The MTZ-80 (82) tractor is a universal machine that can be combined with a wide range of mounted drilling equipment and is widely used in construction, utilities and other industries. Several models of MTZ-based hole drills have been developed and are successfully operating, among which you can select equipment for any task. Each drilling rig has its own design features. Some models are suitable for use on any soil, others have restrictions on operating conditions.

Models of pit drills based on MTZ

Several modifications of drilling equipment have been implemented on the basic basis of a wheeled tractor:

- hole drills - drilling devices for developing relatively shallow holes (up to 3 m) using the “dry” method (without cleaning) using a simple, extendable or telescopic drill;

- drilling and crane rigs - used to create wells with a depth of 6-20 meters; the presence of a lifting mechanism allows you to work with large loads.

The equipment is used to drill holes of a wide range of diameters and depths for various purposes:

Drilling and crane machine at work

- installation of poles, power lines;

- laying foundations and piles;

- tree planting;

- installation of wells;

- geodetic studies of soil;

- detection of shallow water layers.

Drilling machines based on MTZ are equipped with auxiliary attachments necessary for the comprehensive implementation of assigned tasks (brushes, dumps, winches), which makes it possible to do without the use of additional equipment.

The wheeled base ensures high maneuverability and mobility of drilling rigs. The car is capable of reaching speeds of up to 40 km/h. Compact dimensions make it possible to carry out drilling operations in hard-to-reach and limited-area areas, when using a full-size rig is impossible or unprofitable.

Specifications

The dimensions of the drill manipulator depend on the base chassis used and are:

- length - 7.625-8.58 m;

- width - 2.2-2.56/4;

- height - 2.5-3.455 m.

The unit can drill a well 3 m deep in one pass. Deeper holes are made in several stages with soil unloading. The productivity of the machine with a well diameter of 0.25 m and a 2-meter depth is 40-50 holes/shift.

Chassis

Pit drills are produced on different KamAZ chassis, differing in wheel arrangement, load capacity, and dimensions. These are machines with indexes:

- 4326. The vehicle is 2-axle, with all-wheel drive, which provides it with high maneuverability. It has a KamAZ engine 740.31-240 (240 hp), a cab with a berth, and a load capacity of 3,275 tons.

- 43114 with 3 axes. All wheels are driven, so the vehicle has increased cross-country ability. With a high 3-seater cabin, which can have a berth. It has a carrying capacity of 6.09 tons.

- 43118. The chassis is 3-axle, with all-wheel drive, characterized by high cross-country ability and a load capacity of 10 tons.

The best KamAZ drilling rigs

To manufacture hole drills on KamAZ chassis, different drilling rigs are used:

- Junlin SA-040C, mounted on a KamAZ-4326 or 43114 chassis. It is capable of drilling wells with a diameter of 0.35-1.2 m to a depth of 10.5 m with a distance of 3.7-13 m from the base machine. The unit can operate as truck crane, lifting loads to a height of up to 15 m. The same height of lifting the cradle if the machine works with aerial platform equipment.

- SA-100CII from Junlin. KamAZ with a drilling rig of this model is capable of drilling holes of the same diameter as the previous machine. It differs from it in the ability to do this to a depth of 14 m and at a distance from the installation site of 5.8-16 m, with a lifting capacity in truck crane mode of 10 tons.

- UBG-SA brand Berkut. A Yamobur with such a drilling rig has a KamAZ-43114 base and advanced technological capabilities (drilling diameter - 25-45 cm, depth - up to 300 m). The package may include a compressor and a pump, which can be used to purge or flush the hole being installed. The unit is distinguished by its ability to install the drill on a point with high accuracy.

- LBU-50-10. The chassis for the unit is used with the index 43118. The drilling rig provides drilling of wells of different diameters and depths in hard, rocky ground.

Drilling and crane rig 205-D

Universal equipment used to perform a wide range of tasks in construction, landscaping and public utilities, thanks to the presence of a lifting mechanism and a blade for removing snow masses. Main operating parameters:

- dimensions in folded/working condition (length/width/height) – 6.8*2.5*3.95/6.8*2.5*7.6 m;

- total weight of the installation including the base – 6,450 kg;

- maximum drilling depth – 3 meters;

- hole diameters – 36, 50, 63, 80 cm;

- Possible operating angles are 60 - 105 degrees.

Drilling and crane rig 205-D

Machine Yamobur BM-205-V

A universal hole drill based on the MTZ tractor is used for drilling work both on non-frozen soils and in permafrost conditions. The unit is complemented by a front-end loader to perform related loading and unloading operations, cleaning the site and backfilling trenches.

The equipment is highly productive and is actively used where it is necessary to perform a large volume of drilling work in a short period of time.

Yamobur BM-205-V

Features and main parameters:

- overall dimensions in transport/working position (length/width/height) – 7.4*2.1*3.99/7.4*2.1*7.5 m;

- weight with base – 6,500 kg;

- cyclic drilling method;

- type of rotary drive – mechanical;

- plane inclination angle – 60-102 degrees;

- maximum drilling depth – 2-3 meters;

- drilling speed – 15 m/h;

- torque – 4900 N/m.

What you need to know about pit drills?

Motor drills, in principle, cannot be classified according to the type of surface with which they are capable of working.

If, when purchasing equipment, a sales consultant still tries to do such things, this indicates his incompetence.

Simply put, there is practically no fundamental difference between gasoline “ground” and “ice” hole drills.

Much more significant are the differences in the knives and the augers themselves, especially since today you can find the required equipment for any tool.

So, with suitable equipment, “ground” models can easily cope with ice, in fact, as in the opposite conditions.

Drilling equipment E-01-06

Designed for drilling only in soft soil, not suitable for working on frozen soil or layers similar in hardness. The E-01-06 drilling machine exists in several modifications, differing only in the diameter of the drill. Light weight and simple fastening design allow for quick installation and dismantling of equipment. Main technical parameters:

Drilling machine E-01-06

- hole diameter depending on the model - 20, 25, 30, 35, 40 cm;

- drilling rig weight – 235 kg;

- maximum drilling depth – 1.5 meters (when using an extension – 2.5 meters);

- torque – 1300 N/m;

- rotation speed of the equipment – 80 rpm;

- weight – 235 kg.

Purpose of pit drills

The main area of application of the pit drill is construction, where the construction of individual structures and full-fledged buildings begins with excavation work.

Drilling tools are used to form cylindrical holes primarily for the installation of pillars, supports, and any vertical structures.

A hole drill is also used to drill under a pile foundation, and some models are capable of forming holes of a conical section.

Yamoburs take an active part in landscaping areas.

So, with their help, you can quickly plant a large number of young seedlings, and this will require significantly less effort and resources than, for example, using the same shovel.

Drilling wells of various depths is also possible with these mechanisms, and therefore they are used by surveyors in water exploration and collection of geological data.

Due to its design features, an earthen hole drill is used specifically for drilling soil, and its analogue, an ice drill, is intended for drilling holes in ice.

Special equipment Yamobur BKM-2MT

One of the specialized drilling rigs based on MTZ, designed to develop water wells when the water layer occurs at a depth of up to 20 m. It is also used to develop holes for power line supports, communication poles, columnar foundations in soils of categories 1-4. Main characteristics:

- overall dimensions in transport/working position (length/width/height) – 5.8*2.5*3.9/5.3*3.6*7.25 m;

- maximum drilling depth – 6 m;

- hole diameters – 36, 42, 50, 60 cm;

- operating angle – 60 – 105 degrees;

- type of drilling – rotary;

- expandable auger drill.

Yamobur BKM-2MT

What can you drill with a hole drill?

The working part of the hole drill is configured in a special way for the purpose of effectively drilling soil or rocks of a specific density and structure.

So, for example, some devices penetrate rocky soil well, for others viscous clay does not become a hindrance, and still others are designed to quickly drill through thick ice or frozen soil with similar characteristics.

In principle, for drilling work in any type of soil, you can select a suitable hole drill, which ensures high efficiency of the drilling process itself.

Installation BUER 1030

A pit drill based on MTZ is most often used for servicing electrical networks, installing screw piles, and during loading and unloading operations. Can be used on rocky and hard soils. Equipped with support jacks to ensure stability on inclined surfaces.

Technical specifications:

- working body – auger expandable drill;

- dimensions (length/width/height) – 5.54*2.22*3.58 m;

- hole diameters – 36 – 60 cm;

- maximum depth – 8 meters.

Yamobur BUER 1030

Drilling rigs based on the MTZ tractor can be equipped with additional special equipment, which can be attached and dismantled in a few minutes:

- DRU-01 - a fastening device designed to facilitate work with rotten wooden supports - the device reliably fixes the post in one position, thereby ensuring the safety of work at heights;

- DPO-01 – a device in the form of a hydraulic cylinder for quick and easy removal of supports from the ground; The installation allows you to significantly increase the speed and productivity of labor.

DRU-01

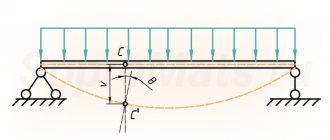

Hydraulic system of MTZ tractor

The MTZ tractor is equipped with a reliable hydraulic system that controls drilling attachments. Hydraulics has the following main parameters:

Diagram of the hydraulic system of MTZ tractors

- number of cylinders – 3;

- cylinder type – double acting;

- pump type – gear;

- pressure in the system is 16 MPa.

MTZ-based hole drills are distinguished by their simple design and compact overall dimensions, reliability, ease of maintenance and high productivity. In addition to the main function, drilling rigs perform additional types of work - one unit of equipment replaces a whole range of related equipment. Availability of spare parts increases the degree of repairability.

Related video: MTZ-82 tractor drilling

Publications on the topic

How to make a drilling rig with your own hands

Features of application and review of popular models of crawler drilling rigs

Rent of pit drills in Chelyabinsk companies