Structurally, they are containers made of carbon steel 3 mm thick. A stamped bottom with a stand-shoe is welded to a single-seam welded cylinder on one side, and a hemispherical neck for installing a valve on the other. Various filling or dispensing equipment is connected to the latter. The majority of propane consuming devices (gas stoves, titaniums, welding torches, heating boilers) require reduced pressure. To do this, a reducer is installed on the valve (the most common is BPO-5-5). On the upper part of the neck there is a passport on which the main technical parameters of the device are stamped. These include: name of the manufacturing plant, quality control department stamp, individual number, month and year of manufacture, inspection date (updated every 5 years), volume, weight in empty and filled state.

Components of a gas cylinder

Requirements for production processes and technical characteristics of gas cylinders are regulated by rather old GOSTs 949-73 and 15860-84.

The maximum operating pressure in the devices ranges from 1.6 MPa to 19.6 MPa, and the wall thickness can vary from 1.5 to 8.9 mm.

The protective cap on gas cylinders can be screwed onto a special neck thread, completely closing the valve, or it can be welded to the body and only protect the valve from accidental external impacts.

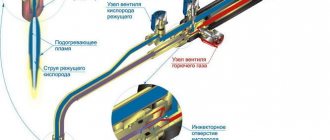

A standard gas cylinder assembly consists of the following elements:

- Cylinder body.

- Valve closing cap.

- Backing rings for fixation and transportation.

- Support shoe.

Valve with shut-off valves.

An important element of the cylinder is also the technical information stamped on it.

The information stamped on the cylinder is used by service centers when refueling and re-inspecting equipment, so you should not paint it heavily

The bottom of the cylinders is shaped like a hemisphere for uniform distribution of internal pressure. For better stability of the body, a shoe is welded on the outside, on the lower edges of which there are often holes for attaching the cylinder to horizontal surfaces.

Material of manufacture

Propane tanks are made from steel or fiberglass. The first are obtained by welding the bottom and cover to a cylindrical pipe. They have a wall thickness of 3 mm. This design is acceptable since the gas passes into the liquid stage inside and does not create excessive load on the walls of the container (unlike methane). The maximum pressure does not exceed 3 MPa, and the working pressure is usually at the level of 1.5 MPa. Metal tanks are cheap, but they gradually rust and can leak.

Composite cylinders are made on a fiberglass base, which provides increased strength. Additionally, the vessel is enclosed in a plastic casing. Windows are provided to monitor the remaining liquefied gas. Composite cylinders are lighter than steel, stronger, have a longer service life, but are more expensive.

Both types of cylinders are suitable for connecting kitchen stoves, heaters, and welding equipment. The only thing is that composite cylinders are better protected from corrosion. They are also lighter, so you will have less strain on your back when frequently transporting welding equipment.

Video source: Hexagon Ragasco Russia

Thread on the cylinder valve

Tell me about the carving. There is a cylinder (same as in the photo). What is the output thread on the valve? The 1/2″ nut does not screw on. 5/8″ is too big. The pitch was measured with a thread gauge. We thought that most likely M22x1.75. It turned out to be inch threads from 1/2″ to 7/8″. At the same time, the market sells all adapters for them that normally screw tightly onto the thread of the cylinder. But no one knows what kind of carving this is??

Nobody knows what??

It's a metric thread.

hardly. step 1.5 is not suitable. 1.75 is suitable only for the first 4 turns, then the divergence begins. There's an inch step. But 1/2″ is not secured and 5/8″ is very loose. I would even believe that the cylinder has an oversized thread, but I have two other 10L (large) cylinders for compressed air. there is exactly the same thread. So the thread on the cylinder seems to be standard. But what kind?

for some reason I always thought that it was M22x1.75

I myself am suffering with such a cylinder, I can’t find the nut, I was thinking about cutting the thread. Asked a question about this in silence. Or like in the last post

Why don’t thread gauges (metric and inch) and calipers help? The threads are listed in the reference book based on the number of threads per inch (pitch) and outer diameter.

I myself am suffering with such a cylinder, I can’t find the nut, I was thinking about cutting the thread.

D21.7, 14 threads, 55 degrees.

Tap for cutting threads in metal.

[QUOTE][B]And so, if you are not friends with technical literature,

1. Outer diameter of the thread (accurate to tenths of a millimeter)?

2. Thread pitch (measured with a thread gauge). I have the opinion that with an inch thread gauge (no one has measured it for a thread with a profile angle of 55. I would like to know what pitch you understand.

try on the nut from the welding gearbox.

DIY valve replacement guide

Before installing the valve, it is necessary to thoroughly degrease the connecting surfaces using rags treated with dishwashing detergent or solvent. Next, the surface is washed with clean water and allowed to dry.

Unscrewing the valve from the gas cylinder

Valve replacement algorithm:

- The connection is sealed by winding the tape with tension in 4-5 layers; it is better to tighten it than to make a loose connection.

- The old tap is removed again, and the cylinder is purged again. Before changing the valve, a special sealant or fum tape is applied to the threads. The thickness of its layer for gas connections differs from plumbing and is 0.1 - 0.25 mm, and its coil is yellow.

- Reinstall the old faucet, remove the old paint and give it a fresh coat of paint.

- The vessel is thoroughly purged with compressed air and inspected from the inside with a flaw detector.

- Drain the remaining condensate away from people, as it has an unpleasant odor.

- The vessel is laid on the ground, one master holds the body so that it does not rotate, and the other, using a gas wrench with an extension pipe, holding the square edges of the gas cylinder valve, unscrews it. It will be difficult to make only the first 1-2 turns, then it twists easily “by hand”.

- The valve warms up to 65 with a construction hair dryer to remove old paint, on the screw thread of the cylinder.

- With the old valve closed, check for leaks.

- Before replacing, check the vessel for corrosion or mechanical damage.

- The valve is closed with a torque wrench. The indicator for fittings made of brass is 250 Nm, and for steel – 480 Nm.

- Allow the sealant to cure for 3 days.

- The cylinder is taken to a specialized organization for testing, for example, in Moscow. The company must be included in the certification bodies in the unified state register of organizations that have the right to carry out this type of work.

Gas cylinder with valve turned off

Propane tank thread

Propane gas is used to ensure the operation of cooking stoves, heating residential, industrial and warehouse premises, refueling cars, gas welding and metal cutting. In our country, steel propane cylinders with a capacity of 5, 12, 27 and 50 liters are most often used for domestic gas supply. Such containers are easy to distinguish from others - they are always painted red. The word "PROPANE" must be written in white capital letters approximately 6 cm high.

In order to order a propane cylinder, you just need to call us or fill out the feedback form on the website. Our consultants will be happy to provide comprehensive information on any issue related to gas equipment. Our offers are transparent and profitable, just like propane gas itself.

Purpose of the gas valve

PSK is a safety valve element responsible for the safety of the gas pipeline and gas equipment connected to it. During operation, the valve is in a closed position, therefore it is classified as a closed pipe fitting.

Such devices are installed not only on gas pipelines, they are an integral part of other communications - water supply, heating networks. Everywhere they perform the same function - they stabilize the pressure in the network, provide the operating parameters necessary for the proper functioning of the system.

The valve serves to relieve excess gas if pressure parameters become critical. Fuel that creates an imbalance in the system is discharged into an auxiliary pipeline or discharged into the atmosphere

The pressure surge is usually short-lived and depends on a number of factors.

Reasons that can cause excess pressure in the system:

- breakdown of connected gas equipment - double-circuit boiler, instantaneous water heater or capacitive boiler, shut-off valves;

- use of fuel of inappropriate composition;

- change in temperature indicators in the pipeline;

- failure in the thermal-mechanical circuit.

The installation location of the gas safety valve is standard, depending on the efficiency of the application: either in the pressure regulator, or immediately behind it. After automatic operation of the valve, it returns to its operating – closed state.

In a gas network, the valve is a separate device or integrated into the pressure regulator. It is triggered if the operating gas pressure exceeds the nominal level by 15%

What are the consequences of the absence of a PSK on the network? The most common consequences are mechanical destruction of the pipeline or breakdown of connected equipment, which can cause a gas leak.

There is also a possibility of an explosion, so it is necessary to constantly monitor the serviceability of the device, carry out timely maintenance and replace failed elements

Along with relief devices, gas safety shut-off valves are also used, with the help of which the fuel supply is shut off. This happens automatically. The shut-off valve element is installed on the pipeline, in the gap between the filter and the pressure regulator.

The operating limit of the SPD is indicated in the technical data sheet of the device. The upper critical parameter is usually equal to the formula: slave. pressure +25%.

Propane cylinder device

Structurally, they are containers made of carbon steel 3 mm thick. A stamped bottom with a stand-shoe is welded to a single-seam welded cylinder on one side, and a hemispherical neck for installing a valve on the other. Various filling or dispensing equipment is connected to the latter. The majority of propane consuming devices (gas stoves, titaniums, welding torches, heating boilers) require reduced pressure. To do this, a reducer is installed on the valve (the most common is BPO-5-5).

On the upper part of the neck there is a passport on which the main technical parameters of the device are stamped. These include: name of the manufacturing plant, quality control department stamp, individual number, month and year of manufacture, inspection date (updated every 5 years), volume, weight in empty and filled state.

Weight and size of cylinders of various capacities

How many kg of propane are in 1 5, 12, 27, 50 liter cylinder? You can find this out in the product quality certificate or in the table below. Here you can also find out how much a 5, 12, 27, 50 liter propane cylinder weighs.

| Volume | 5 liters | 12 liters | 27 liters | 50 liters |

| Empty cylinder weight, kg | 4 | 5,5 | 14,5 | 22,0 |

| Propane tank weight, kg | 6 | 11 | 25,9 | 43,2 |

| Mass of stored gas, kg | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height, mm | 290 | 500 | 600 | 930 |

| Cylinder diameter, mm | 200 | 230 | 299 | 299 |

What is the thread on a propane tank?

Valves of the VB-2 type are installed on most household cylinders for propane-butane mixture. These shut-off devices are manufactured in accordance with GOST 21804-94 and are designed for pressures up to 1.6 MPa. The tap has a left-hand thread SP21.8-1 (6 turns), which allows you to connect any gearboxes with a union nut and a similar thread.

The valve provides a strong connection to the neck, complete tightness, has clear markings and a modern design. Threaded surfaces are lubricated with a special lubricant that reduces friction during operation. The screw plug with rubber gasket prevents gas leakage during transportation or storage. The device provides protection against unqualified repairs by persons who have not undergone appropriate training. The reliability of the locking device contributes to long-term and safe operation of the gas cylinder structure.

How many m3 of propane are in 1 5, 12, 27, 50 liter cylinder?

We have made special calculations that conditionally transform propane-butane into a gaseous state. Under standard conditions (100 kPa, 288 K), 0.526 m³ of propane or 0.392 m³ of butane is formed from 1 kg of liquefied gas. Taking into account the percentage of the mixture (60% prop.), the volume of combustible gas is calculated using the formula M*(0.526*0.6+0.392*0.4). How many cubic meters are in a propane tank can be seen in the table below. The last line shows the number of liters of propane-butane mixture (in the liquid phase).

| Cylinder capacity (l) | 5 | 12 | 27 | 50 |

| Capacity (cubic meters of flammable gas) | 0,95 | 2,59 | 5,38 | 10,01 |

| Liquid propane volume (liters) | 4,3 | 10,2 | 22,9 | 42,5 |

MAIN PARAMETERS AND DIMENSIONS

1.1. Cylinders must be manufactured for a working pressure of 9.8; 14.7; 19.6 MPa (100, 150 and 200 kgf/cm2) from carbon steel and for operating pressure 14.7 and 19.6 MPa (150 and 200 kgf/cm2) from alloy steel.

1.2. The main parameters and dimensions of the cylinders must correspond to those indicated in the drawing and table. 1.

Official publication Reissue (June 1992) with Changes N∙ ], 2. 3, 4, approved in October 1976, October 1980, February 1982. June 1986 (IUS 11-76.1-81, S-82. 10-86).

© Standards Publishing House, 1974

© Standards Publishing House, 1992

Rice. 1 1 – support shoe; 2 – cylinder body; 3 – neck ring; 4 – valve; 5 – safety cap.

Dimensions in mm

Table 1

| Cylinder volume, l | Diameter of cylindrical part | Wall thickness of pressure cylinders, MPa (kgf/cm2), not less | Pressure cylinder body length, MPa (kgf/cm2) | Mass of cylinders for pressure MPa (kgf/cm2), kg | ||||||||||||

| carbon steel | alloy steel | carbon steel | alloy steel | carbon steel | alloy steel | |||||||||||

| 9.8 (100) | 14.7 (150) | 19.6 (200) | 14,7 (150) | 19.6 (200) | 9.8 (100) | 14.7 (150) | 19,6 (200) | 14,7 (150) | 19,6 (200) | 9,8 (100) | 14,7 (150) | 19.6 (200) | 14,7 (150) | 19.6 (200) | ||

| 0,4 | 70 | 1,6 | 2,2 | 2,9 | 1,0 | 1,9 | 165 | 170 | 175 | 165 | 165 | 0,6 | 0,8 | 1,0 | 0.6 | 0,7 |

| 0,7 | 255 | 260 | 270 | 255 | 255 | 0,9 | 1,2 | 1,5 | 0,9 | 1,0 | ||||||

| 1,0 | ,89 | 1,9 | 2,8 | 3,6 | 1,9 | 2,5 | 240 | 250 | 255 | 240 | 245 | 1,2 | 1,8 | 23 | 1.2 | 1,6 |

| 1,3 | 295 | 305 | 315 | 295 | 300 | 1,5 | 2,2 | 2,? | 1.5 | 1,9 | ||||||

| 2,0 | 425 | 440 | 455 | 425 | 435 | 2,1 | 3,1 | 4,0 | 2,1 | 2,7 | ||||||

| 2,0 | 108 | 2,4 | 3,4 | 4,4, | 2,4 | 3,0 | 320 | 330 | 340 | 320 | 325 | 2,5 | 3,7 | 4.7 | 2,5 | 3,1 |

| 3,0 | 445 | 460 | 480 | 445 | 455 | 3,4 | 5,0 | 6.4 | 3,4 | 4,3 | ||||||

| 3,0 | 140 | 3,1 | 4,4 | 5,7 | 3,1 | 3,9 | 310 | 325 | 335 | 310 | 320 | 4,1 | 6,0 | 7,9 | 4,1 | 5,3 |

| 4,0 | 385 | 400 | 415 | 385 | 395 | 5,0 | 7,3 | 9,6 | 5,0 | 6,5 | ||||||

| 5,0 | 460 | 475 | 495 | 460 | 470 | 5,8 | 8,5 | 11,4 | 5,8 | 7,6 | ||||||

| 6,0 | 535 | 555 | 575 | 535 | 550 | 6,7 | 9.8 | 13,1 | 6,7 | 8,8 | ||||||

| 7,0 | 610 | 630 | 660 | 610 | 625 | 7,6 | 11,1 | 14,9 | 7,6 | 9,9 | ||||||

| 8,0 | 140 | 3,1 | 4,4 | 5,7 | 3,1 | 3,9 | 680 | 710 | 740 | 680 | 700 | 8,5 | 12,4 | 16,6 | 8,5 | 11,1 |

| 10,0 | 830 | 865 | 900 | 830 | 850 | 10,2 | 15,0 | 20,1 | 10,2 | 13,4 | ||||||

| 12,0 | 975 | 1020 | 1060 | 975 | 1005 | 1,9 | 17,6 | 23,5 | 11,9 | 15,6 | ||||||

| 20,0 | 219 | 5,2 | 6,8 | 8,9 | 5,2 | 6,0 | 730 | 740 | 770 | 730 | 28,5 | 33,3 | 42,0 | 28,5 | ||

| 25,0 | 890 | 900 | 935 | 890 | 34,0 | 38.7 | 50,5 | 34,0 | ||||||||

| 32,0 | 1105 | 1120 | 1165 | 1105 | 42.0 | 47,7 | 62,5 | 42,0 | ||||||||

| 40,0 | 1350 | 1370 | 1430 | 1350 | 5i,5 | 58,5 | 76,5 | 51,5 | ||||||||

| 50,0 | 1660 | 1685 | 1755 | 1660 | 62.5 | 71,3 | 93,0 | 62,5 |

Notes:

- 1. The weight of cylinders is indicated without valves, caps, rings and shoes and is a reference value and a nominal value for the manufacture of cylinders with a weight limit.

- 2. The lengths of the cylinders are indicated as reference and are accepted as nominal when manufacturing cylinders with a limited length.

- 3. The approximate weight of the metal cap is 1.8 kg; fiberglass - 0.5 kg; rings - 0.3 kg, shoes - 5.2 kg.

1.1; 1.2. (Changed edition, Rev. N4).

1.3. Cylinders must be manufactured with normal and increased precision.

1.4.

Cylinders of normal precision are manufactured with a limitation in volume; cylinders of increased precision are manufactured in terms of volume and outer diameter or length and outer diameter. Maximum deviations should not exceed those indicated in the table. 2. Table 2

| Limit deviations | For standard precision cylinders | For high precision cylinders |

| By volume: | ||

| for small volume cylinders | +10% ‘ | . +5% |

| for medium volume cylinders | + 5% | +5% |

| By lenght: | ||

| for small volume cylinders | – | ?6 mm |

| for medium volume cylinders | – | ?15 mm |

| By outer diameter: | ||

| for carbon steel cylinders | – | ?1,5% |

| for alloy steel cylinders | – | ?2,0% |

Notes:

- 1. Maximum deviations in outer diameter for medium-volume cylinders made of carbon steel, which have been assigned the State Quality Mark, must not exceed ? 1.0%.

- 2. The curvature of medium-volume cylinders is no more than 0.5% of the length of the cylindrical part of the cylinder.

(Changed edition, Amendment No. 1, 3).

1.5. At the customer's request, alloy steel cylinders can be manufactured with weight restrictions. In this case, the mass of the cylinders should not exceed by more than 10% the mass indicated in the table. 1. Examples of symbols:

cylinder with a volume of 4 liters for a pressure of 14.7 MPa (150 kgf/cm2), made of carbon steel, standard manufacturing precision, for air:

- Air cylinder 4-150U GOST 949-73

the same, from alloy steel, increased manufacturing precision, volume limitation, no weight limitation, for nitrogen:

- Nitrogen cylinder 4p-150L GOST 949-73

the same, with normal manufacturing precision, with a weight limit, for air:

- Air cylinder 4-150 L-M GOST 949-73

the same, with increased manufacturing accuracy in terms of volume, with a limitation on weight, for medical oxygen:

- Cylinder for medical oxygen 4P-150L-M GOST 949-73

the same, increased manufacturing precision, cylinder body length 400mm, with weight limitation, for nitrogen:

- Nitrogen cylinder 4-150L-400-M GOST 949-73

the same, short volume 2 liters for a pressure of 14.7 MPa (150 kgf/cm2), made of carbon steel, increased manufacturing precision with a length limitation, without a weight limitation, for air:

- Cylinder for. air K2-150U-330 GOST 949-78 (Changed edition, Amendment No. 4).

Rules for the safe operation of propane cylinders

- When using and storing, do not allow the cylinders to overheat (for example, leave them in direct sunlight for a long time);

- It is not recommended to bleed out the propane-butane mixture until the tank is completely empty (under certain conditions it can suck in air, and this is dangerous);

- When transporting, be sure to use plugs and safety caps;

- in case of detection of dents or other defects, the product must be sent for an unscheduled recheck;

- Individuals are allowed to transport no more than five cylinders in one vehicle (they must be separated by spacers from each other).

- It is necessary to constantly monitor the condition of the cylinders, because it is not for nothing that they are considered fire and explosive objects.

What is the gas pressure in a propane tank?

According to GOST 15860-84, the working pressure in the tank should not exceed 1.6 MPa. In this case, the proportion of propane in the hydrocarbon mixture must be no less than 60%. This is very important for the safe operation of gas cylinder installations. Of course, products are designed for significantly higher pressures - more than 5.0 MPa. Production and periodic tests are carried out under a pressure of 3.0 MPa.

Refueling standards

At gas cylinder refilling stations, employees are familiar with the regulations. Since a cylinder that is filled too much can explode or its valve can be torn off. So, if you refuel from a reliable supplier, you have nothing to worry about.

| Cylinder type (l) | 5 | 12 | 27 | 50 |

| Maximum permissible quantity of propane, l | 3,5 | 8,4 | 18,9 | 35 |

Safety rules when working with valves

If you have never worked on unscrewing a tap, then it would be a good idea to familiarize yourself with the safety rules before starting such work.

The operation of the valve is regulated by documents such as PB 12-368-00 “Safety Rules in the Gas Industry”, Resolution No. 91 of June 11, 2003 “Rules for the Construction and Safe Operation of Pressure Vessels” and GOST 12.2.008-75.

Disassembly, repair and replacement of the valve should only be carried out by persons authorized to repair gas equipment. Repairing a device under pressure is strictly prohibited. Therefore, if you notice that the valve is leaking or faulty, then the right decision would be to contact a gas service representative, rather than carry out repairs at your own peril and risk.

If you want to disassemble an old cylinder in order to make a useful homemade product from it, such as a potbelly stove, smokehouse or gas grill, then it is worth remembering that these actions cannot be called safe. And you will have to bear the consequences.

Home craftsmen are rich in ideas for constructing interesting and functional homemade products from old gas cylinders. Thus, a home grill will become not only a useful device, but also a very stylish addition to the interior of the gazebo.

All actions to unwind the cylinder should be carried out outdoors or in a well-ventilated garage or other room. But this is strictly forbidden to do in an apartment - such an experience could end in an explosion.

Next, let's look at the basic safety rules that are important to follow:

- To release the remaining gas, you should smoothly and slowly unscrew the valve flywheel.

- Do not disassemble or cut a pressure cylinder under any circumstances.

- There should be no other cylinders near the vessel being disassembled.

If you are just about to unscrew the valve and have not had time to do anything yet, and the smell of gas is clearly audible in the garage where the cylinder was located, you should ensure that this room is ventilated as much as possible. Why open the gates, windows, doors (if any), and immediately leave.

How much does a 5, 12, 27, 50 liter propane cylinder cost?

The price depends on the specific area in which the customer lives. How much an empty propane cylinder costs in our region, as well as the cost of refilling, is shown in the following table:

| Cylinder volume (liters) | 5 | 12 | 27 | 50 |

| Estimated cost of an empty new cylinder | 1080 | 1380 | 1500 | 2250 |

| Cost of refilled propane | 1155 | 1560 | 1905 | 3000 |

*prices are indicative depending on the manufacturer

The price of a cylinder is sometimes several times higher than the cost of the contents. But repeated refilling allows the tanks to be used for many years and even decades.

how many cubic meters are in a 50 liter liquefied gas cylinder?

Answer: 5 cubes.

How many cubes are 1000 liters? Answer: 1 cubic meter. 10000 liters how many cubes? Answer: 10 cu. m. 140 liters is how many cubes? Answer: 0.14 cubic meters. 1500 liters how many cubes? Answer: 1.5 cubic meters.

To simplify the calculations, we suggest you use our online calculator for converting liters to cubes, but you can always do it yourself by using a regular calculator to convert cubes to liters or liters to cubes.

| Author | Message |

| Hello ! I ask the moderators not to scold me yet, I don’t know where else to ask. I bought a couple of empty freon cylinders and want to make a small air receiver. The compressor is also from a domestic refrigerator. What pressure can these cylinders withstand? so don't rush!!! I looked through your forum on refrigerator accessories and did not find the answer. but I found a photo of the cylinders. |

Where to buy a propane tank

Our company provides you with the opportunity to buy propane at a competitive price.

Our region has a wide network of certified companies selling and refilling cylinders. The most common are tanks with a capacity of 27 and 50 liters, but upon pre-order, you will be supplied with products of 5 or 12 liters in the shortest possible time.

When refueling, of course, it’s faster to exchange your cylinder for an already filled one. However, many people prefer to wait a little to get theirs back. After all, it definitely does not allow gas to pass through and passed the necessary tests on time. The operator himself ensures that the amount of liquid propane does not exceed 85% of the geometric capacity of the vessel. This is necessary so that when heated, the internal pressure does not exceed the permissible threshold. If there are residual contents at the bottom (so-called condensate), the refiller must drain it into a special container.

Cylinders for technical gases.

Cylinders for technical gases.

Oxygen cylinders

designed for oxygen refilling and its further storage and transportation. Manufactured according to GOST 949-73.

Oxygen balloon

filled with gas to a pressure of 150 atm.

The working and test pressure of the cylinder is stamped by the manufacturer at the bottom of the passport, which is stamped in the upper part of the cylinder under the neck. (P150 atm P225 atm) or (P200 atm P300 atm). Once every five years, cylinders undergo mandatory technical certification, undergoing a hydraulic pressure test of 225 or 300 atm. Oxygen cylinders come in different sizes from 1 to 50 liters (small or medium volume) and are painted blue or blue with the inscription oxygen in black. Oxygen cylinders from 5 to 50 liters are equipped with valves VK-94-01

, VK-99

.

Small volume cylinders from 1 to 10 liters can be equipped with a VK-94-01 valve, used.

07. Oxygen cylinders for medical gas are equipped with a

VKM-95

made of stainless steel. Medical oxygen is used for medical purposes for breathing apparatus, oxygen cocktails, etc.

Cylinders for technical gases manufactured in accordance with GOST 949-73 can be designed for different types of gases. ( Argon

, carbon dioxide , nitrogen , welding mixture

, etc.).

They also differ in volume. The cylinder must not have mechanical damage, traces of loose rust, or welding. All elements of the cylinder (shoe, neck) are attached to the shell using hot crimping. The cylinder passport must be easy to read. The service life of a cylinder produced since the beginning of 2015, according to the order of Rostechnadzor dated March 25, 2014, is 20 years

.

Gas content in the cylinder;

Oxygen, argon, nitrogen, helium, welding mixtures: a 40-liter cylinder at 150 atm contains - 6 cubic meters. m/8kg. Acetylene: 40-liter cylinder at 19 kgf/cm2 – 4.5 cubic meters. m / 5.5 kg of dissolved acetylene. Carbon dioxide: 40-liter cylinder - 12 cubic meters. m / 24 kg of liquid gas Propane: 50-liter cylinder -10 cubic meters. m / 42 liters of liquid gas / 21 kg of gas.

Empty cylinder weight 40 liters

: Oxygen, argon, nitrogen, helium, carbon dioxide, welding mixtures, amounts to 65-70 kg without taking into account the weight of the protective cap.

Weight of a 40 liter acetylene cylinder

:

– 90 kg Weight of a 50 liter propane cylinder

:

– 22 kg

Threads for valves in the necks of cylinders according to GOST 9909-81.

W19.2 – from 1 to 10 liters. W27.8 - 40 liters of oxygen, carbon dioxide, argon, helium, as well as 5, 12, 27 and 50 liters of propane. W30.3 – 40 liters acetylene.

Thread on the valve for connecting the gearbox:

G1/2″ – found on cylinders from 1 to 10 liters; a special

adapter

. G3/4″ – standard thread on 40-liter cylinders. oxygen, carbon dioxide, argon, helium, welding mixture. SP 21.8×1/14″ – left-hand thread for propane.

The procedure for carrying out regular tests of cylinders

Regular tests of cylinders are carried out in accordance with RD 03112194-1094-03 and RD 03112194-1095-03. Employees who perform such work must undergo appropriate training and have the appropriate knowledge and skills.

The next tests are carried out in the following sequence:

- Acceptance of containers. At this stage of the inspection, the completeness of the cylinder is checked and the external surface is inspected. At the same time, the date of the last inspection and pressure testing is checked. If necessary, the inner surface of the container must be cleaned.

- Inspection of the inside of the container is carried out using specialized equipment.

- The fittings are dismantled and inspected. In addition, during the inspection process, technological parts can be installed, without which it is impossible to conduct hydraulic tests.

After hydraulic testing (pressure testing), it is necessary to dry the vessel from traces of the reagent. Return the dismantled fittings to their place.

The cylinder must be prepared for priming and painting. To do this, it is sandblasted. After applying a coating of the appropriate color and drying it on the surface of the cylinder, it is necessary to carry out marking in accordance with regulatory documentation. The completion of the survey work is documented by a corresponding act. The total time to complete all of the above work is 3 – 5 hours. This time includes both preparatory and main operations.

Cylinders for technical gases.

Cylinders for technical gases.

Cylinders for technical gases.

Oxygen cylinders

designed for oxygen refilling and its further storage and transportation. Manufactured according to GOST 949-73.

Oxygen balloon

filled with gas to a pressure of 150 atm.

The working and test pressure of the cylinder is stamped by the manufacturer at the bottom of the passport, which is stamped in the upper part of the cylinder under the neck. (P150 atm P225 atm) or (P200 atm P300 atm). Once every five years, cylinders undergo mandatory technical certification, undergoing a hydraulic pressure test of 225 or 300 atm. Oxygen cylinders come in different sizes from 1 to 50 liters (small or medium volume) and are painted blue or blue with the inscription oxygen in black. Oxygen cylinders from 5 to 50 liters are equipped with valves VK-94-01

, VK-99

.

Small volume cylinders from 1 to 10 liters can be equipped with a VK-94-01 valve, used.

07. Oxygen cylinders for medical gas are equipped with a

VKM-95

made of stainless steel. Medical oxygen is used for medical purposes for breathing apparatus, oxygen cocktails, etc.

Cylinders for technical gases manufactured in accordance with GOST 949-73 can be designed for different types of gases. ( Argon

, carbon dioxide , nitrogen , welding mixture

, etc.).

They also differ in volume. The cylinder must not have mechanical damage, traces of loose rust, or welding. All elements of the cylinder (shoe, neck) are attached to the shell using hot crimping. The cylinder passport must be easy to read. The service life of a cylinder produced since the beginning of 2015, according to the order of Rostechnadzor dated March 25, 2014, is 20 years

.

Gas content in the cylinder;

Oxygen, argon, nitrogen, helium, welding mixtures: a 40-liter cylinder at 150 atm contains - 6 cubic meters. m/8kg. Acetylene: 40-liter cylinder at 19 kgf/cm2 - 4.5 cubic meters. m / 5.5 kg of dissolved acetylene. Carbon dioxide: 40-liter cylinder - 12 cubic meters. m / 24 kg of liquid gas Propane: 50-liter cylinder -10 cubic meters. m / 42 liters of liquid gas / 21 kg of gas.

Empty cylinder weight 40 liters

: Oxygen, argon, nitrogen, helium, carbon dioxide, welding mixtures, amounts to 65-70 kg without taking into account the weight of the protective cap.

Weight of acetylene cylinder 40 liters

:

- 90 kg Weight of propane cylinder 50 liters

:

- 22 kg

Threads for valves in the necks of cylinders according to GOST 9909-81.

W19.2 - from 1 to 10 liters. W27.8 - 40 liters of oxygen, carbon dioxide, argon, helium, as well as 5, 12, 27 and 50 liters of propane. W30.3 - 40 liters of acetylene.

Thread on the valve for connecting the gearbox:

G1/2″ - found on cylinders from 1 to 10 liters; a special

adapter

. G3/4″ – standard thread on 40-liter cylinders. oxygen, carbon dioxide, argon, helium, welding mixture. SP 21.8×1/14″ - left-hand thread for propane.

OKP 14 1200

By Decree of the State Committee of Standards of the Council of Ministers of the USSR of December 19, 1973 N 2717, the introduction date was set from 01/01/75.

By Decree of the USSR State Standard dated August 14, 1991 N 1352, the validity period was lifted.

This standard applies to cylinders made of carbon and alloy steel, small volume - up to 12 l and medium volume - from 20 to 50 l with a working pressure of up to 19.6 MPa (200 kgf/cm2), made from seamless pipes and intended for storage and transportation of compressed , liquefied and dissolved gases at temperatures from minus 50 to plus 60°C.

The standard complies with the CMEA standardization recommendation PC 2496-70.

The valve structure on a gas cylinder and how to replace it if necessary

Cylinders are universal equipment for storing and transporting gaseous substances for domestic and industrial purposes. The shut-off valves in them do not last forever, so over time the valve on the gas cylinder needs to be replaced. You can do it yourself, following a number of safety rules.

We will tell you how to choose the right valve for equipping a gas cylinder. For independent craftsmen, we provide detailed instructions on how to change a worn-out device. Here you will learn what safety measures must be observed when installing a shut-off device on a gas tank.

Indications for replacement

In order to send the cylinder in time for repair work and performance testing, perform an external inspection and pay attention to the following:

- Is the shut-off valve flywheel spinning?

- on the body and valve of the cylinder, whether mechanical deformation is visible in the form of abrasions, cracks and traces of corrosion damage;

- validity of technical inspection data;

- feeling the smell of the gas-air environment next to the cylinder;

- skewed or damaged shoe at the base;

- absence of a plug on the fitting.

Before replacing the valve of a gas cylinder with your own hands, the user needs to be able to not only externally determine the malfunction of the cylinders, but also identify counterfeit products. All cylinders that are permitted for use in Russia must be produced in a certified production facility and comply with GOST requirements. This can be easily determined by examining a metal plate on which the main text is located on 2/3 of its area, and all letters must be the same height, equal to 6 mm.

Data on the cylinder:

- Permissible pressure in MPa;

- test pressure in MPa; volume in liters;

- factory number;

- date of issue “MM.YY.AA”, where M is the month, G is the year of manufacture, A is the year of the next inspection;

- empty tank weight in kg;

- mass of container with gas in kg;

- the next check is in the “R-AA” format, where “R” is the stamp of the state verifier, A is the year of validity of the certification.

To replace the valve you need a gas wrench

Components of a gas cylinder

Requirements for production processes and technical characteristics of gas cylinders are regulated by rather old GOSTs 949-73 and 15860-84.

The maximum operating pressure in the devices ranges from 1.6 MPa to 19.6 MPa, and the wall thickness can vary from 1.5 to 8.9 mm.

A standard gas cylinder assembly consists of the following elements:

- Cylinder body.

- Valve with shut-off valves.

- Valve closing cap.

- Backing rings for fixation and transportation.

- Support shoe.

An important element of the cylinder is also the technical information stamped on it.

The bottom of the cylinders is shaped like a hemisphere for uniform distribution of internal pressure. For better stability of the body, a shoe is welded on the outside, on the lower edges of which there are often holes for attaching the cylinder to horizontal surfaces.

You will learn about the types of gas cylinders and the features of their markings in this article, which we recommend viewing and reading.

Review of the best ways to unscrew the valve

But the considered method is not the only one. Many home craftsmen offer a number of other options, using various available tools. We offer 7 simple ways to unscrew the valve using available tools. If you don't succeed the first time, you can always try another option.

Method #1 - clamping the shoe in a vice

You need to clamp the cylinder body in a vice. Why is the shoe securely fixed with a vice?

You will also need an adjustable wrench and a pipe to extend the handle.

Having secured the cylinder shoe, put a key on the valve. In order to have enough physical strength to unscrew the valve, a metal pipe is put on the handles of the key

Having put on mittens, all that remains is to grab the extended handle of the key and, with some effort, turn it counterclockwise. At first everything will go tight, but after making half a turn, the valve will move much easier. Finally, you can unscrew it by hand.

Method #2 - clamping the tap in a vice

The second method is no less simple than the previous one. All you need is to hold the cylinder valve in a vice and twist it by the body using belts.

If there are no belts, but there are chains, then they can also be used. Why do you need to fix them on the body of the cylinder, with a valve secured in a vice, and use a crowbar or a long metal pipe to twist it counterclockwise?

The first turn will be difficult, but then you can complete the twisting manually by putting the metal pipe aside.

Method #3 - vice + metal corner

This option provides for the same type of fastening of the cylinder in a vice as the previous one - with a tap in a vice. But instead of belts and chains, you will need a metal corner. It is welded to the shoe in two places.

A corner about 1 m long needs to be welded with an offset to the right - you have to unscrew the cylinder counterclockwise, so it should be convenient for the user to do this

This welding method is simple if you have a welding machine in your garage and know how to use welding. As for safety, there is no need to be afraid to weld a metal structure to the shoe - this way you will not damage the cylinder in any way.

Method #4 - using two keys

To implement this method of unscrewing the valve, you will need two keys - No. 5 and No. 3.

Use a large wrench (No. 5) to tighten the thread onto which the shipping cap is usually screwed to protect the valve.

And key No. 3 will be used to unscrew the tap. It is advisable to lengthen its handle using a suitable piece of pipe.

If you do not have experience in unscrewing a faucet in this way, then it is advisable to invite an assistant to implement this method. While one person holds key #5, a second person can turn the faucet counterclockwise using key #3 with a lever

Method #5 - welding the shoe

If you have a welding machine and know how to handle it, a convenient method will be to weld the base of the cylinder (shoe) to any surface. For example, to metal table legs or to a workbench. Moreover, it is enough to fix the stand by welding in two places.

Then you can use the same wrench #3 with a lever (a long metal pipe that fits over the handles of this wrench).

You can also weld a corner to the shoe and secure it with improvised means. Or invite an assistant - he will hold the corner so that the cylinder does not move while unscrewing the valve

Method #6 - belts + key

Using belts or chains, you have to pull the body of the cylinder to something firmly fixed - a corner, a tree trunk. Then take key No. 3 and unscrew the tap, remembering that it has a conical right-hand thread - i.e. You need to turn it counterclockwise.

As a strong support, you can use a tree growing on the site, or any other device suitable for these purposes. If the thread does not give in, you can take key No. 5

Method #7 - fixing the cylinder in the hole

Another reliable method of fixation is in a hole. First, you will need to screw a metal tube up to 1 m long to the shoe. For this, you can use the existing holes in the shoe. If they are not there, then drill them.

Then dig a hole approximately half the height of the vessel, place the prepared cylinder with a screwed-on tube inside, cover it with earth and compact it lightly.

All that remains is to take the key and unscrew the valve counterclockwise.

The method of burying a cylinder is simple, but it will require a significant investment of time and effort from the performer - after all, a rather large hole will have to be dug. But you can do without an assistant

In winter, instead of a hole, you can use an ice hole by freezing a balloon in it.

Having figured out how you can unwind a gas cylinder at home, you can safely use any of the methods you like. But at the same time, it is important not to forget about safety - working with a cylinder can result in very disastrous consequences. Read more about this.

Types and design of valves

The threads of valves for gas cylinders are standardized, but they themselves can have a variety of designs. The choice of valve model is influenced by the type of chemical substance being stored, production features of operation and the amount of money.

Before purchasing new equipment, you should familiarize yourself with the design options and the internal structure of the valves.

Classification of shut-off valves for cylinders

The design features of gas cylinder valves are determined not by the whims of engineers, but by safety considerations.

Depending on the material used, shut-off valves are divided into brass and steel . The choice of metal for the manufacture of the valve body is determined by the type of gases contained in the cylinder.

There are the following types of shut-off valves, depending on the type of chemicals stored:

- Acetylene. The body of such cylinders is painted white. Special valves are used in cylinders containing acetylene, chlorine, ammonia and other aggressive substances.

- Oxygen . The cylinders are painted blue and are intended for storing oxygen, argon, hydrogen, nitrogen, carbon dioxide and other inert gases.

- Propane-butane . They are painted red and are intended for storing substances corresponding to the name and other gaseous hydrocarbons. The most common valve type model for such a cylinder is VB-2.

Valves for acetylene cylinders are not made of brass because the substances they contain may react chemically with copper. Typically, carbon or alloy steel is used to manufacture shut-off valves of this type.

What is domestic gas

Let's remember the basics of school organic chemistry.

The first saturated hydrocarbon is methane. The molecule of this gas consists of one carbon atom surrounded by four hydrogen atoms. If you slightly lengthen the chain - instead of one of the hydrogen atoms, “attach” one carbon, and attach hydrogen atoms to the remaining three of its bonds - you get the next member of the family of saturated hydrocarbons, ethane.

Starting from the beginning of the chain, we have:

- methane CH4;

- ethane C2H6;

- propane C3H8;

- butane C4H10.

The last two compounds - propane and butane - are the contents of household gas cylinders.

Adapters

A variety of adapters allow you to use burners with cylinders that were not originally intended for them. For example, the most common case is the need to connect a cheap collet cylinder to a threaded torch with a hose. To do this, an adapter is connected to the burner connector, and gas is connected to it. Such adapters come with a support that helps fix the capricious fuel container in the desired position.

The downside of all adapters is the formation of an additional “weak point” in the system. Burners with a hose already have three of them: the connection between the hose and the burner, with the flame regulator, and the thread between the regulator and the cylinder. And with the use of an adapter, a fourth is inevitably formed. To reduce risks, I use a thread-collet adapter with a support for the torch nozzle. This design is more stable than directly connecting the burner to a threaded gas cylinder, since the fuel container serves as an additional support point. At the same time, there are only two connections in the resulting system: the thread between the burner and the adapter and the connection with the cylinder.

Detailed instructions for unscrewing the tap

Are you looking for information on how to quickly and safely turn off the tap on a propane-butane gas cylinder? Then read our instructions and see the step-by-step photos posted just below.

In order to cope without any difficulties with the valve, which can “sit tightly” in the neck of the cylinder, you will need to apply force. And, depending on the equipment at hand, you may need an assistant.

If you have only one cylinder, and you are going to twist the valve for the first time, you will have to tinker with it until you get the hang of it. If you are going to disassemble the cylinder and start making various homemade products from cylinders, then you simply cannot do without good tools at hand.

First you need to release the remaining gas, if any, in this cylinder. To do this, it is enough to turn the valve flywheel in the direction indicated on it. If there is still gas left inside, you will hear a characteristic hissing sound - this is the remaining liquefied gas coming out.

Then you need to secure the cylinder body. How to do this depends entirely on your imagination and the devices at hand. For these purposes, they use welding, metal pins, a vice, a board, clamp the cylinder with the wheel of a large car, fasten it to a tree with a belt, and many other options. Therefore, choose for yourself the method of fixation that will be convenient for you.

The main task is to immobilize the balloon. We will look at the process of unwinding a valve using the simplest example - using a vice. Step-by-step instructions can be found in the following photo collection.

Comments 50

So how do you twist an old valve? And then it seemed like they started, got stuck in the thread and forgot what they were talking about?!

Air receiver in 15 minutes... just need to find such a cylinder. I haven't seen them since 2000...

What a rarity - the price is still Soviet... 20 rubles...

Please write what size is the fitting that is screwed into the cylinder?

external thread is 34″ and internal thread is 12″, it says

Cool! How do you drain water from it?

Was there any fragrance in the bottle already?

As I understand it, one cylinder is 50.5 liters. How about pumping up atmospheres in the same way?

16 eye working pressure. More is possible, but not necessary.

Sorry 16 eyes is how much in atmospheres

Approximately 16 atmospheres.

My pleasure. 1 MPa = 10.2 atm.

How to unscrew the old valve? He's screwed there to death.

there is a left hand thread...

The first time I've heard. Are you confused? I know that it’s cone-shaped and it’s a sealant, but the fact is that it’s on the left - you’re the first one to say that, and you can see in different videos that you unscrew it counterclockwise as usual.

Cylinders WITH ANY FLAMMABLE GAS have a left-hand thread. This is done so that it is impossible to connect a pipeline with oxygen or air (right-hand thread) to a cylinder with flammable gas, since otherwise an EXPLOSIVE mixture will form. GOST 9909-81 Basic standards of interchangeability. The conical thread of valves and gas cylinders is funny because no one can unscrew it... because they tighten it instead of unscrewing it

On any forum, upon request, how to unscrew the valve from a gas cylinder, I will prove the opposite to you. It turns out that in all the videos on YouTube people are unscrewing the valve against the thread? Then our country cannot be defeated!

I don’t need to prove anything, look at the view “d” in the picture... my cylinder had a LEFT THREAD

Dear, I’m holding a wuntel in my hands, the thread is normal - not left-handed.

The following details should alert you when purchasing a cylinder

- Valve malfunction - the flywheel does not turn or there are other problems;

- Corrosion, dents or other damage on the body of the cylinder and valve part;

- The inspection date has expired;

- You can feel the gas in the air;

- A crooked or damaged cylinder shoe;

- There is no plug on the fitting.

Important! Under no circumstances should the contents of the gas cylinder be completely used. During cessation of operation, the residual pressure inside should remain at 0.5 kgf/cm2.

Detailed instructions for unscrewing the tap

Are you looking for information on how to quickly and safely turn off the tap on a propane-butane gas cylinder? Then read our instructions and see the step-by-step photos posted just below.

In order to cope without any difficulties with the valve, which can “sit tightly” in the neck of the cylinder, you will need to apply force. And, depending on the equipment at hand, you may need an assistant.

If you have only one cylinder, and you are going to twist the valve for the first time, you will have to tinker with it until you get the hang of it. If you are going to disassemble the cylinder and start making various homemade products from cylinders, then you simply cannot do without good tools at hand.

First you need to release the remaining gas, if any, in this cylinder. To do this, it is enough to turn the valve flywheel in the direction indicated on it. If there is still gas left inside, you will hear a characteristic hissing sound - this is the remaining liquefied gas coming out.

Then you need to secure the cylinder body. How to do this depends entirely on your imagination and the devices at hand. For these purposes, they use welding, metal pins, a vice, a board, clamp the cylinder with the wheel of a large car, fasten it to a tree with a belt, and many other options. Therefore, choose for yourself the method of fixation that will be convenient for you.

The main task is to immobilize the balloon. We will look at the process of unwinding a valve using the simplest example - using a vice. Step-by-step instructions can be found in the following photo collection.

Comments 50

So how do you twist an old valve? And then it seemed like they started, got stuck in the thread and forgot what they were talking about?!

Air receiver in 15 minutes... just need to find such a cylinder. I haven't seen them since 2000...

What a rarity - the price is still Soviet... 20 rubles...

Please write what size is the fitting that is screwed into the cylinder?

external thread is 34″ and internal thread is 12″, it says

Cool! How do you drain water from it?

Was there any fragrance in the bottle already?

As I understand it, one cylinder is 50.5 liters. How about pumping up atmospheres in the same way?

16 eye working pressure. More is possible, but not necessary.

Sorry 16 eyes is how much in atmospheres

Approximately 16 atmospheres.

My pleasure. 1 MPa = 10.2 atm.

How to unscrew the old valve? He's screwed there to death.

there is a left hand thread...

The first time I've heard. Are you confused? I know that it’s cone-shaped and it’s a sealant, but the fact is that it’s on the left - you’re the first one to say that, and you can see in different videos that you unscrew it counterclockwise as usual.

Cylinders WITH ANY FLAMMABLE GAS have a left-hand thread. This is done so that it is impossible to connect a pipeline with oxygen or air (right-hand thread) to a cylinder with flammable gas, since otherwise an EXPLOSIVE mixture will form. GOST 9909-81 Basic standards of interchangeability. The conical thread of valves and gas cylinders is funny because no one can unscrew it... because they tighten it instead of unscrewing it

On any forum, upon request, how to unscrew the valve from a gas cylinder, I will prove the opposite to you. It turns out that in all the videos on YouTube people are unscrewing the valve against the thread? Then our country cannot be defeated!

I don’t need to prove anything, look at the view “d” in the picture... my cylinder had a LEFT THREAD

Dear, I’m holding a wuntel in my hands, the thread is normal - not left-handed.

Safety regulations

Gas cylinders with a capacity of more than 5 liters cannot be stored in a residential area - if they leak, the gas can fill the interior of the room and explode, destroying the building. Outdoor metal cabinets are used for storage. They lock to prevent theft. Placement on landings, attics, and balconies is also prohibited.

When transporting a large number of cylinders in the back of a truck, racks or Eurocontainers are needed to prevent impacts and falls of the tanks. It is convenient to transport cylinders locally in trolleys, which can be single or double.

To protect the valve from accidental impact and breakage, overhead caps are used. They come in plastic and steel. When gas welding and cutting, oxygen and gas cylinders are installed at a distance of 5 m. The same distance is maintained to hot objects (heating radiator, cutting site). The oxygen cylinder should be kept away from the oil and should not be handled with dirty hands.

Answers to questions: types of gas cylinders and their use

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

Conical threads with a taper of 3:25 are used for valves and gas cylinders. With a pitch of 1.814 (mm), its working length is 24 (mm) - 26 (mm), and the nominal diameter ranges from 19.2 (mm) to 30.3 (mm).

Standard gas thread sizes:

- Nominal diameter: 19.2 (mm), 27.8 (mm), 30.3 (mm).

- Pitch: 1.814 (mm).

- Working thread length: 24 (mm), 26 (mm).

- External thread length: 16.000 (mm), 17.667 (mm).

According to individual requirements, it is possible to increase the thread length taking into account the valve design.

Important: for some gas thread parameters, maximum deviations are permissible. For the peak and valley it should not exceed ±0.025 (mm), for the step - 0.04 (mm) - 0.07 (mm), for the length - ± 0.03 (mm) - ± 0.07 (mm). The angle of the external thread should not deviate from the norm by more than 1°, internal thread - 1°30°.

The axial displacement of the plane of gas threads from its nominal location cannot exceed ± 1.5 (mm).

Marking:

For example: W 19.2 – gas thread with a nominal diameter of 19.2 (mm).

The main regulatory document is GOST 9909-81.

Gas cutters, lamps, heaters

Gas cutters are widely used in construction, but in order to come up with a use for them on a hike, you will have to try. The only thing I can think of is helping to start a fire in winter or in wet weather.

Lamps powered by gas cylinders are more of a camping equipment. Taking into account the gas consumption of 40-80 grams per hour of operation of the device, a regular electric flashlight with a pair of spare batteries seems to be a much more convenient and lightweight option.

The situation is almost the same with gas heaters. The best use for them is camping in cold weather, winter fishing with a tent, and hunting. Gas consumption ranges from 60 grams per hour for compact tent models to 120 for powerful systems capable of heating rooms up to 15 square meters. Some, like the Kovea Fire Ball, allow you to cook food while heating the space and can be an alternative to a stove for winter weekend camping trips.

Ecology

Used gas cylinders must be taken with you and disposed of with household waste in the community. To do this, they can be pierced with a special key or even a simple knife (the pressure in an empty cylinder is close to atmospheric) and flattened with a stone or a heavy boot. The weight of the used cylinder - from 100 (collet) to 220 (large threaded) grams - should not burden the backpack of the person who brought it full into the forest.

It is hardly possible to clear the forest of old garbage, but not to create new ones - everyone can do it! Take care of nature, friends, and your hikes will become not only more enjoyable, but also safer.