A crucible furnace is a furnace with a container made of refractory material (crucible) in which metal or other material is melted, cooked, or heated.

Navigation:

- Induction oven

- Salt fog chamber

- Heat cold moisture chamber

A crucible furnace is used for melting almost all types of metal: steel, aluminum, copper, precious, non-ferrous metals, etc., but in small quantities. Note. The capacity of the furnace ranges from two kilograms to 30 tons.

Crucible electric furnaces have become widespread due to the fact that they can reach very high temperatures, which can be easily controlled by an electronic unit. If there are power limitations, you can use a transistor converter, which allows you to select the required power and, accordingly, the furnace load. An example is the induction melting crucible furnace IPP 45 (the price may change depending on the configuration).

A crucible melting furnace can have three types of crucibles:

- ceramic;

- graphite;

- cast iron

Ceramic crucibles are most widely used, since they do not in any way affect the properties of the melted substances.

An induction crucible furnace is operated as an independent equipment or in combination with other equipment, bringing the melt to the required composition.

Advantages of using crucible furnaces:

- there is no need for intermediate heating elements, since the energy is released directly in the loading chamber;

- uniform heating of the metal or alloy due to the electrodynamic circulation of the substance in the container;

- the atmosphere and pressure in the working chamber can be created in any range;

- ease of use, since a small container allows you to completely drain the metal, and the relatively small weight of the lining quickly cools and allows you to switch from one alloy to another in a short period of time;

- ease of maintenance and process control due to the possibility of automation;

- minor air pollution.

But there are also disadvantages; crucible induction melting furnaces have:

- low durability of the lining due to its small thickness, because its temperature changes quite often;

- low temperature of slags, which are heated by the metal;

- high cost of equipment.

An induction crucible furnace, which can be purchased at a specialized factory, can have quite different types.

Note. Due to its simplicity of design, you can even order a custom-made stove or make it yourself.

But basically, the shaft crucible furnace is divided according to the following criteria:

- according to the size of the working container;

- according to temperature conditions;

- according to design features.

Capacities from 2 to 1000 kg have a small furnace and are used for smelting precious metals, smelting alloys in small quantities or as a laboratory crucible furnace. A more capacitive crucible melting furnace - for melting non-ferrous and ferrous metals on an industrial scale. It all depends on the needs of the manufacturer and the melted substance. For example, a crucible furnace for aluminum and alloys with it most often ranges from 0.04 to 2 tons, and for copper and copper alloys - from 0.1 to 0.6 tons.

A crucible furnace, the price of which depends on the size and design, generally has a maximum temperature of up to 1400 - 1600 degrees. But there is a high-frequency crucible furnace, for which 2000 degrees is the operating temperature.

Structurally, a stationary electric crucible furnace differs from a rotary one. Typically, stationary furnaces are small in size and are used for laboratory research, while rotary furnaces are used on an industrial scale for ease of casting.

Note. A stationary furnace is excellent for smelting metal and storing it in liquid form.

In addition, there is a crucible furnace (you can buy it of any design) of open and closed type. The first type allows smelting to be carried out in the open air, and the second - in a vacuum space.

Note. The vacuum power in closed crucible furnaces ranges from 0.1 MPa to 10 Pa.

Direct crucible furnaces, also called resistance crucible furnaces, allow metal to be heated in a very short time by converting electrical energy into heat.

If it is necessary to move away from the electrical medium, crucible flame furnaces are used. Heating in them occurs from a gas flame burner between the lining and the crucible; their productivity is about 400 kg of metal per hour. Therefore, such crucible furnaces are often used for melting aluminum and other non-ferrous metals.

Induction electric crucible furnaces

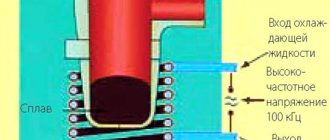

Induction crucible furnaces are the most technologically advanced equipment, which is why the furnaces are used in many foundries. An induction furnace operates under the influence of eddy electric currents that arise inside the metal due to electromagnetic induction.

| Crucible furnaces with gearbox 5 – 150 kg | Crucible furnaces with gearbox 100 – 3000 kg | Hydraulic crucible furnaces 400 – 5000 kg |

In induction electric crucible furnaces, overheating of the melted materials can be avoided due to the uniform temperature distribution throughout the entire volume of the crucible. Due to this, the composition of the alloy is homogeneous. Such stoves are very popular in Russia today.

Differences between homemade and factory units

To understand the difference, you need to take the purpose of using the equipment as a starting point. Home-assembled units are usually needed for periodic use (breaks can be significant), so the minimum cost, the ability to perform simple manipulations, and low maintenance requirements come to the fore.

If the results of smelting are used to earn money, it is more advisable to purchase a factory induction model - such equipment promotes accurate work, helps to accurately observe measurements, and reduces to zero the likelihood of unwanted impurities. The same equipment is difficult to do with your own hands - assembling an inductor, choosing a crucible , screen arrangement requires specialized skills. Not everyone can create a capacitor bank and generator.

DIY crucible furnace

The ergonomic characteristics of stoves should not be overlooked. In artisanal preparations, they are given a minimum of resources; as a rule, such variations are inconvenient to use and are often dangerous due to the use of improvised materials. In the factory lines, proven technologies are used to ensure comfortable work, in particular, this concerns the configuration and rotating mechanism of the crucible. It is important that they create conditions to prevent injuries.

Crucible electric furnaces for melting aluminum and copper

Crucible electric furnaces are used for melting aluminum, copper, steel and cast iron. The maximum crucible load for such furnaces ranges from 5 to 5000 kg. Electric crucible furnaces, due to the action of an electromagnetic field, liquefy the metal, bringing it to a homogeneous state. The quality of such metal is considered to be the best for casting.

During melting, thermal energy from the heating element of the electric furnace is not transferred, but is generated inside the metal. After all, alternating current passes through it, resulting in the formation of an electromagnetic field. Electric furnaces operate at different current frequencies: industrial (50 Hz), high (0.5 - 10 kHz), high (66 - 440 kHz).

Salt fog chamber

The salt fog chamber is designed to determine the corrosion resistance of materials when exposed to salt fog.

Tests in a salt fog chamber take up to 30 days, during which the material is exposed to salt fog, which is evenly sprayed over its entire surface. The KST salt fog chamber allows you to reproduce operating conditions as much as possible and achieve the necessary anti-corrosion characteristics.

Certification of a salt fog chamber involves determining the dispersion and water content of the solution. The salt fog chamber certification methodology is described in detail in the relevant regulatory documents.

According to certification, the most common types of cameras have the following characteristics:

- salt fog chamber KST 2 - dispersion 1-10 microns, water content 1-2.5 ml/h;

- salt fog chamber KST 1m – dispersity 1-10 microns, water content 2-3 g/cub.m;

A world leader in the development of new technologies, Atlas Material Testing Technology is a global leader in the development of new technologies, and the Atlas Salt Fog Chamber is popular in a variety of industries due to its quality and durability.

The salt fog chamber (the price depends on the design and manufacturer) is fully automated, only the operating modes are regulated. During the experiment, the composition of the solution and the purity of the water are constantly monitored and maintained. If necessary, a salt fog chamber, which can be purchased in Russia, can also change the position in space of the sample.

Crucible electric furnaces - lining

The lining of crucible furnaces includes the main parts: crucible, collar, hearth, overflow nose and lid. Properly made lining and selection of refractory materials will extend its service life and provide a large number of heats. The main part of the furnace lining is the crucible; it is made by stuffing the buffer part or by laying fire-resistant materials:

- quartzite SiO2 (Acid lining);

- magnesite MgO;

- spinel MgO + Al2O3;

- corundum Al2O3;

- mullite ЗAl2O3 2SiO2

- mullite corundum Al2O3;

- fireclay;

- zirconium Zr2 · SiO2;

- chamotographite;

- graphite.

Acid lining of crucible furnaces is the most common lining and is used for melting steel, cast iron and carbon metals. Acid lining is not used at a certain content of carbon, phosphorus and silicon in the smelting of high-alloy steels. After all, the combustion of impurities (calcium oxide) occurs faster at high temperatures. Also, heat-resistant steels and melts cannot be used in this lining, because their overheating is close to the melting point of quartzites.

To correctly select the lining of induction crucible furnaces, it is necessary to take into account the type of charge that will be used. The main criterion for selection is service life to ensure the following requirements:

- obtaining good metal;

- a large number of swimming trunks;

- safe work for operating personnel;

- elimination of interruptions during melting;

- cost and economic effect;

- release of harmful impurities.

The lining of a crucible furnace is necessary to enhance the refractory properties of the crucible, because it affects the physical and chemical properties of the metal. Correctly selected lining ensures high quality of smelted metal, safe operation of the crucible furnace, long operation of the furnace without the need for repairs, and a minimum amount of waste harmful to the environment.

When adding deoxidizing agents during melting and interacting with lining materials, it can affect the formation of undesirable impurities, which will later manifest themselves as non-metallic inclusions. Thanks to high-quality lining, the thermal stress in the crucible is reduced and reliable protection of the inductor is ensured.

Crucible melting furnace for melting non-ferrous metals and gold bars, high-frequency UPV-16/50

| p/p | Characteristic | Unit change | Quantity |

| 1 | Power consumption | kW | 16 |

| 2 | Crucible capacity (copper) | kg | 50 |

| 3 | Time to enter mode | min | 35 |

| 4 | Melting time when crucible is 50% full | min | 30 |

| 5 | Cooling water consumption | l/h | 20-100 |

| 6 | Generator dimensions | mm | 580x760x410 |

| 7 | Oven dimensions | mm | 900x900x800 |

| 8 | Total weight | kg | 220 |

| p/p | Contents of delivery | Unit change | Quantity |

| 1 | Generator VBG-16 | PC | 1 |

| 2 | Melting device UP-50 | PC | 1 |

| 3 | Remote Control | PC | 1 |

| 4 | Rubber hose | PC | 3 |

| 5 | Mold No. 3 SCH-20 | PC | 1 |

| 6 | Graphite spout NG-2 | PC | 1 |

| 7 | Crucible AA-50 | PC | 1 |

| 8 | Kaolin felt | kg | 5 |

| 9 | Liquid glass | l | 2 |

| 10 | Crushed fireclay | kg | 5 |

| 11 | Mold grip | PC | 1 |

| 12 | Crucible lid | PC | 1 |

Crucible electric furnaces - advantages

The advantages of induction crucible furnaces are obvious: contamination of the metal with other materials is excluded. Uniform temperature distribution in the crucible and, as a consequence, uniform chemical composition of the alloy. Low level of waste formation of alloying elements. Easy temperature adjustment. High performance. Compact dimensions of the furnaces, which do not require large working areas. Favorable working conditions with crucible furnaces , due to low noise levels, minimal thermal radiation and a small amount of smoke.

Heat cold moisture chamber

The climatic chamber heat cold moisture is used to test substances for resistance to climatic conditions (temperature and humidity).

To create a uniform low or high temperature, the cold and moisture heat chamber is equipped with a wide-blade screw at the rear. High and low humidity are created by heating or cooling water and forming a “water bath”. Moreover, the test climatic chamber of heat, cold, moisture simultaneously regulates both of these parameters, creating the necessary conditions.

Crucible electric furnaces - application

The use of crucible furnaces is especially important in repair and foundry shops that produce small and medium-sized castings or repair castings. Safety precautions when using a crucible furnace include compliance with safety precautions when using electrical devices of the same class. Accidents that may occur during work with a crucible furnace are associated with damage to the lining. To prevent this kind of situation, a special system has been developed that turns off the power to the furnace and signals unacceptable thinning of the crucible walls or the appearance of cracks. In order to ensure operational safety, high demands are placed on the equipment of the induction crucible furnace . The furnace is powered through a transformer connected to a high or high frequency generator. Crucible furnaces are characterized by simplicity and ease of adjustment and control of the smelting process. The melting process in crucible furnaces can be automated or mechanized. Crucible furnaces are used in the following areas:

- metallurgical plants and small foundries: smelting, roasting, mixing, casting metals, smelting ore;

- metalworking: casting, firing;

- laboratories and research institutes: increasing the strength of metals, combustion, melting;

- chemical industry: dissolution and combustion.

Crucible melting furnace for melting non-ferrous metals and gold bars, high-frequency UPV-25/100

| p/p | Characteristic | Unit change | Quality |

| 1 | Power consumption | kW | 25 |

| 2 | Crucible capacity (copper) | kg | 100 |

| 3 | Time to enter mode | min | 40 |

| 4 | Melting time when crucible is 50% full | min | 30 |

| 5 | Cooling water consumption | l/h | 20-100 |

| 6 | Generator dimensions | mm | 580x760x410 |

| 7 | Oven dimensions | mm | 950x950x800 |

| 8 | Total weight | kg | 250 |

| p/p | Contents of delivery | Unit change | Quantity |

| 1 | Generator VBG-25 | PC | 1 |

| 2 | Melting device UP-100 | PC | 1 |

| 3 | Remote Control | PC | 1 |

| 4 | Rubber hose | PC | 3 |

| 6 | Graphite spout NG-5 | PC | 1 |

| 7 | Crucible AA-100 | PC | 1 |

| 8 | Kaolin felt | kg | 5 |

| 9 | Liquid glass | l | 2 |

| 10 | Crushed fireclay | kg | 5 |

| 11 | Crucible lid | PC | 1 |

| 12 | Mold No. 3 SCH-20 | PC | 1 |

| 13 | Capturing molds | PC | 1 |

Making crucibles

Now it's time to make your own melting crucible. From the above it is clear that it makes sense to make crucibles with your own hands:

- Steel;

- Ceramic neutral;

- Ceramic graphite.

There is nothing special to say about steel crucibles - they are just a steel vessel with a welded handle. Steel crucibles are used for melting low-melting metals; sometimes - zinc for hot galvanizing with quality up to 3+. Steel crucibles for lead, tin and zinc are only suitable for melting one specific metal, because... after 1-2 melts they themselves are covered with it from the inside.

Ceramic neutral

The composition of the mixture for forming a neutral ceramic crucible is 7 parts of fireclay clay, 1 part of finely ground fireclay (to a fraction of <1.5 mm) and 10 tbsp. spoons of liquid glass (silicate office glue) per 1 liter of dry mixture. Ground fireclay in small quantities can be obtained from pieces of fireclay bricks crushed in an earthenware mortar (sold in hardware stores, medical equipment stores and some pharmacies). You don’t mind spending money on coolness - you can buy agate ones at a souvenir store, they are more durable. If you are going to cast metal regularly and quite a lot, or make crucibles for sale, then perhaps it would be better to use a chain or ball mill for grinding fireclay.

Fireclay mill

Construction of a homemade mill for grinding fireclay

Finely ground chamotte is part of the raw material for molding both neutral and graphite crucibles, and the quality and durability of the crucible largely depend on it, and crushing chamotte using artisanal methods is very labor-intensive and does not produce a completely good-quality material. The structure of a chain mill for mineral raw materials is shown in Fig. on right. Material – steel. Chains – 4; they are hung crosswise so that they sag horizontally by approx. by 1/3 of the tank diameter. An option instead of chains for 1 broken fireclay brick is 2-3 handfuls of balls from the bearing. New store-bought chains will cost more than chains, but old ones from broken bearings are quite suitable. Any drive: manual, electric. Both chain and ball mills are capable of grinding fireclay into dust like cement; To obtain certain fractions, the mill is stopped earlier. To prevent dust from forming, the mouth of the tank is covered with something during grinding. To grind a brick, simply drop it from a height onto a hard floor and load the resulting pieces into the mill.

Preparing the molding material

Mix dry clay with ground fireclay until completely homogeneous (uniform). The ideal option is to scroll 15-20 times in the same mill; if it is spherical, then you don’t have to throw balls into the tank. Unload the mixed mass and add a little water (1.5-2.5 parts), mixing by hand until it reaches the consistency: clenched in a fist, sticks together into a lump, but does not stick to the skin and is not pressed between the fingers. Add liquid glass, also stirring until completely homogeneous, this is the most labor-intensive step.

Deaeration

Just one remaining air bubble in the ceramic crucible mixture can cause the crucible to burst due to heating. Therefore, you need to knock the air out of the mass. To do this, lay a clean film on the hard floor; newspaper, as some manuals advise, is not necessary - the mass will accumulate from paper fibers.

To knock out the air, the entire lump of mass is thrown forcefully onto the floor many times. Practically - after the bubbles have stopped jumping out of the flopping mass, at least 10 more times.

Storage

For storage, the beaten mass is placed in a glass container with a hermetically sealed lid. In plastic, and especially when wrapped in several layers of film, the mass dries out in a few weeks and cannot be restored, but in glass in a cool place it is stored for more than six months.

Usage

Crucibles from the resulting mass are simply sculpted by hand or molded in a destructible plaster mold or in a collapsible one, as described below. The molded crucible is dried, and, which is absolutely necessary for this mass, after drying it is annealed in a muffle furnace for an hour or two at a temperature of 800 degrees. It is at this temperature that the liquid glass will melt and firmly bind the other components. Below - the crucible will collapse during the first melting; higher – during annealing. This is a very significant drawback of this technology, because The muffle furnace equipment is not cheap or simple, although it is also possible to make it yourself. The maximum operating temperature of the resulting crucibles is up to 1600 degrees; resource, with high-quality grinding of chamotte - up to 30 melts.

Graphite

Manufacturing technology of graphite crucibles for melting any metals, incl. black scrap, using any heating method, is well described in an article by the author A. Ramir from 2006 (see dendrite-steel.narod.ru/stat-ramir-3.htm). A. Ramir, apparently, is self-taught, but even more credit to him - his products fully correspond to good industrial designs. However, firstly, his article was rewritten many times by rewriters who clearly did not cast metal in their lives. Secondly, you can’t always get to it in a search, and for some reason the drawings are not downloaded, although they seem to be freely distributed. Thirdly, there is something to add to A. Ramir’s materials, no offense to him. One of the rules of engineering is that in a good design there is always something to improve. Therefore, we will repeat and supplement the main points of this publication.

Drawings of crucibles from the mentioned article are given in Fig.:

Drawings of crucibles for melting metal

The maximum weight of melted steel is indicated in kg; it must be recalculated for another metal. The main difficulty in this case is the manufacture of the flask - the round shell of the mold. Its inner surface is conical, otherwise the finished crucible cannot be removed after molding, so A. Ramir used turned flasks.

How to choose the right clamp for clamping the mold shell for a crucible

Meanwhile, a flask for any of these forms can be made from a piece of plastic pipe. It is secured in 3 places, at the bottom, in the middle and at the top, with screw clamps, and heated from the inside with a hairdryer. By tightening the clamps, the surface is not completely conical, but the flask will be removed from the crucible. You only need to use worm-drive clamps (see figure on the right) or their homemade analogues. Any other clamp deforms the pipe across. The flask from it will most likely come off the crucible, but it will not last long or will crack during the first melting.

The composition of the mixture used by the author is 7 volume parts of ground fireclay, 3 parts of pottery or oven clay and 1 part of ground graphite. A. Ramir also gives a recipe with 2 parts of graphite, but in terms of reducing power this is clearly too much, and the likelihood of cracking a crucible from a 7:3:1 mixture will be reduced to zero if the fireclay is crushed into dust in a mortar or ground in a mill (see above) .

It is necessary to soak the fireclay brick, as A. Ramir advises, only before crushing it using the artisanal method he described. The dry components are mixed until completely homogeneous in the specified sequence (fireclay, clay, graphite) and mixed with water with continuous stirring until the consistency is as described above. There is no need to knock the air out of this mass, because... it is de-aired during the molding process. The mixture is not stored, so it must be prepared immediately before making the crucible.

Forming a crucible for metal melting

To form the inner surface of the crucible, you need to carve a block from hard wood (filled with gray in positions 1-5 of the figure), sand it and, very preferably, walk over it with leather until the surface is completely smooth. In the center of the surface of the block that forms the bottom of the crucible, drill a blind hole and insert a toothpick or, better, a round smooth plastic stick from an ear picker into it. The match that A. Ramir used is not the best option - when pulled out, it often breaks, and as a result the product is damaged.

Note: the use of any lubricants when forming the crucible is unacceptable - they will be absorbed into its material, and the crucible will burst from heating.

The mold is filled with the mixture in layers of 15 mm, and each layer is compacted with a wooden tamper. This is the most critical stage: bubbles and uneven compaction of the mixture are unacceptable. When approx. remains to the top of the flask. 12 mm, the mixture is compacted with an already turned lid with a hole for the rod in the center, pos. 2. The mixture is added in layers of 1-2 mm until the gap between the very tightly pressed lid and the upper edge of the investment box reaches 1-1.5 mm, pos. 3. If the gap is larger, part of the mixture can be taken away. Next, the lid is removed and the rod is carefully pulled out of the block using pliers, the lid is put back and the mold is turned over. A handle is attached to the bottom of the block with self-tapping screws and, carefully turning it back and forth, it is pulled out of the casting.

Note: if the rod is not inserted into the bottom of the block, it will be impossible to remove it without destroying the casting - the vacuum under the block will not work.

The formation of a crucible with a flat bottom (which is 1.2 kg) has its own peculiarities - you can’t just pull it out. Therefore, when the compacted mass rises to the flat top of the block, a circle of toilet or filter paper is placed on it.

Now the hole from the rod and minor defects in the inner surface of the crucible are sealed with the same mass. It must be completely smooth, otherwise the probability of destruction of the crucible during melting is quite high, so after correcting the defects it must be smoothed out. The best way to do this is to line it with toilet paper (item 4), insert a block (item 5), and turn it several times.

All that remains is to remove the flask. To do this, it, together with the crucible, is turned over again into the working (for the crucible) position, a round wooden block is placed and the flask is carefully pulled together, pos. 5 and 6. If the flask is plastic, then its protruding upper edge is slightly bent outward in several places with your fingers; Most likely, the flask will come off like clockwork after this.

And finally, the finished casting is dried. Equipment – kitchen stove with oven. The casting is placed upside down on a baking sheet and placed in the oven. They heat for half an hour on the lowest gas, then another half an hour on medium (the temperature according to the built-in thermometer is about 150 degrees) and another 2 hours on full. After this, turn off the fire and leave the casting in the oven to cool until tomorrow morning. Do not open the oven during the entire drying period!

Before use, the crucible must be checked for hidden cracks. To do this, hold it by the bottom with your fingertips and tap it with your nails in a circle from top to bottom. Every knock should ring. If somewhere it doesn’t ring, it’s a defect, you can’t melt with this. Annealing is not required for a crucible manufactured using this technology. It rings everywhere - you can immediately melt in it.