SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Processing of wood blanks is carried out using special turning equipment. Using a device of this type allows you to perform various operations with high precision. If necessary, you can make a wood lathe with your own hands. This will save money. To manufacture this device, you need to familiarize yourself with its design features and take advice from experts.

The design of a homemade wood lathe can be extremely simple, but to obtain the desired result you should understand in detail its specifics and application features

Features of wood lathes

In a number of cases, a hardworking owner has a desire to make furnishings and utensils that have a circular cross-section throughout their entire length.

Most often these things are:

- Holders for hammers and files;

- Stair posts, flowerpots, handles for railings;

- Rolling pins, potato presses, grape crushers;

- Vertical pencil cases;

- Cups, mugs, saucers, plates, trays, stoppers.

It will be impossible to cut such things with planes and saws. In this case, you will need at least the most primitive machine.

Buying a lathe

Today you can purchase such a device with a click of the mouse by going to a specialized online store. True, such a purchase will hurt your pocket, especially if you choose a high-quality model and not a cheap Chinese craft.

However, this does not mean that the idea of founding a miniature workshop will have to be given up. The problem of high cost can be solved by taking a different route. A simple and durable electrical unit must be made by hand.

Turning round architectural decorations

Such a mechanism will be an excellent help if you need to make inexpensive repairs to a cottage equipped with

- Flights of stairs with wooden balustrades;

- Decorative trims;

- Carved shutters;

- Window earrings.

Installing the headstock and tailstock

One of the most important parts of the machine is the headstock and tailstock. The workpiece is clamped between them. The headstock directly rotates the product.

Important!

To make the base of the headstock - the spindle shaft - you need to turn to professional metal turners or find a finished part or generally ready-made headstock modules in specialized stores.

The design of the front tank consists of two bearings of type S, V or U, which are bolted to the frame of a shaft machined from carbon steel with a diameter of 40 mm, a chuck for clamping the part.

The shaft is equipped with three or four pins that help eliminate vibration. The shaft is passed through the bearing and pins are attached to it with a key or other fastener for cylindrical parts, after which the shaft is fixed on the second bearing, which is already tightly bolted to the steel corners or the board of the frame.

The tailstock also produces rotational movements, but does not set the product in motion. It is especially important to fix the tailstock on the same axis as the front one, because all subsequent work will depend on this.

Reference. For subsequent control of the axis, the headstock can be designed with adjustment screws, which will allow slight changes in the axis of rotation of the headstock.

The tailstock consists of the following elements:

- A base of angle steel or similar material, similar to the base of a headstock.

- Guide pipe.

- Inner tube or quill. It is made in such a way that it can be placed in a guide pipe, and then a drive screw can be passed through the quill.

- Drive screw. A screw with a nut thread for the quill tube. An 8 mm thread is provided for mounting the flywheel on the rear.

Profitable and promising business

Having gained some experience in the production of decor, it will be possible to move from banal savings to a profitable business. This could be the production and sale of chess pieces. If you sell them through online auctions or retail chains, then an additional source of income will appear in the family budget.

Handmade items quickly find demand, especially if they are offered for sale at a reasonable price.

In the future, this hobby will develop into full-time commercial employment, giving you a chance to acquire professional tools and start earning very good money.

Materials and components

Metal is usually used to construct machines, but as practice shows, you can assemble a small lathe from improvised means, for example, pieces of plywood, wooden blocks and metal plates.

The simplest and most successful material for work is plywood; it is a strong and lightweight material that can withstand heavy loads. It’s not for nothing that plywood is used to build airplane fuselages, and if it can withstand overloads there, then it can withstand the overload as the main material for a lathe.

Connections can be made using furniture bolts, confirmat, self-tapping screws. Strengthening the structure can be done using furniture steel plates.

Main components

The most important components of such a device include

- Bed;

- Electric drive;

- Front and back headstock;

- Stand for accessories.

Support frame base

The bed is a frame that allows you to connect all the parts into a harmonious mechanism. The strength and reliability of such a support directly determines the stability and durability of the entire device. It is better and easier to use a steel angle to make the frame; another suitable material is a rectangular profile.

First of all, it is necessary to mark the dimensions of the assembled automatic sharpening machine. These parameters are determined by what exactly this machine will be used for. As a rule, a stand for an apartment or garage modification does not exceed eighty centimeters in length.

Choosing an Electric Motor for Woodworking Operations

An equally important element of the machine is the engine. The main characteristic that needs to be given enough attention is power. Regardless of the type of motor - single-phase or three-phase, the power can range from 1200 to 2000 W.

Perfectly suited engines:

From a washing machine, if a lathe is needed for small-volume work and the size of the workpiece will not exceed 30–40 cm, in this case the exact maximum length is selected experimentally. Such engines can help in processing small items, dishes, small knobs for stairs and similar interior elements.

Some models of washing machines are equipped with an asynchronous electric motor, in which, by changing the winding, you can step by step change the shaft rotation speed. Similar motors are also installed in floor fans, only there they have a lower power of about 40–100 W. This motor is enough for a mini-machine for small household products.

Frame manufacturing process

The slats selected for assembling the frame must be laid so that their upper edges are strictly in the same plane. The parallelism of these guides is checked by measuring the distances between their ends on each side.

- Longitudinal fragments are secured with clamps. The transverse parts are made from the same profile.

- There will be three crossbars in total. Two of them are fixed at the edges of the device, and the third is placed a couple of tens of centimeters from the left end.

At the next stage, all components are joined by welding into a solid composition. It is important that the resulting connecting joint is strong and smooth.

How to make a handicraft at home?

The support for guiding the cutter along the shaft of the workpiece is a tool rest. It is best to make it from a steel pipe or angle iron, because wooden supports wear out quickly and are not able to withstand as heavy loads as a metal part of the same size.

You can make it by welding two pipes in a T-shape, or you can do it even simpler and fix a piece of board with a wooden boss on the frame, but the accuracy and wear resistance of such a design is not durable. The main thing in arranging a tool rest is that the upper edge of the pipe or angle must correspond to the axis of rotation of the workpiece: in this case, the risk of breaking the chisel is minimal.

Important!

When working on a lathe, only the lower part of the workpiece can be processed! Failure to do so may cause the incisor to become jammed or fractured, which can result in serious injury. When operating a woodworking machine, be sure to wear safety glasses to reduce the risk of injury.

Selecting an Electric Powertrain

When choosing a motor to power the turning system, it is necessary to clarify how powerful it is. For the construction of a homemade self-heating unit, an indicator in the range of 1.2 - 2 kW is quite sufficient. In this case, you should find out exactly what scheme the connection is made according to.

For desktop woodworking, a motor from a household centrifuge is sufficient. Although he is not able to provide turning of a massive workpiece, he will definitely master the processing

- Miniature souvenirs;

- Kitchenware;

- Various types of furniture accessories.

A simple way to make your own frame

The reliability of the bed is a key characteristic of the machine. Human safety and the quality of the product depend on the properties of the material and the quality of the connection of the parts of the frame.

Based on these requirements, the choice falls on metal profiles, chipboard, plywood or solid wood (preferably solid wood: oak, birch or the most common: pine).

If the choice is on a metal frame, then you need to choose a channel, an I-beam or a profile pipe that will carry the load-bearing functions of the machine. Here the choice depends solely on the availability of the material, its price and ease of installation. However, the metal frame is the simplest in design: you only need two I-beams, on which the engine, tailstock, tool rest and caliper are then mounted.

If the choice is wood or chipboard, then based on a preliminary sketch-drawing with the existing dimensions of the engine and all other elements, the design of the frame is formed. As a rule, it consists of a table top, which acts as a base, a stand for the tailstock and a box on which the motor and headstock axle are mounted.

In addition, two parallel slats are run between the headstock racks, on which a movable support board is attached. A gap of 5 cm is maintained between the slats. Afterwards, it is necessary to weld the frame with a welding machine - this will give additional strength to the structure.

If the machine is supposed to be a tabletop machine, then there is no need for legs, but when processing heavy and massive elements, the bed should be independent and its stability should not raise questions. In this case, it is necessary to provide legs. They are made from rolled steel, for example, angle or timber.

The dimensions of the machine primarily depend on the goals pursued by the master. Most operations at home are performed with products up to 80 cm in length, so most often the length dimensions of the machine are 80 cm. If the frame is made of metal, then two blanks of equal length are cut with a grinder.

Functional front lock

For figured turning, the workpiece is fixed between two clamps, which are usually called headstocks. At the same time, torque from the electric motor is transmitted to the front, and therefore it will be somewhat more difficult to assemble it.

The front clamp of a home lathe is an iron U-shaped structure, between the sides of which a shaft and a pulley system are mounted on bearings. The body is assembled from thick rolled steel segments.

Why is it needed and how does it work?

A lathe is designed for the manufacture of wooden products that have a cylindrical or similar shape. This is an indispensable thing when renovating a country house with a wooden staircase, a carved porch, but not only.

If you have some experience, a turning tool will allow you not only to save on purchased decorative elements, but also to earn money, because handmade wooden products are highly valued.

Whether such a machine is needed in a home workshop is up to the master to decide.

Of course, if you need several handles for chisels, it is easier to buy them, but if you want to make an all-wood staircase, then a set of balusters will cost a very large sum. It is much cheaper to make them yourself. By the way, you don’t even have to spend money on buying equipment - a simple machine can be made in your own workshop using scrap materials.

The operating principle of a wood lathe is not particularly complicated. The cylindrical workpiece is fixed along the axis of rotation. Torque is transmitted to it. By bringing various cutters or grinding tools to the workpiece, it is given the desired shape.

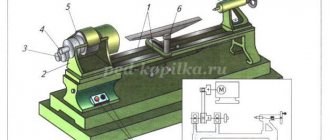

Main parts of lathe:

- a frame on which all components are fixed;

- electric drive;

- headstock;

- tailstock;

- handyman

For ease of operation, schemes for changing the rotation speed are used. In professional equipment, this is a real gearbox, a system of gears that allows you to regulate speed within a very wide range. This is difficult; it is enough to equip a homemade wood lathe with a belt drive with several pulleys of different diameters.

Installation of the second clamp

The purpose of the rear analogue is to support the conditional cylinder to be sharpened and provide it with freedom for rapid rotation. The more firmly the tailstock holds the workpiece, the better the final result will be.

- An indispensable condition for proper installation of the second clamp is maintaining alignment with the first.

- Faced with great difficulties at this stage, it makes sense to significantly simplify the task by purchasing a completely finished unit.

The use of an electric drill chuck will allow you to significantly modify the engineering solution. A shaft is clamped in it, the end of which must be pointed.

Mini machine for small jobs

Often there is a need to turn several small wooden parts, in this case it is not at all necessary to make a full-fledged machine; you can get by with a mini-wood lathe. Its production does not require much labor and will not take much time.

The design of such a machine is extremely simple. A motor from an old tape recorder, powered from an external power supply, is ideal as an electrical component. The bed of the mini-machine will be a piece of board of the required length.

The engine must be secured. Of course, a belt drive is not suitable for a small machine; the workpiece will have to be mounted on the motor shaft. The best device for this is a faceplate. The drive housing is a U-shaped plate, in the center of which a hole is drilled for the shaft. The engine in the housing is mounted on the frame using self-tapping screws.

The main part of the machine is ready, all that remains is to make the tailstock. Its body is made of a block of suitable size. A hole for the shaft is drilled in it exactly at the height of the engine; a dowel-nail of suitable length is used as it. The headstock is attached with glue and several screws.

Using a power source with the ability to adjust the output voltage, you can create a machine with variable rotation speed. It is convenient to regulate the speed using the foot control pedal. The design of this device can be very diverse, it all depends on the available parts.

Convenient turntable

All that remains is to make a tool rest, where needle files, jigsaws, sandpaper, planes and hacksaws will be laid out during work. Its outlines are not regulated in any way, but it must be completely comfortable.

It is better to design such a table with the participation of the master who will become the main user of the automatic sharpener.

The best option is a swivel stand in the shape of a trapezoid. It is cut out of a thick iron sheet, after which it is mounted on a rotary hinge with a large two-way angle. It will be easy to move such a table in order to bring files closer to you or move them away for a while.

Design and principle of operation

For wood turning units, such elements have different designs. However, despite all the diversity, the following elements can be distinguished:

- frame;

- control element;

- a flywheel that moves the quill along the center line;

- feed screw (the direction of movement of the workpiece is adjusted);

- spindle.

The case is an all-metal part, which ensures reliable fastening of all elements. The movable part of the tailstock of a lathe must ensure reliable fastening of the workpiece during the entire machining process. The dimensions of this element of the turning unit determine the diameter of the permitted workpiece that can be secured for processing. The tailstock cone of a woodworking machine acts as a locking element. Its center is directed towards the middle of the workpiece. The center axis must exactly coincide with the axis of symmetry.

The design of the tailstock largely determines the technical capabilities of the machine. Each unit is performed in accordance with the requirements of accepted standards.

Cutters of different calibers

Cutting attachments are sold in every major hardware supermarket. At the same time, it is possible to buy both single cutting parts and sets.

With a wide selection of cutters available, the turner will create any complex and intricate configurations, including

- Grooves;

- Chamfers;

- Cones;

- Dashed lines;

- Edging;

- Wavy lines.

Selecting a transfer method

The transmission of torque from the engine to the workpiece can be carried out in two ways.

Direct transmission

Direct transmission of the drive to the workpiece is the simplest design method, but not the most perfect. Disadvantages of direct transmission:

- It is impossible to regulate the rotation speed, since the motor without additional units cannot change the rotation speed by simply changing the incoming voltage. This drawback is especially noticeable when working with hardwood, such as oak, teak or apple tree.

- High load on the motor shaft and shorter service life compared to belt drive. Heavy products will have a particularly strong effect on engine wear. This is primarily due to the fact that the bearings of most motors (except for motors in washing machines) are not designed for longitudinal load. You will also have to pay more attention to the centering of the material, because any inaccuracy will lead to excessive vibrations, which at high speeds can make the work impossible.

Belting

This method of transmitting rotation guarantees a longer service life of the motor and makes it possible to regulate the speed of rotation of the workpiece. In this case, the engine itself is located offset from the axis of rotation of the wooden product, and the torque is transmitted using a belt and several pulleys.

If you provide the machine with pulleys of several radii, it will be possible to change the rotation speed of the headstock. With three or more pulleys of different diameters, you can tackle hardwood with confidence. If you stock up on the necessary tools, you can even work with soft alloys.