Wood lathes are one of the oldest power tools. Not a single carpenter can do without it. Probably, it is for this reason that in the modern electrical equipment market you can find a wood lathe for the home in a wide variety of designs: specifications and prices vary, and it’s easy to get confused. And since woodworking has made significant progress in recent years, many home craftsmen prefer to have such equipment at their disposal. Fortunately, you can purchase it at a very reasonable price. Moreover, manufacturers of woodworking equipment are ready to offer wood lathes in a very wide range. Our review is intended to tell the user about the most popular models offered by the market. Let's take a look at the best woodworking machines for your home workshop!

Photo: https://www.youtube.com/

Content:

- Screw-cutting lathe CALIBR STD-450/1000

- Vertical turning lathe ZUBR ZSTD-350-330

- Screw-cutting lathe STAVR STD-400

- Screw-cutting lathe Enkor Corvette-76

- Screw-cutting lathe Performax PWL-1440L (909001M)

- Wood lathe Corvette-73

- Wood lathe JET JWL-1015

- Screw-cutting lathe CALIBR STD-400

- Screw-cutting lathe BELMASH WL-300/450VS (S079A)

- Wood lathe Enkor 90740

Screw-cutting lathe CALIBR STD-450/1000

Photo: market.yandex.ru

The top wood lathe for the home is the woodworking lathe Caliber STD 450/1000. It is designed for turning or sanding wood products up to 1000 mm long. A wood lathe finds its application in small-scale and individual production. Operates from an electrical network with a voltage of 220 Volts. The machine is installed on a workbench or table. Four spindle speeds allow you to choose the optimal approach to processing. The painted metal body prevents corrosion.

Screw-cutting lathe CALIBR STD-450/1000

Advantages:

- Long workpiece length

- Light weight

- 4 spindle speeds

- Special holes for mounting to a workbench

- Asynchronous motor

- Easy use of the machine

Safety precautions when using lathes

If you purchased a lathe and installed it correctly, then there is no need to rush to use it right away. First you need to learn about the rules for operating this equipment. Operating safety requires compliance with all requirements and recommendations contained in the operating instructions for this equipment.

Before turning on the machine, it is necessary to check the serviceability of the devices that provide user protection. If during its inspection any defects in the equipment or protective devices with which it is equipped were identified, then in this case the malfunctions that have arisen should be eliminated. To do this, you must first disconnect the equipment from the electrical network, and then perform all the necessary manipulations. The workplace must be free of workpieces and objects that could interfere with the implementation of necessary activities.

Another important point in safety precautions is that the machine must be in a stable position. To do this, place it on a flat and hard surface . The wiring must be routed in such a way that it does not interfere with the work process. The room in which the lathe is used must have good lighting conditions. The equipment must be installed in such a way that there is sufficient space for its maintenance during operation.

Under no circumstances should the machine be left running unattended. If you need to leave the workshop, you should turn it off. When processing a workpiece, you should carefully inspect it before securing it in the machine and remove nails and foreign objects, if any, in it.

Turning operations on equipment should only be performed using well-sharpened cutting tools. Before processing the workpiece, you should make sure that it is securely fastened. Before turning on the lathe , you should make sure that the workpiece is clamped securely. If the workpiece is curved or large in size, then it must be processed on turning equipment at minimum speed.

Vertical turning lathe ZUBR ZSTD-350-330

Photo: market.yandex.ru

The rating of wood lathes for the home continues with the BISON ZSTD 330 model. This is a very compact tool designed for turning cylindrical wood blanks. Electronic adjustment of the spindle speed allows you to effectively perform this or that operation without overloading the engine. The small dimensions of the machine allow it to be transported in a passenger car. It is widely used in everyday life and carpentry workshops. The manufacturer ZUBR produces the best wood lathes!

Vertical turning lathe ZUBR ZSTD-350-330

Advantages:

- Small dimensions

- Metal structure

- Simple controls

- Economical in terms of power consumption

- Electromagnetic switch

- Faceplate for processing large workpieces

Important indicators of turning equipment

Mini-machines designed for wood processing have a whole set of important parameters that you should know and take into account when choosing this equipment.

Power - it talks about the performance of a particular model, and also indicates the amount of electricity consumed by the equipment during its operation. For mini-lathes for desktop use, this figure is 350 W.

Spindle rotation speed - this parameter largely depends on the accuracy of material processing and its hardness. The rotation speed of modern models of woodworking machines varies from 400 to 3500 rpm.

Along with the parameters listed above, the cost of turning equipment for domestic use is no less important. Currently, the market offers a large selection of machines for household use, so every home craftsman can choose equipment that is suitable for price and functionality. When choosing a lathe, you should consider not only the price, but also the quality of the equipment.

Screw-cutting lathe STAVR STD-400

Photo: market.yandex.ru

Our review also did not ignore the wood lathe for home model Stavr STD-400, which has special holes for installation on a workbench. The faceplate and screw quill make it possible to secure workpieces with a diameter of up to 300 mm and a length of up to 1 meter. The movable handle allows you to rigidly fix the supports for the cutter. Thanks to the magnetic switch, the model is protected from spontaneous start-up after an emergency power outage. The small wood lathe has four spindle speeds, which are changed by moving a belt on two pulleys. High build quality ensures long service life.

Screw-cutting lathe STAVR STD-400

Advantages:

- For installation on a workbench

- Frequency – 50 Hz

- Network cable length 3 m

- Easy to transport

- Does not require special maintenance

- Faceplate for processing large workpieces

- Magnetic switch

- 4 spindle speeds

Purpose

The machine is used to process rotating parts by applying cutting tools to them. The workpiece is clamped on both sides by a faceplate and a chuck. A cutter is fed into the working area, which has 2 freedoms of movement - along and across the workpiece. If you attach a drill to the chuck, you can make an axial hole .

Using this equipment, the following operations are performed:

- processing flat surfaces using a faceplate;

- longitudinal turning of wooden parts;

- facing, rounding and trimming the workpiece at various angles;

- axial drilling.

Screw-cutting lathe Enkor Corvette-76

Photo: market.yandex.ru

If we consider a wood lathe in the price ranking, the leader here is the Enkor Corvette-76 90760 lathe - this is convenient equipment for processing wood workpieces of any species. On such a machine you can not only grind parts, but also grind or polish the surfaces of workpieces. The adjustable support and tool holder expand the machining capabilities. The machine is installed on wide legs and is stable.

Screw-cutting lathe Enkor Corvette-76

Advantages:

- You can install a copier

- Magnetic starter prevents spontaneous start-up of the machine after a temporary power outage

- Capable of grinding and polishing

- Small dimensions

Features of working on a homemade lathe

Many home craftsmen with extensive experience make such devices on their own . This is a good option for those who are well versed in turning. Of course, it will not be possible to turn complex parts on a homemade lathe, but the most primitive workpieces of the simplest geometric shapes can be made without much difficulty. Using a homemade turning device, you can turn parts of the following shapes :

- Ball;

- Cylinder;

- Cone;

- Cube;

- Prism;

- Prism with a truncated apex.

When working on such a device, you need to pay special attention to safety precautions . If the machine is not made correctly, you can easily get injured. Details about safety precautions when working on a homemade machine can be read in textbooks for students of vocational schools.

Screw-cutting lathe Performax PWL-1440L (909001M)

Photo: market.yandex.ru

In the rating of wood lathes for the home based on reliability, we included the JET Performax PWL-1440L 909001M household lathe. This equipment is a household-grade model for turning wooden workpieces with dimensions up to 350x1000 mm: balusters, furniture legs, racks and supports. A wood lathe for the home is used in home workshops. 4 pairs of pulleys allow you to set the most suitable mode of rotation of the faceplate - 800 rpm, 1180 rpm, 1700 rpm or 2500 rpm. Power consumption is 350 W. The tailstock is made of cast iron, its quill stroke is 25 mm. The material of the frame is steel. The base of the machine has holes for rigid fixation on the workbench.

Screw-cutting lathe Performax PWL-1440L (909001M)

Advantages:

- 4-speed belt drive

- Fixing the tool rest and tailstock with rotating handles

- Lightweight frame made of steel profiles

- The spindle is threaded for installation of the drive center and faceplate, which are included in the package

- The motor is asynchronous without brushes, requires no maintenance and is designed for a long service life

- The tailstock is made of cast iron, is fixed to the frame with a threaded clamp and has a movable quill equipped with a center rotating on a bearing

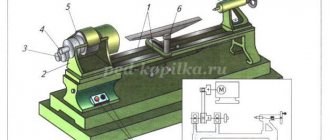

Design and principle of operation

Like any industrial lathe, the main element of equipment for domestic use is the bed. components of this equipment are attached to it . The most important ones include:

- a headstock equipped with a rotating spindle;

- rear locking headstock;

- movable thrust bearing.

The headstock, or, as it is often called, the driving chuck, is designed to rotate the workpiece. To securely fix the parts, use a tailstock. By means of the thrust bearing, the optimal choice of distance to the workpiece is ensured.

Wood lathe Corvette-73

Photo: market.yandex.ru

The Corvette-73 home workshop lathe is lightweight. The machine bed is made of angle and sheet steel. This significantly reduces the weight of the machine and its cost. A lathe with a center distance of 1000 mm becomes more accessible to private consumers. The mini woodworking machine for home has 4 spindle speeds. Speeds are changed by rearranging the belt on stepped pulleys. The design of the machine provides holes for attaching the machine to the workbench. The maximum length of the processed workpiece is 1000 mm. The maximum diameter of the workpiece to be processed above the bed is 350 mm. The maximum diameter of the workpiece above the tool rest mount is 300 mm. Transmission - belt.

Wood lathe Corvette-73

Advantages:

- Economical electric motor

- Ease of use of the machine

- The machine does not require special maintenance

- The machine is lightweight and suitable for transportation in a car

- Belt drive protects the engine from overloads

Jet woodworking machines for industrial use.

Jet wood lathes for woodworking shops and carpentry shops are massive equipment on cast iron adjustable feet, designed for turning and grinding large/heavy workpieces. The price of wood lathes for professional, stationary use is from 52 thousand rubles. up to 353 thousand rubles.

Technical parameters of the machines:

Jet JWL-1443 The machine is equipped with an asynchronous motor with cooling fins, has a power of 0.75 kW and provides processing of parts up to 1 m with a rotation speed of 500-2200 rpm. The V-belt variator allows you to select one of 10 fixed speeds without stopping the machine. The model weighs 103 kg and is equipped with a rotating headstock, a 3-axis adjustable tool rest, a set of support legs, and a tool tray.

Jet JWL-1440VS High-performance wood lathe weighing 100 kg with a large processing area, center distance 1016 mm. It is equipped with an asynchronous motor (1.3 kW) with a variator for stepless speed control within the range of 350-2500 rpm.

Jet JWL-1642 Machine weighing 190 kg and power consumption 2 kW. Made with a center distance of 1090 mm and a rotating headstock, it has a rotation speed controller up to 3200 rpm. The frequency converter allows you to smoothly change the rotation speed, the value of which is displayed on the digital display.

4224B Powermatic Model with a center distance of 1067 mm, weight 395 kg, power consumption 3.6 kW, 3-stage speed control (40-3500 rpm). The vacuum workpiece fixation system allows you to hold the part without damaging its back surface.

3520B Powermatic New in the line of wood lathes for processing large diameter workpieces. Model weighing 286 kg with a center distance of 876 mm, 2.6 kW engine, electronic speed control in the ranges of 50-1200 rpm, 125-3200 rpm. with digital display.

High-performance models of professional Jet wood lathes are equipped with a movable headstock with the ability to rotate 90° / 360°, a rotating tool rest for turning tools, a rotating stop center and fixed centers for holding the workpiece sample. Smooth speed control using a variator and belt drives allows you to obtain high torques in the process of turning large workpieces. Options for floor-standing Jet models include extensions for the frames and convenient hand rests.

Wood lathe JET JWL-1015

Photo: market.yandex.ru

The JET JWL-1015 home woodworking lathe is used for turning small wooden pieces - elements of drawers, decorations, dishes. The small dimensions of the machine allow it to be placed on a workbench about 1 meter long. Thanks to the movable tailstock, the operator has the opportunity to work with workpieces of different lengths. Reinforced spindle bearings are highly wear-resistant, which increases the overall service life of the machine. To switch from one speed to another, the operator moves the serpentine belt to one of 6 possible positions - this operation does not require special tools and does not take much time.

Wood lathe JET JWL-1015

Advantages:

- Tailstock quill stroke 50 mm

- 24 indexing positions

- Option – bed extension up to 533 mm

- Rotation diameter above support 185 mm

- Output power 370 W

- Massive cast iron bed

- Eccentric fixation of toolrest and tailstock

Methods for securing the workpiece

Two methods can be used to secure a part on turning equipment.

- Between the centers of the headstock and tailstock.

- Using a faceplate.

The first method of fastening is the most common. Most often it is used for processing short bars without the need for end processing. With this method of fastening, the accuracy of fastening is of great importance. It is important that when the workpiece rotates, there is no situation of part runout. To eliminate this, use an angular center finder.

The second method is more reliable, which is used in cases where processing of the ends of the workpiece is necessary. It differs from the first fastening method in that it is fixed using bolts or chuck teeth. This fastening ensures reliable retention of the part when performing comprehensive turning of the workpiece.

A lathe designed for processing wooden blanks differs from a metal lathe by the presence of a manual feed of the cutter, which is a chisel or other cutting tool for wood. It is secured only if a copier is used . In all other cases, when processing a workpiece, the chisel is held by the master. He also controls it manually, relying on the thrust bearing when performing the operation. The only thing that is done automatically is the spindle rotation speed.

The whole process takes place in two stages. First, roughing is performed, which is performed at an angle of 15-30 degrees. Upon completion, finishing is carried out at an angle of 45 degrees. When performing both operations, the chip thickness should be no more than 1 mm.

Screw-cutting lathe CALIBR STD-400

Photo: market.yandex.ru

Wood lathes caliber STD-400 are used for turning or sanding wood products. Smooth speed control allows you to perform this or that operation as efficiently as possible without overloading the engine. The machine is installed on a workbench or table - you can choose the optimal height to suit the operator’s height. The quick-release clamp of the support support and the tailstock travel stopper are made of high-strength plastic with metal bushings. Smooth adjustment, magnetic table made of cast iron - reliable, stable, durable. If you want to buy a wood lathe for your home, then take a look at this model.

Screw-cutting lathe CALIBR STD-400

Advantages:

- Easy to use

- Does not require special maintenance

- Economical in terms of energy consumption

- Rigid bed ensures precision machining

- Spindle thread 1 (25.4mm) 3.0

- Maximum reach of support caliper 125mm

- Hand rest width 180mm

- Maximum quill stroke 55mm

- Small dimensions and weight

Screw-cutting lathe BELMASH WL-300/450VS (S079A)

Photo: market.yandex.ru

The Belmash lathe BELMASH WL-300/450VS S079A is used by home craftsmen and carpenters in small industries. Ground guides guarantee smooth processing. The design allows turning workpieces with a diameter of up to 305 mm and a length of up to 455 mm. Depending on the task being performed, as well as the hardness of the material, the user has the opportunity to choose one of three possible speed ranges: 450-1100 rpm, 960-2400 rpm, 1400-3500 rpm. The range is adjusted by moving the belt. There is a handle for smooth adjustment of speed in a given range. The long service life is due to the high strength of the structure. The headstocks (front, rear), tool rest and bed are made of cast iron.

Screw-cutting lathe BELMASH WL-300/450VS (S079A)

Advantages:

- Commutator motor with quick-change brushes

- Hand rest length 200 mm

- Stable design

- Long service life

- Ease of use

- Compact body

- Cast iron bed reduces vibration levels

Wood lathe Enkor 90740

Photo: market.yandex.ru

The Enkor Corvette-74 90740 lathe is used for turning, grinding and polishing wood workpieces of any species. The machine is economical in terms of power consumption and efficient. Continuous speed adjustment facilitates fine tuning depending on the operation (roughing, finishing, grinding). The massive structure stands stably on four legs, reinforced with cross bars.

Wood lathe Enkor 90740

Advantages:

- Equipped with a powerful asynchronous motor

- Magnetic starter prevents spontaneous start-up of the machine after a temporary power outage

- Belt drive protects the engine from overloads

- Smooth adjustment of spindle speed using a variator

- Possibility of installing a copier

- For processing workpieces of relatively large diameter and short length, the machine is equipped with a faceplate

- The headstock rotates to handle larger diameters without being above the bed

- Adjustable tool holder

- Base included as standard

#Top 10

Read us first - add the site to your favorite sources.

Add a comment

{"commentics_url":"\/\/express-novosti.ru\/comments\/","page_id":1413040,"enabled_country":false,"enabled_state":false,"state_id":0,"enabled_upload": false,"maximum_upload_amount":3,"maximum_upload_size":5,"maximum_upload_total":5,"securimage":true,"securimage_url":"\/\/express-novosti.ru\/comments\/3rdparty\/securimage\ /securimage_show.php?namespace=cmtx_1413040″,”lang_error_file_num”:”\u041c\u0430\u043a\u0441\u0438\u043c\u0443\u043c %d \u0444\u0430\u0439\u043b\u043e\ u0432\u043c\u043e\ u0436\u0435\u0442 \u0431\u044b\u0442\u044c \u0437\u0430\u0433\u0440\u0443\u0436\u0435\u043d\u043e.","lang_error_file_size":"\u041f\u043e \u0436\u0430\u043b\ u0443\u0439\u0441\u0442\u0430, \u0437\u0430\u0433\u0440\u0443\u0437\u0438\u0442\u0435 \u0444\u0430\u0439\u043b \u0440\u0430\ u0437\u043c\u0435\u0440\u043e \u043c \u043d\u0435 \u0431\u043e\u043b\u0435\u0435 %d MB.","lang_error_file_total":"\u041e\u0431\u0449\u0438\u0439 \u0440\u0430\u0437\u043 c\u0435\u0440\ u0432\u0441\u0435\u0445 \u0444\u0430\u0439\u043b\u043e\u0432 \u0434\u043e\u043b\u0436\u0435\u043d \u0431\u044b\u0442\u044c \ u043d\u0435\u0431\u043e\u043b\ u0435\u0435 %d MB.","lang_error_file_type":"\u041c\u043e\u0436\u043d\u043e \u0437\u0430\u0433\u0440\u0443\u0436\u0430\u0442\u044c \u0442\u0 43e\u043b\u044c ""lang_text_loading":" u0437\u043a\u0430 ..","lang_placeholder_state":"\u0420\u0435\u0433\u0438\u043e\u043d","lang_text_country_first":"\u0421\u043d\u0430\u0447\u0430\u043b\u0430 \u0432\u044b\u04 31\u0435 \u0440\u0438\u0442\u0435 \u0441\u0442\u0440\u0430\u043d\u0443″,”lang_button_submit”:”\u0414\u043e\u0431\u0430\u0432\u0438\u0442\u04 4c","lang_button_preview":" \u041f\u0440\u0435\u0434\u0432\u0430\u0440\u0438\u0442\u0435\u043b\u044c\u043d\u044b\u0439 \u043f\u0440\u043e\u0441\u043c\u 043e\u0442\u0440″,”lang_button_remove ":"\u0423\u0434\u0430\u043b\u0438\u0442\u044c","lang_button_processing":"\u041f\u043e\u0434\u043e\u0436\u0434\u0438\u0442\u0435..."}