Anti-corrosion metal coating is one of the most common ways to protect metal structures or communications from all kinds of negative external influences.

Protecting the coating from corrosion is the creation of an additional layer on the surface that prevents direct contact of the metal with air, moisture or water.

There are various types of anti-corrosion coatings, thanks to which you can successfully extend the life of metal devices.

Which brand of anti-corrosion agent is better to choose?

Due to the large assortment, even experienced motorists cannot always answer which anticorrosive agent is better. First of all, buyers focus on positive reviews, quality and price. But, according to experts, imported products are in great demand. The rating includes automobile anticorrosives from the following manufacturers:

- Runway – the company uses American raw materials for the production of auto chemicals. Factories are located in Russia, China and the USA.

- V alvoline is an American brand famous for producing high-quality car cosmetics. The company was the first to offer a money-back guarantee on motor oil.

- Liqui Moly is a German company that is rightfully considered the best in Germany, offering high-quality auto chemicals and motor oils.

- Vanger - the line offers a variety of anti-corrosion products for cars. The Dutch company is in great demand among car enthusiasts.

- Rust Stop is a Canadian company AMT Inc. presents the best anti-corrosion agents to combat rust on the body and underbody.

- Normex is a company that produces high-quality and inexpensive products for car body repairs.

- Dinitrol is a German brand that has been producing anti-corrosion products for 60 years, helping to protect cars from rust.

- O ilright is the oldest Russian company supplying oils, additives and lubricants of its own production.

- VELV - products of the northwestern company are popular among car enthusiasts. The company's assortment includes more than 300 auto chemical products.

Anti-gravel

Anti-gravel polymer coating protects the car body from mechanical damage. Reliably resists fine gravel, sand, dust. Does not lose anti-corrosion properties even at low temperatures.

Rubber polymers, phenol and urea in the anti-gravel composition add plasticity and can resist deformation. Feature: can be applied to existing rust spots. The preservative effect will allow the part to “live” a little longer, slowing down the development of rust.

Applying anti-gravel is quite difficult. Before starting anti-corrosion treatment, it is better to consult a specialist or watch some videos on the Internet:

Rating of anti-corrosion agents

The TOP includes products of domestic and foreign production that are not inferior in quality. Here you can find both inexpensive materials for finishing the surface of a car and premium class acrylics. When choosing, we took into account price, composition and expert opinion. To get a good result, you need to pay attention to the following factors:

- Chemical composition. The products are made from synthetic resins, polyvinyl chloride and rubber, oil, paraffin and wax.

- View. Quick-hardening mastic is intended for external elements, and non-drying mastic is intended for hidden ones.

- Hydrophobicity. A good composition repels moisture and electrolytes from the surface of the car.

- Consistency. The flowing material fills all cracks and damage.

- Smoothness. After drying, an elastic protective film should form on the surface.

- Structure. The homogeneous mass lays down easily and is evenly distributed over the metal.

- Strength. The protected surface easily withstands impacts from gravel and dust.

- Reliability. High-quality anti-corrosion protection does not crack or peel under load.

Modern protective equipment extends the life of the car and increases comfort in the cabin. The above criteria will help you make the right choice and buy a quality product that will always be at hand. It is better to carry out surface treatment immediately after purchasing the machine.

The best brake fluids

Choice of mastic

Mastics are the most popular in the fight against corrosion. Manufacturers divide them into several categories:

- Bitumen-rubber. It has proven itself well among motorists as a durable moisture-resistant barrier. Thanks to its chemical structure, it protects the car from the influence of electrolytes.

- From slate. Most often used for the bottom and racks.

- Rubber mastic with the addition of bitumen. Copes perfectly with protective functions at low temperatures. Plasticizer polymers provide high elasticity and wear resistance.

- Threshold anticorrosive. It is used on surfaces that are already covered with corrosion. The antioxidant pushes out moisture and prevents further rust development. However, before application, it is necessary to treat the rust area with an additional preservative to avoid the ingress of air and electrolytes.

The best anti-corrosion agents for the underbody

Anticorrosive for the underbody of a car primarily protects the metal surface from electrolytes. It must be elastic, durable and withstand climatic conditions. Most often, bitumen mastic is purchased, which protects against mechanical stress and does not collapse when colliding with obstacles. Corrosion-inhibiting materials are also commercially available.

Runway

The products in this line include a polymer mixture that reliably protects the coating. The bottom becomes resistant to any mechanical damage and rust. You can buy such an anticorrosive agent inexpensively at any car dealership. Particularly popular is galvanic coating, which contains zinc. A chemical reaction with a mechanical surface forms a strong, gray film. The material is also used when priming the body before painting. This is a good option for cold winters and long frosts.

Advantages

- Low price;

- Effectively protects against corrosion;

- Protects for three years;

- Dries instantly;

- Sold in any stores.

Flaws

- Poor insulation from noise;

- Low quality aerosols come across.

The composition is often purchased in northern cities. Buyers are attracted by the affordable price and acceptable quality of the product.

Valvoline

Tectyl Bodysafe is considered the best product of this company. This anti-corrosion agent contains zinc, which can withstand harsh operating conditions. The composition of medium viscosity is packaged in buckets with a capacity of 1 and 5 liters. The product is easy to apply and penetrates into crevices without problems. According to customer reviews, the anticorrosive agent is durable and is not afraid of sudden temperature changes. It also has good inhibitory properties. Even with prolonged exposure to salt and subzero temperatures, the coating remains durable.

Advantages

- High-quality penetration into microcracks;

- Frost resistance;

- Does not collapse when exposed to salt;

- Durable coating;

- Large selection of goods.

Flaws

- High price;

- Low sound insulation.

Since the product has poor protection against stone impacts, it is recommended to double treat the underbody of the car with an anti-corrosive agent. A thoroughly dried surface is required for uniform application.

Liqui Moly Unterboden-Schutz

This anticorrosive agent for the underbody is popular both in Russia and among foreign buyers. The product from the German brand is famous for its good adhesion and stable properties. The layer remains elastic and durable for a long time. This prevents the appearance of rust on the metal. A 1 liter black canister is available for sale. Despite the high quality, the price of the product is optimal and affordable to every car enthusiast. Additionally, you can purchase a spray that allows you to care for the metal parts of the machine.

Advantages

- Reliable anti-corrosion properties;

- Easily lays on any surface;

- Has good elasticity;

- Affordable price;

- Quickly grips.

Flaws

- There are no repellent properties.

The surface is susceptible to dirt and dust, which you may not like. To obtain a durable layer, you will need to process the bottom twice.

Advantages of anti-corrosion coatings

The anti-corrosion coating has a whole range of positive properties.

Among them, the following stand out:

- resistance to water,

- resistance to various types of fuel,

- prevention of reactions with most chemical elements that can destroy the protective layer.

- electrical insulation,

- weather resistance.

Such materials are able to provide both passive and active protection against corrosion. As passive protection, a layer of paint and varnish physically isolates the metal from moisture. It is worth noting that the main types of paint protection used specifically for the passive protection of metal structures are materials using synthetic binders and alkyd-based paints. If you need a thin but high-quality coating, you should take a closer look at bitumen-based paints. If it is necessary to use it in an aggressive environment, at high temperatures, then you should pay attention to silicone enamels.

At the same time, active anti-corrosion protection itself implies the use of chemical inhibitors in paints that slow down the oxidation process of metals, as well as various other additives. It is worth noting that such coatings will last several times longer than any other layer of passive protection.

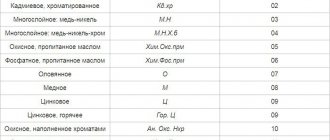

Types of anti-corrosion coatings

It is worth noting that there are different types of anti-corrosion coatings for metal. Anti-corrosion coatings to protect metal from the external environment are one of the most important areas of production activity in the paint and varnish industry.

The best universal anti-corrosion agents

The compositions are suitable for treating any external and internal surfaces. Their range is small, since manufacturers try to produce anti-corrosion agents for specific purposes. But buyers like to purchase a universal product that does not require costs. Such products are usually made in Russia.

Oilright

The Russian company offers several compounds that protect against corrosion. Anticorrosive Oilright Movil and Oilright Cannon lard is sold in 2 kg plastic cans. It is used to process thresholds, door frames, side members and other hidden car cavities. The layer also temporarily protects the wheel arches and underbody. As the manufacturer assures, the mixture can be applied to a damp and corroded surface. The product is used in molten form as a preservative and anti-corrosion coating.

Advantages

- Protects against rust;

- Has increased adhesion;

- Does not wash off with water;

- Low price;

- Suitable for any surface.

Flaws

- Poor external treatment.

To cover the bottom, it is better to choose hard cannon fat, and it is advisable to cover the internal cavities with soft one. This will create maximum protection and strength of the layer.

VELV "Movil-5E Extra"

This composition from a Russian company has been known since Soviet times. It perfectly pushes out water thanks to drying oil and oil. Many car enthusiasts, out of habit, choose domestic anticorrosion protection, since its price is very low. The mass is easy to apply, so no special skills are required. Anti-corrosion immediately stops the development of rust, but does not remove old corrosion. Unfortunately, the product is not able to dry completely, so it gradually flows down. Chemical reagents quickly destroy the applied composition.

Advantages

- Has hydrophobic properties;

- Low price;

- Easy to apply;

- Allows you to apply paint;

- Stops the development of corrosion;

- Available in any store.

Flaws

- Penetrates poorly;

- It flows down the walls.

According to car mechanics, it is worth buying more effective and durable compounds. A large pocket of corrosion under a layer of anticorrosion will most likely become damp and disappear.

Movil

Wax-based anti-corrosion preparation. It is used on both external and internal surfaces. Before application, it requires high-quality treatment of the body and thorough cleaning of rust spots.

After contact with a metal surface, it reliably seals it and isolates it from the ingress of electrolytes. Movil contains petroleum polymers, which create an elastic film. Anticorrosive agent interacts well with any type of paint and varnish coating.

Which anti-corrosion agent is better to buy?

Before you buy anticorrosive for a car, you need to study the requirements. Any composition should ideally fill hard-to-reach places and chips, repel water, and adhere well to the surface. To coat the internal parts, a liquid, homogeneous consistency is chosen. The bottom is treated with an elastic and durable layer that will withstand the impacts of gravel and protect from scratches.

- The best anti-corrosion agent for the underbody can be called Tectyl Bodysafe from Valvoline. A double layer will enhance strength and sound insulation.

- Among the anti-corrosion agents for hidden cavities, Dinitrol ML is often chosen. Swedish-made products are distinguished by quality and good penetrating abilities.

- If you need a universal composition, then it is better to choose Oilright Movil or Oilright Cannon fat. You can buy it at any auto store.

In addition, you need to pay attention to the climatic features of the region of residence and the expected operating conditions. To extend the life of the car, it is important to treat the car with a protective compound in a timely manner. You can do this yourself or at a car service center. The specialist will advise which anticorrosive agent is better and more profitable.

What should you pay attention to?

However, excessive use of existing production volumes will not only lead to overspending and a large increase in the time required to dry the metal structure, but also, too thick a layer of paint often causes cracks in the coating that form during drying.

Much depends on the quality of the paint applied. If before applying the coating to the surface you notice that it is too liquid and spreads quickly, the manufacturer may have added an excessive amount of water. Then you will have to purchase another paint or you should add special substances to your existing paint to prevent excessive spreading of the paint material.

At the same time, if you apply paint very thinly, this can lead to ineffective protection of metal structures, which affects the molecular bonds of the paint coating, and also leads to too rapid destruction - that is, the paint will simply rub off and the original appearance of the coating will be lost.

Safety at work

In order to most effectively eliminate the likelihood of poisoning and illnesses arising from work related to the application of paint and varnish coatings, you will be required to strictly follow safety regulations.

First of all, in the rooms where work will take place, it is necessary to ensure good ventilation. Then, if this is a large room, then the people performing paint and varnish work must be provided with all the necessary personal protective equipment - that is, mittens and overalls.

Moreover, special attention from this list should be paid specifically to respiratory protection equipment - that is, masks and half masks - respirators. Also, you or your workers should remember about personal hygiene. To clean your hands from paint and varnish materials, you can use special cleaning pastes. But under no circumstances use solvents to clean the skin, as this leads to the appearance of a rash on the skin, as well as various allergic irritations.

In order to promptly identify various diseases of this nature, it is necessary that people who do paint and varnish work undergo periodic medical examinations in order to prevent the occurrence of these dermatological diseases.