These electrodes are used for welding carbon and low alloy steels. Scope of application: metal structures of special reliability, which must operate under large variable loads, including in cold climates or in refrigeration units, which makes them suitable for shipbuilding purposes. They are suitable for pressure vessels, thick sheet materials and for repairing casting defects.

This type includes the following brands: VN-48, OZS-2, SM-11, UONI 13/45, UONI 13/45A, UP-1/45, UP-2/45, TsU-6. (See also the neighboring type E42 in terms of characteristics).

Quality certification

Welding electrodes type E42A have a GOST R certificate confirming compliance with GOST 9466-75; NAKS certificate; River Registers of the Russian Federation: Certificate of approval, Certificate of recognition No. ВВФ030; Maritime Register of Shipping of the Russian Federation: Certificate of approval of welding materials; Sanitary and epidemiological report on the electrodes.

For your information! Although certification of electrodes in the Russian Federation is voluntary, nevertheless, the E42A material always has a certificate, since it is used for work in places where increased responsibility is required.

Welding electrodes 4 GOST 9467-75: type E42A - Moscow

How to get profitable offers from material suppliers: Moscow

Welding electrodes 4 mm GOST 9467-75: type E42A.

As a rule, in the construction field you can often encounter the fact that this or that material is needed right now. and it doesn’t matter what city it is, Moscow or a completely different region.

Today, to solve this problem, we offer a Supplier search system that helps clients and customers find mutually beneficial cooperation. Want to know exactly how this happens?

Quite simple if you use the latest technology and the World Wide Web. So, you go to the website METAL100.ru and leave your request, let it be Welding electrodes 4 mm GOST 9467-75: type E42A, indicate the region Moscow. Although, it is worth noting that your search may not be limited only to the capital. These may be other regions of the Russian Federation, and with one click you can cover all cities of the CIS. At this point, your work is almost finished, since the automatic system itself sends out mailings to suppliers. And they usually respond within 3 minutes.

It is after this period of time that you will begin to receive offers for Welding electrodes 4 mm GOST 9467-75: type E42A to your email. The information will contain not only wholesale and retail costs, but also delivery times and possible delivery conditions if the region is not Moscow. As you can see, everything is quite simple and such a system is somewhat reminiscent of a virtual tender, which you can announce without filling out a whole stack of papers.

Now, of course, you want to know which link you can use to submit your application. You will find her address below:

Send a request to suppliers

You understand that from now on you have a unique opportunity through which you can save your time. Forget about unnecessary searches. After all, now all suppliers themselves will offer you their goods. And you decide who to give preference to. By the way, the site is also good because information about the cost of rolled metal is updated daily and you can verify the obligations of the supplier if he is an authorized user. This will help you avoid possible mistakes and save you from scammers.

Profitable deals are a reality, which tomorrow can become a great chance for you to buy everything you need of excellent quality at the lowest price.

New construction portal STROIM100.RU - Main suppliers and prices for building materials.

| Concrete products | Plastic pipes | Drywall | Corrugated sheet |

| Brick | Metal-plastic | Fasteners and hardware | Galvanization |

| Cement and concrete | Pipe fittings | Sawmatirial | Metal tiles |

| Soil and sand | Valves | Plywood | Roofing steel |

| Crushed stone and gravel | Flanges | Fiberboard chipboard OSB | Additional elements |

The project brought to your attention is an information portal where prices of the main suppliers of building materials, such as Brick, Concrete, Floor Slabs, Drywall, Metal-plastic pipes and much more are presented.

The main goal of the project is to provide potential buyers, on the basis of free access, with information about the availability, price and quality of various building materials, indicating the coordinates of potential suppliers.

Convenient navigation of the Stroim100 portal makes it as easy as possible to navigate, select the desired type of building materials, see supplier prices, send applications, announce tenders. The features offered to users reduce the time spent searching, help select the best items and compare prices from suppliers.

Happy shopping and transactions on the portal!

Decoding what E42A means

This is the type of electrode, since electrodes are classified primarily by type. There is GOST 9467-75 for the designation of electrodes.

In general, due to the large range of alloys used in industry and their pairs that can be welded, the number of types of electrodes is difficult to enumerate. Some electrodes are used more often than others. E42A is one of these.

E – in the type designation means electrode.

42 – this is the tensile strength in Megapascals per 1 square mm of seam section (corresponds to a force of approximately 40 kg). This may mean that a wire with a cross-section of 1 sq. mm, made from weld metal, will withstand a load weighing up to 40 kg. Designers who specialize in strength materials can calculate the strength of tensile or bending seams using these data. That is, the type of electrodes itself already carries useful information for specialists.

The letter A in the designation means “improved” (compared to E42), that is, with special properties that are suitable for increased requirements for welding quality: plastic properties, viscosity, chemical. compound.

Technical indicators

Products of type E42 comply with GOST 9466 and GOST 9467. Welding is carried out with direct and alternating current.

The choice of a specific brand is determined by the type of rod coating. E42 coating can be acidic or rutile.

Weld metal produced by an acid-coated electrode is prone to cracking. If the seam is made with a rutile-coated product, its metal does not form cracks and corresponds to mild or semi-mild steel.

Thanks to the coating, the rod is well resistant to the effects of gases - nitrogen and oxygen, released during welding. The coating ensures the maintenance of the arc and enriches the alloy with the necessary alloying components.

Main parameters of the E42 characteristics:

- Temporary tensile strength.

- Impact strength.

- Relative extension.

- Bend angle.

Chemical composition of E42 electrodes: carbon - 0.08%, manganese - 0.7%, silicon - 0.1%, sulfur - 0.035%, phosphorus - 0.035%.

Properties of E42 electrodes:

- Temporary tensile strength - 420 MPa.

- The length of a rod with a diameter of 4 mm is 450 centimeters.

- Welding is carried out at temperatures from (- 20 degrees) to (+ 20 degrees).

- For 1.6 kg of float, 1 kg of auxiliary material is consumed.

- The impact strength of the seam is 150 J/sq.cm at a temperature of (+20), at (-40) it is 35 J/sq.cm. cm.

- Seam elongation no more than 22%.

Features of E42 electrodes

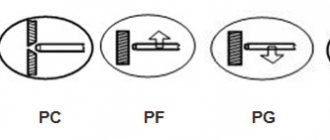

Welding of metal structures is carried out in all positions, except for the vertical position from top to bottom. When marking rods, this requirement is indicated by the number “2”.

A weld produced by an electrode with a diameter of 4 mm E42 is characterized by uniformity and the absence of voids.

The slag crust resulting from the formation of a seam is easily removed.

During the welding process, the hot deposited material does not spread.

When using E42 electrodes, the arc ignites quickly. It is stable.

The seam is durable and flexible.

Using E42 type rods you can weld rusted and wet metals.

The welding quality is high and does not depend on the arc length and power surges in the network.

If alternating current is used, welding must be done with reverse polarity.

Rods should be selected according to the required materials and specific working conditions . In order for the choice to be correct, it is necessary to know the thickness of the metal being welded, the grade of steel, the type of electric current and the welding position.

For what steels

Type E42A is used for welding carbon steels 08, St3, 20, 20L . In addition, they can be used to work with alloy steels 14G2 and 09G2 . When welding, direct current of reverse polarity . You can weld in any position, with the exception of only vertical seams from top to bottom. When welding, a seam is formed with a small hydrogen content and there are no cracks that can form during metal crystallization.

Keep in mind! Type E42A provides excellent weld quality if you follow the technology , which when working with this type of electrode is that you must maintain the welding arc mode . It is not allowed to be extended ; the welder must maintain a short distance along the entire length of the seam.

The arc does not ignite very easily.

Decoding the abbreviation and brand

For electric welding you must have:

- Electrode.

- Connected elements of metal structures.

- Power supply for welding transformer.

In the welding process, an electrode is a metal rod that supplies current to the steel elements being welded. More than a hundred types of rods are used to melt metal during manual arc welding. One of them is the E42 type rod.

The marking of this type shows the strength characteristics, which is the main factor.

E - electrode for electric arc welding.

42 - strength 420 MPa.

Metal rods with a diameter of 4-6 mm are used for welding carbon and low-alloy steels. The most famous brands of electrodes are OZS-42, OZS-12I/42, OMA-2, Ogonyok and OZS-23.

There is an improved type of these electrodes - E42A brand UONI-13/45 . They are used for welding metal structures that require increased reliability and operate under large alternating loads, including at low temperatures. And also for thick sheet materials. The technical characteristics of E42A electrodes require welding only with direct current with a short arc, excluding damp rods.

Restrictions on use

You cannot use AC welding, or weld vertical seams from top to bottom. Not suitable for welding high-alloy and stainless steels, cast iron and non-ferrous alloys.

Damp electrodes E42A will not allow you to work at all. The coating begins to conduct current and the arc ignition conditions deteriorate greatly; in addition, the weld becomes saturated with hydrogen, which leads to porosity. The electrode will stick .

Damp electrodes cannot be used for another reason. When the arc burns, due to strong heating, the moisture will boil in the coating and it will begin to crack (burst) and fall off the electrode . The amount of slag will become insufficient to protect the weld pool and at the same time the arc burning conditions will worsen.

Attention! Consumers often overlook the need to dry electrodes, which leads to failures and defects.

Coverage options

The above characteristics mainly depend on the coating option:

- Sour.

The basis is oxides of elements such as silicon and iron, and also contains manganese oxide. The resulting compound is characterized by an increased tendency to hot cracks. - Rutile.

The basis of the coating layer is titanium dioxide.

E42A electrodes with this type of coating help to obtain a connection that is more resistant to cracking, in contrast to an acidic coating. In addition, the use of a rutile layer ensures stable and strong arc combustion and helps reduce metal waste during spattering. Due to the rutile coating, the slag crust is better separated and the seam is formed well. - Basics.

Fluorine compounds in combination with carbonates are used as a basis. The chemical composition of the deposited layer corresponds to that of mild steel. The weld material is characterized by significant ductility, as well as high impact strength at standard and low temperatures; it is resistant to the appearance of hot cracks.

Analogues of electrodes E42

If necessary, these products can be replaced with similar ones. The main thing is that for new electrodes the chemical composition of the welded wire is close to E42. For welding wires of these electrodes, grades Sv-08 and Sv-08A are provided. Using E42, you can join carbon and low-carbon steels. The resulting seams are characterized by high viscosity and plasticity. These electrodes are used primarily when it is necessary to form a weld with a temporary tensile strength of up to 50 kg/mm. sq.

If higher values of weld metal are required, the welder should use a different type of electrode. The filler material ANO-6 is widely used. These electrodes are equipped with rutile coating. Their working diameters vary between 4-6 mm. Using this grade, the edges of the steel products being joined do not need to be cleaned. A short or medium arc is provided for work. When welding fillet welds, the craftsman should hold the electrode at an angle of 50 degrees. The use of ANO-6 ensures the absence of mini-pores and cracks in the seams. You can also select other analogues for E42. One of them is E42A electrodes. The tensile strength of these products is 412 MPa.

Also, depending on the tasks performed, the welder can use the following brands of E42 type electrodes:

- "Spark." Using these electrodes, steel products with a thickness of 1 to 3 mm are connected. In addition, Ogonyok electrodes can be used for top-down welding.

- "ANO-6M". Welding work is carried out using a short or medium arc. Spattering is minimized.

- "ANO-17". These electrodes are intended for joining thick metals. Their use is characterized by the formation of long welds.

- "WCC-4". This brand is used for welding work with pipelines.

- "VSC-4M". Using these products, pipeline joints are processed.

- "OZS-23". With their help, you can perform welding work in steel structures that have a small thickness. Electrodes have low toxicity.

- "OMA-2". The welder uses an extended arc. Using these electrodes, you can weld vertical metal structures, the thickness of which varies between 0.8-3 mm. This filler material is characterized by low melting ability. Welding work with OMA-2 is carried out on an oxidized surface.

Swedish filler materials OK-4600, OK-4332, OK Pipeweld-6010 are considered very high-quality analogues of E42 type electrodes.

Interpretation, features and purpose of E42A electrodes

Explanation of the designation:

- Electrode type - E. The letter is considered the official designation of the consumable material.

- 42 - the numbers indicate the tensile strength and are measured in Megapascals. The calculation is based on 1 square mm of seam section. The finished seam can withstand tension up to 40 kg.

- A - electrodes with this letter are considered an improved analogue of E42. They have better properties important for welding, namely chemical composition, ductility and toughness.

Before you start working with these consumables, you need to know the features and specifics of their use:

- After completion of work, the slag crust is easy to remove.

- You do not need to have extensive practical experience to work with E42A electrodes.

- Economical consumption.

- The finished weld has high ductility and strength. It can withstand significant fracture loads.

- Optimal price/quality ratio.

- The arc ignites easily.

- Variety in terms of choice of diameters (from 4 to 12).

- Can be combined with a large number of flux coatings.

- The seam formed during welding with these consumables is uniform. If the technology has been followed according to all the rules, it will not have pores or voids.

Important! Regardless of the diameter of the electrodes of this brand, they cannot be used to make seams from top to bottom. It is also necessary to use welding only with reverse polarity.

Consumables for welding machines of this type are common in the construction market due to the fact that they produce high-quality connections for parts made of low-carbon steels. They are common in construction and various industries. However, when working with high-carbon steels, the weld turns out to be of poor quality. During operation, cracks appear at the connection, which will gradually render the structure unusable.

Using these consumables, you can carry out installation work on uncleaned surfaces. They can be used to connect both thin and thick sheets of metal. Before you start joining parts more than 4 mm in thickness, you need to prepare the edges. To weld parts with a thickness of more than 8 mm, it is necessary to use electrodes with a diameter of 8 mm.

Important! To prevent the metal from flowing down the seam and lingering on it, the current should be reduced when working.

With initial drying and calcination, the arc will light without problems for the first and subsequent times. When melting metal on consumable elements, it does not spread and creates a tight seam. The disadvantage of E42A electrodes is that they have poor ductility. Because of this, seams on thin metals are unreliable. To compensate for this disadvantage, you need to use flux.

E42 electrodes are used in industry and private production. When using them, metal structures are created and work of low responsibility is carried out. They are often required in workshops specializing in repairs. It is important to use E42 electrodes if a large number of parts made of metals with low carbon content pass through the workshop. Can be used to repair gas and water pipes. Important conditions in this case are thin pipes and low gas or liquid pressure in them.

Acquaintance

Electrodes E42 (GOST No. 9466, 9467) are metal rods equipped with a special coating. During welding operations they are used as auxiliary filler materials.

The range of these products on the modern market is quite wide. The consumer can purchase E42 electrodes with a diameter of 1.6 mm, 2-3 mm and 4-6 mm. Standard sizes of auxiliary products vary between 250-400 mm. The length of E42 electrodes with a diameter of 4 mm can reach 450 mm.

Product Features

- Electrodes of this type, despite their overall dimensions, have unchanged chemical composition, physical properties and mechanical characteristics. When carrying out welding work with the same material, the master can use filler substances of different lengths. This will not affect the quality of the connection in any way.

- Judging by consumer reviews, the slag crust formed as a result of crystallization of the seam is easy to remove.

- If all the rules of welding technology are followed, then the weld is characterized by uniformity: there are no micropores or voids in it.

- The seam has strength and ductility.

- The welding process using these electrodes is quite simple. During work, there is no spreading of the hot deposited material over the surface and no strong splashing of the hot metal. Therefore, even a non-professional welder can use electrodes of this type.

- When using E42, many consumers noted rapid ignition of the arc, which is characterized by stability.

- Using E42 electrodes, you can connect rusty and wet metals.

- The quality of welding work does not depend on the arc length and voltage drops. The source can be either alternating or direct current. In the latter case, welders use reverse polarity.

Some consumers are interested in the question of whether it is possible to use E42 type electrodes to connect stainless steel parts? According to experienced welders, for high-quality welding of stainless steel products, it is necessary to use only those filler materials that are characterized by a proportional content of chromium and nickel. Electrodes of type E42 are not suitable in this case. The resulting seam will have reduced mechanical properties and be subject to corrosive processes. As a result, such welding will be pointless.