When installing a staircase with your own hands, one of the important steps is the manufacture of railings. They are very important, as they ensure safe ascent and descent and give the march a complete, harmonious look. The cost of manufacturing and installing railings for staircase structures is quite high. However, safety and aesthetics should not be neglected. You can make and install balusters with your own hands. With the right material selected and all technologies followed, you can get a result that will pleasantly please you.

How to choose the right balusters?

When choosing supports for fences of various designs, various factors are used. Among them:

- appearance;

- price;

- size;

- performance material.

When ordering fencing installations from specialized organizations, they produce structural elements from wood of the same species. The same principle must be followed when installing fencing yourself. You cannot install balusters made of oak, and railings made of alder or larch. The purchased products must have the correct geometric dimensions. They should not have:

- defects;

- deformations;

- blue on the surface;

- emptiness inside.

You should not buy products with fallen knots or made from raw wood.

Prices for various types of balusters

Balusters

What type of wood to choose

In order for the staircase to remain strong and presentable for a long time, it is recommended to make all elements: railings, balusters, steps from the same type of wood. When making supports for stairs, it is best to choose hard wood:

- Oak. Noble and strong, it has the highest performance characteristics. It is durable, resistant to temperature changes, moisture and decay. Oak products have a beautiful dark shade. The products practically do not crack or warp. Despite the density of the wood, oak can be processed in all available ways.

Example of carved oak balusters - Ash. It has a very beautiful texture of valuable wood. The main advantage of ash is its resistance to moisture and rot. The structure of the tree is elastic and dense, withstands heavy loads well, bends well, and is resistant to deformation.

- Beech. Beautiful and easy to process, beech is almost as strong and durable as oak. The wood is perfectly polished and sanded, and lends itself well to decorative finishing with various compositions. The disadvantage of beech is its susceptibility to rotting and deformation in places with high humidity. In order for beech products to be of high quality, you need to choose properly dried wood.

- Birch. Rarely used for making balusters. The main disadvantage of birch is its tendency to rot, cracks and severe shrinkage.

Drawings and patterns of birch balusters

Although wood has good strength indicators, it is easy to process, sand and paint. After appropriate processing, birch can be given the appearance of noble wood. - Larch. Over time, wooden larch balusters only become stronger. The wood is resistant to warping and high humidity, it does not rot and burns very poorly.

- Pine. A budget option with good resistance to fungi, moisture and temperature changes. Wood lends itself well to processing with cutting tools and is the most popular material for creating stairs.

To make balusters with your own hands, it is important to choose wood of the correct moisture content, without cracks, knots and other defects. Overdried wood is very fragile, and wet wood can crack after drying.

Various types of carved balusters

It would also be wiser for novice craftsmen to choose inexpensive types of wood - pine or birch, which are easy to process. Valuable species such as oak or walnut are too expensive to be damaged during the training process.

Manufacturing technology of wooden balusters

The wood lends itself well to processing. This allows you to apply patterns of various types and complexity to the surface of the blank balusters. Craftsmen create supports suitable for interiors from modern to high-tech. Work begins with the development of a product sketch. After its approval, a drawing is drawn up indicating all dimensions, including bends and cuts. Before starting to manufacture the support, the dimensions indicated in the drawing are transferred to the workpiece and marks are made. Each of them is assigned a number. Cutting out decorative parts requires cutters of various shapes.

Cutters for cutting out decorative elements on balusters

Round supports are made using the rotation method. The operation of lathes is based on this principle. They are adapted for processing blanks made from various types of wood. In a lathe, the workpiece is fixed in the spindle head. It rotates at a given speed around its axis. The ornament is applied to the surface using a rigidly fixed support of the cutter. The position of the tool is adjusted using movable slides. They can move manually or automatically. The type of ornament applied to the surface of the blank depends on the position of the cutter.

On milling machines, a rotating spindle is used to secure the cutter. A stationary workpiece is fed to it using a support. The industry produces universal machines that combine turning and milling functions. They make products with complex ornaments. In the absence of universal CNC equipment, difficult-to-cut patterns are made on sequentially used lathes and milling machines.

Making balusters on a CNC machine

After applying the pattern to the surface of the products, they undergo finishing treatment. First, the supports are ground by hand or machine and then polished. Products prepared in this way can be coated with wood varnish or paint.

Find out how to age wood with your own hands, and also familiarize yourself with aging methods and mistakes when working in a special article on our portal.

Video - How to make Roman-type balusters yourself?

Stages of work

When making flat balusters with your own hands, be sure to make a sketch and drawings of the flat balusters - the future product. This will not only save you from mistakes, but will allow you to look at the model of your plan (photo). If your enclosing structure consists of identical elements, then it is enough to build one of them on paper, and then transfer it to the board and start cutting. (Prepare a set of cutters.) And if you decide to create a complex ornamental design, each baluster will have its own appearance and you will need several drawings of the product.

The next step in the work will be processing the edges of the baluster. You need to grind carefully, maintaining symmetry in all details and achieving smooth edges. Then, the sawn parts of the structure need to be connected. Before gluing the balusters, they must be degreased and thoroughly cleaned. Special glue is selected and applied to both parts to be glued. If you are planning to create a complex ornament from flat balusters, then be careful when assembling them into a single canvas, do not deviate from your sketch. (video) In the case of a simple design (when the elements of the fence are the same), maintain the width of the step between them. Now that the balusters are glued together, they can be installed and covered with railings. This design may not be very stable, but aesthetically it is very attractive. A special topic will be the installation of balusters for wooden stairs. Firstly, you need to remember that in this case the wood from which the staircase itself is made must also be used for flat carved balusters. Otherwise, the design will not be perceived as stylistically unified, not to mention possible distortions; different types of wood behave differently in operation. Secondly, installing balusters on steps requires special training and qualifications. But if you wish, you can master this skill by following the advice of experts.

Conclusion

So, making a fence from flat balusters is very exciting and economical, and flat balusters look attractive in the photo. If you have a desire to decorate your home or cottage with such an original architectural element, do not deny yourself this pleasure. By doing the work, you will gain new knowledge, skills and create a kind of amulet for your home, because any thing made with your own hands is filled with creative energy and will be a true protection for you and your home.

Flat balusters: step-by-step instructions

Flat supports are easiest to make yourself. Their production does not require complex equipment. Skillfully made supports have an attractive appearance. They can decorate any interior.

Step 1. The first stage of work is devoted to preparing the materials and tools necessary for the manufacture of balusters: jigsaw, paper, marker, scissors, ruler, sandpaper or sanding machine, dry boards or plywood.

Electric jigsaw

Prices for popular models of jigsaws

Jigsaw

Step 2. At the second stage, a sketch of the future support is developed. To do this, the full size of the contours of the product and patterns are applied to the paper. After this, a support template is cut out according to the dimensions marked on the paper.

Stencils

Step 3. The third stage is devoted to applying a stencil to the workpiece, drawing the contours of the future product on it and cutting out a support along them with a jigsaw.

Flat balusters cut with a jigsaw

Step 4. At the fourth stage of work, the surface of the products is processed. For these purposes, use sandpaper or a grinding machine.

Prices for popular models of sanders

Sanders

Sanding a piece of wood with an emery wheel

Step 5. To extend the service life of products, their surface is treated with an antiseptic. After it dries, the supports are coated with wood varnish. This improves their aesthetic appearance.

Features of varnishing stairs

Find out how to make a wooden countertop for a bathroom sink with your own hands in a special article on our portal.

Preliminary calculations

A staircase is primarily a functional structure, and the aesthetic aspect is always secondary. Movement should be comfortable, for which all parameters are calculated for each element separately.

Baluster height for stairs

The most convenient is considered to be a handrail located 800-900 mm from the floor. This height is typical for molded fittings. The permissible range lies in the range of 650-1500 mm and is dictated by personal preferences, so that it is comfortable to lean on the railing, but at the same time the design is not unnecessarily bulky.

Distance between balusters

This value can only be determined by calculating the total number of columns and their size. For balusters with a thickness of 40-80 mm, a distance of 120-150 mm will be normal. If there are children in the house, it is recommended to install balusters no further than 80-100 mm from each other for safety reasons.

Mounting supports: options

When choosing the fastening of supports for enclosing structures, various factors are taken into account:

- wood type;

- size and shape of products;

- fencing design.

Professional craftsmen most often use wooden pins or dowels to attach volumetric supports. It is recommended not to make their diameter larger than 1/4 of the diameter of the baluster base. This may cause the product to crack.

Fencing fastening diagram

According to the requirements of the current SNiP, fencing is installed on stairs with more than 5 steps. The minimum distance between the supports is 10-15 cm. The upper part of the supports is attached to the handrails. The method of fixing the lower part of the balusters depends on the type of structure. They can connect:

- with steps;

- bowstring or stringer;

- landing.

It is not allowed to use nails to connect structural elements. During use they quickly become loose. This leads to loss of strength and imbalance of the fence. When fastening balusters to a narrow string, a special board of greater width is placed on it. It serves as the lower support of the baluster.

Staircase design elements

Incorrectly installed and poorly secured supports make the operation of the ladder dangerous. The most durable mounting should have support posts. Intermediate balusters are installed between them at equal intervals. When attaching the supports to the string, their base and upper part are cut to the slope angle of the flight of stairs.

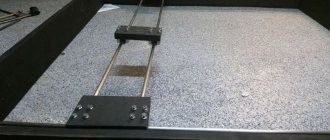

Fastening supports with dowels

The fastening process begins with marking the location for drilling holes for installing dowels. It is located exactly in the center of the base of the baluster. The depth of the hole is equal to 1/2 the length of the dowel inserted into it. The strength of the connection of structural elements is increased with the help of wood glue. They fill the hole before installing the dowel.

Scheme of fastening the structure with a dowel

The recesses are drilled in 2 stages. They start with a hole with a diameter of 5 mm, and then gradually expand it, changing drills of different diameters. The dowel should not go completely into the hole. The length of the outer ends of the fasteners must be at least 5.5-6 cm. Before installation in the base of the stairs, they are lubricated with glue and sprinkled with fine sawdust. This increases the adhesion strength of structural elements.

Fastening the supports with a metal pin

One end of the fastener should have a screw thread, the other should have a nut thread. The depth of the hole for the stud in the base depends on the length of the fastener. Usually it is from 10 to 20 cm. First, a 1-2 mm indentation is made with a drill in the center of the base of the support. After this, they begin to screw the fasteners into it. The ends of the studs protruding from the supports are inserted into the holes drilled through the steps, after which a nut and washer are put on them and tightened until they stop.

Fastener location diagram

Find out how to make a hatch to the attic with a ladder with your own hands, and also read the step-by-step instructions in a special article on our portal.

Fastening supports with self-tapping screws

The easiest and fastest way to attach. Self-tapping screws ensure the strength of the connection of the elements, but have one big drawback - after installation of the structure, their caps are visible. This spoils the aesthetic appearance of the staircase. This type of fastening is widely used for connecting flat balusters when constructing gazebos and porch railings.

Purpose and advantages of wooden racks

Balusters for stairs perform the following important functions:

- ensure safety of movement along a flight of stairs;

- perform a supporting function;

- add additional rigidity to stair railings;

- are the most noticeable element of the decor.

Wooden balusters are in high demand due to the special properties and advantages of wood products:

- Environmental friendliness. Natural wood is absolutely safe and does not emit substances hazardous to the body. On the contrary, natural resins and essential oils have a healing effect.

Ready-to-install railings assembled from wooden balusters - Energy and attractiveness of natural material. Balusters and railings for stairs made of wood can be very elegant and original. Products made from valuable types of wood in combination with decorative finishes make the interior luxurious and unique.

- Large selection of wood products. Wood is an excellent material for realizing any design and stylistic ideas.

- Wood goes well with any style and material.

- The ability to make balusters with your own hands. You can make staircase racks yourself, saving significant money.

- High strength and durability. High-quality wood products can last a very long time. The minimum service life of balusters made of hardwood is at least 50 years.

Option for installing railings made of wooden balusters - Possibility of repair and replacement of damaged elements. Replacing or repairing a damaged part is not difficult.

The role of stair railings

Supporting columns help to update structural elements (staircases, railings) and interiors, focusing the observer's attention on small details and decor. It is the properties of the material that dictate the scope and possible shape of the fences. Calculations of permissible load, safety rules, required distance from one rack to another and the manufacturing features of stair elements reduce the number of possible design options, deducing some general rules that are valid for columns of any type.

The distance between the balusters should be selected so that the staircase looks harmonious. To do this, you need to take into account the size, shape and material of the columns, as well as the style of the room.

The spacing between balusters must comply with the standards

Concept and types of structural element

Wooden balusters are an architectural element that consists of columns of staircases and ground fence railings carved from wood. Initially, balusters were installed on the porch of the house, and these were panels made of solid boards. Their main purpose was to protect the porch from bad weather. Later they became a decorative element, as a result of which their appearance acquired the familiar outline of a column.

In Russia, mostly flat balusters made of wood were used, in contrast to round-shaped products (such decorative elements are characteristic of Western European countries; you can see them, for example, in Catholic churches). Russian balusters, covered with carved ornaments, were used both to decorate residential buildings and for household buildings and gazebos at home. Everything depended on the desire and skill of the owner of a particular household. The shape of the product was conducive to the most daring design experiments.

Balusters have several varieties, and they are divided into different types depending on:

- forms;

- material;

- the presence of decorative elements;

- method of fastening to other elements of the building structure.

In addition, the most common balusters in our country can be decorated with various types of ornaments:

Scheme for attaching balusters to railings and steps.

- deaf;

- end-to-end;

- contour;

- stapled;

- embossed.

At the same time, when studying information on how to make balusters, you should simultaneously select drawings and decorative carving options. This will allow you to integrate these decorative elements into the exterior of a building or structure without any problems. An experienced woodcarver can create several options for balusters, the combination of which will add originality to the architectural image of the house.

Flat wooden balusters can be decorated with elements of the same shape, placed in random order, their pattern can repeat the pattern of the previous element. The third type does not have an internal thread, and the element is cut out to a given shape.