The functionality of bearings is very wide. They are indispensable for ensuring reliable fixation, easy rotation or rolling, and reducing friction between two parts of the structure. The simple invention is one of the leading in the industry and is used everywhere. The performance and wear resistance of the machine largely depends on its quality. The variety of such assemblies is as great as their purpose. What is a bearing, what types exist and their classification according to their main characteristics, we will tell you in this article and show photographs.

What is a support

At its core, the part is the basis of the assembly unit. Its main function is to provide reliable support and support a certain moving part of the structure. How rigid such fixation will be depends on the device, material and many other factors.

Fixing the position in space allows for rotational movements and rolling with minimal resistance. This way the load is transferred from the moving part of the unit to others, maintaining wear resistance.

What are the types and types of bearings?

All assemblies can be classified according to their operating principle. Two main groups are devices that provide rocking and sliding. They are the ones most often used in mechanical engineering. The first can be represented by ball and roller devices.

Magnetic structures deserve special attention. The principle of their operation is different from the others, and they are used less often. In addition, due to their functional features, they must be accompanied by spare units.

Bearings are parts that help to obtain maximum efficiency from a machine, maintaining its performance without special repairs and maintenance.

Sliding supports

This group of parts allows you to slide freely when two contacting surfaces rub against each other. In this case, various lubricants are used - oils, water, chemicals, graphite and some gases. Structurally, such devices can be either integral or collapsible. Manufactured complete with bushing and connecting part.

Devices by rolling type

Such units are made in the form of two rings, bodies that provide a rocking effect, and a separator. They are manufactured in accordance with established standards, which allows them to be used in most cars, complex equipment and aircraft.

Ball bearings

Functionally, they are part of a group of node parts that operate on the rolling principle. Ball bodies are located on the surface of the outer rings of the parts. During operation, they create a small friction moment, which means they practically do not limit the rotation speed.

Roller bearings

They are part of the rolling group, but they are based on balls replaced by rollers. This allows them to withstand much greater loads. This performance is highly valued in the design of industrial machines and railway construction.

Magnetic supports

They work on the principle of levitation of attraction, ensuring complete non-contact of two adjacent parts. They can be used in aggressive environments, but are not yet as common as the types already listed. If you do not back up such a design with another, more traditional one, you can lose the entire car overnight.

Plain bearings

The main task of such parts is to ensure free friction between two mating sections. They can be used for both moving and fixed surfaces, which significantly increases the functionality of the application.

Types of sliding support units

This type of node part can be detachable or integral. The first consists of two liners installed in the half-holes of the base and cover. They may have a thick or thin wall relative to the outer diameter. The thickness is determined by the material used. For example, thin-walled ones are most often made of light low-carbon steel. The one-piece design involves a special assembly, in which a hole is drilled in the part into which a metal sleeve is pressed.

Varieties

The most common classification is based on the ability to absorb load in direction. In this case, devices are divided into 3 groups:

- • Radial – accepting perpendicular load from the axis.

- • Persistent – take on the entire load.

- • Radial-thrust – combine the properties of both.

There are several other options for separating nodes, but they are rather secondary.

Sliding bearing standards

The quality of workmanship of parts, the material used in the work and other production conditions are described in the Interstate ISO standard and GOST. The first one complies with international requirements valid in 165 countries of the world. The second is internal to the Russian Federation. All components presented undergo mandatory certification for compliance with the stated rules.

Plain bearing lubrication

This type is designed to provide free friction between two parts of the structure. For normal operation, one of 4 types of lubricants is used:

- • Liquid – various synthetic and mineral oil fluids for metal supports or water for non-metallic ones.

- • Plastic – made from base oil and thickener.

- • Solid – used in dry and boundary contact conditions. The materials most often chosen are graphite and molybdenum disulfide.

- • Gaseous – required when the structure operates under light load, but in hot conditions and at high speeds.

Advantages and disadvantages

Among the advantages are their high reliability when operating at high speed and their small size. As for the disadvantages, we note the need to constantly adjust the amount of lubricant, reduced efficiency and production from expensive materials.

Where are the devices used?

The scope of application of the devices is wide. Quite often they are used in high-speed equipment, steam and turbine units, in equipment for navigation systems and other precision instruments.

Requirements according to GOST

The bearings are manufactured according to the state standard of the Soviet model. This has its advantages: models with certain markings have strictly specified characteristics. This greatly simplifies the selection of products. The part has a numerical marking - a code that determines the diameter of the hole in the inner ring, its outer cylindrical surface, the nominal width of the product, and the coordinate of the mounting chamfer. A GOST thrust roller bearing, which has a specified marking, also corresponds to its weight. The weight of the product is also listed in the state standard table, which is convenient for the user. It is easy to replace a part with a similar one, select a product to complete the device, etc. This is important, because the slightest discrepancy can lead to equipment failure and defective work. But in most cases, an element that has other characteristics cannot be installed due to size mismatch.

Rolling bearings

These nodal supports consist of two rings, but in addition to them, at the base there are always bodies that provide rocking and a separator. On the inner surface there are gutters that act as tracks. In rare cases, the separator may be absent, but then the level of resistance becomes higher.

Purpose

The main purpose of the devices is to serve as a stop for rotating parts of mechanisms. This is why they are more popular than slip knots. They are used in electrical machines and other structures where it is necessary to ensure wear resistance and long-term operation without lubrication.

Classification

Such parts can be divided according to several criteria, but the most common is the division according to the shape of the bodies and the acceptance of the load. The first group includes the previously mentioned ball and roller joint bearings. The second is similar to the division of sliding bearings by type of load.

Specifications

To select a particular device, you need to take into account several basic parameters. The most important are:

- • Overall dimensions established by the ISO standard.

- • Basic and complete designation, including an alphanumeric code indicating type, size and design.

- • Tolerances corresponding to classes.

- • Clearance, the total distance that one ring can move relative to another.

It offers to select the necessary part in accordance with all the characteristics. Our range includes a wide variety of bearings suitable for any mechanism.

Advantages and disadvantages

The main advantages are: low cost and mass production. If necessary, they can be easily replaced, which means installation and maintenance of the machines will become more convenient. Lubricants are used in small quantities, which allows you to avoid spending a lot of time on caring for mechanisms.

The disadvantages include:

- • Excessive sensitivity to vibration and shock loads.

- • Excessive heat and risk of destruction at high speeds.

- • Large radial dimensions.

- • Noise during operation.

Despite significant shortcomings, today they are the most popular all over the world.

Ball bearing

This type of part uses balls that move freely along tracks as the body that provides rocking. Used for rotating structures that do not require strong friction between two moving parts.

Description

The unit consists of 2 rings made of steel. Together they form a kind of “bed” for ball bodies. In this case, the inner part of the device is fixed on the shaft, and the outer part is fixed on the support. Despite their simplicity of design, they are widely used in industry.

Varieties

What types of bearings with ball bodies there are can be guessed based on the general classification. Like most rolling parts, they are divided into: radial, thrust and with 4-point contact. The peculiarity of the latter is the ability to perceive load in two axis directions or simultaneous combined and axial load on one side.

Application

Different types are used in electric motors and various household appliances, in woodworking machines, in medical equipment, machine spindles and pumps. Ball bearings with 4-point contact are widely used in gearboxes.

Marking

When manufacturing products such as bearings, standards must be observed. And of course, manufacturers of such devices, according to regulations, must provide consumers with all the necessary information about them. The marking of bearings produced in Russia usually consists of three parts:

- main designation;

- additional characters on the right and left.

For clarity, here is an example of bearing marking:

- 6-180306US17SH.

Here the main part consists of six digits. The additional sign on the left (“6”) indicates the accuracy class of the product. The marking on the right US17SH stands for this:

- U is the degree of roughness;

- C17 - type of lubricant;

- Ш - degree of noise.

The main numbers indicate:

- types of bearings;

- series by outer diameter and width;

- internal diameters;

- design features.

Roller bearings and their varieties

In their structure, these supports are similar to the previous type, but instead of balls, a body shaped like a roller is used here. This way the device can take on a heavier load.

Description

The design is designed in such a way that it shows resistance to radial pressure, but at the same time the speed of the roller along the track is in no way inferior to ball bearings. The only thing you should pay attention to is the axial load. To make the device more resistant to it, the rolling element is replaced with a conical one.

Kinds

This type is classified according to the body used. Separately distinguished:

- • Cylindrical.

- • Conical.

- • Needle-shaped.

- • Spherical.

Application

Roller bearings are often used in pumps, high-power gearboxes, the railway industry and the automotive industry. All types of roller bearings are presented in pictures on the website mirpl.ru.

Magnetic support units

Unlike others, this device works on the principle of magnetic levitation. This ensures complete non-contact between the two parts of the structure.

Description

The elements are made in such a way that the shaft floats without contacting other surfaces. To ensure reliable operation, a large number of sensors are provided to coordinate all movements.

Varieties

There are two groups: active and passive. The first composition includes the bearing itself and the electronic system. The work of the second group is based on the presence of permanent magnets. They are less stable than in the case of an electronic control system, and therefore are used much less frequently.

Application

Such devices can be used in gas centrifuges, turbomolecular pumps, in various electromagnetic suspensions, in cryogenic technology, in vacuum devices and other complex mechanisms.

Advantages and disadvantages

As advantages, we highlight the wear resistance of parts and the possibility of their use in an aggressive environment, including in space. The disadvantages are manifested in the instability of the magnetic field, due to which traditional rolling or sliding devices are additionally built into the mechanism.

How to determine dimensions

There are cases when it is difficult to choose a thrust roller bearing. A catalog of dimensions in which the dimensions are specified in detail can help if there is no information about the characteristics of the part. The simplest option is to purchase a model similar to the one that was lost or damaged. But this is not always possible. The solution may be a dimensional grid, which provides for minimal deviations from the norm. The device has a thread, a groove, which provides for the use of a certain size of the product. After taking the necessary measurements, you can choose the appropriate option. If the thrust bearing that will require replacement was not marked, solving the problem is much easier: a few measurements are enough to determine the marking. But the details are important - for example, the outer diameter of the part is measured along the outermost visual line, covering the entire bearing diagonally. First you need to find out the inner diameter, then the outer diameter, and then the height of the bearing. This will be its marking.

Other types

Let's consider several more types of nodal supports, differing in some functional features.

Tapered bearings

This is a type of roller, but the body here is made in the form of a cone and is installed on the track at an angle. They cope well with both radial and axial loads.

Self-aligning double row

They differ from others in their low friction, which makes them possible to operate at the highest speeds. Installed on a conical or cylindrical shaft journal.

Needle type

Here, a thin and long roller acts as a rolling body. The elements look more compact, but at the same time provide greater performance and reliability, and are economical to use.

Thrust ball bearings

The main purpose is the perception of axial loads. It belongs to the group of ball joints, so its appearance completely corresponds to them.

Spherical

Provide low friction. The design simultaneously includes two rows of rollers arranged symmetrically.

Heat resistant

Designed to work in hot conditions. They are distinguished by reliability and ease of operation.

Floating Nodal Support

Allows the shaft to move linearly. Bears only radial load. Easily adjustable and easy to operate.

Speed devices

Provides normal rolling at high speeds. They are distinguished by excellent quality and wear resistance.

Spindle

Has good load capacity. Often used in fans, powerful pumps and machine tools, as it works well at high speeds.

High precision

They have high performance characteristics, due to which they are often used in aircraft construction, astronautics and the military industry.

Closed

Equipped with seals that close open space. This allows for increased wear resistance in difficult conditions.

Flange bearings

The built-in flange increases the reliability of the fastening so that the part can withstand heavy loads.

Supporting

Perceive gravity along the axis of rotation. The scope of application is very limited, therefore it is less common than other options.

Linear Motion Devices

They have high performance qualities with minimal friction.

Hydraulic thrust bearings

In hydraulic thrust bearings, the axial load is absorbed by an oil cushion in a closed cavity fed by a pump. The shaft is maintained in a constant vertical position by means of oil distribution devices.

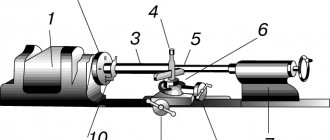

In the simplest design (Fig. 724, a), oil is supplied to the annular groove m of the thrust bearing, from where, through the flat n and a radial hole in the shaft, it enters the closed space under the end of the shaft.

The position shown in the figure (the edge of the flat touches the edge of the annular groove) is equilibrium: the oil supply groove is blocked; oil is not supplied to the shaft end. When the shaft is lowered, the radial hole communicates with the annular groove, oil flows under the end of the shaft, returning it to its original position. Thus, the shaft continuously oscillates with a small amplitude near the equilibrium position.

The flat, which ensures the opening of large sections at once, helps to reduce the amplitude of vibrations.

Thrust washer 1, located with a small gap relative to the thrust bearing flange, serves to fix the shaft in stops.

In design (b), the oil cushion is fed by means of a needle valve controlled by a shaft. The equilibrium position is when the end of the shaft lightly touches the valve shank, which is in the closed state. When lowered, the shaft opens the valve and oil enters the cavity, returning the shaft to its original position.

The load-bearing capacity of hydraulic thrust bearings depends on the oil supply pressure and the cross-sectional area of the shaft. At a pressure of 3-4 MPa, the load capacity is comparable to the load-bearing capacity of mechanical thrust bearings of the same radial dimensions.

If diameter d = 50 mm, supply pressure p = 3 MPa, then load-bearing capacity P = 0.785 d2 p = 0.785 502 3 = 6 kN.

Friction (meaning friction on the oil pad) is negligible.

If the oil cushion is powered by a pump with an independent drive, then during the periods of start-up and run-down there is no semi-fluid friction on washer 1.

The disadvantages of hydraulic thrust bearings are high oil pressure, relatively high power consumption to create an oil cushion, and insufficiently precise fixation of the shaft in the axial direction.

Hydraulic thrust bearings are used for shafts of small diameter (up to 50 mm on average) loaded with forces of up to 10 kN. For heavy loads, it is advisable to use energy-efficient hydrostatic bearings.