In order to increase the strength and hardness of materials, they are subjected to heat treatment: they are heated and kept in a thermal oven and cooled. But this method is not always suitable. In particular, it is not used for metals such as copper and aluminum.

Then cold hardening is used - a technological treatment that involves changing the shape of the product through cold plastic deformation. At the same time, the hardness and strength of the material increases, but its ductility - the ability to deform without destruction - decreases.

Cold hardening and cold hardening

For some alloys, cold hardening is the only possible way to increase strength. Such alloys, for example, include corrosion-resistant alloys of chromium and nickel.

The study of a process such as cold hardening (hardening of metal) is one of the important and interesting problems of materials science. For example, as a result of cold hardening, the hardness of the surface layers of steel increases several times.

The terms cold hardening and cold hardening are often considered almost synonymous, meaning:

- the process of changing the structure of the material;

- increasing its hardness and strength as a result of these changes.

But in some literary sources these terms are distinguished: cold hardening is a process that can be either spontaneous or purposeful, while cold hardening is a deliberate process, the purpose of which is to strengthen the metal.

From this point of view, cold hardening can be a process both useful and harmful, and cold hardening is a process that can only be useful.

As the temperature increases, the cold hardening ability decreases noticeably. For example, cold hardening of aluminum is impossible at temperatures above 200 °C. This temperature (recrystallization temperature) will be different for different substances. For low-melting metals (including zinc, lead, tin), the recrystallization temperature can be negative.

Process description

Let us consider the essence of the phenomenon of cold hardening. As is known, almost all metals and their alloys (for example, aluminum or copper and their alloys) have an ordered crystalline structure. But it's not that simple. They consist of grains, within which the arrangement of atoms is ordered. But the grains themselves are located chaotically in relation to each other, that is, disordered.

Under mechanical load, dislocations (microscopic defects) appear in the structure of the substance. As the load increases, dislocations move and interact with each other.

Another structure is formed. It resists the deformation that remains after the load is removed (plastic deformation). The ability of the metal to resist deformation increases.

But it should be borne in mind that with cold hardening, the plastic properties of the material become worse. For example, the ductility of low-carbon steel decreases by 5-6 times. The resistance to plastic deformation also decreases when its sign changes (the so-called Bauschinger effect).

After hardening, the state of the substance is thermodynamically unstable. If ductility needs to be increased, hardening is removed by recrystallization annealing, heating the material above the recrystallization temperature. In this case, the material goes into a more stable state. The need to remove hardening arises, for example, in metallurgy during the production of wire or tape.

The dislocation density increases during work hardening, which leads to a decrease in bulk density. In this case, the metal grains are stretched in the direction of the forces that act on them. This grain orientation is called deformation texture. Due to texture, anisotropy of the mechanical properties of metals and alloys occurs.

The following conclusions can be drawn:

- after cold hardening or hardening, the hardness and strength of the material increases;

- The fragility of the material also increases.

In particular, cold hardening of steel is relevant for products in which it is necessary to prevent surface cracking and such phenomena as metal fatigue, which leads to the accumulation of internal stresses, the occurrence of cracks, and ultimately to the destruction of the material.

Types of hardening

Basically, there are two types of cold hardening:

- phase, when changes in the crystal lattice are caused by phase changes;

- deformation, when lattice changes are caused by external forces.

The formation of deformation hardening occurs when the surface being treated is exposed to balls or a stream of pellets.

Hardening equipment

Equipment for the process of cold hardening of aluminum and other metals and alloys is quite diverse. In industry, cold hardening is a fully automated process that is performed on electronically controlled devices.

In particular, when deformation hardening is formed, the number and feed rate of pellets is automatically adjusted.

Application

In industry, cold hardening is used to impart strength to products made of stainless steel, copper, aluminum and its alloys. This is very important for mechanical engineering, since various components and mechanisms often operate in unfavorable conditions and wear out over time.

Mechanical hardening

Hardening of parts is the deliberate distortion of the crystal lattice of a metal as a result of mechanical action, thermal and thermomechanical treatment.

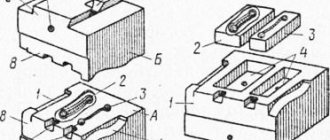

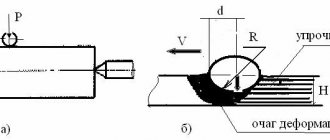

The essence of this processing is that under the pressure of a solid metal tool (roller, ball, smoothing broach or piercing), protruding micro-irregularities of the processed surface are plastically deformed, while the surface roughness decreases, the surface layer of the metal is strengthened, residual compressive deformations are created on the surface of the part - it turns out hardening

Container ship Charlotta B, Gulf of Finland Source: www.shipspotting.com

Plastic deformation is used to process:

- carbon;

- some special steels;

- cast iron;

- copper and aluminum alloys.

Rolling of parts Technological processes for increasing the strength and durability of ship parts are carried out by special rolling with balls and rollers made of hardened carbon or alloy steel under pressure. The knurls, rotating, capture oil and lubricate the inner surface of the race and the points of contact with the surface of the knurled part.

Oil circulates intensively inside the knurling housing, which ensures continuous abundant wetting of the surface (ball, roller) with oil and its cooling. A ball or roller, transmitting pressure to the points of contact with the part, increases the wear resistance of steel parts by 25-80%, the corrosion endurance limit by 2 to 2.5 times when parts operate in chemically active environments.

The use of two or more balls or rollers at the same time prevents deformation of thin workpieces. Maximum rolling speeds up to 80-100 rpm, feed to ensure high roughness up to 0.5 mm/rev, pressure required to improve the surface roughness of steel parts, for example for steels 45-50G - 4-8 MPa.

Hardening is a hardening method based on the principle of dynamic impact of balls (rollers) on the surface being processed. This uses the centrifugal force of balls (rollers) that sit freely on the radial holes of a rapidly rotating disk mounted in the spindle of a grinding machine or a specially adapted lathe.

Container ship Baltic Tern, Gulf of Finland Source: www.shipspotting.com

The required surfaces of ship parts can be hardened using ball hardeners on lathes, cylindrical grinders and other metal-cutting machines, having previously treated the surfaces by fine turning or grinding.

Hardening increases the fatigue strength of parts by 2-4 times. The hardness of the hardened surface layer increases on average when processing steel 25 by 45%, cast iron by 30-60%, brass by 60%, silumin by 60%. The depth of hardening reaches 0.6–0.8 mm or more.

During the work hardening process, the required tension is ensured by installing the hardener at a certain distance from the part using a transverse screw of the support or machine table. When strengthening the outer surfaces of parts, various designs of ball hardeners are used. The hardener body is made of steel 45 (hardness 30-35 HRC). Balls for strengtheners are used with a diameter of 15 to 16 mm.

Diamond smoothing of shaft surfaces is carried out on lathes with a special tool - a diamond smoother. The tool is secured either rigidly or elastically. When rigidly fastened, the diamond smoother is installed in the tool holder like a cutter, and its position relative to the workpiece is determined only by the kinematics of the machine.

By moving the caliper, the tool is brought into contact with the rotating shaft, it is fed to the required depth and the longitudinal feed is turned on. This method has the ability to increase the accuracy of the dimensions and shape of the smoothed surface, but subject to increased requirements for rigidity and for the accuracy of installation of the shaft and tool.

Burnishing with elastic fastening of the tool is carried out using a spring mandrel (Fig. 1), which is fixed into the tool holder of the lathe support.

Rice. 1 Mandrel for diamond smoothing: 1, 9 - diamond smoother; 2 - screw; 3 - bushing; 4 — body; 5 — indicator; 6 - spring; 7 - nut; 8 - adjusting screw; 10 - diamond grains-crystals

Using a transverse support, the spring mandrel is brought to the rotating shaft until the smoother touches the surface being processed and the required tension is set on the indicator according to the schedule, corresponding to this force. At the same time, its longitudinal feed is turned off. With this method, shape errors obtained during pre-processing are not corrected.

The working part of diamond smoothers consists of synthetic or natural diamond crystals, sharpened to a spherical surface. The burnishing force is in the range of 50-250 N and depends on the hardness of the material being processed, surface roughness, and burnishing radius.

Diamond burnishing increases:

- fatigue strength;

- wear resistance;

- contact endurance and corrosion resistance of treated surfaces.

Technology of cold hardening and cold hardening of metal

Hardening is a phenomenon in which the strength and hardness of a metal product increases. Changes in properties are achieved through plastic deformation. Metal hardening occurs at a high temperature, the value of which is not sufficient for recrystallization of the workpiece. This phenomenon can be both harmful and beneficial.

Hardening is a technological process that pursues the same goals as cold hardening. The main difference is that the latter phenomenon can occur as a result of conscious or unconscious actions.

For example, during machining by cutting with high speed and cutting depth, the surface acquires excess strength, which increases the fragility of the product. Cold hardening is only useful strain hardening, the use of which is deliberate.

The essence and purpose of cold hardening and cold hardening

As a result of plastic deformation, changes occur in the crystal lattice and phase composition of the material. The process of cold hardening of metal is accompanied by the formation of defects in the internal structure of the product. In this case, the properties of the material change as follows:

- resistance to mechanical damage increases (metal strengthening);

- the hardness of the material increases;

- resistance to dynamic loads is reduced;

- plasticity is lost;

- there is a decrease in resistance to plastic deformation with the opposite sign - this is called the Bauschinger effect.

Thus, the yield strength of the metal is reduced. This parameter determines the maximum stress on the product at which it will begin to deform plastically. If the degree of load does not exceed the permissible value, after the cessation of external forces, the metal will return to its previous state.

This parameter is especially important for cold-worked steel, which is used as the main material in load-bearing structures of various buildings and structures. The project is drawn up taking into account the maximum loads on individual elements and the object as a whole.

The study of the metal structure suggests that after exceeding the yield strength, the product receives strain hardening. To harden the surface by cold hardening, special equipment is used, which will be discussed below.

When exposed to steel and other ferromagnetic materials, an increase in the magnetic field strength is observed. This parameter is called coercive force. At the same time, the magnetic permeability of the product decreases.

The phenomenon under consideration helps to improve the performance properties of ductile metals. When cold-working aluminum and alloys based on it, a significant increase in hardness and increase in yield strength are observed.

The convenience of working with ductile metals lies in the fact that for cold deformation processing you can use any of the following methods:

- rolling;

- deep drawing;

- forging;

- flange.

In what cases is cold hardening used, and when is cold hardening used?

The physics of these processes is based on strain hardening of a metal product. The difference is this:

- Hardening is any strain hardening of metal, the effect of which can be both positive and negative.

- Hardening is considered only a process that is deliberately applied to a product in order to improve performance characteristics.

Technical documentation, including state standards, ANSI and ISO, does not contain the term peening. For example, deformation-hardened aluminum is called cold-worked aluminum. For this metal, the degree of processing is indicated by the letter H. It is followed by a numerical definition, which can contain from one to three digits.

Types of hardening

Strain hardening of metal is classified according to the processes that are activated in the workpiece during the formation of the work-hardened layer.

In the case of the formation of new phases that differ in a different specific volume, the phenomenon is called phase. If the cause of the changes is the action of external forces, hardening is called deformation hardening.

There are two categories:

- Centrifugal ball. The product is affected by balls that are located in the rim sockets of the installation. Its operating principle is based on rotation, when, under the influence of centrifugal force, the elements exert a mechanical effect on the workpiece being processed.

- Shot blaster. This method is based on the use of kinetic energy. Shots with a diameter of up to 4 mm, made of durable material: cast iron, steel or ceramics, are used as processing elements. According to technological requirements, the flow speed can reach 70 m/s.

Analysis of methods for hardening machine parts and cutting tools

UDC 621.924.093

Analysis of methods for strengthening machine parts

and cutting tools

,

Increasing the service life and wear resistance of machine parts and tools by hardening is an important task, the solution of which contributes to a significant increase in their durability and ensures savings in expensive and scarce materials, energy, and labor resources. In mechanical engineering, a variety of hardening methods are widely used, the choice of which depends on the properties of the cutting and processed material, operating conditions and the economic efficiency of using the hardening method.

composite hardening coatings,

laser hardening and alloying

,

electric spark alloying, epilation, magnetic pulse processing

INTRODUCTION

One of the most promising areas for increasing the reliability and durability of wearing parts of machines and tools is strengthening or modifying working surfaces by creating surface layers with higher mechanical and tribological characteristics.

An analysis of scientific sources has shown that surface hardening can be carried out using coatings, heat treatment or using various types of energy. At the same time, the experience of laboratory research and operating practice shows that it is difficult to choose a universal processing method, since each of them reveals its potential capabilities in a certain case, often in a very narrow range of operating parameters.

METHODS OF SURFACE HARDENING

parts FOR “HEAVY” friction modes

Units of products operating in “heavy” friction modes widely use surface hardening methods. The wear resistance of a friction pair is influenced by a complex of physical and mechanical characteristics: strength, plasticity and hardness. The surface layer has a special influence on wear resistance, since it absorbs loads and makes contact with the external environment.

On the other hand, the surface layers also have more defects (pores, microcracks, inclusions of an unusual crystalline structure, etc.) than the entire volume of the part.

During the wear process, the contacting surfaces must successfully resist plastic deformation, shearing - chipping of microvolumes of material, the introduction of solid particles (abrasive particles from the external environment, separated particles or build-ups during adhesion), as well as the effects of aggressive environments and temperatures.

The main impact is perceived by a thin surface layer, and the remaining cross-section of the material perceives only a small fraction, due to the inertia of the materials. Therefore, it is necessary to differentiate the physical and mechanical properties of the surface layers and the rest of the section, which is achieved by various methods of surface hardening.

Let's consider the most used methods, while taking hardness as the criterion for assessing the layers being strengthened - the only material characteristic obtained by non-destructive testing methods (table).

Table. Applicability of methods for surface hardening of parts depending on the hardness of the hardened surfaces

Table. The use of surface strengthening methods depending on hardness of strengthened surface

| No. | Hardening methods | Hardness, MPa |

| 1 | Surface plastic deformation (SPD) | 3000 ….5500 |

| 2 | Heat treatment (HT) | 5500 …. 7600 |

| 3 | Chemical-thermal treatment (CHT) | 5700 ….20000 |

| 4 | Boriding | 20000 ….22000 |

| 5 | Friction-diffusion hardening | 11000 …. 13000 |

| 6 | Electrospark hardening (ES) | 6500 …. 30000 |

| 7 | Weldable coatings | 6000 …. 16000 |

| 8 | Sprayed coatings | 6500 …. 3000 |

| 9 | Laser hardening (LU) | 7500 …. 13500 |

| 10 | Detonation coating | 10000 …. 14500 |

| 11 | Composite coatings | 6000 …. 22000 |

The table shows that the hardness of the coatings of the hardened layers is more than twice as high. However, the merits of the method cannot be fully judged by surface hardness alone. It is necessary to consider the positive and negative aspects of other methods when comparing the mechanical properties required for the application.

PPD – increases hardness, reduces ductility, and has low abrasive wear resistance.

TO – the “working” threshold of the wear regime is the temperature in the friction zone, which is C.

CTO – increases wear resistance, which is determined by the temperature resistance of chemical compounds. Thus, nitriding can withstand temperatures up to 600-650, and boriding up to 9000C and higher.

Welded and sprayed coatings are characterized by high wear resistance, which depends on the chemical composition of the applied coating, but requires sophisticated technology, including preparatory operations and operations to relieve internal stresses. For spraying, it is also necessary to introduce an operation to increase the adhesion strength of the coating to the base (thermal deformed delamination).

Laser hardening makes it possible to obtain thin layers that differ from the TO structure due to the high heating rates of the layers. The disadvantage of this hardening method is the low temperature threshold, which is about 2000 C.

Detonation treatment makes it possible to obtain a coating of higher quality than sprayed coating and does not require deformation resorption. The disadvantages of the method include the complexity of implementing the technological process and the difficulty of installing the part in the technological equipment.

Composite coatings are currently most widely used. Main advantages: the ability to obtain fairly thick layers (up to 4 mm); the use of wear-resistant powder compositions from hard alloys, relit, borides and special alloys; creation of coatings with solid lubricants, where graphite, molybdenum disulfide, sulfides, selenides, etc. are used as fillers.

Despite significant advantages, the methods have not been widely used due to a number of significant disadvantages: the complexity of the coating technology, including special preparation operations for sealing the hardening zone; use of high temperatures (up to 12000); temperature deformations and stresses are observed, since the entire strengthening system is heated; the use of expensive materials both as a matrix (silver, nickel, cobalt, copper) and as fillers (borides, carbides, hard alloy); the need to include operations to relieve internal stress.

Analyzing methods of surface hardening, it should be noted that by increasing hardness, we reduce ductility, which leads to a decrease in the danger of seizure of mating surfaces, on the one hand. On the other hand, a decrease in ductility increases sensitivity to local high pressures, which can even lead to local failure of the surface.

So, in the hardened surface layer it is necessary to ensure sufficient ductility, high hardness and strength. These requirements can only be realized in a composite coating, organizing a strengthened layer consisting of a plastic base (matrix) with solid inclusions.

METHODS FOR SURFACE HARDENING OF METAL-CUTTING

tool

The performance of a metal-cutting tool can be ensured only if its working part is made of a material with sufficient hardness, strength, wear resistance, temperature resistance and thermal conductivity. The coating applied to the working surfaces of the tool is a fairly universal and reliable means with which you can take a new approach to the problems of improving the properties of the tool material, increasing its performance and controlling the cutting process.

Tool material with a wear-resistant coating is a new composite type material that optimally combines the properties of the surface layer (high values of hardness, heat resistance, passivity in relation to the material being processed, etc.) and the properties manifested in the volume of the tool body (strength, impact strength , crack resistance, etc.). A hard alloy tool with a composite coating has a high resistance to adhesive-fatigue and diffusion wear at a temperature of C. The coating increases the resistance of a high-speed steel tool to abrasive and adhesive-fatigue wear, and significantly increases resistance to corrosion-oxidative wear [1].

Obtaining a coated tool using chemical and physical metal deposition has disadvantages: the complexity of the coating technology, including special preparation operations to seal the hardening zone and the use of high temperatures; temperature deformations and stresses as a result of heating; use of expensive materials.

To level out these negative aspects of the process, a scheme for applying a composite multilayer coating for carbide tools is proposed. The coating contains several intermediate layers, each of which has its own functional purpose: ensuring a strong connection of the multilayer coating with the working surfaces of the tool; implementation of adhesive bond between functional layers; performance of barrier functions, for example, increasing the thermodynamic stability of the coating at increased cutting speeds, etc. All compounds widely used as coatings are characterized by an increase in microhardness up to 2.5 GPa, but are quite brittle, which significantly narrows the scope of their application. Therefore, coatings made of nanomaterials are of particular interest. Surface coatings in the form of a thin film have characteristics that differ significantly from bulk (monolithic) material, and the thinner the film, the stronger it is [2].

Improvement of coated carbide is always aimed at combating the fragility of its surface layer. Recently, coatings called “Low stress coating” have been used; the technological process consists of applying a multilayer coating to a carbide substrate using standard technology. After this, the front surface of the plates is polished along the front surface, as a result of which the layer of titanium nitrides and the top layer of aluminum oxide with a thickness of only 2..3 microns from the total thickness of the coating are completely removed, which makes it possible to reduce the level of internal tensile stresses by 2 times and remove most of the crack nuclei [3].

Hardening of cutting tools made of high-speed and alloy steel by carbonitration in gaseous products, carbonitridation in hydrogen-free glow discharge plasma (GDT) increases the hardness, wear resistance and heat resistance of the tool. After nitriding, the tool can withstand temperatures up to 600-650, and when boriding - up to 9000C and higher. The diffusion layers obtained after carbonitration with a thickness ranging from several microns (for small-sized tools) to 0.01-0.02 mm ensure an increase in tool life by 1.5-2 times. Tests of cutting cutters, drills, taps, and reamers hardened by carbon nitriding have shown that their durability is 2-2.5 times greater than that of unhardened tools [4].

The use of a concentrated plasma jet with a power of 30 kW for surface hardening, generated by an indirect plasma torch with a sectioned interelectrode insert [5], provides hardening to a significant depth (3.0-3.5 mm). In this regard, it is of practical interest to harden small-sized tools (cutters, drills, dies, etc.) made of low-alloy tool steel 9ХФ and high-speed steel R6M5 during hardening with a powerful plasma jet. But the hardening process requires sophisticated technology, including preparatory operations and operations to relieve internal stresses.

Laser hardening (HL) of cutting tools made of high-speed and alloy steels is carried out by pulsed irradiation of the working edges of the tool on a laser technological installation [6]. In this case, the tool life can be increased by 1.5-3 times. Under the influence of laser radiation, rapid heating of the metal occurs in the region of the austenitic state and subsequent cooling of the metal. The strengthened layer has a particularly dispersed austenitic-martensitic structure. As a result, a layer 60-80 microns thick with microhardness N/mm2 is formed on the surface. But the LT process does not help maintain the level of plasticity required for the tool. Another disadvantage is the violation of the tool geometry due to melting without increasing the penetration depth.

Laser surface alloying is a promising technological method for ensuring and increasing the reliability of various tools (stamps, molds, cutting tools), the working surfaces of which have been subjected to pulsed laser alloying using paste-like compositions. After experiments, a process was introduced into production using a paste containing fine powders of boron and hard alloy with the addition of fluoride activators, mixed in glycerin until thick. The oxide film leads to a reduction in the time to achieve a fixed wear value in the running-in section along the tool’s rake surface by 2-3 times compared to an unhardened tool, to a significant expansion of the range of cutting conditions, and at the same time, the expected reduction in cutting temperature is 100-120°C.

A promising way to increase the durability of tools made of carbon and alloy steels is magnetic-pulse treatment of them with a low-intensity field at room temperature. But this method also has a number of disadvantages: limitations in application in terms of thickness and dimensions; dependence of the quality of processing on the magnetic permeability of the material. This is explained by the fact that magnetic pulse modes do not provide the required structure.

The electroacoustic spraying process, based on the combined use of electric spark discharge and ultrasound energy, increases the service life of high-speed tools. Mechanical longitudinal-torsional ultrasonic vibrations imparted to the electrode form an interelectrode gap upon contact with the surface being treated.

Electrospark alloying (ES) of drills, cutters and other cutting tools made of high-speed steel increases their durability by 1.5-2 times [6]. At the same time, EL has a number of disadvantages, the main one of which is the formation in many cases of an unacceptable level of residual tensile stresses and unacceptable roughness of the treated surfaces.

Increasing the durability of a cutting tool can be obtained by applying epilam to the surface of the tool - hardening the cutting tool by epilaming. Epilams are compositions consisting of a solvent or mixture of solvents that contain a surfactant (fluorine). From solution, the surfactant is adsorbed onto a solid surface in the form of a monomolecular layer, removing microhardness and, consequently, surface energy. When epilam is applied to the surface of a cutting tool, its wear resistance increases by 2-5 times. The extremely high chemical activity of fluorine is a significant disadvantage of epilation.

Currently, high-energy methods of surface hardening of the working profile of tool cutting edges, such as laser and plasma hardening, magnetic pulse processing, are used to a limited extent (mainly due to the high cost of equipment and the complexity of technological processes). The main methods of hardening blade tools still remain volumetric hardening and hardening with high-frequency heating, which are associated with warping of the working profile of the tool, the occurrence of thermal stresses and other disadvantages.

CONCLUSIONS

Numerous research results show the convincing benefits of tools and machine parts with new coatings and confirm the promise of new developments. Promising technologies for the near future include the combination of implantation with coating, as well as work in the field of combining heat treatment of products with coating.

The above allows us to conclude: the hardening methods under consideration have certain disadvantages; their use for parts and tools requires improvement of specific technological processes and further research; At the same time, it is necessary to search for new methods.

List of references used

1. Vereshchak cutting tools with wear-resistant coatings. – M.: Mashinostroenie, 1993. – 336 p.

2. Maslov high technologies: reference book // Engineering magazine. –2008. – No. 1. – P.10-24.

3. On the classification of coating application methods (terminological aspect) // Bulletin of mechanical engineering. – 1988. – No. 9. P.54-57.

4. , Matyushenko, aspects of technical hydrogenation of metals and its influence on wear resistance // Durability of rubbing machine parts. – 1986. – No. 1. – P. 191-195.

5. , Kravets of tool reliability by laser alloying // Bulletin of mechanical engineering. – 1987. – No. 1. – P. 44-46.

6. , Sidorenko, electric spark hardening treatment for wear of separation dies // Bulletin of mechanical engineering. – 1987. – No. 2. – P.53-55.

THE ANALYSIS of METHODS for strengthening MACHINE PARTS And CUTTING TOOLS

IT Syechjov, IA Sokolova

Threading the service life and wear resistance machine parts and tools by their strengthening is an important task the solution of which secures the economy of expensive and deficit materials, energy, labor resource. Mechanical engineering uses various strengthening methods, choosing of which depends on the properties of cutting material and material to be cut, performance and economical effectiveness and strengthening method.

with omposite strengthening plating, laser strengthening and alloying, electro-spark alloying, apyloming, magnet –impulse treatment

, candidate of technical

Sciences, Associate Professor, Department of Materials Processing Technology

Federal State Educational Institution of Higher Professional Education "Kaliningrad State Technical University", Russia, Kaliningrad, Sovetsky Ave., 1,

tel.: + 7

, Candidate of Pedagogical Sciences, Associate Professor of the Department of Materials Processing Technology

Federal State Educational Institution of Higher Professional Education "Kaliningrad State Technical University", Russia, Kaliningrad, Sovetsky Ave., 1,

tel.:

e-mail: *****@***ru

Dr. IT Syechjov, PLD, ass. prof. Mechanical Engineering department The Kaliningrad State Technical University

Russia, Kaliningrad, Soviet pr., 1, tel.: + 7

Dr. IA Sokolova, PLD, ass. prof. Mechanical Engineering department The Kaliningrad State Technical University

Russia, Kaliningrad, Soviet pr.,

1, tel.:

e-mail: *****@***ru

Technology of hardening and hardening of metal, tape, in Russia | MetalEnergoHolding

In the metal rolling industry, cold hardening or strain hardening is a controlled technological process that is used to increase the hardness of metals and increase their strength characteristics.

This technology is applied to those materials that cannot be refined by heat treatment. Hardening is not used to change the mechanical properties of rolled products made of copper, aluminum alloys, low-carbon steels, and chromium-nickel alloys.

For such materials, strain hardening is the only way to increase strength characteristics.

The definitions cold hardening and cold hardening are used to denote the process of changing the structure of the metal, as well as increasing its hardness as a result of external influence. At the same time, the concept of hardening includes both natural processes occurring in the structure of the metal and those controlled by special processing methods.

According to its origin, cold hardening can be:

- Phase. In this case, structural changes are caused by phase changes that occur as a result of heat treatment of the metal.

- Deformation. Strengthening and increasing hardness occurs as a result of the influence of external forces.

In particular, phase hardening (undesirable) occurs when cutting alloys that have ductility and softness. Too deep a cut with a large thickness of the workpiece, made at high speed, causes intense hardening, a decrease in the ductility of the metal, and an increase in fragility.

Unlike cold hardening, cold hardening is a controlled process. Hardening is not always beneficial. When hardening occurs, the plastic properties of materials decrease. For example, the ductility of low-carbon steel alloys is reduced by more than 5 times. At the same time, there is a decrease in the resistance of the metal to mechanical stress - tensile, tensile, compressive and bending loads.

Thermal and chemical-thermal treatment

To relieve internal stresses arising during surfacing and obtain a homogeneous metal structure, annealing, normalization and tempering are used. The wear resistance of parts is increased by surface hardening with heating by high frequency currents. Residual compressive stresses arise on the surface of the hardened layer, which contribute to increasing the fatigue strength of the parts. The use of hardening makes it possible to use relatively cheap materials and available protective environments for surfacing.

To increase the wear resistance of parts, chemical-thermal treatment (cementation, nitrocarburization, nitriding, etc.) is also used.