A gun drill is a tool that is used to drill through and blind holes of considerable depth. Holes of this type are made in shafts for various purposes, in spindles, as well as in other parts characterized by a significant length. For this purpose, not only gun drills are used, but also, in particular, single-edged and double-edged drills with internal chip removal. Drilling with the help of the latter is characterized by low productivity, but the deep holes made are characterized by high cleanliness, accuracy of geometric parameters and straightness.

How to choose the right tool

When choosing drills for deep drilling, you should consider a number of factors:

- diameter and depth of the hole to be made;

- characteristics of the processed material;

- the type of equipment that will be used to perform the processing.

Scheme for calculating drill length when working on a universal machine

It should be borne in mind that the device on which such a drill will be installed must be designed specifically for deep drilling.

Before starting drilling, you should select the optimal speed of rotation and feed of the cutting tool, as well as ensure its effective cooling. For materials that produce long chips when cutting, it is best to use a drill with polished flutes.

Gun drills can be single- or double-sided cutting

This is interesting: Making a homemade drilling machine from a steering rack

Kinds

There are the following types of cutting tools that are used to make deep and very precise holes:

- cannon - on the working part of the tool there is a groove made in the form of the letter V; it is necessary in order to remove waste metal shavings from the hole;

- ejector - this tool is used for machines in which the cutting element is located in the horizontal direction;

- rifle - an option that is equipped with carbide steel plates, which are located on the intermediate and main cutting plates;

- rifle - with cutting parts and surfaces made of steel and hard alloys;

- rifle - in which carbide cutting plates are fixed to the body by soldering;

- spiral - having a shank, which is presented in the form of a cylindrical structure.

Gun and gun drilling tools are single-cut options. Thanks to them, you can drill a hole whose diameter parameters range from 0.5 mm to 10 cm.

During operation, the drill heats up; it can be cooled by supplying cutting fluid to a special space located inside the working part of the drill. Gun and gun drills, the cutting plates of which are made of steel hard alloys, have a working shank with a cone-shaped configuration. This shape guides the cutting tool more precisely to the drilling area.

Gun drills

Gun drills are used for drilling gun barrels and other deep holes of small diameter.

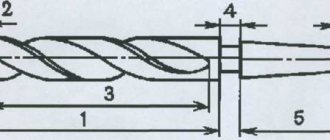

Fig. 1. Gun drill with external chip removal.

In Fig.1. Shown is a drill for holes with a diameter of 3-17mm. The drill consists of a working part 1 and a stem 2. The working part is a high-speed steel tube rolled so that a space C is formed (defined by the angle φ) for removing chips and a crescent-shaped channel Ж for supplying coolant. The stem is rolled along its entire length in the same way, with the exception of the section used to secure the drill in the tip of the machine support. The dimensions of space C and channel F are important; The difficulty in selecting their sections is due to the fact that with a change in one of them, the other also changes. With a decrease in the cross-section of channel C, the cross-section of channel Z increases, which leads to improved conditions for the supply of coolant and an increase in the rigidity of the stem, but at the same time, chip removal becomes more difficult, and vice versa. It has been practically established that the most satisfactory angle is φ=110/120°.

To facilitate cutting and better direction, the top of the drill is shifted relative to the axis by an amount L. As a result, when the drill operates, a cone is formed at the bottom of the hole (Fig. 2, a), which contributes to the direction and centering of the drill.

Fig. 2 Diagram of the action of cutting forces on the cutting edges of a gun drill.

The displacement value of the drill tip L is assumed to be equal to (0.25/0.2)d. It is desirable that the size L be less than α and the angle φ1 less than φ2. Typically, for this purpose, the size α is taken equal to 0.3d, and L=0.2d. Angle φ1=50°, and angle φ2=70°. In this case, the force P1 is less than P2 (Fig. 2.b), and the drill will be pressed by the guide cylindrical surface of the body against the wall of the hole, which prevents the drill from moving away.

Fig. 3. Gun drill with a milled groove for external chip removal.

To reduce the surface of contact of the cylindrical part of the drill with the wall of the hole and improve the conditions for washing the working part of the drill with coolant, a flat of width K is provided (Fig. 1) leaving a calibrating tape f = 0.15/0.4 mm. The drill is equipped with a reverse cone equal to 0.1/0.3 mm per 100 mm of the length of the working part.

The cutting blade of the drill is shifted relative to the center by the amount H (Fig. 1), as a result of which, when drilling, a zero rod remains in the center, the diameter of which is usually 2H<0.03d. With a larger diameter, the zero rod is difficult to break off.

The front surface of the drill can be equipped with chipbreakers, the depth of which S ranges from 0.05-0.4 mm depending on the diameter of the drill.

Gun drills for holes with a diameter of 18-45 mm (Fig. 3.) differ from drills of smaller diameter in that the working part of the drill is made of solid material. To supply coolant, a hole with a diameter of d1 = 5/12 mm was made in the working part of the drill. The working part of the drill is welded to the stem with two milled grooves: one with an angle φ is used to remove chips, the other with a width of d1+(1.5/2mm) is for soldering a copper tube through which coolant is supplied to the working part of the drill. Several chipbreakers with a width of 3-6mm (depending on the diameter of the drill) are made on the front surface of the drill.

Similar articles:

- To drill through and blind multifaceted holes on conventional drilling, lathe or turret machines, the drills shown in Fig. 1.2.3.4 are used. Fig.1. Drill and guide sleeve for drilling triangular holes. Fig.2. Drill bit and guide sleeve for drilling four...

">Drills for drilling multi-faceted holes

- To machine conical holes with a taper of 1:50 in one pass, conical twist drills are used (Fig. 1). Fig. 1. Twist drill for processing conical holes. The drill has a short cylindrical section Lx, accepted for drills with a diameter of d=3/16mm within (1.5/2) d; stayed...

">Conical twist drills

- To process center holes (sockets), center drills and countersinks in the form of sets are used. Fig. 1. Centering drills and countersinks. Scope and standard sets.

"> Centering drills and countersinks

- Spiral high-speed drills designed by A.I. Isaev are used to drill holes with a diameter of up to 25 mm in textolite and press board. Fig. 1. Dimensions of drills for drilling textolite. To drill holes with a diameter of over 40 mm in sheet PCB (thickness up to 8 mm), it is recommended to use a circular...

">Drills for drilling plastics

- It is advisable to drill holes with a diameter of over 75 to 100 mm using annular (trepanning) heads, leaving a central rod, which is removed after drilling is completed. Fig. 1. Drills for deep annular drilling: a - Annular head; b - head for deep annular drilling...

">Ring (trepanning) heads

News archive:

- Spoon drills, or "spoons", are used to drill holes with a diameter of 25-100mm in solid material. Spoon drills come with external and internal chip removal. A spoon with external chip removal (Fig. 1) has a stem 1, to which a cutter 3 is attached with a bolt 2 at an angle of 30°. To guide…

">Spoon drills.

- Spade (gun) drills (Fig. 1) are used to drill out pre-drilled holes. The drill is a rod, one end of which is cut off and forms the front surface in the form of a blade with an angle Υ=0°, and the rear surface is sharpened at an angle α= 10°/20°. Sometimes the drill...

“>Single-cut drills for deep holes.

- Spindle (feather) drills for deep drilling are used for processing holes in hydraulic cylinders, holes in machine spindles, etc. Fig. 1. Spindle drill for deep drilling. Figure 1 shows a spade drill with a helical flute head and two guide strips. Oh…

">Spindle (feather) drills for deep drilling

- When deep drilling, the working conditions of the drill sharply deteriorate - chip removal and cooling of the cutting part become difficult, and the rigidity of the drill decreases. Deep holes (holes in machine tool spindles, channels in shafts, etc.) are usually subject to high requirements in terms of surface cleanliness, straightness...

">Drills for deep holes.

- Drills equipped with carbide plates, compared to conventional drills, have a shorter working part length, a larger core diameter and a smaller helical flute angle. Fig.1 Twist drill equipped with a carbide insert. Fig.2 Twist drill equipped with hard...

“>Drills equipped with carbide inserts.

Next page >>

Daoist Yoga

Criterias of choice

The dimensional parameters and technical characteristics of gun and cannon drilling tools are regulated by GOST standards , according to which these drills belong to products of a long series. Using a drill is only possible on a special machine designed for deep drilling. When choosing a drill design, you need to take into account the required parameters of the hole - its diameter and length. For high-quality performance of the task, the feed speed of the drill, as well as the type of its tail part, is of great importance.

The main recommendations taken into account when choosing a drilling tool are the following:

- when making a hole whose length will be more than 400 mm , it is recommended to use 2 drills with different dimensions; first you need to use a tool whose size is 9.95 by 800 mm, and then the hole is expanded with a drill, the size of which is slightly larger and is 10 by 400 mm;

- if during drilling the metal produces a long type of chip , you need to choose a cutting tool that has long and polished grooves to remove it;

- if you need to process soft metal alloys , for example, aluminum, then you should use a cutting tool, the design of which includes one cutting blade sharpened at an angle of 180°;

- the content of the lubricant component in the coolant must be at least 10% of the total volume of this composition;

- if soft material is being processed , then it is necessary to reach the maximum speed of the drill in stages and this must be done in 3 steps; in addition, the hole is also made in stages - first, pilot drilling is done with a tool of a smaller diameter, and then the hole is expanded with a drill of the required size;

- when changing one drill diameter to another size, you can stop the rotation of the tool by turning on the high-pressure supply of the lubricant and cooling compound for 1–2 seconds; After completing the hole according to the specified parameters, the drill is turned off, ceasing to supply coolant into its hole.

To choose the right drill for making deep holes, it is important to consider not only its dimensions equal to the dimensions of the hole, but also the characteristics of the metal alloy, as well as the type of drilling equipment on which the work will be performed.

You need to start work at minimum rotation speeds of the drill, and it is important to ensure a supply of cutting fluid for it from the very beginning.

To learn how to drill deep holes with HAMMOND gun drills, see below.

Basic steps for drilling deep holes

Drilling deep holes in metal is usually performed in the following sequence:

- A preparation hole with a slightly smaller diameter with a tolerance of H8 is drilled into the part.

- The main processing tool is started at low speed and slowly moved towards the end of the part.

- Gradually bring the tool to the speed required by the technology and begin supplying the lubricant and cooling liquid.

- Drill the part to the required depth. In this case, the tool is not removed from the hole.

- If the technology uses a tool of considerable length, then the first quarter of the cut is performed at a reduced rotation speed. The rest of the hole is cut at rated speed.

- When the required depth is reached, the supply of lubricant is stopped.

- coolant to the tool.

- Then the drill is quickly removed from the drilling area and the operation of the unit is stopped.

This technology is standard and may differ depending on the tool used and metalworking equipment.

Step drill 5 mm vs getinax. Drill out and maintain alignment.

Step drills are actually a brilliant invention in the world of consumables. On the one hand, they allow you to drill holes of a fairly large diameter with a fixed shank, without changing the drill; on the other hand, such a drill is self-centering along the first hole, so all subsequent ones are coaxial. It’s been a while since I reviewed inch step drills; the set attracted me with its versatility and suitcase. I use them very often on wood materials, but there are certain difficulties when you not only need to drill a hole coaxially, but also make it of a certain depth for a specific metric diameter. And as you know, the depth of the hole corresponds to the height of the drill step, and feather and Forstner drills, as a rule, are not inch, so centering them in a hole drilled with an inch step drill is not very possible.

I don’t like step drills with a standard 6.3 mm hex shank, firstly, it is not power-operated, and secondly, there is no need for it. Therefore, the order was made in favor of a cylindrical shank.

The drill arrived simply in a package, and was not damaged by the naked eye:

The workmanship is good, the laser markings of diameters are clear. One piece of garbage - the numbers are constantly clogged with sawdust, they have to be cleaned during work:

The diameter of the shank turned out to be 13 mm, keep in mind that if you have a drill with a chuck up to 10 mm, you will have to look for a chuck up to 13 mm. Although the farm should always have a 13 mm drill.

Compared to the inch one, the coating is different, the shank is shorter and the diameter is larger - 13 mm versus 9.5 mm for the inch one. In addition, I like the inch shank because it has 3 wide edges:

One of the applications, as I said, is to drill holes without disturbing the alignment. As an example, there is a central hole for a 6.3 mm crown:

It is required to drill it on both sides by 15 mm and 12 mm to a certain depth while maintaining alignment and neatness of the edges, for example, for fitting on a shaft:

This is easy to do; I drill the part with a step drill to the diameter of the main drill:

Then I drill into depth with another drill:

The step drill is great for making various recesses for fasteners:

The material that I drilled in this case is textolite-PT with a thickness of 16 mm (laminated sheet pressed material based on cotton fabric and a thermosetting binder)

The drill, of course, does not hit, it drills cleanly. I did not notice any difference in quality between inch and metric.

In this case, a drill with diameters of 5-7-10-12-15-17-20-22-25-27-30-32-35 mm is shown

To complete the picture, I advise you to purchase a 4-32 mm drill (4-6-8-10-12-14-16-18-20-22-24-26-28-30-32)

I didn’t show it, because it’s the same thing, but I used exactly what’s in the review in my work.

And also a drill 3-12 mm (3-4-5-6-7-8-9-10-11-12)

This drill will be an excellent addition, if only because it has an intermediate step height of 5 mm, and a step of 1 mm:

That's all.

Deep drilling

The type of mechanical processing of ferrous metals by cutting holes with rotating mechanisms is called drilling.

There are simple and deep drilling.

In the second case, the depth of the hole must be more than 10 cm, or the depth of more than 5 original diameters (5*d). Using drills, holes of various depths and diameters or multifaceted sections are made.

This is interesting: Metal scraper: purpose and types of scraping tools

Important Features of Deep Hole Drilling

Deep drilling of holes in metal is a specific metalworking process and requires an appropriate approach. This operation should be performed on deep drilling machines specially designed for this purpose.

An important feature of the process is the precise centering of the tool and the elimination of drill deviation along the axis. It is necessary to avoid tool runout. To obtain a hole with precise dimensions and a high-quality surface, it is important to provide the processing area with a sufficient amount of coolant.

Chip removal grooves must be smooth to ensure timely removal of chips from the processing area.

Drilling blind holes differs in the direction of complexity in that during the work you need to constantly monitor the depth of the hole. For deep holes this causes some difficulty.

Processing a workpiece for drilling can be done in several ways:

- The workpiece rotates, while at the same time the longitudinal feed of a non-rotating drilling tool is performed;

- The workpiece does not rotate, it is fixed;

- Simultaneous rotation of the workpiece and tool.

All these methods are widely used in practice. The greatest demand for the deep drilling process is in the following areas: metallurgy, pipe production, oil and gas and aerospace industries, production of heat exchanger plates and boilers, and many others. The most commonly used parts with deep holes are: rotors, shafts, axles, bushings, liners, cylinders, bandages, metal shells and much more.