The manufacturer of dust collection and gas cleaning equipment "PZGO" offers for consideration methods and equipment for such processes as air purification after sandblasting and shot blasting, collection and ventilation of emery and other abrasive dust.

For more than 30 years now, using our own technologies and patents, on our own full-cycle lines, we have been creating highly efficient, compact and affordable industrial dust cleaning systems, which today operate with dignity at more than 200 industrial enterprises in Russia and abroad, showing an average efficiency of ≈ 99%.

or request a consultation on dust collectors

Sandblasting chamber

Many service stations and car enthusiasts require a sandblasting chamber. Intended for the purpose of processing surfaces and parts of a different nature, using various materials that have abrasive characteristics. It is mandatory to remove the molding primer; during work there should also be no scale, old traces of metal oxidation and matting. It is needed for preparation and then for cleaning the top layer before painting.

But most often sandblasting is used as a suitable method for metal surfaces. The procedure is carried out by applying abrasive powder or sand (always using high pressure).

Production sandblasting chamber

Structure

The sandblasting machine necessarily includes the following components, familiar to everyone:

- the device itself;

- compressor system;

- abrasive.

To accelerate the movement of abrasive particles, energy is needed, which is generated due to air compression. The goal can be achieved by regulating the forces hidden in the latter. It is the compressed air that acts directly on the abrasive material. In order to ensure effectiveness through this type of cleaning, the use of high-quality equipment is necessary. It is also impossible to do without professional skills and mandatory quality control.

The characteristics of chambers powered by jets containing sand differ from each other, but the basic data varies regarding:

- chamber volume (90–990 liters);

- productivity (from 0.5 to 10 m2/hour);

- air flow (from 283 to 452 l/min);

- pressure (within 4–8 atmospheres).

If processing is carried out by an operator who is located within the chambers, then such equipment is called inhabited. The walls of such products are sheathed with soft material. This is necessary to ensure human protection from ricochet, as well as noise effects. The operator is required to have equipment.

It's called habitable. This sandblasting chamber has a special type of structure. The principle of injection using a working mixture is used specifically in sandblasting chambers. Based on this process, they are called pressure. The performance level of such equipment is different. It is several times superior to ejection-type chambers when comparing identical directions for performing tasks.

Industrial and homemade cameras are safe to use. But this is in case of full compliance with safety precautions. We must not forget about protective equipment, such as:

- special protective clothing;

- glasses;

- respirator.

Application benefits

The main advantage of cameras is that their use does not require separate rooms. Surface treatment can be done anywhere. Cleaning must be carried out indoors (this requires a closed space). The working area is so small that the specialist's hands are in it, and nothing else. No additional clothing required. This is the main “plus” of use.

Cameras on the Russian market have two types of material supply. You can choose both ejector and pressure models. Ventilation of sandblasting chambers is a separate issue.

You should also be prepared for a significant increase in energy costs. After all, all this work requires a very powerful compressor. In addition, there is no avoiding an increase in the consumption of sand volumes, as well as its significant loss.

Sandblasting equipment KSO

When the time comes to dispose of the latter, it contains many pieces of dirt, there are cleaning products, a problem arises. The use of effective filter systems in this case is very helpful.

Conditions of use

If high processing productivity is required, a pressure-type chamber is used. Ejector chambers are significantly inferior here. Productivity increases if you use acceleration of the air-abrasive mixture in the nozzle. The latter is supplied from a pressure apparatus and transmitted through a jet hose.

Air consumption in this case is 2.5–5.0 cubic meters. m/hour. A number of materials and elements are used for work:

- steel high-silica sand;

- steel or cast iron shot, fraction up to 2.0 mm;

- electrocorundum;

- compressed air, purified from moisture and oil, classified no lower than the second class according to GOST 17433-80.

Sandblasting of all kinds of surfaces is carried out manually through the use of cameras. It is better that they are of the injection type. The main advantage of this type of equipment is the consumption of compressed air in extremely small quantities. Indicators vary from 0.2 to 1.2 m3/min.

If we compare ejector and pressure type chambers, the first one wins. The reason is that the cleaning of surfaces produced, when used, will be softer. To operate such a chamber, compressed air is used. It is cleaned from moisture and oil no lower than according to class 2 of GOST 17433-80. You will also need cast iron or steel shot. Their fraction should not exceed 2.0 mm. Electrocorundum becomes a necessary element. You can’t do without steel high-silica sand.

Abrasive for sandblasting

Ventilation in the sandblasting chamber is designed to maintain the necessary air conditions in a limited external space. As well as calculating the power that the equipment has.

Sandblasting chamber: how to make

Craftsmen who want to save significantly on waste prefer to create sandblasting chambers with their own hands. But these are not all goals. Such cameras will have the required size and configuration. Another advantage of creating equipment in an artisanal way is the ability to create equipment that is suitable for the purpose of processing certain products.

If you need processing of small parts, then the camera can be created in the form of a box, small in size. But if it is necessary to process large-sized metal structures, then it can even be a small building, for example, a barn or hangar. You can create a sandblasting chamber yourself, even if you have a small amount of finance.

DIY sandblasting chamber

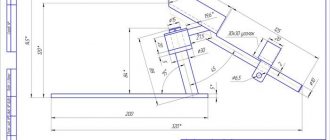

Shortly before making a sandblasting chamber, you should understand the purpose of use and decide on the dimensions. You can’t do without a drawing either. For a person with a technical education, it will not be difficult to compile it.

You also need to think about the place where the camera will be installed. The concept, as indicated above, what size of products you will have to work with directly affects what dimensions this equipment should be.

Please note that the internal size should not be too large, since particles of abrasive material or sand will ricochet off the walls during operation. Therefore, the quality of the work performed may suffer. If you need to make a large chamber, then it is recommended to line its inner walls with soft material, for example, technical rubber plates. At the bottom, it is advisable to install a grating or a pull-out tray with a pipe where sand or other abrasive material used will fall. Once cleaned, it can be used again.

Sandblasting chamber diagram

To assemble the camera you won't need much:

- Nozzle. We recommend purchasing it rather than making it yourself. It is unlikely that you will find suitable materials for its manufacture. Tip durability in a homemade nozzle may be questionable;

- Adjusting ball valve (it will be needed as a part responsible for the flow of the mixture based on a combination of sand and air);

- Fasteners (it must have reliable sealing elements);

- The gun itself works like a sandblaster.

To assemble a sandblasting chamber, you must have a ventilation system with powerful room air purification capabilities. Dust removal is an important factor for operator health. Because under the conditions of product processing, it is formed in large quantities. No matter how well the camera is made, the importance of protective equipment cannot be neglected. Concern for the protection of the eyes (special glasses), respiratory organs (respirator) and body (protective suit) becomes on the same level with the purposes of using this type of equipment.

To control the sandblasting nozzle, you must have two symmetrical holes in it. They will be located inside the chamber. More specifically, in its front part. The diameter of these holes is about 100 mm. Gloves are subject to wear and tear during operation. We are talking about those that are located inside the chamber. It is reasonable to provide the ability to easily and quickly replace them with new ones.

Industrial sandblasting chambers

In order not to reduce the level of control over the work process and manage it effectively, one should not forget about the presence of an observation window. In addition, in the interior of the camera it is necessary to consider options for the lighting system. Lighting is best done at the top of the chamber, using two lights at two opposite ends. It is best to use impact-resistant plastic in the viewing window. Glass is not very suitable for such a device, as it can quickly fail if it cannot withstand heavy loads.

The do-it-yourself sandblasting chamber, the drawings of which will be in front of you, is based on the use of exclusively high-quality materials for the construction.

Safety precautions

Safety precautions in any production are very important. To prevent accidents in the workplace, every worker must adhere to certain rules. Working with sandblasting chambers is no exception.

When working with the camera, increased dustiness appears in the air. Including flint-containing dust. Increased noise in the workplace, flying particles during processing, compressed air. These are all risk factors that can injure the operator. To ensure the safety of the sandblaster and not harm his health, several conditions must be provided.

The most important thing in blast chambers is good ventilation. Therefore, it is necessary to either equip the room where the camera is located with good ventilation, or provide the worker with a special protective suit.

Safety precautions when operating a sandblasting chamber

With open type devices everything is more complicated. If you do not have the opportunity to work outdoors, then you need to think about how to properly equip the room. Work, as noted above, is accompanied by increased noise. This means that the room needs soundproofing. The presence of a special suit is simply necessary; moreover, an air filter must be connected to the protective helmet, which will supply the operator with fresh air. The helmet must be reliable and protect the worker’s head and face from abrasive ricochets.

We also do not forget that the suit should be made of fairly dense fabric that can easily protect. Gloves are also an important element of protection. They should be comfortable when the operator works with the nozzle.

Strictly following the pre-drawn drawing and following all the recommendations of specialists is the basis for achieving a high-quality result. This will ensure durability and high efficiency of use of a sandblasting machine of any configuration. Even created by hand.

Great Encyclopedia of Oil and Gas

Page 2

Continuous sandblasting chambers are designed for cleaning castings that pass continuously on any transport device. [16]

The sandblasting chamber and compressor must be placed in special booths separated from metallization workplaces. A system of intensive exhaust ventilation from machines and work tables on which metallization is carried out must be provided. [17]

The premises of sandblasting chambers and workshops must be separated from neighboring premises. Sandblasting chambers and devices must be equipped with exhaust ventilation with appropriate dust collection devices. [18]

The premises of sandblasting chambers and workshops must be separated from neighboring premises. [19]

| When performing cleaning work (abrasive blasting, shot blasting), a large concentration of suspended dust is formed in the working area. This dust consists of small particles that were formed both from the surface being cleaned (rust, old paint, particles of the top layer of the surface of the product), and due to the breaking of the abrasive itself during impact. Suspended dust significantly limits the visibility of sandblasters, reduces the productivity of their work, and gets onto parts of the equipment, which can cause increased wear. Therefore, ventilation in the shot blasting chamber is, first of all, necessary to ensure visibility when the operator is working and to remove the resulting suspended dust during cleaning work. Also, the resulting dust can fall on the chamber floor and enter the used abrasive, increasing the dust concentration in it. This causes an increased load on the abrasive separation (regeneration) system and can lead to faster wear. The choice of a specific ventilation system (dust collector filter with fan) depends on the volume of the shot blasting chamber and in many cases is carried out individually. For air purification (filtration) in such systems, special cartridge filters made of special filter material (polyester, cellulose, cellulose-polyester) are most often used, which trap dust on their walls. To ensure high-quality purification of polluted air and ensure long-term operation of cartridges, a special automatic filter cleaning system is used. The filter cleaning system, after a given period of time, generates a pulse of compressed air of the required duration and strength, due to which the adhering dust is shaken from the surface of the filter elements. The ventilation systems are connected to the shot blasting chambers by an exhaust air duct through special exhaust ducts (ducts) that have labyrinth or fender protection against abrasive ricochet. Most often, the ventilation unit is connected in a cyclic mode of operation: 95 - 97% of the purified air emitted is returned through the input air duct back to the shot blasting chamber, and 3 -5% of the output air is removed outside the workshop building. This connection scheme is especially relevant in winter to save heat and also avoids the entry of additional dust into the work area of the workshop. As a rule, air circulation in the shot blasting chamber is longitudinal. For normal dust removal, the air speed in the chamber should be on average about 0.20 - 0.25 m/s. Different intensity of cleaning work requires different amounts of so-called. air exchange cycles. |

| Air exchange rate. [20] |

Air is sucked out of closed-type sandblasting chambers and devices through the ventilation pipes located in them. Exhaust ventilation in sandblasting installations is carried out through local suction. [21]

In sandblasting chambers, a MIOT-49 helmet is used with a forced supply of filtered air from the compressor line through a rubber hose to the helmet. The helmet consists of a metal (aluminum) frame and a cape that covers the worker’s chest, head and shoulders. [22]

In large sandblasting chambers, workers must be protected from dust by protective suits. Air is supplied to the latter under pressure from 0 1 to 0 15 atm. Excessive air pressure creates conditions for air to escape through the leaks of the spacesuit and prevents the entry of harmful dust from outside. [23]

Nozzles for sandblasting chambers are most often made of white cast iron. They usually serve one shift, after which they become unusable. Pobedite nozzles are more durable; their service life is determined at 250 - 350 working hours. [25]

Before starting to operate sandblasting chambers and devices, it is necessary to turn on the supply and exhaust ventilation and cleaning devices, and also check the reliability of the nozzle connections and the condition of the hoses supplying sand and air. [26]

| Scheme of a suction installation from sandblasting machines. [27] |

The diagram of the suction installation of the sandblasting chamber is shown in Fig. 6.3. The air passes through a cyclone, where large dust particles settle, and enters the humidification chamber; From here the air is directed into a wet gravel filter and removed using an exhauster. [28]

Before starting to operate sandblasting chambers and devices, it is necessary to turn on the supply and exhaust ventilation and cleaning devices, and also check the reliability of the nozzle connections and the condition of the hoses supplying sand and air. [29]

A diagram of the suction installation of a sandblasting chamber or apparatus is shown in Fig. [thirty]

Pages: 1 2 3 4

Principle of operation

There are two ways to filter the air in the sandblasting chamber:

- A fan is a simple and cheap way to organize a hood. Its performance must be calculated in such a way that the total volume of air in the chamber changes in no more than 2 minutes. But this method has quite a few disadvantages: dirty air will escape into the street, an additional cleaning filter will be required, and under heavy loads the fan quickly breaks down.

- A cyclone with a self-cleaning filter system is an expensive but effective way to clean an uninhabited sandblasting chamber. The design consists of a powerful dust-proof fan and cartridge filters equipped with a shaking system. The principle of operation is to suck air from the chamber and supply it to the filters. At the exit, it is cleaned of dust and small abrasive particles. The equipment is connected to the power supply network.

The cost of installing ventilation with self-cleaning filters is 15–20 times more expensive than a fan, but it can eliminate problems with environmentalists for a long time and provide comfortable working conditions.

Ideal processing room

Anyone who has ever encountered such a technically complex procedure as painting a car knows how difficult it is to ensure that the paint goes on smoothly and without defects.

If the preparatory work can be done with your own hands, then it is very difficult to paint and dry the car so that everything goes without a hitch.

The same applies to cleaning off old paintwork and corrosion, if any has appeared on the car. Sandblasting work, although technically not very difficult, is labor-intensive and produces a lot of dirt.

There are special chambers for this kind of work: sandblasting chamber and painting booths.

Treating a car before painting in a sandblasting chamber

Sandblasting metal is the treatment of a surface with abrasive materials under the influence of compressed air pressure. Electrocorundum, clean sand of various fractions, and fine metal shot are used as abrasive materials, depending on the purpose of the work.

There are two methods of sandblasting: sandblasting using a machine and working in a sandblasting chamber. The camera is used in cases where it is necessary to process large surfaces or complex paintwork.

The term “sandblasting chamber” can be considered in two meanings. This is an industrial chamber in which very large surfaces are processed, and also where a person with a sandblasting gun works.

The second type is used to process the car. You can even design them with your own hands, if you wish.

How to make a camera with your own hands? And why do it?

There are several reasons for using a sandblasting chamber. Firstly, the abrasive material used in the chamber is not sand. The chambers use a different abrasive material that can be reused.

For example, metal shot. It can be collected, separated (cleaned) and put back into use. If the abrasive collection process is mechanized, the productivity will double.

Secondly, sandblasting is a very dirty job, and if carried out in the air, not only people, but the entire environment may suffer. If the chamber has well-functioning ventilation and good filters for the chamber, then the process will be environmentally friendly.

To make a sandblasting chamber, you need a sandblasting machine. This is a banal statement. But it must be said that it must have a remote control valve.

This is very important, since sandblasting is hard work, a person can lose consciousness, be out of sight of the auxiliary worker who turns the installation on and off, and the device will work. The result is a danger to health and life.

A suitable room is selected for the sandblasting chamber. Usually a shipping container is used. It should not be too large, since the abrasive will ricochet off the walls, and if the room is large, then the ricochet force will increase.

A distance of at least 1 m must be provided between the walls and the car for safe operation and an emergency exit. Thus, there should be two exits.

The walls of the chamber are usually lined with rubber plates. As you might guess, this is for less rebound force. Rubber plates are not completely attached to the walls, but at a short distance to reduce the impact force.

The floor in the chamber is made in the form of a lattice. The abrasive material will bounce off and fall through the grate, collecting in the receiving compartments. From there it is taken out manually and subjected to separation.

A very important part is ventilation. To calculate the fan power, there are special formulas that must be used, since the ventilation must be strong enough, but in moderation so as not to complicate the operator’s work.

The supply and exhaust ventilation of the chamber provides for air flow from above, and the exhaust is done from below along the width of the entire chamber. Clean air pushes a cloud of dust and dirt to the floor, making the operator's work easier.

The sandblasting unit itself is placed outside the chamber, but not in an open space. If the device is inside, the installation may be damaged by abrasives.

And lastly: we must not forget about the means of protecting the person himself and in no case neglect them. This is a helmet, overalls, goggles, and a respirator.

Painting booths for cars.

The most important thing in painting a car is to achieve an even coat of paint and proper drying. Otherwise, defects cannot be avoided, especially if it is painted in several layers. This is how cars are coated in a metallic color or the now fashionable “chameleon” color.

In the spray booth, it is necessary to provide cleaning filters, set up a ventilation and heat exchange system, since an important condition for good car painting is a constant temperature and ideal cleanliness of the room.

First of all, it is necessary to debug the supply and exhaust ventilation, since it will have to work through three cycles: clean the air from dust, supply it to the chamber, balance the temperature in the range of 20-40 degrees (this is the best temperature for applying paint), then air again to dry the car is cleaned and the temperature is raised to 60-80 degrees.

Spray booth

What is needed for a spray booth?

The room for work is chosen to be quite spacious. Filters for the chamber, air intake and air outlet will provide air supply and exhaust. elements heating the air will raise the temperature to the desired degree. All equipment can be controlled from the control panel provided in the camera.

The sequence of construction of the spray booth is the same as in the case of a sandblasting booth.

There are, however, some differences. So it’s better to choose an empty garage for your work space. Raise the floor of the chamber by half a meter and make a convenient bridge for entering it. The floor should be metal, this will ensure rapid heating of the air.

It is necessary to provide good side and top lighting in the painting booth: in poor lighting, possible painting defects will not be visible. The most effective lamps are fluorescent and LED, the degree of illumination is 1.5 -2 thousand lux.

You can also provide for the installation of portable lamps, as lighting of individual places may be required.

The most important system in a paint booth is the ventilation and air filtration system. When painting, many harmful substances are released that have a bad effect on human health. The painting of a car is also negatively affected by the fumes and fog generated during the operation of the spray gun.

To avoid this, supply and exhaust ventilation must be installed in the painting booth. The painting booth contains painting tanks, as well as tables, above which additional hoods are installed.

Usually two fans are installed, one blows air in, the other exhausts, but their power should be different, it depends on the purpose for which the spray booth is intended.

A uniform air flow is supplied to the room; after painting, the polluted air is nailed to the floor, paint particles fall on the filters, since they are heavier than air. Two-stage filters purify the air and enter the external environment through the exhaust fan.

Clean air is again supplied to the chamber through a blower fan, the heating element raises the air temperature, the drying process of the car is carried out evenly, and the layers of paint do not cause defects.

A heat gun is used as a heater; it is effective in such cases. The injection fan is located under the ceiling, the exhaust fan is located at floor level or slightly higher. This is how natural heat and air exchange occurs.

Working safety in the painting booth plays an important role. All equipment in the chamber must be non-explosive, and the finishing must be non-flammable. You must work in protective equipment.

Of course, you can paint a car in your garage with improvised means, but it’s still much more convenient to do it in a spray booth. The main thing is not to be afraid of difficulties.

DIY hood

To make a hood with your own hands, you will need:

- electric motor with a power of 0.3-0.75 kW;

- volute for air removal or propeller with blades;

- filter.

The sandblasting chamber is equipped with a compressed air supply hose, volute or blades connected to the engine. The snail’s “nose” is mounted inside the chamber and sealed tightly. The blades, using an electric motor, will create the necessary vacuum to suck in polluted air.

A cleaning filter made of polyester, cellulose or a combination is installed at the outlet. With proper installation and complete sealing of the structure, correct operation and durability of the system can be guaranteed.

The chamber of the sandblasting machine must have a ventilation system. For small volumes, you can use a homemade fan-based hood. For production scales, a ventilation system with self-cleaning filters is ideal.

see also

- CO2 sensors for ventilation systems

- Do-it-yourself ventilation installation in the kitchen

- Air dehumidification in ventilation

- Mechanic for maintenance and repair of ventilation systems

- Ventilation efficiency act

- Ceiling ventilation

- DIY ventilation in the bathroom and toilet

- Design of air conditioning and heating systems

- Axonometric diagram of the ventilation system

- Ventilation in the furnace with a wall-mounted gas boiler

- How to clean the ventilation in an apartment building