When manufacturing metal structures, installing fence posts, assembling a house and profile pipe, an important step is cutting the products to the required dimensions. There are several ways to cut the profile as accurately as possible and avoid skewing. How to cut a profile pipe and how to do it quickly and correctly without the involvement of specialists - this is what we dedicate this article on our website to.

How to cut a pipe at 45 degrees

When installing a pipeline, quite often you have to cut the pipe at an angle. Moreover, the angle should have exactly the degree that is needed for the structure. If the angle is made incorrectly, it is impossible to produce exactly the dimensions of the pipeline that were supposed to be made. For example, the pipe will rotate 45 degrees during installation, therefore, you need to know how to cut the pipe at 45 degrees. To do this we need marking tools, a grinder or a hacksaw.

Rules for cutting pipes from different metals

A grinder, even in the hands of a master, is a rather dangerous tool. When working with it, you should take precautions and be as focused as possible. Otherwise, you can not only damage the metal workpieces, but also injure yourself.

Every metalworking specialist should know how to properly cut a pipe at 45 degrees with a grinder. The disc circumference should be installed with the pattern facing up, and clamped with a special nut. Pipes made of different metals are cut in compliance with certain rules.

Working with aluminum blanks

Aluminum is a soft type of metal, so a different type of disc is used for cutting with a grinder. When working with soft metals such as aluminum or copper, it is impossible to make the cut in one go. The cutting disc simply gets stuck in the material.

Cutting with a special disc is performed very carefully. You need to go through the same section several times.

Cutting aluminum pipes

How to cut cast iron pipes

Cast iron is characterized by increased strength, but at the same time it is a rather fragile material. For sawing cast iron pipes, it is recommended to use diamond-coated discs. You can cut fragile material with a grinder only in a straight line.

Important! It is necessary to carry out work with sawing cast iron, steel, and aluminum only with the use of personal protective equipment (wearing a respirator, safety glasses and gloves). During the cutting process with a grinder, a large amount of dust is generated.

Cutting large pipes

The grinder is often used for cutting large diameter pipes. Large metal products have thicker walls and greater weight. To work with large metal workpieces, it is more convenient to choose large disks.

Heavy, non-lifting products must be firmly installed on low supports or on a flat surface so that they do not change their position when cutting the final section.

When working with large pipes, you should choose the correct direction of rotation of the grinder disk circle. Otherwise, it is difficult to hold the tool in a fixed position, and the disc wears down too quickly.

If the pipe is profile

But, for example, we have a profile pipe, not a round one. Manual marking of a profile pipe can lead to a huge error. The best way out of this situation would be to make a template from the same profile of a larger diameter. Take a small piece of profile pipe and use a protractor to mark an angle of 45 degrees. We cut along the markings with a grinder and grind the edges so as not to get hurt by the burrs while working. Then all we have to do is insert a profile of a smaller diameter into the template and, having made markings, cut it off.

In this article we looked at how to cut a pipe at 45 degrees. Using one of the methods listed above, mark and make a cut. For a more even cut, it is better to use a grinder. When cutting by welding, experience is required, otherwise the cuts will end up with unevenness. As a last resort, you can use a hacksaw. Currently, there are a large number of different devices for cutting pipes at an angle on sale, but purchasing them requires extra costs. It’s easier and cheaper to make a template for yourself once and use it as needed.

Marking using a sheet of paper

One of the easiest ways is to mark the corner using a sheet of paper. We fold the square sheet strictly diagonally. We take the pipe and wrap it with a folded page so that the edges of the diagonals are opposite each other. So, on the smaller side of the page we have an angle of 45 degrees. We take any marking tool and mark the location of the future pipe cut along the mowing line. To prevent the markings from being accidentally erased, you can use narrow tape. This marking method is convenient for a long pipe of enormous diameter, and the cut point of which is somewhere in the middle.

Using a water container

What should we do if we are dealing with a small-diameter pipe, and we need to cut the pipe at an angle somewhere near the edge? A deep container filled with water will come to the rescue. Before you start working, you need to calculate the angle of inclination and make a mark on the container. Then all we have to do is carefully lower the edge of the pipe into the water and tilt it towards the mark on the container. We remove the pipe, mark the line in contact with the water, and boldly cut it according to the markings. This method is optimal when marking a huge number of pipes. A ready-made template from a container of water will speed up the process of our work.

Computer program to help

I would also like to consider the method of marking using a computer program. This is a super complicated method for those who are not used to working with a computer. It requires knowledge of a PC, programs for developments and drawings. We begin work by making a drawing indicating the size of the circle and the slope. We make a so-called virtual template.

After this, we print the image on a sheet of paper using a printer. The larger the diameter of the pipe, the more pages with markings there will be. Using scissors, we cut out all parts of the drawing and, using tape, glue them together. The finished template is applied to the pipe, and we make markings along the edge of the paper. This marking method is considered one of the most correct. If your computer does not have such programs, you can use the Internet. It is possible to download a pattern for marking on the Internet. In addition, you need to print it on a printer and cut it out. We wrap the finished pattern around the pipe and make markings.

That is why the video will show you how to cut a pipe at an angle of 45 or 90 degrees using a computer program:

Cutting a profile pipe using a pipe cutting device at forty-five degrees:

Programs for calculating cutting angles

Pattern cutting technology allows you to obtain different cutting angles. But to form a pattern at angles other than 45º, you will need to perform mathematical calculations and cut out a template from paper or similar materials based on the calculated data.

True, there are computer programs designed to save the master from making calculations. Patterns for cutting pipes are printed by such programs on a printer.

A simple calculation program created on the basis of the MS Excel application allows you to calculate and draw up a pattern for almost any pipe diameter and required cutting angle.

All the user needs to do is enter the appropriate values in the “Outer diameter” and “Cut angle” cells. Using these parameters, a pattern will be generated that can be sent for printing.

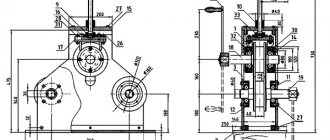

Simple cutting equipment

Metal products of round and rectangular shapes with fairly thick walls can be conveniently cut at an angle using simple electromechanical equipment.

READ Tools for working with metal-plastic pipes rehau

The cutting element of such a tool is a cutting disc or circular saw mounted on the electric motor shaft. In turn, the electric motor with the cutter is part of the entire equipment, which includes a work table, a pendulum support, and a clamp.

To install the pipe at the desired angle and then fasten it, a regular clamp and two metal corners are used. One corner (short) is attached to the base of the rotating mechanism - the pendulum. The second corner (long) is in a free state.

Pipe laying and cutting procedure:

- The rotating mechanism sets the required cutting angle (for example, using a ruler and a protractor).

- The found position is fixed with clamping screws.

- Pipes are laid between the short and long corners and pressed with a clamp screw.

- Voltage is supplied to the electric motor.

- By applying a slight pressure force to the cutter disk, the pipe is cut in the right place.

The advantages of this technique are fast work, accurate cutting, and the ability to process a large number of pipes in a short period of time.

Disadvantages: restrictions for use in domestic conditions, increased noise, work with pipes of only small and medium diameters. In addition, the cutting process with equipment is performed stationary at a distance from the installation site, which is not always acceptable.

If you are going to make a copper pipeline at home, you will need special pipe cutters, we advise you to familiarize yourself with the selection rules.

Application of thermal methods

HOW TO LEARN TO CUT A PROFILE PIPE STRAIGHT!

With the help of such machines, thick-walled metal pipes can be cut. However, it is extremely difficult to obtain a perfectly even, high-quality cut using electric welding or gas autogen.

Cutting technology using electric welding and autogen is widespread everywhere. The technique does not provide high cutting accuracy, but when installing pipes this factor is often not decisive

Typically, after thermal cutting, products undergo additional processing. The cutting line is aligned and the required angle values are adjusted. This approach is economically unprofitable, as it is accompanied by additional costs for mechanical processing.

As a rule, thermal cutting techniques are used in industrial production conditions. True, housing and communal services also often resort to this technique.

Any angle on a profile pipe without a protractor or protractor!

Thermal cutting is also used to work with plastic materials. There are devices - thermal guillotines. The sharp thin blade of such devices is heated to a high temperature, after which the cut is performed.

Thermal guillotines support cutting at an angle, and this is their advantage. However, these devices cannot be used to work with materials that are more rigid than polyvinyl chloride, wood, or chipboards.

To cut metal-plastic pipes, you need pipe cutters that can evenly divide products with a multilayer structure into parts. Our recommended article is devoted to their varieties and methods of application.

What you need to cut a pipe

The profile pipe can have a square, rectangular or round cross-section. Products that have flat surfaces are easier to cut. They are easier to fix and hold on the surface.

When cutting round rolled pipes, additional devices for fixation should be provided, since it is more difficult to hold such material in your hands independently. If there is no available equipment. Then you should involve an assistant in the work, who will ensure that the profile is captured and held during cutting. Any misalignment can cause the cutting line to become skewed or the saw blade to break.

You can use a jigsaw as a tool. But the efficiency of such a device is low, and the cuts themselves are not always accurate. Therefore, it is better to cut profile pipes using an angle grinder. People call it Bulgarian. Such a tool is more productive and efficient.

When using an angle grinder, you will definitely need to ensure that you have a high-quality abrasive disc. This is a special metal disc with a corundum (high-hardness) coating. When performing large-scale work, it is better to make a reserve of 2-3 such disks.

How to cut a profile pipe at an angle

The marking of a profile pipe differs from a round one. Doing it manually can lead to significant errors. The best way to solve the problem is to create a cutting template from the same profile, but with a larger diameter.

You will need a small piece of profile pipe. Using a protractor, mark a 45 degree angle on it. Now, using a grinder, you need to cut off part of the workpiece along the marked mowing line. The edges of the cut need to be sanded and defects eliminated. All that remains is to simply insert the original product into the template for cutting pipes at an angle. Then you need to mark the cut of the larger profile along the mowing line. And the pipe itself is cut along it.

The text describes ways to cut a pipe at an angle of 45 degrees. When the marking is already completed, it is recommended to use a grinder. With its help you can make an even cut. You can replace it with a hacksaw. You can also cut the product by welding, but you need experience in handling the tool, otherwise there will be unevenness. “How to cut a pipe evenly - tools and cutting methods.”

Pipes are a widely used building material. They are used in the installation of various systems. During the installation process, situations arise when pipes need to be joined at an angle. The technology for producing such work is not standard, but you need to know about it.

To create a complex connection configuration, the pipe must be cut at an angle. We will tell you how such operations are performed and what cutting methods exist.

How to cut a gas pipe correctly

The work of cutting gas pipes is dangerous and quite difficult, so it is best left to the professionals. Before starting work, be sure to turn off the gas supply.

The next step involves freeing the pipe cavity from residual gas. To do this, you need to light the gas burners on the stove and wait for them to go out. Only after carrying out the above manipulations should you begin marking and subsequently cutting the metal.

High-quality cutting of metal pipes is a complex process. However, if you take precautions and listen to the advice of professionals, you can cut metal of any density and thickness using a grinder. A grinder with a cutting round disc is rightfully considered a universal tool in everyday life. The main rule is not to forget about safety precautions when working with dangerous cutting tools.

Marking a corner with a piece of paper

Marking with a paper sheet is one of the simplest ways to complete the task. A square sheet is required. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross-section.

Then an angle of 45 degrees is formed on the smaller side. All that remains is to mark the cutting line using a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape to prevent it from being accidentally erased. This method is excellent for long, large pipes with the cut location approximately in the middle of the product.

Using the computer program

To implement this method of marking pipes for cutting, you will need a computer with special programs. First, you need to draw up a drawing that shows the transverse dimensions of the product, as well as the planned cut angle. You need to get a virtual template.

Print it on your printer. And here it is worth understanding that the larger the diameter of the pipe, the more sheets will be required to print it. Then you need to carefully cut out the details of the drawing from all the pages and glue them together; it is best to use stationery tape for this. All that remains is to attach the template to the pipe and apply the markings.

This method of solving the problem is highly accurate. All necessary programs can be downloaded on the Internet, they are free to download and use. There you can also find a template for cutting pipes at an angle. All you have to do is print it and cut it out. To mark, the pattern is simply wrapped around the pipe.

Pattern for cutting pipes at 45 degrees

In various situations, home craftsmen often come to the question of correct marking for precise cutting of pipe blanks at an angle of 45 degrees. Today there is a huge selection of tools for both domestic and industrial cutting of pipes at any angle. The cost of such devices can be quite high.

READ How to cut PVC pipe straight

It is proposed to consider methods for marking workpieces for cutting at an angle of 45 degrees in domestic conditions without the use of expensive professional equipment.

The nuances of working with a rectangular section

To cut rectangular products, it is recommended to prepare template corner cuts in advance. They can be easily made from a metal corner, having previously been marked with the same protractor.

Marking can be done at different angles. To use a template, just attach it to the rectangular pipe in the right place and mark the cutting line. Then, using any suitable tool, make a cut along the intended mowing line.

Cutting a pipe according to a template

This method involves making a cross cut at an angle of 90 degrees. A finished piece is used as a template. It needs to be attached to the profile pipe, aligned with one of the ends.

Using a square and a ruler, we visually mark a line on the pipe that we are cutting. A marker is better for visual perception.

To cut a profile pipe smoothly, you need to perform the actions smoothly and gradually. A light cut is made with a disc along the intended line. This must be done so that instead of the drawn line, a furrow of shiny metal appears.

When the marking is ready, the profile is cut. Using a slight back-and-forth motion, make the cut at the corner. Gradually you need to move towards the opposite corner at the same time going deeper along the side wall.

How to properly cut a pipe at 45 degrees: tools

In various situations, home craftsmen often come to the question of correct marking for precise cutting of pipe blanks at an angle of 45 degrees. Today there is a huge selection of tools for both domestic and industrial cutting of pipes at any angle. The cost of such devices can be quite high.

How to cut a pipe at an angle

It is proposed to consider methods for marking workpieces for cutting at an angle of 45 degrees in domestic conditions without the use of expensive professional equipment.

Techniques for cutting round pipes at an angle

Round pipes of various diameters are cut at an angle when changing the direction of the pipeline, but it should be taken into account that a straight cut at the required angle, as opposed to a rectangular section, will not lead to a tight connection of the edges. Therefore, special patterns are used in which the marked edge has a curved shape, which makes it possible to obtain a higher joint density.

Collar insert

To obtain branches of iron pipeline lines such as tees, a collar insert is used, which requires cutting the edge of a round pipe adjacent to the walls of another at a right angle. To implement the method do this:

How to cut a cast iron pipe

The main difference between cast iron and ordinary steel is its high fragility and large wall thickness; its precise cutting must be performed in the following sequence:

- The marking angle is drawn according to the template using a scriber, for

supports under the part are placed on a wooden board or board.

- Use a grinder to make a shallow cut of the surface around the entire perimeter.

- Next, the groove is deepened in several passes until the two parts are completely separated.

For industrial use

We seem to have sorted out local and individual engineering, but the question remains of how to evenly cut a large-diameter pipe. In this case, special equipment (often stationary) comes to the rescue, with which professional builders work.

I once worked as a housing department foreman, so I had to deal with such units. I'll tell you about the most interesting ones:

- Lathes. These units perform any processing of round pipeline parts, including those used for transporting aggressive liquids.

The maximum size of pipes processed depends on the cross-section of the spindle holes and the distance between the fastening heads. In addition to banal cutting, lathes can chamfer, cut pipes and perform other operations, including in automatic mode.

- Band cutting machines. Used for cutting large diameter sewer and water pipes that are already laid in trenches (or placed in buildings).

The band cutter is capable of performing operations even on highly deformed products. In addition to direct cutting, the device can chamfer the desired shape.

- Disc cutting machines. Used for processing metal parts, including non-ferrous metals. They can cut both round and profiled pipes of large diameter (section).

Such devices, in most cases, are part of a technological mowing line and are equipped with a device that collects and packages a certain number of identical pipes for shipment to customers.

- Manual disc cutters. Used for cutting a large number of pipes from different materials directly at the installation site.

These devices have a special clamping device that firmly holds the part during processing without deforming it. Therefore, you can cut metal, copper, and metal-plastic pipes.

Some cutters are equipped with a rotation system and orbital welding. That is, pipes can not only be cut, but also joined to each other.

However, if you only have a greenhouse at your dacha ahead, you don’t need to buy anything special. Below I will tell you how to cut a pipe using the most common tools that, in my opinion, every thrifty owner has.

How to ideally prepare any joint on a profile pipe?!

Tools used

There are several ways to cut a pipe; for this, construction and industrial tools for metal processing are used. Of all the types, only the grinder allows you to obtain curved surfaces without further processing with the closest arrangement of edges.

Tools used

A simple operation at first glance, cutting pipes in practice reveals many nuances and pitfalls. If not, just cut the tubes evenly:

- Thin-walled.

- Large diameter.

- With a bevel.

It is very important to choose the cutting method and special equipment suitable for each specific case. It is divided into individual, household and industrial.

For individual use

They are used in households, private construction and small businesses. Deal with small and medium diameters (up to 250 mm) used in systems

- Water supply.

- Heating.

- Sewer.

- Ventilation.

Such tools include:

- Cutters. Used to evenly cut polymer pipes up to 75 mm. To make an even and neat cut they have a gear mechanism. The workpiece is first clamped with a shelf clamp, which securely fixes it and prevents it from leaving the cutting line.

- Disc cutter. Suitable for ventilation and sewer polymer pipes with a diameter of up to 200 mm. The blade is not a secateur type, but in the form of a disk rolling along the surface of the workpiece. The cut is made in several turns. Not suitable for rolled metal-plastic, as it can crush the thin metal liner.

- Guillotine. The flat oblique knife moves in the guides and allows you to cut exactly the required length in one pass. It is available both with an electric drive, which provides greater productivity, and with a manual drive.

- Hacksaw for metal. A classic metalworking tool allows you to evenly cut a workpiece clamped in a vice. When using, it is important to drive the saw smoothly, with constant force and without distortion. Burrs formed after using a hacksaw should be cleaned with a file.

- Angle grinder, angle grinder. In everyday life it is called “grinder”. This universal tool can handle any materials and diameters. In order to cut a pipe with a grinder, special abrasive cutting discs are used.

- Electric jigsaw. A very popular tool among home craftsmen, it can also cut pipes, but due to the flexible blade moving to the side, you can only dream of accuracy.

- Reciprocating saw. The instrument has not yet become widespread among Russian craftsmen. The adjustable stop of the saw and its powerful blade allow you to cut off rolled products even while suspended and close to the wall.

How to cut a pipe straight

To ensure an even cut from a general-purpose tool, special devices should be used to fix the workpiece. These can be templates, vices or miter boxes. In addition, it is very important to correctly mark the future cut and, while working, make sure that the cutting line does not go to the side.

For industrial use

Such equipment is used in industries where the volume of work is large or large diameter pipes have to be cut. To cut straight, use:

- Lathe. Suitable for high-precision cutting of workpieces, chamfering, making ledges, diameter transitions and other shaped processing. Allows you to lathe and cut threads, both internal and external. The length of the part is limited by the overhang of the machine head. Diameter - overhang of the chuck jaws.

- Tape machines. They are used to cut a large diameter pipe without removing it from a trench or collector point. They also work on deformed products.

- Disc cutting machines. Highly automated installation with a pendulum saw and a workpiece feeding mechanism. Often included in the production line, it is used for high-performance cutting of rolled products into equal pieces.

- Manual disk installations. Mobile equipment is used to cut the rolled products exactly right at the installation site. Equipped with a multifunctional clamp that allows you to securely fix products of different diameters and cut them evenly without damaging the edges. The rotating work table allows you to cut smoothly at any angle. The most advanced models are equipped with an orbital welding system. This allows you not only to cut, but also to connect segments.

READ ALSO: How to replace a sewer? Useful tips that will be useful to everyone

CNC Pipe Cutting Machine

How to cut a pipe at 45 degrees with high precision at home

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the mowing line, while the pipeline is cut and then welded at the desired angle. Most often, the direction changes by 90 degrees, and the question arises - how to cut the pipe at 45 degrees in order to accurately connect the joints when welding.

You can cope with the problem of cutting edge angles of 45 or 90 degrees if you have the appropriate knowledge and techniques that will help save not only time, but also materials during the work. At other rotation angles, it is impossible to solve the problem using a ruler and a sheet of paper - you will have to call computer technology for help.

How to cut a cast iron pipe

The main difference between cast iron and ordinary steel is its extreme fragility and large wall thickness; its precise cutting must be done in this order:

- The marking angle is drawn according to the template using a scriber, for

supports under the part are placed on a wooden board or board.

- Use a grinder to make a shallow cut on the surface around the entire perimeter.

- Then the groove is deepened over several passes until the two parts are completely separated.

READ At what degree to cut ceiling plinth

How to cut a cast iron pipe

Cast iron as a material has its own specifics and differs from iron alloys in a number of physical and mechanical features. Despite its highest strength, cast iron is a very brittle material.

How to cut a round pipe at 45 degrees to connect at 90.

The metal pipe exactly like the iron pipe. Before work, you should place wooden logs for support. Using an angle grinder with a cutting disc, make a shallow cut around the entire circumference. Next, the chisel inserted into the cut must be struck with great force. The product will split evenly along the saw line.

If the angle grinder is out of reach, you will have to make a ring cut with a hacksaw.

Cutting a profile pipe at 45 degrees

Cutting pipes at an angle. a typical task in the manufacture of metal structures. Often there is a need to cut a pipe at an angle. The cut pipes are welded at a given angle to the walls of the structures, and two-link elbows are made from them.

Before cutting, use patterns (templates) placed on the pipe to mark the cutting line. For each diameter and each angle of the selected diameter, a separate unique pattern (template) is required. The proposed Excel table allows you to obtain dimensions for constructing a pattern for marking pipes of any diameter, cut at any angle. Enter the outer diameter of the pipe, the cutting angle, and the length of the segment into the yellow cells of the table and you will instantly receive the ordinates and abscissas of these points.

Transfer these points to paronite or cardboard and smoothly connect them together. The pattern (template) is ready. For the convenience of manual construction, the user himself enters the length of the segment on the X axis (a multiple of 5, 10 mm) and receives up to 40 construction points depending on the length of the segment and the length of the pattern. You should get a curve like this.

When using a table with a macro, there is no need for manual construction. The program itself draws the scan based on the entered data. All you have to do is print it out and cut it out. The user adds allowances on the printout.

When making an elbow, the cutting angle should be equal to half the angle of the elbow.

An example of determining the cutting angle for making a 135 degree elbow (9045). Not to be confused with a sharp 45 degree knee! Formula: 135/2=67.5. We cut the pipe at an angle of 67.5 degrees, we get two pieces of pipe with cutting angles of 67.5 degrees, we connect them using a cutting line tied to a common generatrix, we weld them and we get an elbow (67.567.5) of 135 degrees.

While working, I made the following observation. When working with large diameters, the manufactured pattern, when wrapped around the pipe, was clearly shorter, did not cover the entire pipe, and a gap of 20-30 mm remained.

The Gostov diameter of the pipe was indicated correctly, and the pattern was shorter. In my opinion, this error is caused by the fact that it is impossible to press the pattern tightly to the pipe and the outer diameter of the pipe has increased (rust, dirt). I had to use a “belt” to measure the circumference and divide by π (3.1416). Enter the resulting diameter into the table.

Watch the demo video

(Drawings, descriptions, formulas were taken from the book by I.Kh. Brodyansky “Marking of welded shaped parts of pipelines”, 1963)

Upon successful payment, you will immediately receive a link to download the worksheet.

Cutting technology

Typically, the volume and complexity of work that lies ahead for a home craftsman does not require the introduction of high-performance and expensive production-level equipment. When making a greenhouse frame, you can completely cut the pipes with a grinder or a classic hand hacksaw.

Each type of cut has its own aspects, and some require special tricks.

Paper pattern for pipe

To cut evenly at 45°, you can make a paper pattern yourself. To do this you should:

- Measure or calculate the length of the outer circumference.

- From the corner of a sheet of A4 printer paper, draw a fishing line at an angle of 45°. If there is no protractor, such a fishing line can be obtained by folding together the edges of the sheet adjacent to the corner.

- Mark the circumference on it.

- This will be the hypotenuse. Add an isosceles right triangle to it. One side will be the edge of the paper, the second should be lowered perpendicular to the second edge from the set point.

- Cut out the resulting triangle - this will be the pattern for cutting pipes at an angle of 45°.

It should be wrapped around the workpiece, aligning the ends of the hypotenuse. The cut will pass along the mowing line. The line must be emphasized with a marker or cardboard tape. Then, using the marked mowing line, you can evenly cut off a piece with the required bevel.

The method is suitable for pipes with a diameter of up to 63 mm.

READ How to cut a corner of a ceiling plinth without a miter box

Abrasive disc machine

In fact, this is the same grinder, which is simply fixed in a special frame for convenience. This tool is quite dangerous, but allows cutting at an angle of 90 or 45 degrees. Before using such a device, you need to take into account several nuances, otherwise you may get injured during operation:

- The machine must be well fixed on a horizontal surface;

- Cutting a profile pipe should only be done with glasses or a special mask;

- The movement of the tool itself must coincide with the rotation of the metal disk;

- Before work, the metal pipe must be securely secured in a vice.

Features of cutting thin-walled pipes

Sawing thin-walled metal has its own characteristics. When cutting these products, there is a high risk of crushing the edges at the cut points. To prevent this, experts recommend filling the pipes from the inside.

A wooden stick of suitable diameter or sand may be suitable as a filler. For a thin-walled profile, when cutting with a grinder, thin cutting discs are chosen. Working with such material is much faster.

Gas pipe cutting

Features of cutting at an angle of 45 degrees

Cutting a profile pipe at a 45 degree angle presents some challenges. After all, with manual marking, large errors can be made, which is why during the assembly process the elements may not fit together. To cope with the problem, it is best to make a small template from a part with the same cross-section.

- Using a protractor, measure a 45-degree angle on a small piece of pipe;

- Using a machine with a grinder, make a cut and sand the edges of the workpiece;

- Now insert the profile with a smaller diameter into the finished template;

- Make markings using a homemade protractor.

Cutting a profile pipe at an angle can be carried out with tools for both thermal and mechanical processing of parts.

Precision cutting devices

Band saws are characterized by the highest stability of the plane of movement of the blade and cutting accuracy. They are also widely used in procurement areas of small-scale and medium-scale production. They are characterized by versatility, reliability and superior performance.

For personal implementation, the MASS company from Italy offers a small-sized band sawing unit. It is equipped with a manual pressing device and can evenly cut pipes with a diameter of up to 65 mm, as well as rolling any profile of the same thickness.

The rotary device allows you to set a random cutting direction from 0 to 45°. The frequency of movement of the cutting blade is up to 45 cycles per minute. An economical 370 Watt engine allows you to use an ordinary home single-phase power supply with a voltage of 220 V.

Laser equipment

Laser cutting of a profile pipe will be one of the highest quality and less labor-intensive compared to mechanical processing options. This is professional equipment that gives an absolutely even cut, which no mechanical tool is capable of. Thanks to laser equipment, you can easily make cuts at an angle of 45 degrees, which is very difficult to achieve when using a cutter or grinder.

Pipe profile cutting to size:

- The maximum thickness of the metal layer is 6.5 mm;

- Maximum part radius – 80 mm;

- The maximum length of the material is 3-3.5 m.

The photo shows a laser machine that automatically cuts metal parts.

Hacksaw machine

This tool consists of a handle, a mobile frame, a cutter and an adjustment screw. Before cutting, the product is secured using a vice and then cut. A mechanical machine for cutting profile pipes is quite convenient to use, but has several disadvantages:

- The cutter may become very hot during operation;

- Mechanical cutting takes a lot of time;

- The edge of the cut pipe will have burrs that will have to be sanded down.

Methods for cutting profile pipes

When constructing or laying a pipeline, you often have to deal with cutting profile pipes. And the difficulty is to make the cut perfectly smooth without burrs. We will look at several basic methods and tools for cutting metal parts perpendicularly and at an angle.

Fireless cutting of metal parts involves the use of tools that often do not give a very clean cut. After work, the edge of the part must be sanded to remove all burrs. Equipment for thermal cutting does not have this drawback, but it is used mainly in manufacturing enterprises.

Sources:

https://crast.ru/instrumenty/lekalo-dlja-rezki-truby-pod-45-gradusov https://mirkys.ru/raznoe/rezka-pod-uglom-trub.html https://www.toolspipeline. ru/izdelij-iz-trub/rezka-trub-pod-uglom.php https://trubygid.ru/sposoby-rezki-profilnoj-truby

How to cut a pipe evenly with a grinder

To ensure an even cut from the grinder, it is recommended to use special devices for fixing the metal workpiece. Prepared templates, miter boxes or vices are suitable for this.

It is necessary to mark the place for cutting very evenly so that the cut does not go to the side. For large volumes of work, for industrial purposes, special equipment in the form of lathes or tape machines is used to cut pipes.

You can make vertical and horizontal cuts on a metal profile, and cut it at any angle.