The drive-in anchor can withstand very high static loads for a long time and is optimal for installation in solid foundations made of concrete, brick or stone. Its design includes two bushings: one has grooves that ensure its deformation, and the second is a spacer part. For the manufacture of drive-in anchors, high-quality and corrosion-resistant metals are used: brass and stainless steel, steel alloys with anti-corrosion treatment. For stable fixation, the outer walls of the anchor are equipped with spikes.

Features of drive-in anchors

It’s worth starting with what distinguishes drive-in anchors from other tools for construction or repair. In other words, identify the features of this device.

The main difference between anchors and other fastening elements is the method of fastening.

- An unusual technology is used here, the essence of which is that the collet is not fixed in advance, but only at the moment when the rod element is driven into it.

- The very principle of attaching an anchor to a wall is not particularly technologically advanced and is based on the basic laws of physics studied at school.

- When a rod element is inserted into concrete or brick surfaces, the friction force acts quite strongly on the working fluid.

- Due to this, a special stop is triggered and the workpiece is secured.

Also, there are more equipped models with special fastenings. You won't have to strain too hard to attach the entire structure, just follow the instructions.

Application of products

Fasteners are designed for use in dense materials:

- solid brick,

- dense heavy concrete;

- natural stone.

Fasteners are not used when fixing to:

- cellular and porous concrete,

- concretes with inclusions, like slag concrete,

- For brick walls, you can only use products up to 8 mm.

The exception is the Zikon drive-in anchor. For him, porosity and the presence of shells are not an obstacle.

Fastening elements can be:

- metal and wooden suspended structures;

- equipment;

- consoles, hanging furniture;

- cable ropes, lamps;

- can be used for mounting suspended structures on the ceiling, but taking into account the fact that the resistance to vertical load of the product is low. It makes more sense to limit yourself to wall mounting.

This video shows the installation process of a drive-in anchor:

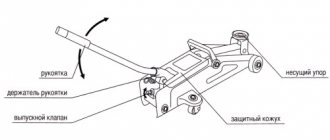

Components of this device

When the features and operating principles of drive-in anchors have been described in general detail, it’s time to talk about what it consists of. Overall, the design is not that complicated. There are only two defining details.

The first is a kind of conical bushing. It is equipped with a thread on one side. The caliber of this thread varies depending on the size of the fastener and the materials used in manufacturing.

- On the reverse side of the bushing you can find a special split element.

- It is used to drive a driven anchor through concrete or brick material.

- The element may consist of two or four parts, depending on the size of your copy.

- The second defining detail is the wedge-cone. This element is installed inside the bushing.

- Its main function is to give and maintain a conical shape to the anchor as it penetrates the wall.

Permissible loads

Working loads of all types of anchor fasteners should be no more than 25% of the maximum pull-out load when used in concrete with a strength of 200-250 kgf/cm

2

(corresponds to concrete grades M200 and M250). As the strength of concrete increases, the recommended load of fasteners increases proportionally. If there are cracks in the concrete, the pull-out load is multiplied by a factor of 0.6.

Types of drive-in anchors

Such mounts have been produced for quite some time. It all started, of course, with the most ordinary models, which were limited only to performing their main function - securing.

Now the most technologically advanced specimens with wide functionality and a wide range of applications have appeared.

- Basically, the classification is based on the principle of material. They mainly produce steel, galvanized, electro-galvanized and brass models. The first type is the most common and basic. It is reliable and without any special features.

- Steel hammer anchors are produced in a very wide range and can be found in almost any hardware store. The only noticeable disadvantage is that some unscrupulous manufacturers neglect to treat the workpieces with anti-corrosion liquid.

- This leads to the fact that the fasteners can quickly rust and fail. To avoid this, you need to check this point with the seller at the hardware store.

Galvanized models are, in general, similar to classic metal drive-in anchors. The main differences lie mainly in appearance. The specimens in question are treated with a special galvanized coating at the production stage.

This provides a characteristic shine, resistance to corrosion and sudden changes in temperature parameters. If fastening is carried out outdoors, then you do not have to worry about sudden changes in temperature or changes in air humidity.

Galvanized drive-in anchors easily withstand all these external irritants.

An extreme, but no less interesting model that will be considered is brass drive-in anchors.

- Brass, in itself, is not a very popular material in construction and industry for a number of reasons related to its physical characteristics.

- However, this soft metal is ideal for making a variety of fastening materials.

- If you need anchors not for industrial purposes, but simply for domestic use, then brass models are what you need.

- The metal has a pleasant appearance, is not afraid of corrosion and weighs a little.

- The best option for inexperienced builders or those who simply need a set of fasteners for work in a house or apartment.

There are several more exotic types of drive-in anchors, but only those models that have been tested by time are presented.

Classifications

Anchors are classified according to service life:

By size, fasteners are divided into:

- Small (up to 5.5 cm long and up to 0.8 mm in diameter).

- Medium (up to 12 cm long and up to 1.2 cm in diameter).

- Large (up to 22 cm long and up to 2.4 cm in diameter).

According to the base material, anchors are distinguished:

- For dense concrete, brick or stone materials.

- For hollow brick and concrete foundations.

- For sheet materials - plasterboard, chipboard and fibreboard.

According to the method of fastening, the following are distinguished:

- Mechanical

Fastening is carried out due to the direct mechanical effect of the working part of the anchor on the base (wedging, friction, stop, material resistance, etc.).

- Chemical

Additionally, a gluing mechanism (force) is used; for fastening, adhesive based on polyester resins is used.

What anchor do you use?

ChemicalMechanical

Mechanical anchors according to the technique of insertion into the base are divided into the following types:

- Wedges.

- Spacers.

- Hammers.

- Screw.

- Bushings.

- Expandable.

- Spring.

Spacers

Expansion anchors are a classic type of this type of fastener. They are a rod in the form of a bolt or pin with a cone-shaped end and an external element in the form of a sleeve, bushing or spring ring. The conical element, under the influence of the translational movement of the rod, expands the sleeve and secures the structure in the base.

Expanding

An expansion anchor consists of a threaded rod, which can be a bolt, stud or screw, and a sleeve consisting of 4 longitudinal petals with a spring ring and a cone nut on one side. When the rod rotates, the cone nut unclenches the sleeve petals, as a result of which the anchor expands and is secured in the base due to friction.

Wedge

Wedge fasteners are a long rod, at the end of which there is a deformation sleeve. After screwing the rod into the drilled hole, the sleeve petals expand. This type of fastener can withstand heavy loads.

Spring

Spring anchors are used when working with thin-walled bases, for example, when arranging the interior. Often, spring anchors are used as ceiling anchors and are equipped with a hook. The anchor is secured by unrolling the spring.

Screw

Screw anchors, or Molly bolts, are used when working with hollow structures with low load-bearing capacity - hollow brick, plasterboard, particleboard and fiberboard, etc. The Molly bolt is equipped with a special collet, which, when the bolt is tightened, opens and rests against material on the reverse side.

Bushing

Sleeve-type anchors consist of 3 or more elements, the main one of which is the collet - a spring split sleeve. The sleeve anchor design also includes a riving element and a threaded rod. When the anchor is twisted, the wedging element enters the collet and pushes it apart, thereby securing the fastener to the base.

Drivers

The basis of the driven anchor is a metal deformation sleeve with a conical hole, cuts in the body and internal threads. A firing pin is installed at the bottom of the sleeve. The sleeve is installed into the drilled hole manually or using an air gun. When the outer end of the sleeve is struck, it is deformed, after which a bolt or pin is screwed into the sleeve, necessary for fastening any object.

Popular manufacturers

If you have already become familiar with the characteristics, design and types of drive-in anchors, it’s time to start thinking about a specific choice.

Anchors are produced by a lot of companies around the world, but it is important not to get confused in all this variety of products and choose the best quality.

Experienced buyers and experts in this field highlight the following list of leading companies from which you can safely purchase different types of drive-in anchors without worrying about quality and durability:

- German manufacturers Fischer. Everyone has probably heard about the famous German quality. The production of anchors is no exception. The above-mentioned company is the absolute leader in the market for these materials. The company has well-established logistics and delivery anywhere in the world. The only drawback is the high price for the CIS, but it is justified by the incredible quality.

- Mungo. A Swiss company that is also famous for its quality. Unfortunately, the company focuses on the production of other materials, so the circulation of drive-in anchors is very limited.

- Koelner. The European company producing this material is the closest to Russia. The quality of the product is also excellent, but the pricing policy is also quite affordable. This is the most acceptable option for ordinary builders or for basic repairs.