23.03.2020

- Design and operating principle

- Classification of cutters: by what parameters

- Types of cutters for metal

- Classification of cutters according to some characteristics

- Nuances of choice

- Storage and operation rules

- Wide range of milling machine capabilities

During milling metalworking, it is important what type of metal cutter the master has chosen. In the article we will talk about the numerous varieties and features of their use - both a beginner and a professional will need this for repetition.

Design and operating principle

This tool is widely used on modern equipment to create a cut of any shape on a workpiece. This is a fairly optimal device that allows you to make holes, grooves, and also remove excess steel.

The tool unit is created from a durable tool alloy with maximum precision. To fulfill the parameters stated in the specifications, processing is used with an end tool with a large set of teeth - cutting inserts adjust the parameters to 1 micron.

Structurally, the cutter has several sharp working edges. Inserts are often made from diamond, ceramic and carded wire for durability.

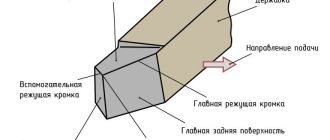

The structure consists of:

- • Parts to work with.

- • Tail.

- • Center hole.

- • End teeth and grooves between them.

- • Necks in the middle.

Each tooth has, in turn, a front and rear surface, a cutting edge.

The operating principle is that the tool rotates quickly. At the same time, the workpiece moves. Upon contact, the top layer of steel is cut off mechanically under the influence of pressure.

Storage and testing rules

Testing of disc cutters for performance and durability takes place on samples made of steel 45, with a cutting speed of 20-100 meters per minute. Tests are carried out on milling machines using a special mandrel and dressing rings. The total milling length of each tool that is subjected to metal testing is 25−50 cm.

Test treatment is carried out with the obligatory supply of coolant and an aqueous emulsol solution. After the test is completed, there should be no staining phenomena on the cutting parts of the cutting disc cutters. If after testing the cutter is ready for further use, it is considered to have passed the performance test.

The appearance of the equipment is analyzed visually, according to GOST. The inspection is carried out using a magnifying glass with fourfold magnification. Hardness is tested according to standard 9013, and roughness - 9378.

Types of cutters for metal

Usually, with versatile activities and numerous tasks, the milling machine operator has a complete set, and he himself knows perfectly well how they work. But newbies need to do a little review.

Disk

They are a disk with teeth. In this case, the cutting edges are either on one side or on both, depending on the purpose. During the metalworking stages (from roughing to finishing), the size of the notches may change. Carbide tools are used under difficult cutting conditions, when it is very difficult to remove chips from the work area. When to use this type of cutter:

- • for trimming edges or sawing;

- • for cutting grooves;

- • for chamfering, etc.

Accordingly, among the disk ones you can find cut-off, slotted and other subspecies. Let's talk about some of them that have design differences.

Double sided

The teeth of such discs are equipped with two cutting edges - a classic one on the end part, and also on a straight surface. This modification is more expensive and more productive.

Tripartite

Even more dangerous teeth - now they are equipped with three blades, that is, on each side - along the edges, at the ends and on top.

Grooved

There is only one edge, located on the working surface. The tool is suitable for not very deep and precise sampling of steel. It can be with a different number of teeth and depth of recesses. One common name for this type of cutter is dovetail. Why? Because the cutting zone has the shape of a truncated cone, like the feathers of a swallow.

End

From the name it is already clear that such a tool works with its side part. It is the ends of the cylinder (of different widths) that are equipped with blades that process the plane of the metal workpiece. The part is installed, respectively, perpendicular to the steel part.

Very often they come with removable plates, which saves the milling machine consumables. This is possible due to the overall massiveness of the structure. The advantages include:

- • Ease of working with flat elements, sheets and stepped surfaces.

- • High metal processing speed.

- • Smooth process.

Cylindrical cutters for metal - what are they?

Shape: cylinder. Quite a massive tool that is convenient for processing planes. This is the main type of equipment for both classic mechanical and CNC machines. The site has a large selection of milling equipment with a numerical control panel. A modern modification allows you to increase the speed and productivity of one workstation, as well as reduce the risk of errors due to the human factor.

Cylindrical tools can have different tooth shapes.

Direct

Less sought after and versatile, even rare. It is good and convenient, but for a very narrow profile of work: the equipment should be located parallel to the headers, and the metalworking area itself should have easy access and a flat surface. In general, such ideal conditions are rare - these are only narrow planes.

Screw

The most multifunctional, universal and, accordingly, in demand. The cutting lines do not go straight, but along a twisted spiral. The specified tilt angle may vary. Depending on the selected faces, virtually any selection can be made - on various parts. Peculiarities:

- • High effort during operation.

- • Possibility of using double tools when the edges are in opposite directions - this reduces the force acting on the edges.

A separate type of cutter is the “corn” cutter, which is used in the processing of ledges and the creation of grooves and their grinding. They look interesting.

Corner

This is a truncated cone that has sharp outer edges and tooth ends. The main purpose of use is metalworking of corners and uneven surfaces, removal of rectangular chamfers. They are also used to make chip flutes and many additional operations. The cutting edges are made with an inclination, which allows you to achieve any working angle. Let's see what subspecies there are.

Monolithic

The second name is all-metal. Their essence is that the entire structure is made of one durable material. An additional improvement is the presence of annular grooves, which allow the formed chips to be easily removed.

Soldered cutting plates (crowns)

Everything is simple here, the tips are selected and then soldered to the base. The teeth themselves are made of hard alloys; there are many modifications of them; crown teeth are common.

For pre-treatment

These are cutters that are not highly accurate, but are designed specifically for rough cutting of a large volume of metal at once.

For the final stage

They have smaller, shallower carbide teeth with other strong abrasives added. They should not be confused with grinding. The goal is to achieve maximum purity in metalworking.

With cylindrical shank

The tail part is not a working part, it does not interact with the workpiece, but serves for reliable fastening in the base fasteners. When the tail is created in the shape of a cylinder, that is, a barrel, the possibilities are quite limited - movement can only be carried out at one angle, so only straight surfaces are processed.

Why do you need cutters with a conical shank?

This modification has much greater freedom of action only due to its adaptation to tilt. Due to this, they are more common, especially when equipping CNC machines. Modern high-tech equipment can be ordered on the website.

End

They are also called finger-shaped because of their neat external type - an elongated cylinder that resembles a finger. Their main purpose is to insert grooves, create recesses, and work with contour ledges. They are very well suited for metalworking of two perpendicular planes. They are divided similarly to angular ones into:

- • monolithic or with replaceable plates;

- • different shapes of shanks;

- • degree of processing – from initial to final.

Shaped

Suitable for the production of chamfers and turning of broaching shaped parts. If they are short, then usually milling is not used, but broaching is used. The appearance of the equipment is interesting - two circles with notches. There are several varieties.

Sharp sharpening

The second name is pointed. Their cutting edge is clearly visible and can be easily re-sharpened. They are easy to adjust if necessary.

Backed instruments

They are very convenient for processing closed grooves, chamfers, and edges. Their cutting knives protrude slightly beyond the main disk, so they are difficult to sharpen.

What hob cutters are there for metal?

This is a multi-bladed tool. Its purpose is to cut gears and splined shafts that have an involute profile. Metalworking involves point-to-point contact of blades with a surface.

Solid and prefabricated

Monolithic tools are made entirely of tool alloys - they are stronger and more reliable. But the second modification is different in that you can change the tips, and also replace them if damaged, making sharpening more convenient.

Single-pass and multi-pass

This is the number of turns that are on the hob cutter. The more there are, the higher the performance, but the accuracy begins to wane. Therefore, a large number of passes are used mainly only for rough finishing.

With ground and non-ground teeth

Simply put, this is the degree of serviceability. The higher it is (fine processing), the better the grinding occurs. While the roughing, roughing, intermediate and even finishing stages are tools that are not designed for grinding.

Core drills

They are used to create holes. You can use the classic spiral variety, but in terms of accuracy they are 4 times inferior to the option under consideration. Their purpose is for CNC machines.

You can hear the name burr. This is a similar accessory, but it is attached to a hand-held electric drill and performs a similar function.

Keyed

A convenient small cylinder with very smoothly arranged turns of cutting edges on the working part. The peculiarity is that there are special recesses that are designed for easy removal of chips.

Conical

Or conical ones. They have the shape of a truncated cone and are suitable not for straight sections, but for rounded parts. One of the varieties is finger-shaped.

Spherical

Not the most popular, they are used in single-pass metalworking in order to create fairly high-quality grooves and shaped ledges. Small blades are located on all sides of the working area.

T-slot cutter

This shape is necessary when creating recesses in the head of fasteners or when preparing shafts with splined joints. Sometimes they are called a fungus; indeed, they have a similar configuration, but upside down.

Prefabricated

This is a very convenient and versatile tool kit, which consists of a base and several holes for fastening the necessary cutters. On the one hand, this is extremely effective; you can combine a lot of functions in one handpiece. But, like any universal thing, it is inferior to a highly specialized one.

Purpose of the tool

Cutting cutters manufactured in accordance with GOST 2679-93 are intended for processing cast iron and steel blanks and parts. They perform parting, trimming, milling grooves and spline grooves on external surfaces. A disk cutter for metal is used in various operations:

- cutting pieces from rolled products;

- trimming casting allowances and profits on small parts;

- cutting grooves for fixing parts;

- milling of key and spline grooves.

The smooth round axles in the conveyor chain do not fall out of their bushings only due to the fact that a plate is inserted into a narrow slot made by a circular saw.

The grooves at the end of the castle nut have a variable cross-section. Their sides are formed by rays from the center of the radius. Therefore, they are cut out in 2 passes, first along the tangent of one side, then the second end of the crown sample is cut to size.

The splines are cut using rectangular teeth with high dimensional accuracy according to H6 and H7. The spline width and depth are normalized and the tool is manufactured to the appropriate size and configuration.

Classification of cutters according to some characteristics

Of course, the above distinctions (by configuration, purpose) are not the only ways to distinguish between equipment. A real milling machine operator has such a large assortment of products that he will not be able to sort it out without difficulty. What other reasons are there for classification?

Different number of visits

The following are considered standard:

- • Single pass.

- • Two-way.

- • Four-lead.

But there can be any number of turns.

The fewer entries, the larger the allocated area for the grooves. The peculiarity of working with such a tool is that at each moment only one specific cutting edge affects the workpiece. This has a very positive effect on creating a product at high speeds and speeds, as it allows waste to be removed smoothly.

This is also relevant when carrying out activities with soft metals and other substances, for example, plastic or PVC, acrylic. They are also used for roughing and roughing procedures, when quality and accuracy are not the most important indicators.

Multi-pass ones are used when working with materials that have a hard and brittle structure. The movement will be smooth, without shocks, because several teeth touch the surface at the same time.

Chip removal type

Everything is simple here - the waste flies either upwards, which is the direction all milling operators are accustomed to handling, or downwards. The first option is most convenient if grooves or a blind hole are created, since metal does not accumulate there. But there is also a minus - part of everything “flying out” can land again on the working area and interfere with good cutting. The second option, accordingly, has narrower capabilities, but is more recommended for some types of work.

Nuances of equipment selection

Choosing the right tool for yourself is not difficult; you just need to know the characteristics and parameters of the equipment. Such parameters include the number of teeth and the material from which the product is made. The key to choosing a product material is the strength of the metal you are going to cut.

Required number of teeth

The processing speed and cleanliness of the cut depend on the number of teeth the tool has . The greater their number, the cleaner the cutting area will be. But at the same time, the load on the electric motor greatly increases, and the process of removing chips from the cutting site worsens. And because of these reasons, the speed of penetration into the thickness of the metal and rotation of the tool decreases. If the number of teeth is small, then the size of the sinuses between them increases. These factors speed up cutting and facilitate removal of chips. But there will be grooves at the ends, which should be additionally cleaned.

Cutting cutters with a negative angle and overall diameter have more teeth. A device with a positive angle and a small diameter will have a smaller number of teeth.

A small number of teeth ranges from 10-40, an average - 40-80, and a large - 80-90. It is the samples with an average number of teeth that are suitable for various types of cutting. It is these samples that are most effective for working on materials of different hardness.

For finishing milling, cutting disc tools with small teeth are used, and for primary milling, with large teeth. Discs designed for roughing work are characterized by unhindered and quick removal of excess chips from deep cutting areas.

How to choose material

For cutting metals with a strength of 500 to 800 MPa, cutters made of high-speed steel with the addition of molybdenum, the amount of which is approximately 5%, are used. To work with metals whose strength exceeds 800 MPa, choose tools with a cobalt content of up to 5%. To work with precious metals, high-precision cutters are made from high-speed steel of the best quality.

For processing stainless steel, disc tools with tungsten carbide tips are used. These teeth are not ground, they are coated with a PVD layer.

Features of steel for the manufacture of cutters

The equipment is made of high-speed alloys , which include high-alloy steel grades with increased heat resistance. A similar distinctive feature is achieved by introducing molybdenum, chromium and vanadium into the alloy in combination with tungsten. For the production of cutting cutters, the following grades of steel are mainly used: R6M5, R12, R18.

Alloys are supplied to factories for the manufacture of cutting tools in the form of steel blanks (forgings).

When cutters are subjected to heat for hardening , austenite begins to form in the alloy. It contains a relatively small amount of carbon and is heavily doped. The cutting tool receives a special structure after hardening and consists of martensite with small needles, various carbides and retained austenite.

The main alloying additives for high-speed steels are vanadium, tungsten, molybdenum and cobalt. It is these elements that can provide the required red resistance of the material. Chromium must be added to such alloys. Particular attention is paid to the amount of carbon in the steel: its number must be such that carbides of the introduced additives can form in the alloy. If the amount of carbon is less than 0.7%, then the finished cutter will not have the required hardness.

How do alloying elements affect the properties of alloys:

- Phosphorus and sulfur have a negative impact on the characteristics of high-speed steel compositions. In the alloy, their amount should not exceed 0.03 and 0.015%, respectively.

- Tungsten and molybdenum are the main alloying additives. It is thanks to them that a high degree of operational and red-hardness of steel is ensured.

- The alloy should contain no more than 4% chromium. It imparts increased hardenability to the metal.

- Cobalt increases red resistance, but removes carbon from the steel and reduces its strength and toughness.

Most often, the tool is made of steel grade R6M5. Its cost is lower, but the cutter is also less wear-resistant than materials made from the P18 and P12 brands.

The P18 alloy has maximum wear resistance: it contains the largest amount of tungsten, hence the high cost. And in terms of heat resistance, the best tool is considered to be one made of P12 steel.