Main goals

A water valve is usually used simultaneously with surface pumps when organizing individual water supply systems.

Purpose of shut-off valves:

- Stabilizes blood pressure. In houses, cold and hot water supply passes through different pipes and due to the difference in pressure, cold water may not be squeezed out into the mixer. This prevents normal temperature regulation. The non-return valve stabilizes high pressure, allowing you to adjust the temperature.

- Protects the pipeline from pressure drops and hydraulic shocks, and the water supply itself from unforeseen situations and subsequent repairs.

- Does not allow reverse circulation of water.

The last function is especially relevant for sewage systems. A non-return check valve blocks the backflow of wastewater, preventing it from exiting the toilet or sink.

Where is it recommended to use check valves?

These elements are required to be used in the water supply system. In addition, they are indispensable in sewer lines, heating devices, pipes near water meters, in pipe branches in water heating devices, and plumbing units. Shut-off valves in the heating system eliminate the supply of reverse flow, which is important during the operation of water heating devices.

Installation location

Sewer and water systems are not the only places where installing a valve is a necessity. Other areas are:

- Autonomous heating system circuit. The rooms where heating radiators or heated floors are located differ radically in hydraulic and pressure indicators, and therefore require the installation of automatic shut-off valves. The device fits in front of the boiler and allows you to balance the technical indicators.

- Water heater inlet. A check valve installed in front of the boiler prevents the hot water mass from moving back into the cold water pipeline.

- Submersible pumps. If the water supply system is connected to a well or borehole, it is important to install a submersible pump. Its main task is to lift water masses from depth and transport them under pressure to the house. When there is a power outage, the pumped water naturally flows into the pressure tank. To avoid this, a shut-off valve must be installed in front of the pump.

- In front of the water flow control meter. All metering devices, in particular the household water meter, are especially sensitive to disturbances and changes in water supply. Water hammer has a negative effect on the device, up to its failure. Also, the locking device prevents the turbine from turning in the opposite direction.

The safety valve does not allow reverse circulation of water in any of the cases described above.

Connection type

Connection of shut-off valves can be:

- coupling - the product has an internal thread and is simply screwed onto the thread on the pipeline;

- fitting - the valve has a pipe with an external thread, it is attached to the pipe using a union nut;

- flanged - on both sides of the valve there are plates with holes for bolts, which are attached to the mating flanges of the pipeline;

- welded – the reinforcement is welded. This type of connection is required where the tightness and reliability of other types of connections are insufficient (in toxic, aggressive, radioactive working environments);

- pin-type - the presence of connecting pipes with threads and a collar on the pipeline and fittings. The end of the pipeline, which has a flange, is pressed against the end of the valve using a union nut. The most obvious example is connecting a hose to a fire hydrant.

Description of devices

The check valve looks pretty simple. Inside the structure there are the following main elements:

- a small spring that functions as a delay mechanism for the bolt mechanism;

- shutter with seal - can be made of durable plastic or steel;

- a metal body (usually dismountable for ease of maintenance), consisting of two threaded parts.

Today there are a large number of locking mechanisms. Taking into account the design, the device can be supplemented with the following auxiliary elements:

- stem;

- pin on hinges;

- ball bearings;

- springs;

- elastomers;

- disc levers.

To choose the right locking element, you need to take into account the design of the system and the main purpose of the installation.

What does this valve consist of?

In addition to the body, the valve contains a small spring, a shutter, and a seal. Depending on the material from which the element is made, the modification of the device, manufacturers supplement check valves with springs, levers, bearings, and other auxiliary elements.

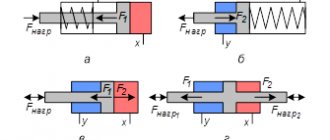

Principle of operation

The work is based on the elementary laws of hydrodynamics and physics. When liquid stops entering the pipeline, the spring completely closes the valve . When pressure and pressure appear on the valve, the spring weakens, allowing water to pass through. After turning off the pump and reducing the pressure, the shutter mechanism is reactivated. The resistance of the spring increases under the influence of direct pressure. This prevents the valve from opening.

The safety structure in the sewer system has a different operating principle. The valve itself structurally consists of a round plate with a seal, a spring lever and a housing. When water enters the sink, the lever opens. When the pressure drops, the shut-off mechanism closes and prevents sewer water from flowing back.

Types of mechanisms

Locking devices are conventionally divided according to several criteria. The most common mechanisms:

- Disc or spring valve. Inside there is a spring with a locking element. When the fluid circulates in the right direction, the spring compresses and allows water to pass through. During reverse flow, the spring expands, closing the valve. These valves are inexpensive and require no maintenance. But over time, mineral deposits appear inside. In this case, the device must be completely changed.

- The lifting locking valve is characterized by the fact that the valve produces vertical translational movements. When water circulates under pressure, the shutter moves upward, opening the way for it.

- The ball locking mechanism is made in the shape of a ball coated with a wear-resistant sealant. The ball rises when the liquid circulates in the desired direction, and falls, closing the passage of water when the flow moves in the other direction. Devices of this type do not need to be replaced after wear. They are easy to repair. At the same time, breakdowns are quite rare, since the elements do not rub inside the structure. The disadvantage is that it requires a lot of space to install the valve lift.

- A butterfly valve is a type of rotary valve. It has two petals that open from the direct direction of water. These structures have high hydraulic resistance, that is, the fluid circulation rate is reduced. Most often they are used in difficult working environments (dirty water, oil), since in this case it is possible to select a suitable seal.

- A rotary or petal valve is a structure of petal plates mounted on hinges that open during forward flow of liquid and close during reverse flow. In this case, there are no springs that collect mineral deposits.

In domestic conditions, lifting valves are most often installed. This is due to the ease of repair: they just need to replace the spring.

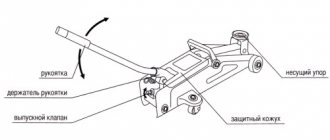

Installation methods

To determine which valve to choose, you also need to pay attention to the installation method. It is necessary to determine whether it is suitable for a particular heating or plumbing system:

- Wafer devices are mounted between flanges. They are small in size and inexpensive.

- Flange locking mechanisms. Mounted using special disc-shaped fasteners. As a rule, they are made spherical. Due to their reliability, they can be used even for large cross-section pipes. Made from high strength steel.

- Welded structures are made of steel. They have an absolutely tight connection. Disadvantages include the impossibility of repair and the difficulty of installation and dismantling. Most often used in the energy sector.

- The coupling locks are secured with threads and are therefore easy to install. They are mainly made as disk ones. They are usually installed for water supply systems of private houses.

The tightness of the housing elements in all models is ensured using seals that are located at the connection areas.

Installation technology

Before installing a check valve on water, you need to determine the location of the insert, as well as the technology, which differs for different systems.

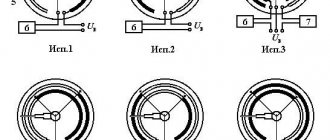

Types of check valves

Experts subdivide these devices not depending on the diameters of the check valves for water, but by the type of shut-off element in them. So, valves can be:

- Disc-shaped.

- Disk.

- Ball.

- Bivalve.

The ball valve is considered quite reliable. The system is based on the fact that the ball moves inside the valve and closes the seat when necessary. However, it does not always fit tightly enough, which creates a pressure problem.

Poppet valves are divided into lift and rotary valves. The latter function under the influence of water. Lifting ones are equipped with a spring-loaded rod, which, under water pressure, presses the spring and the lock comes up.

The disc return element is the most popular and recommended by experts. It is also called spring. The valve is small in size with a simple and reliable latch system. The disk stands across the flow, which presses the spring when pressure appears.

The shutter of a leaf or double leaf valve consists of a pair of flaps mounted on the same axis. The petals are held in place by a spring, but as soon as water hits it, it pushes them out. With such a system, water circulation is reduced, which creates high voltage in the hydraulics.

Maintenance of drain and inlet fittings

Water in domestic engineering networks often contains mechanical impurities (rust, sand, salt deposits), so many malfunctions occur due to clogged plumbing fixtures. For this reason, the vast majority of valve maintenance activities involve cleaning.

When servicing and carrying out preventive maintenance, special attention is paid to the filter, membrane, inlet nozzle of the filler valve, locking ring or bulb, and drain hole. It should be borne in mind that the filter is usually installed in Russian-made models; it is not always found in samples from foreign suppliers.

Another part of the problems is related to improper filling of the tank and leaks. The basis for eliminating these shortcomings is the connection and adjustment of components, the serviceability and tight pressure of the gaskets, and the tightening of the nuts to the end.