Scope of application of the alloy

T15K6 has found its application when performing rough and finishing turning operations.

It is also used to produce thread-cutting tools, which are used for cutting external and internal threads. Cutters made of this material can be used for finishing milling of solid planes. Countersinking, reaming and many other types of processing.

This material is suitable for processing parts made of carbon and alloy steels. To increase the efficiency of steel processing, the technologist must select cutting modes in which the plate will not overheat.

Product range

At specialized powder metallurgy enterprises producing the T15K6 alloy, they produce plates for cutting tools, both brazed and multi-faceted (replaceable). The first ones are used for traditional cutters, which are used on machines such as 16K200, DIP 300. Cutters with replaceable inserts are widely used on equipment operating under the control of CNC systems.

The main difference between these types of inserts is that an ordinary cutter can be sharpened by hand, while multifaceted ones must be straightened only on specialized equipment.

Rate this article:

Rating: 0/5 — 0 votes

Where does the difference come from and what causes it?

M390 steel: composition, decoding and application

The tabulated characteristics of the VK8 alloy are achieved in production most often by powder metallurgy methods. Individual elements of future equipment are pressed into molds and sintered at the melting temperatures of cobalt. As a result, fairly reliable plates for cutters and drills are obtained.

The decoding of the VK8 alloy is simple: the content of tungsten carbide is 92, cobalt is 8% and is always maintained as such for a specific marking. Sometimes this composition is mistakenly attributed to Pobedit (90/10), but the difference of 2% is fundamental for tungsten compounds.

Moreover, metallurgists noticed that the hardness of the VK8 alloy, which came off the assembly line according to the Rockwell table, ranges from 91% sometimes to 86% (with absolutely identical proportions of tungsten and cobalt). It would seem that only 5%, but they greatly influenced the bending strength, MPa. In the first case, it was almost twice (2800) higher than the values of GOST 3882 (1670).

Warehouse with cutters and VK8 plates

Additional studies have shown that the differences extend to material densities of 14.8 and 14.6 g/cm3, impact strength of 35-30 kJ/m², as well as an evaluation characteristic related to the anti-corrosion properties of metal in seawater.

After conducting a series of checks and experimental production of materials, metallurgists came to the conclusion that the following factors influence the production of the VK8 alloy, the composition of which remains unchanged:

condition of the powders used (grain size, humidity);

conditions for combining (mixing) tungsten carbide and cobalt;

set temperature, pressure (accurate to units of measurement).

Given the difference, scrap collection points often indicate the characteristics of the material they buy. In addition to radiological purity, it must meet the requirements of specific technological conditions, which also have their own standards, the buyer informs about them in advance.

Interesting fact. Different grades of steel and alloys are color coded. VK8 GOST 3882 is marked in red, and its varieties are complemented by a blue stripe.

Technical characteristics: subtleties of using reference manuals

The properties of 09g2s steel are largely determined by the chemical composition of the alloy, its specific parameters, which today are quite accurately calculated by metallurgists.

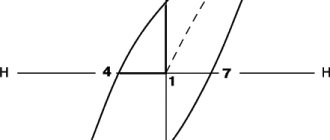

Steel grade 09g2s has the following critical points:

- Ac1 = 732, when austenite transforms into pearlite during cooling processes;

- Ac3(Acm) = 870 (s – from French chauffage/heating) the end point of cementite dissolution;

- Ar3(Arcm) = 854 (refroidissement – cooling) the beginning of the release of Fe3C;

- Ar1 = 680 hypoeutectoid steel, corresponds to ferrite precipitation

The symbols are classic, numbers 1 and 3 indicate the numbers of points on the graph. The symbols cm usually mark hypereutectoid steels.

If we talk about other features of St 09g2s, the following characteristics are noted: easy weldability of the material. For this purpose, RDS, ADS under flux and gas protection are used. Only products that have undergone chemical-thermal treatment cannot be welded.

The mechanical properties of steel 09g2s are tabular values that were developed by a number of GOST standards and describe the material at room temperature, as well as for its other states.

Among the important mechanical properties of 09g2s steel are the following:

- Yield strength for permanent deformation, measured in MPa;

- Relative values of elongation at break and contraction;

- Impact strength (use under load is one of the main applications);

- Brinell hardness (HB).

Strength class of steel 09g2s: the table for the list of grades includes the one indicated, which, as already noted, corresponds to C345. This also includes a number of other brands. Thus, steels that are different in chemical composition and even in the method of producing steel can have the same strength class. This data can be found for 09g2s according to GOST 19281-2014; the characteristics of the alloys are presented in convenient tables that are easy to navigate. You can view (download) GOST 19281-2014 here.

But the opposite situation is also possible. For example, for 09g2s GOST 19281-89 and grade 16GS there is data on strength classes 265 and 296.

The same GOST describes the types of rolled metal:

- Varietal, round, shaped with various sections (including circle 09g2s).

- Wideband profiles with a certain thickness of products.

Large diameter circles steel 09g2s

Similar information is provided for other brands.

The density of steel 09g2s fluctuates, somewhere around the 7800 kg/m3 mark. But alloying elements can either increase the specific gravity or reduce it. Tungsten tends to be the first. The second is achieved by adding: cobalt, nickel, copper.

The hardness of steel 09g2s can be determined by Brinell, Rockwell, Vickers, etc. the choice of system is determined by the type of products for which parameter determination is required. It is also important when choosing a welding method; the hardness of the steel at the weld should remain fairly high.

Most of the listed parameters can be found in TU 14 3 1128 2000 for steel 09g2s, as well as for other grades. The technical specifications describe the requirements for the materials from which pipes are made for servicing gas fields and other areas of the industry.

The permissible stress for steel 09g2s is calculated depending on the following values:

- strength class and grade;

- temperatures at which it will be operated;

- thickness, sometimes configurations (circle, sheet, etc.).

Existing 09g2s analogues are foreign (European, Asian, others), most similar in mechanical and technical properties to the specified brand. However, the chemical composition can vary greatly. The Bulgarian version of this brand has the closest configuration.

Chemical composition and method of preparation

Constantan alloy - properties and applications

According to GOST 3882-74, the VK8 hard alloy is a mixture of tungsten carbide and cobalt grains, acting as a connecting link. Cobalt (GOST 123-2008) is a metal similar in appearance to iron, but has a darker shade. Its main purpose in VK8 is to impart ductility and strength to the alloy. Tungsten carbide (GOST 28377-89) is a compound of carbon with the refractory metal tungsten. Hardness - over 80 Rockwell units.

VK8 is a product of powder metallurgy, since the above properties of the constituent elements do not allow mechanical processing by forging. The production of fine fractions of carbide and cobalt is carried out by reduction from oxides and includes the following operations:

- Crushing the mixture of structural components.

- Sifting through a sieve with a mesh size of 1-2 microns.

- Mixing fractions in proportions according to the required chemical composition of the VK8 hard alloy.

- Pre-shaping by pressing using organic glue.

- Treatment with pressure over 30 MPa and temperature of 1400 ºС.

As a result of these processes, the molten cobalt wets and, during subsequent crystallization, holds the carbide crystals together. As a result, a strong and wear-resistant connection is formed.

Physical properties

VK8, unlike high-speed steels, has greater hardness, which corresponds to 87.5 HRC units. As an example, P12 steel has only 60-70 HRC.

The heat resistance of the alloy, i.e. the temperature at which the material will work without losing rigidity, is 800-1000 ºС. Thanks to this and the high thermal conductivity value (50.2 W/m C), the VK8 cutter can operate at cutting speeds of up to 200 m/min, depending on the type of material being processed. Whereas under the same conditions, P12 steel allows one to achieve a value of only 50 m/min.

Tensile strength 1660 N/mm2, density 14.5 g/cm3, impact strength 35 kJ/m2 - these mechanical properties make it possible to use the alloy under conditions of dynamic and vibration loads.

Physical properties are determined not only by its chemical composition, but also by the grain size of tungsten carbide. The larger the grain, the higher the strength reading and the lower the wear resistance value. And vice versa, if the alloy has a fine-grained structure.

Properties

Basic properties of hard alloys: hardness; heat resistance; strength; wear resistance;

However, it is worth understanding that these characteristics depend on the ratio of the elements from which the alloy is made. For example, materials whose names use the combination of letters “BK” are directly dependent on the size of tungsten carbide. As the carbide grain decreases, the alloy becomes harder. At the same time, there is a high probability of reducing its strength. As the grain increases, the opposite process occurs - the strength increases, but the alloy becomes less hard. Therefore, when purchasing this material, it is important to understand the meaning of the markings, as they directly speak about its properties.

Titanium-containing alloys are harder and heat-resistant. Their melting point exceeds 1200°C. In addition, they are less susceptible to oxidation. Among the disadvantages, we can note worse thermal conductivity compared to materials of the “BK” group, as well as weak bending strength. However, this problem is solved by adding tantalum carbide to the composition - alloys marked as “TTK” are much more durable during operation.

Active use in various industries is also facilitated by the fact that solid metals, oddly enough, are very ductile. Therefore, you can work with them at both high and low temperatures. However, cutting, bending and other mechanical work should be done with great care due to high fragility and low bending strength. When processing a material, it is necessary to know its density, since its strength depends on it. For example, the density of tungsten alloys varies from 14 to 15 g/cm³; titanium-containing – from 9 to 13.5 g/cm³; material with tantalum admixture – from 12 to 13.6 g/cm³.

All of the listed properties determine where and how hard alloys can be used.

Examples of marking of hard alloys

According to the marking principle, hard alloys are divided according to their chemical composition:

Decoding and composition of t5k10

T5k10 alloy belongs to the group of tungsten-titanium alloys. Its main feature is its high resistance to abrasive wear. In particular, sliding chips of the workpiece. In addition, T5k10 has an increased temperature at which the surface sets with steel, which increases the cutting speed, rigidity and durability of the tool.

The alloy is entirely a product of powder metallurgy. The alloy components are pre-crushed and placed in a certain ratio in a special mold. Further, under the influence of temperatures above 3000 ºC and pressure of about 300 MPa, the chemical elements are sintered, actually forming the T5k10 alloy.

T5k10 is a hard alloy with increased oxidation resistance. Its specific gravity is 13100 kg/m3. It does not have high values of both heat and electrical conductivity. It also does not stand out for its elastic characteristics. Limit plastic deformation – 0.4%.

The alloy is extremely resistant to mechanical loads. The ultimate bending strength is 1450 MPa. For comparison, the same parameter for steel of ordinary quality St.3 is only 38 MPa. High hardness, about 88 units on the Rockwell scale, makes T5k10 impervious to surface chipping.

All of the above features of the alloy became so due to the presence of certain chemical elements in its composition. T5k10 can be deciphered as follows:

- T5 – indicates a titanium carbide content of 5%. Their main purpose is to increase strength and resistance to impact loads. In addition, titanium reduces the influence of atmospheric gases on the properties of the alloy, in particular oxygen and hydrogen.

- K10 – indicates the presence of 10% cobalt. With an increase in its content, the strength characteristics increase, but at the same time the wear resistance of the cutter decreases.

- The rest - about 75% of the composition - is tungsten carbide. It is this component that determines the properties of t5k10. Carbides are responsible for hardness, and tungsten for refractoriness and heat resistance.

- Harmful impurities enter the alloy due to imperfect smelting technology and the purity of the starting metals. Also, during sintering, there is a high probability of gases such as oxygen, nitrogen and hydrogen entering the composition.

Analogs

Steel x12MF characteristics, application

Of course, steel smelting and its subsequent processing is, one might say, a widespread phenomenon, which means that the means for that very processing should be widespread and in large quantities. And it is not surprising that among such a variety there are several alloys reminiscent of our T15K6. The decoding of the abbreviations will most likely differ, since the designation system of each country may vary, but in general the composition of the alloys is close or identical to the Russian analogue.

So the list looks something like this:

- Sweden – MS111;

- Poland – S10 and S10S;

- Germany – HS123, HT01 and HT02;

- Czech Republic – S1, T2.

Knowing these names, you can easily find a cutter made from the alloy you need.

Production Features

The production of hard alloys using powder metallurgy technology is carried out in the following sequence:

- To obtain carbides and pure cobalt, technologies for their reduction from oxides are used;

- For production, the particle size should not exceed 1 - 2 microns. And it can only be obtained in ball mills followed by sifting.

- Mixing components in proportions that correspond to the chemical composition of the alloy.

- Cold pressing, for this, glue is added to the resulting mixture, which ensures the molding of the future product and its preservation to its final shape.

- The penultimate operation is sintering. This process occurs at a temperature of 1400 ºC. During heating, upon reaching a temperature of 800 - 850 ºC, the glue burns out. At maximum temperature, cobalt goes into a liquid state and wets the particles of carbide powders. As it cools, the cobalt begins to crystallize and the particles join together.

- The last operation is the mechanical processing of the workpieces. For this, a diamond-coated tool is used. Any other one is simply not suitable for this operation.

To improve the cutting properties of the product, special coatings can be applied to them, for example, titanium nitride.

T15K6. Т15К6Т

| steels, and do not lose cutting properties at temperatures up to 850°C and above. Metal-ceramic hard alloys consist of tungsten, titanium or tantalum carbides and cobalt that binds these substances. There are tungsten-cobalt metal-ceramic alloys (VK2, VKZ, VK6, VK4V, VK6V, VK6M, VK8, VK10, VK10M, VK15M, etc.) and titanium-tungsten-cobalt alloys (T5K10, T14K8, T15K6, T30K4, T60K6, etc. .). The numbers after the letter K indicate the percentage of cobalt in the alloy, and after the letter T - titanium carbides; the rest is tungsten carbides. For example, the T14K8 alloy consists of 14% titanium carbide, 8% cobalt and 78% tungsten carbide. Currently, three-carbide hard alloys of the brands T5K12V, TT7K12, TT7K5, TT10K8B and others are produced, consisting of tungsten, titanium, tantalum, and cobalt carbides. These alloys are characterized by high strength. Hard alloy grade TT7K12 allows working with 1.5 - 2 times larger | feeds per tooth than T5K10 alloy. Hard alloys are produced in the form of plates of standard shapes and sizes. Tungsten-cobalt alloys are used for processing brittle materials: cast iron, bronze, hardened steel, plastics, porcelain, etc. Hard alloys of the titanium-tungsten group are intended mainly for processing steels. When selecting carbide grades, you can be guided by the data in Table. 24. Currently, cutters are increasingly equipped with carbide inserts. Solid carbide cutters are also available. Mineral-ceramic alloys are prepared on the basis of aluminum oxide (AbO3) - corundum by fine grinding, pressing and sintering. They are produced, like hard alloys, in the form of plates of standard shapes and sizes. Mineral ceramic plates of the brands TsM-332 (microlite), TsV-13 and TsV-18 (thermocorundum) have greater heat resistance and wear resistance than some hard alloys. However, they have reduced strength compared to hard alloys and increased fragility. Mineral ceramics are used for finishing and fine milling with end mills (heads). | ||||||||||

| TABLE 24 Purpose of grades of hard alloys | |||||||||||

| |||||||||||

| § 63.WearAnddurabilitycutters During the cutting process, removing chips from the workpiece requires a certain amount of work to overcome elastic and plastic deformations, as well as friction along the front and rear surfaces of the tool. Friction causes wear on the cutting tool and reduces tool life. Tool life is understood as the period of its operation (in minutes) between two successive sharpenings. Each tool material, as mentioned above, is capable of maintaining its cutting properties only up to a certain temperature in the cutting zone. When this temperature is exceeded, the cutting tool immediately seizes. In such cases, they sometimes say that the instrument has “burned out.” | |||||||||||

| Prev Next | |||||||||||

element.uu.ru

Misconceptions about the product and its price

The most famous brand representing VK scrap is Pobedit, its composition is 90/10. It is this percentage of chemical elements that gives it such a loud name. However, people sometimes talk about other tungsten and cobalt alloys this way for ease of explanation. Therefore, the cost of identical scrap differs greatly.

Drill with pobedite tip

Often the price of the entire product is determined upon request, after simple diagnostic work using a metal analyzer. If the buyer offers the cash equivalent per kg of vehicle, then there are always accompanying notes indicating what exactly is being accepted: some specific parts, plates, their blanks, sometimes even indicating a list of manufacturers of the purchased products, the weight of the desired batch (for example, in tons) .

Developments

Today, various studies are being carried out in the domestic industry, including an in-depth analysis of the possibility of increasing the characteristics of hard alloys. They mainly concern the granulometric and chemical composition of materials.

As a fairly successful example over the past few years, we can cite the compounds of the TSN group. Such alloys are specially designed for friction units operating in an aggressive acidic environment. This group continues to develop new compounds in the VN group proposed by the All-Russian Scientific Research Institute of Traumatology and Technology.

During the research, it was found that by reducing the grain size of the carbide phase, characteristics such as strength and hardness of the alloys significantly increase. The use of technologies for regulation and plasma restoration of particle size distribution today makes it possible to produce materials whose fraction size is less than a micron. TSN grade alloys are today widely used in the production of oil and gas and chemical pump components.

Classification

The variety of such materials requires a clear division according to their characteristic features. Classification of hard alloys is made according to the following criteria:

- composition of chemical elements (name, percentage);

- on production technology;

- Areas of use.

Based on the chemical elements present, they are divided into the following categories:

- tungsten-cobalt (marking VK);

- titanium-tungsten-cobalt (TC);

- titanium-tantalum-tungsten-cobalt (TTK).

According to the production technologies used, they are divided into: sintered, cast, and powdered. Sintered, composed of carbides. Divided into three groups:

- single-carbide (tungsten carbide);

- two-carbide (including carbides of two metals: titanium and tungsten);

- tricarbide (welded from three elements).

Based on the percentage content of each element, they are divided into the following groups.

The first includes materials consisting of tungsten carbide and cobalt. They are designated VK. This large group includes alloys: VK4, VK3M, VK6M. The hard alloy VK8 and VK3 is very popular. VK3 stands for the same as all tungsten alloys.

The second combines titanium-tungsten alloys. It has the abbreviation TK. These include: T5K10, T14K8.

The third includes all titanium tantalum tungsten alloys. Designated TTC. For example, TT7K12 and others.

The fourth combines materials that have a wear-resistant coating. They are designated by the abbreviation VP. It includes: VP3115, VP3325. Each of them is based on a well-known alloy. For example, VPZ115 has a base of VK6.

Tungsten-containing hard alloys

They are marked as follows - VK6, VKZM, VK6M, VK8. The main area of application is the production of cutting tools. Alloy VK8 is used for the manufacture of cutters.

Set of tips VK6

It allows you to process cast iron. Used for the production of tools capable of so-called chip-free processing of materials.

Titanium-tungsten-containing hard alloys

Tools for high-speed processing of various types of steel are made from grades T5K10, T14K8, T15K6. They are used to process metals and various compounds with increased hardness and heat resistance.

T15K6

T15K6 Chelyabinsk

| Brand: | T15K6 |

| Classification: | Hard sintered alloys |

| Addition: | Titanium tungsten group |

| Application: | For processing materials by cutting: Semi-rough turning during continuous cutting, finishing turning during intermittent cutting, thread cutting with commercial cutters and rotating heads, semi-finishing and finishing milling of solid surfaces, drilling and boring of pre-machined holes, finishing countersinking, reaming and other similar types of processing of carbon and alloy steels. |

| Foreign analogues: | Known |

Chemical composition in % of material T15K6

GOST 3882-74

| Co | – |

| until 6 | Carbides: WC= 79%. TiC= 15% |

| Note: In the latest version of GOST 3882-74 (with amendments 1-6) chem. no composition |

Properties of material T15K6

| Bending strength 1176 N/mm² Density 11.1-11.6 g/cm³ Hardness HRA no less than 90.0 |

Foreign analogues of material T15K6

Attention! Both exact and closest analogues are indicated.

| Germany | Sweden | Bulgaria | Hungary | Poland | Czech |

| DIN,WNr | SS | BDS | MSZ | PN | CSN |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, [MPa] |

| sT | - Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | -Elongation at break, [%] |

| y | -Relative narrowing, [%] |

| KCU | -Impact strength, [kJ/m2] |

| HB | -Brinell hardness, [MPa] |

| Physical properties: | |

| T | -Temperature at which these properties were obtained, [Deg] |

| E | -Elastic modulus of the first kind, [MPa] |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, [Ohm m] |

T15K6-Hard sintered alloys T15K6-chemical composition, mechanical, physical and technological properties, density, hardness, application

Affordable metal products

Material T15K6 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells T15K6 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, T15K6 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Material T15K6 buy in Chelyabinsk

Individual cost is built through personal communication with each potential customer. Managers take into account the volume of the transaction, offer discounts to regular customers and maintain an open dialogue. As a result, even when controversial situations arise, we are able to find a compromise and come to a solution that satisfies both parties.

Delivery

Logistics work is included in the package of our professional services. We constantly improve our knowledge, acquire the latest equipment, so that the cargo is delivered anywhere in Russia.

The presence of our own railway sidings significantly increases the speed of shipment and subsequent delivery. Having such resources, we guarantee delivery of cargo of any volume and dimensions. This professional approach makes us leaders in the metal products market.

metcontinent.ru

Grades of hard alloys: classification of materials

Hard alloys are classified according to two main criteria.

Method of obtaining

According to the method of production, hard alloys are divided into two types.

- Cast. They are made using casting technology. Alloys of this group include stellites, sormites, and hard alloys with a high nickel content. Typically, pressing and thermal post-processing (hardening, aging, annealing, etc.) are used in production. The result is high quality materials. Cast carbide alloys are intended for surfacing on metalworking tools.

- Sintered. Such hard alloys are also called metal-ceramic due to the fact that the manufacturing technologies are very similar. The materials are produced using powder metallurgy technology. It is supplemented by laser/ultrasound processing or acid etching. The resulting materials are of the highest quality.

Sintered carbide alloys are fixed to tools mechanically or using soldering technology.

Stalinite

This carbide alloy does not contain tungsten, which makes it low in cost. It was also invented in the Soviet years and is widely used in industry. As practice has shown, despite the fact that this hard alloy does not contain tungsten, it has high mechanical characteristics, which in most cases satisfy technical requirements. Stalinite has significant advantages over tungsten materials. First of all, it is a low (1300-1350 degrees) melting point. Tungsten materials undergo changes only starting at 2700 degrees. A melting temperature of 1300-1350 degrees greatly facilitates surfacing and increases its productivity. The basis of stalinite is a mixture of cheap powdered ferroalloys, ferromanganese and ferrochrome. The production of this material is similar to the process for producing tungsten compounds. Stalinite contains 16-20% chromium and 13-17% manganese.