If the joints after repair are not protected from moisture, they will quickly rust and the work will have to be done again. To prevent the connections from coming into contact with the external environment, they are treated with a sealant for car welds. Manufacturers produce compounds for various purposes, so before going to the store, it is useful to familiarize yourself with their characteristics.

What is the suture pattern for?

The body department is a vulnerable element in the structure of a car. It can be damaged in an accident, emergency situations, or the carelessness of the driver or passengers.

Which sealant should I choose to seal the seams on my car? To do this, you need to be able to navigate their properties. Seam sealants are products created to eliminate body defects.

They separate, seal, and glue coatings. In addition, sealants protect the treated area from moisture and corrosion.

Which remedy should you prefer?

Practice shows that the best price-quality ratio is provided by polyurethane and rubber compounds: their properties do not depend too much on the brand and are almost always excellent. Cheap silicone sealants perform the worst - they quickly lose their properties and allow moisture and dirt to pass into the seam area. The choice of acrylic compositions should also be approached with caution. Thus, good acrylic sealants can work uninterruptedly for many years, but a low-quality product almost immediately loses its functionality.

Features and properties of joint sealant

Sealant for sealing seams on a machine has the following properties:

- Strength. The applied material will not lose its properties, including after prolonged use.

- Elasticity. The seam will be elastic and will take the required shape.

- Adhesion with a significant component of coatings. Instantly adheres and connects to metal and rubber.

- Moisture resistance. Does not get wet in conditions of significant dampness or direct contact with water.

The best automotive glass sealants

If body sealants have a thick consistency and may differ in color, then glass glue is a completely different material. It is completely transparent and more liquid. By applying it to a crack in the glass, you not only protect it from further destruction, but also almost completely eliminate the chip. The secret is in a special reflective formula, which makes the glue transparent and completely invisible. It hardens quite quickly and is easy to further process.

Done Deal

Before us is one of the market leaders, producing the best sealants at the most affordable prices. This is an American company that has been producing various materials for car repairs, including glass sealants, for half a century. By purchasing this product, you are guaranteed to receive quality and reliability, but the main advantage is the temperature.

Some low-quality glass sealants only work within a certain range. It can be different, but there are almost always limitations. There are none here. More precisely, the frames are spread so wide that you will never encounter either an upper or lower threshold. The sealant feels great from minus 65 degrees to plus 200. It can be easily dried with an industrial hair dryer without fear of destruction. At the same time, the consistency of the glue is as transparent as possible and has a refractive effect. If you seal a small crack in the glass with this sealant, it is likely that it will completely disappear.

IGLASS CLASSIC

Sealant manufacturers are constantly in search of the perfect composition formula, and so far no one has come to the ideal, although some have come as close as possible to it. For example, this brand is from England, widely represented on the market. This brand produces hundreds of products, including sealants for glass, as well as for the cooling system and body.

And it doesn’t matter what you buy under the company’s brand, any product will have high quality and a lot of positive characteristics. It makes no sense to describe them all, but as car repair experts note, this product has the best adhesion and sealing performance. Despite the liquid initial structure, the glue reliably seals even the most complex cracks, restoring the solidity of the glass. Well, in contrast to high quality is the price. Yes, it is really high, but the sealant is worth the money, and in any case it is cheaper than replacing even the side glass, not to mention the windshield.

ABRO

High quality does not always equal high price. There are products that have better characteristics, and at the same time do not cost an arm and a leg. Here is one such example. This is a glass sealant from the USA. By the way, the company produces many different products, including adhesives for radiators and engines, but it is glass sealant that is in particular demand among them.

Based on reviews from car repair specialists, we can conclude that this is the best combination of price and quality. It copes with its main tasks one hundred percent, but has several drawbacks. For example, it is quite difficult to work with due to its liquid consistency. Professionals cope with this task with various tricks, but if you do not have experience in such work, it is better to choose another product. Long drying times are also noted. To achieve complete adhesion and speed up the process, you have to use a hair dryer, and not everyone has such a tool. All these aspects were the reason for placing this product in such a place in our top.

Sources

- https://kraskainfo.ru/shovnyj-germetik-dlya-avto/

- https://pechistroy.ru/stroymaterialy/8-luchshih-shovnyh-germetikov-dlya-kuzova-avtomobilya-i-sekrety-ih-primeneniya.html

- https://mirsmazok.ru/germetik/vidy-avtomobilnykh-germetikov-i-ikh-primenenie/

- https://top-expert.pro/10-luchshih-germetikov-dlya-avtomobilej/

Types of body sealants

All adhesive substances can be divided according to their area of use. One of them is body work, used for reliable protection against moisture and rust, water resistance when combining parts of the car body.

There are machine sealants designed for sealing seams. There are several types of products, differing in the method of their application and certain data.

Sprayable moisture-curing sealant

The one-component and sprayable product has a huge amount of dry substances, the base of which is MS polymers.

Hardening occurs under the influence of humidity contained in the atmosphere, which guarantees a strong and elastic application to the coating.

The sealant is applied using a gun, it dries within half an hour, and also makes the coating of the seams in the engine compartment, bottom, and trunk similar to the factory one.

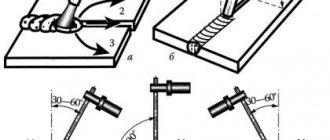

Brush-on sealant

This sealant is used everywhere and is produced in a nitro rubber base. It is considered an absolute reproduction of the factory seam and can be used on the trunk, air freshener mounts, jumpers, trays, wheel wells.

It must be applied with a brush. It does not form streaks, dries within 10 minutes, for further painting - within 1880 minutes, guarantees good protection against moisture, oil and fuel.

Sealant tape

Seam tape is needed to restore factory seams on overlapped joints. This light green self-adhesive tape is very comfortable and easy to use.

To use it, you do not need to wait for the material to dry; it can be already painted, very elastic, and suitable for planes with a small radius.

Acrylic based mixtures

Acrylic sealants are prepared on the basis of polymer compositions. They have good adhesion to the surface, but under strong vibration or shock loads they can peel off due to their average elasticity. It is best to use such products for porous materials and stable joints and seams. Any sealants with acrylic can be painted or varnished.

Anaerobic

Anaerobic sealants are a special class of compounds consisting of dimethacrylate esters with the ability to polymerize without access to oxygen.

These materials harden upon contact with metal surfaces in narrow gaps where atmospheric oxygen does not enter. If at least one of the specified conditions is not met, the sealant will remain in a liquid state. This property is often considered an advantage, since time during operation is not limited, installation can be carried out without fear of the material hardening.

In order for the anaerobic composition to polymerize, it is necessary to tightly connect the surfaces of the parts to eliminate excess oxygen. Once such a sealant gets into a narrow metal slot, it will harden in 25-30 minutes, turning into a solid polymer.

The advantages of anaerobic compositions also include high resistance to aggressive chemical environments, vibrations, pressure changes and temperatures. The composition also prevents the formation of corrosion, oxidation, gas and liquid leakage.

A disadvantage of the material is the filling of relatively small gaps from 0.05 to 0.5 mm. To polymerize the composition on non-metallic surfaces or at low temperatures, an activator will be needed.

Polyurethane compounds

These sealants are the most popular on the market and are available in a huge range. They can be sprayed or paste-like for brush application. Distinctive features of polyurethane sealants are:

- ease of use,

- no spreading from vertical bases,

- high flexibility, elasticity, heat resistance, moisture resistance,

- withstand large mechanical loads.

Silicone

For personal non-professional use, silicone sealant is more suitable. The composition of the material gives it high elasticity and strength. Silicone sealants differ in the level of elasticity of the resulting sealing layer, temperature conditions, and, for application to glass, in color range.

Polymerization of the sealant occurs due to the moisture present in the air; the average curing time is about 10 minutes, during which it is necessary to install the part.

Silicone-based sealants are oil-resistant and heat-resistant, withstand temperatures up to +300 °C. They can be used for most engine components. The material fills gaps up to 6 mm thick and is resistant to high pressure and operating speeds.

When working with silicone high-temperature sealant for a car, it is necessary to thoroughly clean the parts to be joined, which is a slight disadvantage.

Bitumen mixtures

Presented in the form of compositions based on bitumen with the addition of modifiers, fillers, and adhesion accelerators. They look like a dark paste. They do not require careful surface preparation and are suitable for most materials, including any metals. Can be used in damp environments and tolerate direct contact with water.

Synthetic

Synthetic sealants for cars are made on the basis of synthetic resins. The composition of the material makes it a universal product that can be used to seal most elements.

Synthetic sealants are a relatively new material that has not yet gained much popularity among auto mechanics and car enthusiasts.

Extruded sealants

This type of body sealant is used for internal as well as external joints to create a thin and airtight seam. It must be applied using a pneumatic or hand gun.

Similar sealants of various tones are produced specifically for the formation of various substrates.

What sealant should I choose? To best protect your machine, it is advisable to consider a number of factors:

- Area of application of sealant in order to correctly select the right product;

- Proper preparation of the area where it will be applied, which guarantees a high-quality connection, as well as tightness;

- Correct execution of work in accordance with instructions, allowing the use of the substance to be effective, high-quality and economical.

How long does it take for sealant to dry?

How long it takes for car sealant to dry largely depends on the composition used to glue the glass. If you install the double-glazed window yourself, it is important to read the manufacturer’s instructions on the packaging, and if the windshield was glued by a specialist, you need to follow his recommendations; he will tell you how long the glue will take to dry.

Most often, automotive adhesive-sealant dries in about one and a half to three hours; after 24 hours, the sealant will dry, and complete polymerization occurs only after three days. Although you can drive a car in a few hours, it is important to move extremely carefully and carefully. One day after gluing, you are allowed to drive as usual, but it doesn’t hurt to be careful for three days after replacing the glass package.

When gluing glass yourself, it is important to keep in mind how long the primer used takes to dry. Drying time will be indicated on the packaging. If you rush and insert the double-glazed window too early, or, conversely, overdry the primer, then certain areas of the glass will not adhere well.

Drying time in winter and summer

To accurately determine how long the sealant takes to dry, it is important to take into account the period of the year in which this composition is used. In winter, the glass gluing procedure is performed only in a closed garage, and in summer, car glass can be replaced even outside.

Taking into account the difference in air humidity and temperature, in summer the sealant dries for at least one and a half hours, and in winter - from two and a half to three hours. During this time, it is strictly forbidden to move the car or open the doors or windows of the car. Any, even the slightest movement of the car can lead to vibrations of the glass, as a result of which the seal is broken.

Checking the quality of gluing

Before picking up the car from the auto repair shop, it is recommended to check how well the work was done. And when replacing a double-glazed window with your own hands, it is important to read in the instructions how long it takes for the sealant to dry after gluing. In order not to spoil the work, you cannot start checking the quality of gluing before the sealant has set.

To check the strength, you need to press on the glass from the inside and listen to the sound. With high-quality gluing there will be no sounds or crackles.

Regardless of how long the car sealant takes to dry, it is important to start checking the tightness only after three days, so that the glue has time to crystallize. You can also check the tightness by washing the car at a car wash that uses high-pressure washers. If the gluing is done well, no water will leak through the seam after washing. And if there are leaks through the joint sealant, and the gluing was done by auto repair shop specialists, they will have to correct their work.

Features of the use of sealants

The purpose and performance of body sealants depends on the elements from which they are made. This affects the quality of the material, color, scope of application and price.

- To apply certain sealants you will need special equipment, so before purchasing you need to read the instructions or consult with the seller. For example, some silane-modified compounds are applied by spraying, so their use will require a specialized air gun.

- Regardless of the type of material used, the body sealant must be applied to a dry, cleaned and grease-free surface. Certain sealants require an auxiliary base primer.

The amount of material is calculated taking into account the volume and duration of the work. For automobile workshops that specialize in body restoration, a cartridge alone may not be enough, but for an ordinary car owner, 1 tube (150 milliliters) is enough to perform light work.

Best Automotive Body Sealants

Body sealants are characterized by high viscosity and density. They are used to seal cracks and holes in the car body. Later, putty, primer and paint will be applied over the sealant, and it is important that the sealant itself is in contact with these materials. The task is not easy, but this segment is the most widely represented on the market, and we have selected 4 of the most interesting options in different price categories.

LIQUI MOLY Liquimate 8300 Nahtabdichtung

Everyone who owns a car has heard of this German brand. The company produces a huge arsenal of repair materials and chemicals. All brand products are of high quality and, accordingly, high prices. It’s difficult to say how justified it is, but when you come to any car service center, you will be offered products under this brand first of all.

The sealant itself is highly durable and at the same time extremely flexible for processing. This is a very important factor considering how many layers will be applied afterwards. Also, the sealant does not show through and has the most uniform structure. By the way, the color can be selected individually. There are gray, transparent and black colors. Here the choice depends on what color you plan to paint the car in the future. Simply put, this is the best body sealant on the market today, and its only drawback is the high price. Whether to buy it or not is an individual question, but we note that there are many excellent options at a more affordable price.

JetaPro 5593

Polyurethane sealant produced by the JetaPro group of companies. This is not a single manufacturer, but an association of companies producing a product under one brand. And this is the case when you don’t need to look at the company that made the glue itself. If it is under a brand, then the quality is guaranteed to be high, and this is confirmed by numerous online reviews left by professional car repair specialists.

The main advantage here is maximum elasticity. The sealant has a structure in which it itself is able to penetrate difficult areas of the body, and at the same time is easily smoothed out with a brush. Its consistency is semi-liquid, and it is very convenient to work with, although in vertical parts there may be difficulties with the sealant flowing down, but it does not have an expansion effect, which means there will be no problems with excess. And finally, another important advantage is cost. The price is really low and it doesn't reflect the quality of the material. It’s just that different regions have their own manufacturer, which is very convenient and allows you to reduce the price of the final product.

ISISTEM ISEAL

Another widely advertised brand from England. This brand produces various materials and automotive chemicals, and they are all united by high quality and relatively low cost. The most important benefit here is maximum grip. The bottom line is that when working with sealants you have to constantly select accompanying materials. For example, some models do not come into contact with alkyd paints, and this is a minus.

Such problems will not arise here. The glue interacts well even with the most aggressive dyes, which are not capable of destroying its structure. As for the disadvantages, experts note that it hardens too quickly and the consistency is too dense. It’s difficult to call these full-fledged disadvantages, but working with such a sealant will require appropriate experience, as well as patience. But you can choose the color. There are three options to choose from: transparent, black and gray. Their composition is identical and differs only in appearance.

Chamaeleon

The German company Chameleon produces automotive sealants and chemicals, and if you are a fan of sports racing, you have probably seen this name. The brand is not only a sponsor of several rally teams, but also supplies its products to them. This needs to be mentioned, since this aspect immediately allows us to draw conclusions about its quality.

It is really up to par, and the main advantage is its long service life. The sealant not only reliably seals holes in the body or strengthens seams, but also protects the metal, creating an additional layer. The service life is very long and is measured in several decades. It’s difficult to say whether this is true or not, but as experts note, the glue fits perfectly on the surface, tightly adheres to it, and comes into contact with any type of paint, even the most aggressive.

Types of joint sealant

A huge number of compounds with different properties are sold. In many situations, the sealant includes artificial resins.

The main types of joint sealants include:

- Seam sealant. Its volume is 300 milliliters. To use this type, you will need to use a pistol. When used, you will get a seam without defects. This sealant is produced in 5 tones.

- Suture under a brush. It is produced in cans weighing 1 kilogram. This product is intended for sealing joints and welding seams. It is not exposed to moisture or corrosion. They produce it in four tones.

- Machine sealants-tape. They are designed to form an attractive straight seam. Made with a sticky base for easy use. Once they are applied to the vehicle, they do not need to be dried and sealant tapes can be painted.

Acrylic composition

The composition, made from acrylic polymers, is accessible and adheres well to the porous material. It has elasticity, but with significant destruction it can fall off. The layer of this sealant can be treated or painted.

Bitumen compounds

These compositions are presented as paste-like substances, which are based on bitumen, as well as modern modifiers and fillers. They are used in damp environments, have high adhesion to many planes, and do not require careful preparation of the surfaces being repaired.

Polyurethane types

Polyurethane compounds have high levels of moisture resistance, elasticity, and heat resistance. They are able to withstand mechanical stress.

Such changes will not affect the structural characteristics.

Popular Products

There are many sealants on the market designed for body repairs. Let's look at some of them.

Merbenit XS55

High-strength elastic material (tensile strength 4 N/mm2) on a silane-modified base (SMP). Has high adhesion to many substrates. Used to seal weld seams. In addition, it is used in metallurgy, climate control and ventilation technology, the production of automobiles, containers, freight cars, polymers, and in instrument and mechanical engineering.

Advantages:

- Resistant to salt water, aliphatic solvents, oils, alkali solutions and inorganic acids

- High resistance to vibration and shock

- May be stained

- Does not deteriorate when exposed to weather conditions

- Free from silicone, isocyanate and solvents

- Without smell

BODY 999

Polyurethane sealant with minimal shrinkage. Does not crack even when applying a thick layer of material. Used for sealing body joints, welds, filling voids, etc. Not recommended for use in areas exposed to UV radiation.

Advantages:

- Minimum shrinkage

- Does not spread even on vertical surfaces

- Has high adhesion to various substrates

- Can be painted after drying

- Does not crack

- Long service life

3M 08537

Nitrile rubber sealant. It is used to treat a thin layer of joints inside the trunk, internal parts of doors, places where shock absorbers are attached, sealing welds and bolted joints. Apply with a brush.

Advantages:

- Doesn't spread

- Retains structure well

- Oil resistant

- High elasticity

- Water resistance

Terostat 9320

Silane modified spray sealant. Used as an anti-gravel coating and for additional protection of the underbody of the car. Allows surfaces to be cleaned with sandpaper, which increases the adhesion of the material. Accurately reproduces the factory sealant.

Advantages:

- High adhesion

- Long service life

- Dries quickly

- UV resistant

- Helps absorb noise

- does not contain PVC, silicones and isocyanates

Photo of seam sealant for cars

How long does it take for glass sealant to dry in summer and winter?

To more accurately determine how long it takes for a glued windshield to dry, you need to take into account the time of year. In general, the replacement technology in winter and summer is the same, however, in winter the procedure can only be performed indoors, while in summer replacement outdoors is permissible.

If we take into account the difference in air humidity, then in summer the sealant hardens on average in 1.5 hours, and in winter - in 2.5–3 hours. During this time, it is prohibited to open the doors, windows of the car or move it. Any movement can cause the glass to vibrate, causing the seal to be broken.

How to check glass

Before picking up the car from the workshop, you can check the quality of the work performed yourself. And if you replaced the double-glazed window yourself, first check in the instructions how long the windshield should dry after gluing it with the selected glue. If you start checking before drying, you can ruin the work.

To test the glass for strength, press it from the inside and listen: there should be no cracking.

Regardless of how long the windshield adhesive takes to dry, it is recommended to check for tightness only after three days, when the adhesive has already crystallized. To ensure accurate results, it is best to wash your car at a professional car wash using high-pressure washers. After washing, carefully check the seam for leaks. If there are any, and the replacement was carried out in a workshop, the work will be corrected under warranty.

Rules for operating a car after replacing the windshield

Despite the fact that 1.5–3 hours after replacing the double-glazed window you can drive a car, it is not recommended to immediately return to your usual driving style. The first few days you should be extra careful. To do this, follow simple rules during the first three days:

- If possible, avoid potholes on the road and do not run over curbs.

- Do not park on uneven surfaces - the car should not be parked on an incline for long, as the sealant has not yet fully set.

- During the first 24 hours, avoid being exposed to rain and snow, and it is better to wash your car only after three days. In some cases, washing the next day is allowed, but it is better to check this with the workshop where the replacement was carried out.

- Don't slam doors too much.

- Do not abuse the stove and air conditioner.

- Do not accelerate over 70 km/h.

If you are not careful, the seal of the adhesive may be compromised. In addition, experts recommend replacing the wipers, since sand particles usually remain on the old ones, which can scratch the new double-glazed window and significantly reduce its service life.

Sources

- https://elsvarkin.ru/materialy/germetik/

- https://mirsmazok.ru/germetik/chem-zagermetizirovat-svarnye-i-konstruktsionnye-shvy-avtomobilya/

- https://VseProKley.ru/avto/shovnyj-germetik-dlya-avto

- https://kraska.guru/germetiki/avto/shovnyj.html

- https://chistayrabota.ru/kak-dolgo-sohnet-germetik-avtomobilnyj/

- https://GidPoKraske.ru/germet/rabota-s-ger/kak-polzovatsya-germetikom.html

- https://www.bitstop.ru/steklopediya/skolko-sokhnet-lobovoe-steklo-posle-zameny/

Heat treatment of welded joints

Welding involves a high-temperature effect on the metal, which leads to disruption of its structure; the material becomes thinner, so after welding it is required to additionally strengthen it with protective agents. In this case, heat treatment of welded joints may be resorted to. The type of exposure scheme depends on the type of metal and operating conditions.

After welding, it is necessary to further strengthen it with protective agents.

There are a variety of sealants for cars, this makes it possible to choose a convenient type for use. When choosing a product, take into account the area of application and the type of metal base.

Purpose of sealants for car seams

One of the most vulnerable parts of a car is the body. Damage to body parts occurs for various reasons. Most often, problems occur due to careless driving, accidents, etc.

To choose which composition to use, you need to carefully understand their varieties and the properties of each product. For example, car seam sealant is a mixture that was made for repairing a body assembly. With their help, it will be possible to repair the bottom, glue the parts of the car and make them airtight.

Body sealant

allows you to reliably protect your vehicle from corrosion and high humidity conditions.

Properties and characteristics

Seam sealant has many characteristics and properties. Among the most important nuances are the following:

- Moisture resistance

. Seam sealant for cars is not afraid of use in a damp environment. This is due to the fact that it does not become limp even when water hits it directly. - Plasticity

. The sealant for the car applies such a seam that it takes any shape, bends and is not subject to deformation due to this. - Persistence

. If you seal the seams with this composition once, then the next repair will not be needed very soon, because the mixture is ready for long-term use without loss of quality. - Good adhesion to most materials

. In addition to the fact that the mass begins to harden quickly, it can be applied to many surfaces. The composition best holds together iron, rubber elements and much more.

After you have learned the information about the properties of car body sealant, you should take a closer look at the types of mixture.