The need to cut metal products arises in many situations related to construction and repair work. To perform this technological operation, special equipment of various types is used, but if it is not at hand, a drill attachment for cutting metal can help. Using such attachments and a hand-held electric drill, you can effectively cut thin products made from various metals.

Shaped cutting of metal tiles with a cutting attachment for a drill

Sheet metal cutting tools

One of the most popular roofing materials is corrugated sheeting or metal tiles. The use of these materials requires high precision and accuracy, so during installation you must use a specialized cutting tool. Installation of sheet roofing material requires cutting it to appropriate sizes, which depends on the technological task. The following types of cutting tools are used for cutting sheet metal:

- Hand scissors for cutting metal are the cheapest tool, which is inconvenient to use when cutting long sheets. The cutting line is uneven, intermittent, and with burrs

- Hand saw for cutting metal - this tool is also not the best for processing sheet material. If you use a hacksaw for metal, then the work should be done only with a blade without a frame, and the cutting process will take a lot of time, so when performing large volumes of work this method is not relevant

- Jigsaw - to cut sheet metal, you will need a special cutting tool, in the spindle of which you need to install a special blade with fine teeth. The disadvantage of this tool is that when cutting, warping of the walls of the sawn product will occur.

- Circular electric saw - when using a circular saw, you will need to install a special disk or circle for metal processing. A circular saw is expensive, so buying one specifically for cutting sheet material is not at all rational

- A grinder or angle grinder is one of the most popular tools that every craftsman has in his arsenal. Using a grinder is convenient, but to cut sheet material, you will also need a special abrasive disc. Moreover, if a grinder is used for cutting sheet metal, then the circle should be as thin as possible. An angle grinder has its drawbacks - overheating of the metal, which entails a violation of the integrity of the paintwork. The result of using a grinder for cutting metal is damage to the material, as it begins to rust, and after a short period of time it may need to be recoated

In addition to the above tools, manufacturers produce special attachments for cutting sheet metal. These attachments are used directly for cutting sheet material; they are also called attachments, since they work in tandem with electric drills or screwdrivers. It is rational to purchase an attachment for an electric drill when large volumes of roofing work are performed.

The drill attachment for cutting metal tiles operates due to a special design, which is implemented through the use of a matrix. The repetition of the movement of the knives contributes to cutting sheet metal with high precision and accuracy. Using an attachment for cutting metal on a drill makes it possible to perform work with high precision and accuracy, which is why it is recommended to buy such a device.

This is interesting!

The attachment under consideration for an electric drill is called nibblers. Structurally, it is similar to hand scissors (depending on the model), but the operating principle is significantly different.

Why is it better to choose metal scissors for a drill?

If you have to cut sheet material, then for such purposes it is better to refuse to use an angle grinder. Scissor-style metal cutting drill attachments provide the following benefits:

- High quality cutting line. Using scissors on a drill or screwdriver allows you to get the highest quality cut when cutting sheet material

- The attachment is suitable not only for electric drills, but also for cordless screwdrivers, as well as pneumatic tools

- It is convenient to carry out work even on the roof if you use a cordless drill or screwdriver

- There is no need to use high-power electric tools

- The ability to perform not only straight, but also curved cuts

- Versatility, which allows you to use the device for cutting any type of sheet material, not just metal

- High productivity - cutting thin sheet steel with a drill using special scissors allows you not only to get a neat cut, but also to achieve results in a short time

- Easy to use - no additional training is required to learn how to use the attachment

- Easy to maintain - the console does not require special care, as it has a simple design. To start using the tool, just attach the attachment to the power tool chuck.

Knowing the advantages of using an attachment for cutting metal, you can make an appropriate decision about the need to purchase it. Many people are interested in the question of how thick sheet material can be pierced by drill scissors.

Manufacturers do not recommend using attachments for cutting sheet material whose thickness exceeds 3 mm. However, it is also worth understanding that cutting such thick metal reduces the service life of the attachment and also requires the use of special powerful power tools.

Drill scissors can be used to cut materials with the maximum permissible thickness (it all depends on the manufacturer of the attachment):

- Aluminum - up to 2 mm

- Stainless steel - up to 1.2 mm

- Regular steel - up to 1.8 mm

- Copper and brass - up to 1.5 mm

To make a curved cut with nibblers, you will need to get the hang of it. Before you start cutting, you need to practice. The operating principle of nibblers is based on converting the rotational movements of the chuck into reciprocating ones. These movements activate the knife, which is responsible for cutting the sheet material.

Although scissors for drills and screwdrivers have many advantages, they are also affordable, so everyone can afford such a useful device. If you plan to cover a house or an extension using metal profiles or tiles, then using a special attachment will not only make the work easier and faster, but will also allow you to carry out manipulations with high precision and accuracy.

This is interesting!

Using a grinder to cut material requires the craftsman to lower it from the roof to the ground, while special attachments on the screwdriver allow cutting directly from above.

Benefits of using drill attachments

Drill attachments, when compared with such a popular tool for cutting metal as an angle grinder, have a number of advantages.

- The cut performed is of high quality.

- When using a drill attachment for cutting metal, there is no need to purchase additional consumables, which significantly saves money.

- The use of such an attachment ensures high productivity of the cutting process.

- Drill attachments are highly versatile.

- Due to the fact that this tool is equipped with a special handle, the cutting process with its help is very convenient.

- These attachments are suitable for both electric and pneumatic drills.

- The convenience of these nozzles both in use and in maintenance is undeniable.

- With the help of such tools you can make cuts of almost any configuration.

Despite the simplicity of the design of such attachments, their use requires certain skills and dexterity from the user.

Distinctive features of the Cricket drill attachment

The attachment for drill and screwdriver called “Cricket” is presented in the form of cutting scissors used to create an even cut. They can be used to cut not only steel materials, but also plastic. The manufacturer indicates that scissors can be used not only for cutting sheet material, but also for profiled products.

The Cricket device is used for cutting materials of thickness:

- For aluminum up to 2 mm

- For steel up to 1.5 mm

- For stainless steel up to 1.2 mm

- For plastic up to 2.5 mm

The effectiveness of the attachment also depends on the power tool used. High performance of the nozzle is ensured when using a power tool with the following parameters:

- Electric motor power of at least 400 W

- Chuck rotation speed 3000 rpm

- Key or quick-release collet chuck

The peculiarities of working with a cricket attachment are that the tool has two cutting surfaces. When one surface becomes dull, you need to twist the handle to the other side and continue working. The Cricket set also includes an additional replaceable cutting surface. Manipulating the console is simple. To do this, the attachment shaft is fixed in the tool chuck. Work must be carried out with both hands, holding the power tool with one hand and the attachment with the other.

This is interesting!

If we compare the speed of operation of a drill attachment and a grinder when cutting corrugated sheets, then the latter option is inferior. Even if you manage to cut through sheet metal faster with an angle grinder, compare the quality of the resulting cut to make sure that it is rational to purchase an attachment for an angle grinder for cutting profiled material.

Safety precautions

Regardless of the brand of drill and attachment, their price and characteristics, it is very important to follow safety precautions.

Drill Safe Practices

This will prevent injury and damage to the material.

- When working with a drill, you need to wear safety glasses and gloves.

- Before starting work, it is important to check the attachment of the nozzle.

- Be sure to check whether the material to be cut is well secured.

- The drill must be held with both hands using special holders.

- When working with a metal cutting attachment, constantly remove falling chips. For example, when installing a roof, a large amount of chips can damage the surface of the metal tile.

- After completing the work, do not touch the treated metal with your hands for some time and remove the attachments, as they may heat up due to friction.

So, when we cut metal sheets up to 2 mm thick, for example, when installing metal tiles or a fence made of corrugated sheets, and the amount of work is small or one-time, then it makes sense to turn your attention to drill attachments.

Cutting sheet metal with a steel beaver attachment

Another type of attachment for power tools is also used for cutting sheet metal - this is the Steel Beaver attachment. Many craftsmen call such attachments adapters, but they are not such. After all, this is the final mechanism by which useful work is performed.

The steel beaver also works on the principle of cutting shears, thereby eliminating the occurrence of sparks and overheating of the metal. If the sheet material is processed incorrectly, the manufacturer does not guarantee the quality of the overlap or service life. The Steel Beaver set also includes a replaceable die and a punch. The use of the attachment is recommended in conjunction with a power tool that has the following technical parameters:

- The rotation speed of the chuck must be at least 1500 rpm

- Power not less than 350 W

- Collet

Compared to a grinder, special attachments for drills make it possible to change the cutting angle up to 360 degrees. This is convenient when you need to make a shaped cutout in corrugated sheets or metal tiles. The minimum cutting radius when using attachments is 12 mm. The use of a special device is achieved by high cutting productivity of sheet material.

Specifications

Any device for cutting metal has certain technical characteristics, on which the performance and accuracy of the cuts depends. Parameters to consider when choosing devices:

- type of processed metals;

- dimensions of working parts;

- the optimal number of revolutions for the normal functioning of the equipment;

- what force should be applied when cutting the workpiece.

The cutting parts of the equipment must be made of metals of increased hardness.

Turboshear drill attachment for metal cutting

In addition to the “Cricket” and “Steel Beaver”, manufacturers produce a scissors attachment for drills and screwdrivers called Turboshear. This attachment is more like ordinary hand-held metal scissors. Structurally, the nozzle is based on two cutting edges. One edge is movable and the other is fixed. Due to the reciprocating movements of the movable edge of the attachment, the material is cut. Among the advantages of the Turboshear nozzle it should be noted:

- High speed of work completion

- Ability to cut while holding the tool with one hand

- Ease of use

The disadvantage of the Turboshear attachment is that the slightest dulling of the cutting edges reduces the performance of the tool, and the cut results in burrs and chips. To restore the functionality of the device, you will need to replace the knives.

There are many other models of scissors for drills and screwdrivers. Which nozzle is better to buy, it all depends on the amount of work and the technological tasks set. Steel Beaver and Cricket are not expensive compared to Turboshear. The Turboshear nozzle is made in the USA and has high performance and long service life.

Selection principles

Criteria for choosing scissors for a screwdriver and drill:

- maximum permissible steel cutting thickness;

- the ability to make curved cuts;

- permissible angle of rotation of cutting parts;

- blade material, blade;

- optimal number of revolutions.

Advantages and disadvantages

Advantages:

- no overheating of the material when cutting;

- high maneuverability compared to bulky machines and grinders;

- ease of maintenance;

- no sparks when processing metal;

- high cutting speed.

Flaws:

- Difficulty of work. To make accurate cuts, a beginner needs to practice several times.

- When working, you need to use two hands. Press the power tool start button with one, and hold the additional handle, which is installed on the equipment, with the other. Because of this, it is impossible to independently hold the sheet being cut.

Easy to use (Photo: Instagram / helpertool)

Manufacturers and cost

Manufacturers:

- SPARKY 181874 - manufactured in Bulgaria. Cost - 2000 rubles.

- ENKOR 14209 — Cricket scissors. Cost - 1900 rubles.

- Steel Beaver - simple but reliable attachments. Price - 1500 rubles.

- EDMA NIBBLEX - expensive equipment. Price - 5000 rubles.

- Malco turboShear TS1 is a professional nozzle from the USA. Cost - 7000 rubles.

Differences between using an attachment on a drill and a screwdriver

An electric drill and a screwdriver differ not only in purpose, but also in design. The attachment for cutting thin sheet metal can be attached to both drills and screwdrivers. It is important to consider the following factors:

- A screwdriver has a lower chuck rotation speed compared to a drill. The screwdriver also has low power, so when cutting sheet steel you need to choose the right tool

- Ease of use. Unlike a drill, a screwdriver has less weight, and it is not tied to a power cord. This makes it easier to use as a drive mechanism for metal snips

- Lack of inertia - after the power supply is cut off, the screwdriver chuck stops immediately, but on a drill it continues to rotate for some time. When performing high-precision work, the quick stop of the power tool chuck is even better, as it responds more accurately to the press of a button

A screwdriver, like a drill, can be used for cutting sheet materials, but it is necessary to choose a power tool wisely.

How to cut profiled sheet material with a nozzle

To connect the attachment to a power tool, the design of the attachment has special protrusions - shanks. Typically, shanks are hexagonal in shape and are clamped into the collet chuck of the power tool. After securing the shank in the power tool chuck, you can begin to work. When performing work, it is important to follow these recommendations:

- If the work is being carried out for the first time, it is recommended to first practice on the remains of sheet materials

- Work is carried out by holding the tool with both hands. This is necessary not only to comply with safety regulations, but also to ensure that the cut is smooth and neat. If you perform work while holding only a drill or screwdriver, the attachment will vibrate strongly, and therefore you will not be able to get an even cut. The exception is Turboshear brand consoles

- It is better to carry out work below (not on the roof) from a safety point of view, although in exceptional cases it is possible to use tools above

- To get the highest quality cut, you need to carry out the work with an assistant. One person holds the sheet to be cut, and the second does the actual work of cutting the material.

- Before starting work, you need to use a marker or pencil to make markings along which to cut thin-sheet material.

In order for the cuts to be neat, even and without defects, you need to learn how to use the tool correctly. This will take practice.

To summarize, it should be noted that buying an attachment for cutting sheet material is recommended for specialists who deal with roofing houses and other buildings using steel sheet material. If you plan to cover a shed or other outbuilding yourself, then using a drill attachment for cutting metal, you will be able to complete the work with high precision and accuracy.

Design and principle of operation

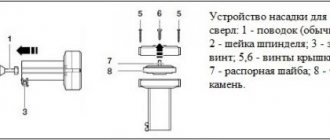

Before you start using a device for cutting metal, you need to familiarize yourself with its design in order to understand how workpieces are cut. The tool consists of several elements:

- A bearing with a freely rotating shaft that transmits force to the blades of the equipment.

- Two blades. One of which is fixed to the frame, and the other to the axis.

- Handles.

- Fastening elements.

The operating principle can be compared to a crank mechanism, but in this case energy is supplied for rotation.

You cannot operate a power tool without a special handle, which is included with the equipment. When cutting metal parts, a drill or screwdriver may rotate around its axis under the influence of torque. The workpiece will be damaged and the master will be injured.

Cordless scissors (Photo: Instagram / men_instryment_)