When a solid and liquid are heated, their temperature increases. This leads to the fact that their volume increases to a certain extent as the temperature rises with each degree. The property that characterizes the relationship between temperature and volume is called the expansion coefficient. The coefficient has different meanings for different substances, and it can also change for one substance depending on its temperature. The principle is used in the operation of thermometers and other instruments used to measure temperature.

General information.

The coefficient of thermal expansion is widely used in engineering calculations.

The Greek letters usually used to denote the coefficient of thermal expansion are β (for volumetric expansion) and α (for linear expansion). On the website, the designation used in calculations is bv and al, respectively.

The coefficient of thermal expansion depends on temperature.

Types of thermal expansion coefficients.

- coefficient of volumetric thermal expansion;

- coefficient of linear thermal expansion.

Dependence of the volume of bodies on temperature

Particles of a solid body occupy certain positions relative to each other, but do not remain at rest, but oscillate. When a body heats up, the average speed of particle movement increases. At the same time, the average distances between particles increase, therefore the linear dimensions of the body increase, and therefore the volume of the body increases.

When cooling, the linear dimensions of the body are reduced and its volume decreases.

As is known, when heated, bodies expand, and when cooled, they contract. The qualitative side of these phenomena has already been discussed in the initial physics course.

Our task now is to become familiar with the quantitative laws of these phenomena.

Linear expansion of solids

A solid at a given temperature has a certain shape and certain linear dimensions. An increase in the linear dimensions of a body when heated is called thermal linear expansion .

Measurements show that the same body expands differently at different temperatures: at high temperatures it usually expands more than at low temperatures. But this difference in expansion is so small that with relatively small changes in temperature it can be neglected and it can be assumed that the change in body size is proportional to the change in temperature.

In the initial physics course, it was established that different substances expand differently when heated: some more strongly, others less; iron, for example, expands more than glass and less than copper.

To quantitatively characterize this important thermal property of bodies, a special quantity was introduced called linear expansion coefficient .

Let a solid body at a temperature of 0°C have a length and at a temperature t° its length becomes So, when the temperature changes by t°, the length of the body increases by Assuming that the increase in length when heated by each degree is uniform, we find that when heated by 1 °C the entire length of the body increased by each unit of length by

(1)

The quantity (Greek “beta”) characterizing the thermal expansion of a body is called linear expansion coefficient .

Formula (1) shows that at t = 1°C and = 1 unit. length, the value is equal, i.e., the coefficient of linear expansion is numerically equal to the elongation that a rod, which at 0°C had a length equal to a unit length, receives when heated by 1°C.

From formula (1) it follows that the name of the coefficient is

Formula (1) can be written as follows:

From here it is easy to determine the length of a body at any temperature if its initial length and linear expansion coefficient are known.

The table below shows the linear expansion coefficients of some substances, determined experimentally.

Volume expansion of solids

With the thermal expansion of a solid body, as the linear dimensions of the body increase, its volume also increases. Similar to the coefficient of linear expansion, for the characteristic of volumetric expansion, you can enter the coefficient of volumetric expansion . Experience shows that, just as in the case of linear expansion, it can be assumed without much error that the increase in the volume of a body is proportional to the increase in temperature.

Denoting the volume of the body at 0°C by V0, the volume at temperature t0 by Vt and the coefficient of volume expansion by we find:

(2)

At V0 = 1 unit. volume and t = 1°C, the value a is equal to Vt - V0, i.e., the coefficient of volumetric expansion is numerically equal to the increase in the volume of the body when heated by 1°C, if at 0°C the volume was equal to a unit volume.

Using formula (2), knowing the volume of a body at a temperature of 0°C, you can calculate its volume at any temperature t°:

Let us establish the relationship between the coefficients of volumetric and linear expansion.

Let us assume that we have a cube whose edge at 0°C is equal to 1 cm. When heated by 1°C, the edge will become equal to cm, and the volume of the cube will increase by cm3.

We can write the following equality:

But

In this formula, the quantities and are so small that they can be neglected and written:

The coefficient of volumetric expansion of a solid is equal to triple the coefficient of linear expansion.

Accounting for thermal expansion in technology

The table on page 124 shows that the expansion coefficients of solids are very small. However, the most insignificant changes in the size of bodies with temperature changes cause the appearance of enormous forces.

Experience shows that even a small elongation of a solid body requires enormous external forces. So, for example, to increase the length of a steel rod with a cross-section of 1 cm2 by approximately 0.0005 of its original length, it is necessary to apply a force of 1000 kg. But the same magnitude of expansion of this rod is obtained when it is heated to 50°C. It is therefore clear that, expanding when heated (or contracting when cooled) by 50°C, the rod will exert a pressure of about 1000 on those bodies that will prevent its expansion (compression).

The enormous forces that arise during the expansion and compression of solids are taken into account in technology. So, for example, one of the ends of the bridge is not fixed motionless, but is installed on rollers; railway rails are not laid closely, but a gap is left between them; steam pipelines are suspended on hooks, and compensators are installed between individual pipes, bending as the steam pipeline pipes lengthen. For the same reason, the boiler of a steam locomotive is fixed only at one end, while its other end can move freely.

Expansion from heating is of great importance in accurate measurements. In fact, if the scale ruler or gauge used to check the dimensions of a manufactured part of a machine changes its size significantly, then the required measurement accuracy will not be achieved. To avoid gross errors during measurement or control, manufactured products are brought to the room where measurements are made in advance so that they have time to take the temperature of the calibers. Most gauges and measuring instruments are made from a material with a very low coefficient of expansion. Such a material, for example, is a special iron-nickel steel - Invar, with an expansion coefficient of 0.0000015.

Rice. 132a. Diagram of a metal thermometer.

As the table on page 124 shows, platinum and glass have the same coefficient of expansion; therefore, it is possible to fuse platinum into glass, and after cooling there is no weakening of the bond of both substances, nor cracking of the glass. In light bulbs, iron-nickel wire is fused into the glass, which has the same coefficient of expansion as the glass. The very low expansion coefficient of quartz glass is noteworthy. Such glass can withstand uneven heating or cooling without breaking or cracking. So, for example, cold water can be poured into a red-hot quartz glass flask, while a flask made of ordinary glass will burst during such an experiment. This feature of quartz glass is a consequence of the smallness of its coefficient of thermal expansion.

Units.

Conversion of units of measurement of coefficient of thermal expansion.

Linear thermal expansion coefficient calculator. Conversion of units of measurement of the coefficient of linear thermal expansion (1/°C, 1/K, etc.)

Enter coefficient of linear thermal expansion (al)

Result of conversion of units of measurement of coefficient of linear thermal expansion (al)

The results of the coefficient of linear thermal expansion calculator when converted to other units of measurement of the coefficient of linear thermal expansion:

Examples of results from the linear thermal expansion coefficient calculator:

/ 2 1/gr. Celsius = 2 1/K

//

115954 1/K = 0

//

0.08 1/K = 0.08 1/gr. Celsius

//

115954 1/K = 115954 1/gr. Celsius

//

24000 1 /gr.celsius = 0

//

10 = 0 1/K

/

Share a link to the calculation:

Units for measuring the coefficient of thermal expansion.

- per degree Celsius

- Designation in Russia:

1/°С . This unit of measurement is widely used in engineering calculations and in modern reference literature; - per degree Kelvin

is a unit of measurement in SI.

Designation in Russia: 1/ K .

Directory

| Material | Coefficient of linear thermal expansion | |

| 10-6 °С-1 | 10-6 °F-1 | |

| ABS (acrylonitrile butadiene styrene) thermoplastic | 73.8 | 41 |

| ABS - fiber reinforced glass | 30.4 | 17 |

| Acrylic material, pressed | 234 | 130 |

| Diamond | 1.1 | 0.6 |

| Diamond technical | 1.2 | 0.67 |

| Aluminum | 22.2 | 12.3 |

| Acetal | 106.5 | 59.2 |

| Acetal, glass fiber reinforced | 39.4 | 22 |

| Cellulose acetate (CA) | 130 | 72.2 |

| Cellulose acetate butyrate (CAB) | 25.2 | 14 |

| Barium | 20.6 | 11.4 |

| Beryllium | 11.5 | 6.4 |

| Beryllium-copper alloy (Cu 75, Be 25) | 16.7 | 9.3 |

| Concrete | 14.5 | 8.0 |

| Concrete structures | 9.8 | 5.5 |

| Bronze | 18.0 | 10.0 |

| Vanadium | 8 | 4.5 |

| Bismuth | 13 | 7.3 |

| Tungsten | 4.3 | 2.4 |

| Gadolinium | 9 | 5 |

| Hafnium | 5.9 | 3.3 |

| Germanium | 6.1 | 3.4 |

| Holmium | 11.2 | 6.2 |

| Granite | 7.9 | 4.4 |

| Graphite, pure | 7.9 | 4.4 |

| Dysprosium | 9.9 | 5.5 |

| Wood, fir, spruce | 3.7 | 2.1 |

| Oak wood, parallel to the grain | 4.9 | 2.7 |

| Oak wood, perpendicular to the grain | 5.4 | 3.0 |

| Wood, pine | 5 | 2.8 |

| Europium | 35 | 19.4 |

| Iron, pure | 12.0 | 6.7 |

| Iron, cast | 10.4 | 5.9 |

| Iron, wrought | 11.3 | 6.3 |

| Gold | 14.2 | 8.2 |

| Limestone | 8 | 4.4 |

| Invar (iron-nickel alloy) | 1.5 | 0.8 |

| Inconel (alloy) | 12.6 | 7.0 |

| Iridium | 6.4 | 3.6 |

| Ytterbium | 26.3 | 14.6 |

| Yttrium | 10.6 | 5.9 |

| Cadmium | 30 | 16.8 |

| Potassium | 83 | 46.1 — 46.4 |

| Calcium | 22.3 | 12.4 |

| Masonry | 4.7 — 9.0 | 2.6 — 5.0 |

| Rubber, hard | 77 | 42.8 |

| Quartz | 0.77 — 1.4 | 0.43 — 0.79 |

| Ceramic tiles (tiles) | 5.9 | 3.3 |

| Brick | 5.5 | 3.1 |

| Cobalt | 12 | 6.7 |

| Constantan (alloy) | 18.8 | 10.4 |

| Corundum, sintered | 6.5 | 3.6 |

| Silicon | 5.1 | 2.8 |

| Lanthanum | 12.1 | 6.7 |

| Brass | 18.7 | 10.4 |

| Ice | 51 | 28.3 |

| Lithium | 46 | 25.6 |

| Cast steel grating | 10.8 | 6.0 |

| Lutetium | 9.9 | 5.5 |

| Cast Acrylic Plastic Sheet | 81 | 45 |

| Magnesium | 25 | 14 |

| Manganese | 22 | 12.3 |

| Copper-nickel alloy 30% | 16.2 | 9 |

| Copper | 16.6 | 9.3 |

| Molybdenum | 5 | 2.8 |

| Monel metal (nickel-copper alloy) | 13.5 | 7.5 |

| Marble | 5.5 — 14.1 | 3.1 — 7.9 |

| Soapstone (steatite) | 8.5 | 4.7 |

| Arsenic | 4.7 | 2.6 |

| Sodium | 70 | 39.1 |

| Nylon, universal | 72 | 40 |

| Nylon, Type 11 | 100 | 55.6 |

| Nylon, Type 12 | 80.5 | 44.7 |

| Nylon cast, Type 6 (Type 6) | 85 | 47.2 |

| Nylon, Type 6/6, molding compound | 80 | 44.4 |

| Neodymium | 9.6 | 5.3 |

| Nickel | 13.0 | 7.2 |

| Niobium (Columbium) | 7 | 3.9 |

| Cellulose Nitrate (CN) | 100 | 55.6 |

| Alumina | 5.4 | 3.0 |

| Tin | 23.4 | 13.0 |

| Osmium | 5 | 2.8 |

| Palladium | 11.8 | 6.6 |

| Sandstone | 11.6 | 6.5 |

| Platinum | 9.0 | 5.0 |

| Plutonium | 54 | 30.2 |

| Polyallomer | 91.5 | 50.8 |

| Polyamide (PA) | 110 | 61.1 |

| Polyvinyl chloride (PVC) | 50.4 | 28 |

| Polyvinylidene fluoride (PVDF) | 127.8 | 71 |

| Polycarbonate (PC) | 70.2 | 39 |

| Polycarbonate - glass fiber reinforced | 21.5 | 12 |

| Polypropylene - glass fiber reinforced | 32 | 18 |

| Polystyrene (PS) | 70 | 38.9 |

| Polysulfone (PSO) | 55.8 | 31 |

| Polyurethane (PUR), hard | 57.6 | 32 |

| Polyphenylene - glass fiber reinforced | 35.8 | 20 |

| Polyphenylene (PP), unsaturated | 90.5 | 50.3 |

| Polyester | 123.5 | 69 |

| Glass fiber reinforced polyester | 25 | 14 |

| Polyethylene (PE) | 200 | 111 |

| Polyethylene - terephthaly (PET) | 59.4 | 33 |

| Praseodymium | 6.7 | 3.7 |

| Solder 50 - 50 | 24.0 | 13.4 |

| Promethium | 11 | 6.1 |

| Rhenium | 6.7 | 3.7 |

| Rhodium | 8 | 4.5 |

| Ruthenium | 9.1 | 5.1 |

| Samarium | 12.7 | 7.1 |

| Lead | 28.0 | 15.1 |

| Lead-tin alloy | 11.6 | 6.5 |

| Selenium | 3.8 | 2.1 |

| Silver | 19.5 | 10.7 |

| Scandium | 10.2 | 5.7 |

| Mica | 3 | 1.7 |

| Hard alloy K20 | 6 | 3.3 |

| Hastelloy alloy C | 11.3 | 6.3 |

| Steel | 13.0 | 7.3 |

| Austenitic stainless steel (304) | 17.3 | 9.6 |

| Austenitic stainless steel (310) | 14.4 | 8.0 |

| Austenitic stainless steel (316) | 16.0 | 8.9 |

| Ferritic stainless steel (410) | 9.9 | 5.5 |

| Showcase glass (mirror, sheet) | 9.0 | 5.0 |

| Pyrex glass, pyrex | 4.0 | 2.2 |

| Refractory glass | 5.9 | 3.3 |

| Construction (lime) mortar | 7.3 — 13.5 | 4.1-7.5 |

| Strontium | 22.5 | 12.5 |

| Antimony | 10.4 | 5.8 |

| Thallium | 29.9 | 16.6 |

| Tantalum | 6.5 | 3.6 |

| Tellurium | 36.9 | 20.5 |

| Terbium | 10.3 | 5.7 |

| Titanium | 8.6 | 4.8 |

| Thorium | 12 | 6.7 |

| Thulium | 13.3 | 7.4 |

| Uranus | 13.9 | 7.7 |

| Porcelain | 3.6-4.5 | 2.0-2.5 |

| Phenolic-aldehyde polymer without additives | 80 | 44.4 |

| Fluoroethylene propylene (FEP) | 135 | 75 |

| Chlorinated Polyvinyl Chloride (CPVC) | 66.6 | 37 |

| Chromium | 6.2 | 3.4 |

| Cement | 10.0 | 6.0 |

| Cerium | 5.2 | 2.9 |

| Zinc | 29.7 | 16.5 |

| Zirconium | 5.7 | 3.2 |

| Slate | 10.4 | 5.8 |

| Plaster | 16.4 | 9.2 |

| Ebonite | 76.6 | 42.8 |

| Epoxy resin, cast rubber and unfilled products thereof | 55 | 31 |

| Erbium | 12.2 | 6.8 |

| Ethylene vinyl acetate (EVA) | 180 | 100 |

| Ethylene and ethyl acrylate (EEA) | 205 | 113.9 |

| Ether vinyl | 16 — 22 | 8.7 — 12 |

Note: Reference data is sourced from online publications and may not be considered "official" or "completely accurate." As a rule, Internet directories do not provide links to scientific works that are the basis of published data. We try to take information from the most reliable scientific sites. However, if anyone is interested in links to experiments, we advise you to conduct an in-depth search on the Internet yourself. We will be grateful for any comments on our reference tables, and especially for clarification of existing information or addition of reference data.

You may also be interested in:

Volume expansion coefficient

TCLE of materials used in electronics

Reference materials.

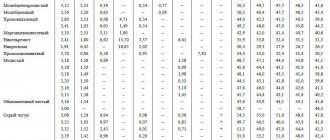

Linear expansion coefficient of steels (GOST 14249-89 “Vessels and apparatus. Standards and methods for strength calculations”).

| steel grade | Calculated value of the coefficient, 1/°С, at temperature, °С | ||||

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | |

| VSt3, 20, 20K | 11,6 | 12,6 | 13,1 | 13,6 | 14,1 |

| 09G2S, 16GS, 17GS, 17G1S, 10G2S1, 10G2 | 13,0 | 14,0 | 15,3 | 16,1 | 16,2 |

| 12ХМ, 12МХ, 15ХМ, 15Х5М, 15Х5М-У | 11,9 | 12,6 | 13,2 | 13,7 | 14,0 |

| 08Х22Н6Т, 08Х21Н6М2Т | 9,6 | 13,8 | 16,0 | 16,0 | 16,5 |

| 12Х18Н10Т, 12Х18Н12Т, 03Х17Н14М3, 10Х17Н13М2Т, 10Х17Н13М3Т, 08Х18Н10Т, 08Х18Н12Т, 03Х18Н11, 08Х17Н13М2Т, 08Х17Н15М3Т | 16,6 | 17,0 | 18,0 | 18,0 | 18,0 |

| 03Х21Н21М4ГБ | 14,9 | 15,7 | 16,6 | 17,3 | 17,5 |

| 06ХН28МДТ, 03ХН28МДТ | 15,3 | 15,9 | 16,5 | 16,9 | 17,3 |

| 08Х18Г8Н2Т | 12,3 | 13,1 | 14,4 | 14,4 | 15,3 |

Let's think about it

Imagine that in front of you is a rectangular metal sheet with a round hole in the middle. If the metal is heated, the piece will expand due to thermal expansion. But what will happen to the hole? Okay, let's take exactly the same sheet without a hole. Draw a circle on it. What do you see? Yes, he got bigger. Therefore, the hole will also increase.

As the temperature increases, objects expand in all directions. The drawings show that solid lines and extended borders with dotted lines mark the original boundaries of the bodies. (a) – The area increases because the length and width increase. (b) – If the damper is removed, the hole will increase in size as the temperature increases

1.7. Thermal deformations in statically indeterminate structures

Statically indeterminate structures are structures in which the number of reactions exceeds the number of static equilibrium equations. Unlike statically determinate structures, when calculating such structures, deflections are taken into account [1, 2].

In a statically indeterminate structure, thermal stresses may or may not occur depending on the design features and the characteristics of temperature changes. To illustrate some of these possibilities, consider the statically indeterminate truss shown in Figure 2.4.

Figure 2.4 - Statically indeterminate truss under the influence of temperature changes

The supports of this structure allow node D to move horizontally. Therefore, when the entire truss is heated uniformly, no thermal stress occurs in it. All elements increase in length in proportion to their original lengths, and the entire truss as a whole becomes slightly larger in size.

However, if some of the rods heat up and others do not, then thermal stresses arise, since the statically indeterminate arrangement of the rods prevents their free expansion.

1.6. Thermal deformations in statically determined structures

Consider the ABC truss of two rods, shown in Figure 2.3. Let us assume that the temperature of rod AB has changed by ΔТ1, and that of rod BC by ΔТ2. Since this truss is statically determinate, both rods can freely lengthen or shorten, resulting in movement of connection B. However, in this case, there are no thermal stresses in the rods, as well as reactions in the supports.

Figure 2.3 – Statically determined truss with a uniform temperature change in each element

This conclusion is generally true for all statically determinate structures, namely: a uniform temperature change in structural elements causes thermal deformations (and corresponding changes in the lengths of elements) without the occurrence of corresponding thermal stresses [1, 2].

1.5. Temperature movements

Let's return to the block of material shown in Figure 1 [1]. We assume that the material of the bar is homogeneous and isotropic, that is, the mechanical properties of the material of the bar are the same throughout its entire volume. In addition, we assume that the temperature change ΔT

is homogeneous, that is, the same throughout the entire block. Under these conditions, we can calculate the increase in any size of a block by multiplying the original size by the thermal deformation. For example, if one of the dimensions of the bar is L, then this dimension will increase by the amount

δT = εT· L =

α · ΔT · L (4)

Equation (4) can be used to calculate changes in the lengths of structural elements after uniform heating, for example, the elongation of a prismatic rod in Figure 2.2. The transverse dimensions of the member will also change, but these changes are not shown in Figure 2.2 as they usually do not affect the axial forces transmitted by the member.

Figure 2.2 – Increase in the length of the prismatic rod as a result of a uniform increase in temperature (equation (4)) [1]

Example.

Let us estimate the elongation of loose aluminum and steel rods 3 m long when their temperature increases by 50 ºС.

For aluminum rod:

δT =

α ΔT L = 23 10-6 50 3000 = 3.5 mm

steel rod:

δТ =

α · ΔT · L = 12·10-6·50·3000 = 1.8 mm

When considering temperature deformations above, it was assumed that the structure had no restrictions on its movements, which allowed it to expand or contract completely freely. Such conditions arise, for example, when an object lies on a smooth surface on which no friction occurs [1]. In such cases, when the entire object is heated uniformly, there is generally no stress generated, although non-uniform temperature changes may cause internal thermal stresses. However, many structures have supports that prevent free expansion and contraction of their size. Therefore, they develop thermal stresses even if the temperature change is uniform throughout the structure.

1.4. Temperature stress

To demonstrate the relative importance of thermal stresses, thermal stresses can be compared with the stresses that occur during force loading [1]. Let us assume that we have a beam that is loaded with forces in the axial direction with longitudinal deformations, which are given by the equality

ε = σ/E

, (2)

where σ

is the stress, and

E

is the elastic modulus.

Let us further assume that we have an identical block that is subject to a change in temperature ΔT .

This means that this block has thermal deformations according to equality (1). Equating these two types of deformations gives the equation

σ = E α ΔT (3 )

Example.

Let us calculate the axial stress σ,

which gives the same deformations as the change in temperature

ΔT

in rods made of aluminum alloy and construction (low-carbon) steel when their temperature increases by 50 ºС.

For an aluminum rod ( α

= 23·106, E = 70000 N/mm2

):

σ = 70000 23 10-6 50 = 80.5 N/mm2

For a low-carbon steel rod ( α

= 12·106, E = 210000 N/mm2

):

σ = 210000 12 10-6 50 = 126 N/mm2

Let us note the well-known fact that with the same change in temperature, the temperature stresses in the aluminum rod are only 2/3 of the magnitude of the temperature stresses in the steel rod. This happens because the magnitude of temperature stress depends on the product

modulus of elasticity and coefficient of thermal expansion (see formula (3)). Therefore, although the coefficient of thermal expansion of aluminum is two times greater than that of steel, the modulus of elasticity of aluminum is three times less than that of steel.

As can be seen from the above calculations, temperature stresses can reach values comparable to stresses from mechanical loads. Therefore, thermal effects on building structures must be taken into account along with other loads, as required by regulatory documents [4, 5].