to apply abrasive at higher pressure due to the smaller thickness of the outlet channel.

Assembly is performed in the following sequence:

- The gun is bored to increase the diameter of the output nozzle.

- The mixing tee is attached to the gun.

- The supply and circulation hoses are installed and attached.

The abrasive is released after the trigger is pressed. The volume of a small plastic bottle is enough to clean surfaces for 30 minutes.

Sandblasting from Karcher: nozzle for Karcher high pressure washer

A DIY sandblasting attachment used for installation on a standard Karcher machine will allow you to turn such equipment into a full-fledged sandblasting unit, useful in many situations.

Most Karcher washing machines operate under high pressure, so their technical capabilities are quite sufficient to supply sand through such a nozzle.

The difference between such a homemade device and a classic sandblaster will be that sand will be supplied through its nozzle along with water, but this is not critical for many situations.

Kärcher wet sandblasting kit

How does a sandblasting nozzle work?

The operating principle of any sandblasting installation is that abrasive material from a special hopper enters the nozzle under the influence of an air flow supplied under high pressure.

In serial installations, a separate compressor is used to create such pressure, due to which a significant amount of kinetic energy is imparted to the sand stream emerging from the nozzle. In the case of a Karcher washing machine, the pneumatic equipment built into it will be used for these purposes.

As a nozzle for such equipment, you can use a serial gun, specially designed for equipping pneumatic treatment plants, but in order not to spend money on such a device, you can easily make it yourself.

In order for your homemade sandblasting nozzle, which you will use for installation on a Karcher device, to be effective and not malfunction, you must use high-quality materials for its manufacture.

Operating principle of wet sandblasting rust cleaning machine

Of course, equipment assembled in this way can, with great stretch, be considered as a full-fledged sandblaster, but it is quite suitable for cleaning various surfaces with a stream of water mixed with sand. When using such a sandblasting device, it is very important to adhere to two recommendations:

- It is better to use distilled water as the working fluid, which will avoid corrosion of the metal elements of the nozzle;

- the sand that will be used as an abrasive must be of a very fine fraction and carefully sifted.

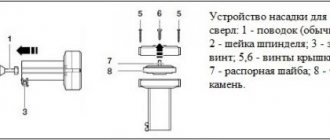

Diagram of a sandblasting nozzle (click to enlarge)

A self-assembled sandblasting machine, the basic elements of which are a Karcher mini-washer and a homemade nozzle, will work according to the following scheme.

- When you press the start button on the nozzle gun, water under high pressure created by the compressor flows past the opening of the intake hose, the other end of which is placed in a hopper with sand. This creates a vacuum in the intake hose.

- Under the influence of vacuum, sand is sucked from the hopper into the main hose, where it is mixed with the water flow.

In order to minimize sand consumption and bring this parameter to a value of 30 kg of abrasive for processing a surface area with a diameter of 70–80 cm, the design of this equipment must be supplemented with taps and dispensers.

Homemade mixer from water taps and tees

Areas of use

The high pressure created by the Karcher compressor allows a jet of water mixed with sand to be thrown through the nozzle, thus effectively and quickly cleaning many surfaces.

The sandblasting nozzle will easily allow you to cope with some tasks in a very short time:

- cleaning various surfaces from complex contaminants;

- removal of building mixtures, glue, paint, varnish;

- cleaning metal from rust and corrosion;

- carrying out stripping of metal products for subsequent processing.

The simplicity of the design and the ease of self-production can significantly facilitate and increase the quality of the work you perform. This attachment will save your time and effort.

Sand for hydrosandblasting

It’s worth starting with the choice of consumables, since the principle of sandblasting itself is trivial. Unless the flow of sand is supplied directly from the compressor unit, but is captured from the tank by a flow of water, which has a sufficiently high kinetic energy for these purposes. This is precisely the subtlety of using sandblasting nozzles for Karcher

The instructions for use recommend that the user only use sand supplied by the nozzle manufacturer. And this is no coincidence. Those who did not pay attention to this detail then pay with a sharp decrease in the speed of the cleaning mixture, and, accordingly, a decrease in the efficiency of sandblasting. There are plenty of reviews on the problem that has arisen.

Sand used in sandblasting nozzles has a number of features:

- Extremely uniform in fraction - 0.3...0.5 mm, no more and no less (a finer fraction will only produce grinding; the disadvantages of larger fractions will be discussed later).

- The particles have a rounded shape in plan, without sharp protrusions and corners.

- The sand must be strong enough so that it does not crush and disintegrate into smaller fractions after the first use.

- The supplied material must be completely dry before mixing with water.

Sandblasting with a high-pressure washer can be used to clean relatively small surfaces of a simple, flat shape (the sand consumption coefficient when working with more complex configurations will be several times higher). The sand itself cannot be recycled or recycled after processing. This is explained not only by the difficulty of collection, but also by the need for particularly thorough cleaning, since waste sand contains particles of materials torn off from the cleaned surface.

The technology for preparing “branded” sand from kärcher is characterized by a high degree of purification of the starting material – river or quarry sand. After grinding in high-precision ball mills, the semi-finished product is additionally calcined. This increases mechanical strength and makes it possible to use the abrasive for sandblasting not only relatively soft non-ferrous metals and alloys, but also steels. During the preparation of sand, larger fractions with a diameter of more than 0.6 mm enter the container: the grains of sand become noticeably heavier, and the kinetic energy of the water flow is insufficient to capture them and deliver them at the required speed (at least 350 km/h) onto the surface to be cleaned.

Safety precautions when working with sandblasting

There are a large number of risk factors in sandblasting. The most dangerous are abrasive dust and suspended particles of dirt. The most vulnerable places in a person are the eyes and respiratory system. Therefore, it is necessary to prepare for work carefully.

The sandblaster must:

- Wear protective clothing made from abrasion-resistant material.

- Protect your hands with gauntlets.

- Protect your head with a special helmet into which purified air is supplied. There must be an air filter.

Basic safety rules:

- Minors should not be allowed to work in sandblasting.

- A person must undergo a training course and be a certified specialist.

- It is prohibited to consume or be under the influence of alcohol or drugs.

- All persons involved in servicing the sandblasting machine must familiarize themselves with the safety regulations each time before starting work.

- Cleaning in cells should only take place under the supervision of persons outside.

- When working at height, it is necessary to use safety belts.

- Persons not involved in the process are prohibited from entering the work area.

- When working near electrical installations or electrical wiring, the power must be turned off.

- The sandblasting machine must be sealed, have a safety valve and a passport indicating the operating pressure.

If safety precautions are followed and the sandblasting device is used correctly, the unit will last for many years. And if it was purchased for your workshop, then you can even develop a business that will generate considerable income.

Overview of species

Sandblasting glass can be done in different ways:

- matte image on a transparent background (painting only the sketch);

- matte background with a transparent pattern (processing of most of the glass);

- bronze sandblasting (using dark tinted material of a brownish tint);

- matting of different densities (processing elements under different pressures);

- “floating” effect of the pattern on the mirror;

- sandblasting treatment on the inside of glass;

- volumetric artistic cutting (deep application of a 3D pattern using the technique of alternately spraying several layers of a pattern onto a matte surface).

Matting is the simplest technique that allows you to achieve flat designs with clearly defined boundaries. If the matting is multi-layered, it is called artistic. In this case, the transitions of textures, tones and colors are more pronounced. Such images are clearer and more naturalistic.

Artistic step-by-step matting takes more time; it is used when processing glass of different thicknesses (from 6 mm). During its implementation, not only film, but also metal templates are used. At the same time, metal templates are distinguished by the simplicity of their ornamentation. Film analogues are used to create complex patterns.

Color tinting allows you to obtain any shade of the glass surface. It is distinguished by the application of sandblasting to the inside of the glass. The facial remains smooth and even, which simplifies care. In order to increase service life, a protective film is applied to the inside. Amalgam involves applying a pattern to the inside of the glass.

Colored glass processing using sandblasting technology involves creating a colored pattern (for example, stained glass, diamonds) or a pattern that glows in the dark. The sandblasting technique is used in the production of compositions with a velvet texture. Cutting or engraving is used to create a detailed drawing.

Sandblasting technology allows you to apply a winter ornament pattern. In this case, the technology of creating an icy pattern (frost effect) is used. For this purpose, a homogeneous mixture is used in the work.

Kinds

Today there are several types of sandblasting guns. For example, you can find an electric air gun, a portable device and many other models in the market.

According to the method of releasing the mixture

According to the method of ejecting the abrasive mixture, guns can be point-based (that is, sand is directed from the nozzle in a straight line to a specific point), or they can have a wide range of action. Often the first versions of devices are considered more effective.

According to the abrasive supply option

Depending on the supply of abrasive material, devices can be:

with a tank (such a gun is similar in characteristics to a spray gun);

Peculiarities

Hydrosandblasting, also known as water sandblasting, also known as hydrosandblasting machine, is one of the types of devices for supplying an abrasive jet when cleaning various surfaces. The specificity of such equipment is that here the jet is formed due to the supply of water.

Therefore, we can say that sanitary and epidemiological standards prohibiting working with quartz sand without eliminating dust are fully observed. In addition, surfaces treated in this way warp less and are better cleaned.

For cleaning, a combination of quartz sand and water is mainly used. Other abrasive materials are in much less demand. An important condition for normal operation of the system is the unhindered pushing of the mixture with water under pressure through the nozzle.

Another advantage of pre-mixing the abrasive with water in the chamber is the ease of handling large parts and hard-to-reach areas. Sometimes it is possible to reduce abrasive consumption by 30-40% when compared with traditional dry processing methods.

In addition, cleaning surfaces with a water jet is a fairly gentle procedure on the material of the parts. Heating of the treated areas is guaranteed to be excluded, so they are not deformed and their appearance does not change.

Also worth noting:

- almost zero risk to the operator’s health (due to the absence of dust);

- obtaining a slightly rough coating (surface adhesion improves, which is good, for example, for subsequent painting);

- effective work with brick and natural stone;

- adjustment of work intensity;

- the ability to wash caustic soda and other detergents;

- guaranteed removal of dirt, rust, scale.

Small particles of sand knock out the dirt. The surface takes on a matte appearance. It is much better to apply primer, varnish or paint to such a base. Additional polishing is greatly simplified. It is hydrosandblasting that makes it possible to obtain samples for studying the macrostructure of alloys. In the industrial sector, many parts cleaned in this way can be ground without lengthy pre-etching.

However, there are also disadvantages:

- it is impossible to work with hygroscopic materials;

- water will splash;

- puddles will appear on the floor.

There are also the following disadvantages:

- the adhesion of wet grains of sand makes it difficult to assess the degree of cleaning;

- the appearance of rust (can be prevented by introducing orthophosphoric acid and some other additives, but this requires additional costs);

- the penetration of water into microscopic cracks allows it to remain under the paint layer and activate oxidation;

- low productivity (dry sandblasting allows you to do much more work per unit of time).