Every man should have such things as a grinder and a drill in his assortment of tools. A grinder can clean metal from old paint and corrosion. In everyday life, a drill can greatly facilitate repair work if you need to stir any mixture or tighten screws.

But each of these tools has a common goal - cleaning the surface from rust and corrosion. For this, metal brushes are used. You can find photos of metal brushes on the Internet so you don’t make a mistake in choosing. In this article we will look at the types of brushes.

Brushes for drills and grinders

Tools such as drills and grinders can clean any surface from rust and corrosion. Let's look at the main types of brushes.

Attachment functions: paint removal, sanding, cleaning and more

Drill attachments perform many functions. With their help, it is possible to remove scale from the surface. This procedure is called brushing. Therefore, nozzles are also often called brushes or brushes.

In addition, devices are used for:

- wood brushing;

- removing paint, primer, slag, tarnish, rust and cleaning products from other contaminants;

- polishing wooden and metal surfaces;

Brushes with shank. Photo by Lessmann

- polishing of metal, wood, glass, paint and varnish coatings;

- grout.

This list is incomplete and the list could go on for a long time. But it is worth noting that brushes are in demand in various areas of production activity. In some cases, there is a possibility that the contractor will not be able to find alternatives to cord brushes.

Cup brush

The brush is capable of cleaning the surface from traces of concrete and corrosion. This kind of metal brush for grinders and drills is often used for processing flat steel products.

If you need to treat a wooden surface, you should use a nylon brush.

What is it used for?

Various devices are used to remove rust or old paint from a metal surface. You can get the job done quickly and efficiently using a grinder and a special brush attachment.

The design is a round base with wire or nylon bristles. The working elements are located evenly around the entire circumference of the cup. The length of the bristles is uniform.

Disc brush for angle grinders, nylon wire with abrasive coating BISON “PROFESSIONAL”

If the wheel is unevenly covered with wire bristles, involuntary vibration of the attachment is observed during grinding. Because of this, the quality of cleaning decreases.

Equipment is selected for an angle grinder taking into account technical indicators. One of the main ones is the number of revolutions per minute. It is unacceptable to use a metal brush with a low speed on an angle grinder with a high rotation speed. The effect of such processing will be minimal. The equipment will quickly fail.

For what purposes are cord brushes used:

- stripping the old protective coating (LCM);

- grinding of metal blanks;

- deburring;

- brushing, roughening of wood blanks;

- cleaning parts before welding;

- removing unnecessary part of the deposited metal from the seams;

- grinding off sharp corners, etc.

Sometimes metal brushes are used as substitutes for abrasive wheels.

Disc brush

If you need to clean a large area of the surface, then use a disc brush. It has high rigidity and strength, so you can use it for a long time.

The brush for stripping metal is manufactured using the latest technologies. This brush is usually called a brush brush and is used in industry.

Types of materials for making nozzles

Materials for the working body vary greatly in softness, elasticity and abrasive grain size. The main ones are:

- Sandpaper. They vary greatly in hardness, graininess and water resistance.

- Soft materials. Serve for polishing and fine finishing.

- Grinding stones. For rough surface treatment and correction of defects.

Grinding stone

The variety of materials and shapes of devices allows you to choose the most suitable one for each specific operation. Thus, a drill attachment coated with diamond powder will allow you to polish surfaces made of the hardest materials, and miniature attachments are suitable for finishing jewelry.

Corbrush

Brushes are used to clean parts from rust and flux deposits. Also, if it is necessary to give the product a marketable appearance, this type of brush is used.

In industry, a good and correct brush is used in the production of aluminum radiators for various brands of cars.

Other types of attachments

In addition to the most common grinding and polishing attachments, there are other types of attachments. This is the already mentioned angular one, as well as:

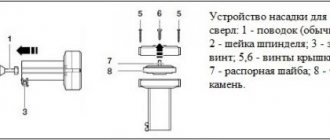

- Sharpening for drills. It has a drill feed mechanism and a sharpening stone inside, and holes for drills of various diameters are provided on the outside.

- Mixer for mortars.

- Feather remover for poultry or wild birds. It is a disk with radial rubber fingers from 5 to 10 cm long. Removes the feather without damaging the skin and meat. Particularly convenient for hunting, fishing and hiking.

- Wood cutters. They allow you to decorate products made of solid wood or MDF with relief patterns, grind grooves, drill holes, including large diameters, and eliminate some defects.

Types of hardness

The work performed depends on the pile. The following wires are distinguished:

- Corrugated. This brush reduces machine vibration and applies gentle pressure to the surface. This happens due to the fact that the brush has springing properties;

- Twisted. The bristles curl and give a harsh action on the plane. The brush has great strength;

- Smooth. The brush quickly loses its shape and over time is unable to do its job.

All brushes differ in their cup diameter.

Types of cord brushes for metal and wood

Modifications of brushes for drills are very diverse. There are nozzles that differ in shape, size, material and type of pile. In addition to brushes for drills, attachments for grinders, as well as hand brushes, are also popular.

Forms

It is the configuration of the nozzle that is one of the main criteria for classifying brushes. There are several types of devices, but despite the variety available, all brushes are round in shape. Moreover, this statement also applies to attachments for the grinder. Only manual cord brushes have other configurations.

Radial

Radial brushes are flat brushes suitable for treating surfaces in hard-to-reach areas . Cord brushes of this shape are also used for working with round products . A drill with an attachment is placed, for example, in a pipe, and thus the internal surface is processed.

Radial brush for drill TM Praktika. Photo 220 volt

Cylindrical

Cylindrical brushes have a shape that is elongated in length and narrow in diameter. Such nozzles are used for processing surfaces in narrow places. Also, cord brushes of this type are designed to work with small and medium-sized areas.

Cylindrical brush for drill. Photo VseInstruments.ru

Disk

Disc nozzles are often called oval or circular. Cord brushes of this type are suitable for processing large surfaces in hard-to-reach places, welding seams and joints. Read more about them here.

Disc brush for drill with brass bristles. Photo Dremel

Cup

Cup-shaped brushes are used to remove various contaminants , to prepare the surface before applying varnish and/or paint, sanding, and are used when carrying out labor-intensive work with large areas of flat products.

Cup brush for drill TM DEXX. Photo InstrumLend.ru

Conical

Conical cord brushes are designed for cleaning surfaces in places where other types of attachments are difficult to reach. The unique configuration of the brushes allows you to perform complex tasks.

Pile material

The pile of drill bits is made from different materials. Each type of bristle is designed to perform specific tasks and work with specific products.

Steel, metal, iron

Metal wire brushes are the most common type of attachments. This type includes brushes with bristles made from:

- become;

- brass;

- other metals.

Flat brush for drill with metal twisted bristles. Photo Matrix

Nozzles with brass-plated steel bristles are in demand among performers .

Devices of this type are suitable for almost all functions , with the exception of wood processing.

Often, metal and steel brushes are divided into separate categories of consumables for power tools.

Nylon

Nylon bristles are soft and delicate , so these brushes do an excellent job of texturing, polishing, removing dirt, brushing wooden products, working with soft metals (copper, aluminum and others), and plastic. They should be used in cases where the aesthetic appearance of the surface is of great importance .

End brush with nylon bristles. Photo Dremel

Type of pile

The bristles of the brush can have different types and shapes, similar to the body of the device.

Harness

Such attachments are devices whose pile is twisted and twisted into strands. This shape ensures increased hardness of the working part of the cord brush.

Cup wire brush for drill. Photo Matrix

Corrugated

Corrugated fibers have parallel wavy curves . Such bristles have springy properties, which reduces vibration of the drill.

Soft cup brush for drill with bristles made of corrugated steel wire. Photo Practice

Dimensions: 26 mm, 50 mm. and others

There are a large number of modifications of cord brushes. Drill attachments are more compact in size compared to grinder brushes. Devices with a diameter of up to 100 mm. should be called standard. Manufacturers offer craftsmen nozzles with a diameter of 25; 50; 60; 75 mm. and others. Large brushes have a larger diameter.

Disc brush for drill with bristles made of twisted steel brass-plated wire, diameter 100 m. Trademark DEXX. Photo Instrumentomania

Brands: Dexter, Dremel and others

Disc brush for drill. Photo Anchor

Craftsmen have the opportunity to purchase cord brushes for drills of various brands and manufactured by Russian and foreign enterprises:

- Dexter;

- DEXX;

- Dremel

- HAMMER;

- FIT;

- Lesmann;

- Matrix;

- Practice;

- Anchor.

When choosing a cord brush, it is worth remembering that attachments from different manufacturers may have slight differences both from each other and from the standard.

Drill attachment for removing old paint.

You can read for a long time and list the various options for cleaning paint, but all of them, as a rule, are not suitable for amateur repairs. This means that you won't have to buy expensive equipment to remove 2-3 square meters of wall with old paint. In the USSR, it was common to paint the bottom half of a room with paint and the other half with white. This applies not only to residential apartments. Now that there is an incredible amount of finishing materials, painting walls, for example in the kitchen, is unlikely to attract anyone. Therefore, during the renovation process, it is necessary to remove this half-century-old paint, and this is not as easy as it seems at first glance.

Spatula-scraper

Classic spatula scraper. The weapon of the unenlightened amateur repairman in the fight against old paint

Wall cleaned with a spatula-scraper

For example, here is a photo of a wall on which I tried to clean off old paint using a regular spatula-scraper. As you can see, the results are not encouraging. It took me about 1 hour to do this, during which mountains of curses were expressed against those who painted this wall in three layers according to all the rules for painting with a primer. The cleared area was less than 0.5 meters. Hands dropped. Of course, you can always buy a router for removing paint for $600 and a professional vacuum cleaner to go with it for the same amount. But is this justified enough to remove another meter of old coating? I think no. You can try other methods, but usually it will be dusty, unhealthy or very time consuming.

Results of using a drill attachment to clean paint.

Now I would like to talk about the results. In three hours, about 3 square meters of wall were processed, the first nozzle was used until it was unusable and the second one was worn out by half. The dust from this method of cleaning old paint is really much less than from a grinder, router, grinder or plane. It is quite difficult to remove paint near the floor, especially if you do not want to damage it, so remove the paint before you level the floor. The popular Makita HR2470 rotary hammer was used as a twisting tool, which worked perfectly. I would like to note that the nozzle does not have any fastening and must be clamped using a classic chuck, which does not exist in hammer drills, so a standard clamping chuck for the hammer drill was purchased additionally.

Wall cleaned using a chain attachment

Getting to the paint near the floor was quite difficult. the first thing that stopped me was the fact that as the rotating units approached, a huge cloud of dust rose. The second is the fear that you can damage the floor, which was recently filled using self-leveling floors.

Cleared wall

Around the sockets and in the corner, it turned out quite successfully and carefully to remove the paint without damaging anything. To remove the layer behind the pipes, it is unlikely that you will be able to use a nozzle, so you will have to use coarse sandpaper and a scraper spatula.

Surface cleaned with different tools

This photo has been specially processed a little to show how different a wall cleaned with a scraper and with a nozzle is.

As you can see, where the hammer drill with chains worked, there are small irregularities that will have a beneficial effect on the adhesion to the plaster. If you need one-time work to clean old paint from walls, then this attachment will really suit you. It may take longer than using a special router, but it is quite suitable as a budget solution to the problem of removing old paint. After treating it with a nozzle, the wall becomes rough, which is very suitable for further priming and plastering. Facebook