Basics of Electric Arc Metallization

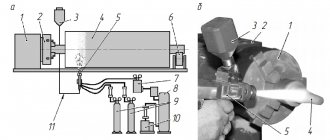

1.1. Electric arc metallization process

Electric arc metallization involves melting two wires with an electric arc and spraying the molten metal of the wires onto the prepared metal surface.

In an electric arc metallization machine, two wires are driven and guided in a gun so that they converge at a point and form an arc.

The air nozzle of the arc metallizer gun atomizes the molten metal produced from the wire and directs it to the workpiece using high pressure air. The metal hardens when it hits the surface of the workpiece, forming a dense coating that protects against corrosion.

Spray speed, wire feed speed and the entire arc metallization process are easy to control. All parameters of electric arc metallization can be set using regulators on the panel of the electric arc metallization apparatus.

1.2. The operating principle of an electric arc metallizer.

The process of electric arc metallization involves heating the ends of metal electrodes with an electric arc to the melting temperature and then spraying the liquid metal with a jet of compressed air.

Wire electrodes of the sprayed material are fed along the burner guides, to which voltage is applied. When shorted, an arc is formed between the ends of the wires. At a voltage of 15-25 V, an arc is formed, which is unstable and intermittent. At high voltage values, the arc becomes continuous and stable. Good arcing results are obtained when the arc gap is small and is approximately 0.8 mm. In an electrometallizer, the angle between the electrodes (sprayed wire) is usually 30-60°. At angles greater than 60°, the deposition process becomes sensitive to changes in deposition conditions and unstable.

When the electrometallizer operates on direct current, the sprayed wire, which acts as an anode, melts approximately 50% faster than the cathode (theoretically, 66% of the thermal energy of the arc is released at the anode).

This means that the anode wire should be fed faster than the cathode wire. However, in practice there is no need for different electrode feed rates. Therefore, the wires are fed at the same speed. The most important thing when spraying is the correct adjustment of the current, which allows you to balance the feed speed of the wires with the speed of their melting and thus ensure a constant arc length. When spraying, the distance from the electrometallizer to the surface to be coated is usually 100-200 mm.

For spraying, wire of standard diameters is usually used.

1.3. Preliminary preparation of the metal surface during electric arc metallization.

Aluminum and zinc coatings cannot be properly applied to an unprepared metal surface. Therefore, the preparation stage for spraying is inevitable.

For all methods of electric arc metallization there are general requirements for surface preparation:

The electric arc metallization process includes the following operations:

· preliminary abrasive blasting of the metal surface to ensure strong adhesion of the sprayed material in the shot blasting chamber or sandblasting chamber;

· spraying of material onto the prepared metal surface in an electric arc metallization chamber;

· processing of the resulting coating after spraying, if necessary (heat treatment, coating compaction, finishing treatment).

1.4. Selection of equipment for electric arc metallization

When choosing equipment for electric arc metallization, the following characteristics should be considered:

- Power consumption. The higher this value, the more efficient the equipment;

- type of drive. There are metallization devices with push, pull or push-pull drives, which differ in the weight of the gun and its maximum distance from the power source;

- Flexibility of settings. Some metallization machines allow you to adjust the voltage, wire feed speed, air speed and volume;

- Spray system. It is possible to adjust voltage, wire feed speed, air supply volumes;

- Additional devices. Some metallization devices can operate at a great distance from the power supply. Various wire unwinding devices, means of mechanizing the spraying process and providing computer control can be used;

- Reliability. We supply only highly reliable arc metallization systems that can spray hundreds of thousands of square meters of surface with minimal maintenance and repair costs.

Areas of application of electric arc metallization.

1. Anti-corrosion coatings (zinc, aluminum, tin, copper alloys, high chromium, chromium-nickel alloys) providing the ability to operate in highly aggressive environments.

2. For applying anti-corrosion coatings to large surfaces: bridges, piers, sea and river transport, freight, passenger, auto and electric transport, road fences, elevators, power line supports, piles, greenhouses, pipelines, oil production and processing equipment.

3. For restoration of parts: steel, cast iron and non-ferrous metals.

4. To protect ferrous metals from corrosion or change their surface properties - to improve wear resistance or thermal conductivity.

5. For on-site anti-corrosion treatment. It is possible to use the equipment in field conditions.

Advantages of electric arc metallization technology.

1 Metal protection in extreme conditions

The applied coating of electric arc metallization is not afraid of frosts down to – 60°C, sea water, impacts, and abrasion by ice. Temperature resistance up to 600°C. No other application method gives this result.

Financial benefits of electric arc metallization

· Increased turnover: high processing speed – up to 15m2/hour

· Savings on production space and personnel - no baths required (as for hot-dip galvanizing), automation

· Tens of times cheaper than stationary workshop equipment

Durability of coating up to 50 years

Electric arc metallization is a guaranteed protection of parts from corrosion. Adhesion up to 80 MPa - with proper preparation, coatings do not peel off from the surface to which they are applied.

4. Maximum coverage reliability

Electric arc metallization guarantees up to 99.9% zinc (or other substance used) in the top layers of the coating. And with hot galvanizing - only up to 40%

No restrictions on part sizes or weather conditions

Processing using electric arc metallization equipment is possible for parts of any geometry, shape, and size. Electric arc metallization is carried out in production conditions, field conditions, even in rain and snow

Mechanical processing of coatings

When it is necessary to obtain a clean surface with exact dimensions and a given roughness, the coating sprayed with a certain allowance is subjected to mechanical processing. The main types of mechanical processing of coatings are cutting and grinding. To process coatings made of carbon and corrosion-resistant steels by turning or milling, you can use high-speed cutting and carbide tools. Grinding of coatings can be carried out either with or without the supply of coolant. “Wet” grinding is preferable in cases where there are no problems associated with the penetration of coolant into the pores of the coating. Rough sanding (whether dry or wet) can cause cracks in the sanded surface. Therefore, in order to obtain a high-quality surface, it is necessary to choose the right grinding wheel and grinding modes. Typically, wheels with a relatively coarse structure and a weak bond are used for grinding applied coatings.

After final sanding, the surface of the coating should have a matte shine and contain small pores. A surface that is too shiny and lacks pores indicates improper sanding.

Compaction of the coating and filling of its pores with sealing materials, when necessary, is carried out before grinding. Sealing materials prevent particles of abrasive materials used during grinding from penetrating into the pores of the coating. If the pores of the coating are not filled with sealing materials, then after grinding it is necessary to rinse the coating and remove particles that got into it during grinding. This is especially important for coatings applied to bearing surfaces. Coatings made of soft materials (tin, zinc, babbitt) can be honed, resulting in a smooth surface with little porosity.

Wire for electric arc metallization.

The quality of the protective coating of a metal surface applied by an electric arc metallizer largely depends on the preliminary preparation of the surface and the quality of the wire used for electric arc metallization.

Electric arc metallization wire is used for spraying protective coatings using flame spraying and electric arc metallization equipment. Electric arc spraying equipment is quite sensitive to the quality of the material. Only the use of wire with a constant diameter and chemical composition can guarantee consistently high quality coatings.

Using wires with the same composition and produced in different ways for electric arc spraying can give completely different results.

Basic requirements for wire for electric arc metallization:

· Degree of purification SAE3.0 · Small deviations in chemical composition · Small deviations in diameter · No cavities · Low roughness

The use of wire for electric arc metallization that does not meet these conditions can lead to deterioration in the quality of the coating and rapid failure of the spraying equipment

The wire used for flame spraying must comply with the following

That is why we carefully select suppliers, guaranteeing high quality materials, which means high repeatability of spraying results. The presence of an equipped warehouse and the constant circulation of materials in the warehouse allows us to avoid the use of “stale” material that has been oxidized or damaged during storage.

Wire for electric arc metallization has standards with diameters of 1.6, 2, 2.5, 3 mm. The price of wire for metallization depends on the price of zinc on the London Metal Exchange. You can view the current price for today on the LMB website

5. Materials for electric arc metallization

Zinc - zinc wire Zn (99.9%) is used as a material for creating coatings resistant to atmospheric corrosion and corrosion in liquid environments. Zinc – for spraying in moderate to low corrosion environments, for water tanks, bridges and general structural steel structures. Zinc – protection of steel structures from corrosion both in an open atmosphere and when immersed in fresh or salt water

Aluminum - aluminum wire Al (99.0%) is used mainly for applying anti-corrosion coatings; Aluminum is used in conditions of more severe corrosion: in coastal coastal areas and in conditions of high temperatures, in oil drilling installations.

An alloy of aluminum and zinc (85%Zn/15%Al) – when you need anti-corrosion protection stronger than zinc, but at a more affordable price than aluminum. Better corrosion protection than pure zinc. Protects steel structures from corrosion both in open atmosphere and when immersed in fresh or salt water. It is more difficult to spray using the electric arc metallization method

Aluminum-magnesium – AlMg5 wire is used to create tread coatings to protect metal structures from corrosion;

Alyunik - Alloy of aluminum and nickel. NiAl wire is used both independently to create insulating anti-corrosion coatings and to create an adhesive sublayer;

Babbitt - Babbitt B-83, B-88, the so-called “sprababbitt” are used for the production and repair of antifriction coatings for Babbitt bearings and liners;

Monel metal - Monel wire on a nickel base NiCu30 is widely used for metal cladding by spraying in cases where the project involves the use of bimetallic materials. Provides insulating corrosion protection in many environments;

Inconel is a nickel-based heat-resistant alloy containing ~15% chromium and up to 9% iron. Developed in the USA, where a number of its varieties are produced, alloyed depending on the purpose with aluminum, titanium, molybdenum, etc. The alloys are distinguished by high strength and toughness at temperatures up to 900 ° C, and resistance to cuts at temperatures up to -78 ° C.

Stainless steels - wires made of stainless steels, for example, food grade stainless steel, are used for spraying corrosion-resistant insulating coatings that are resistant to aggressive environments;

Carbon steels - carbon steel wires are used, as a rule, to restore the geometry of parts damaged during production or during operation;

Hasteloy is a family of corrosion-resistant alloys widely used for protection against chemical corrosion in the energy, oil and gas, chemical, petrochemical and pharmaceutical industries. The general properties of the alloys are resistance to chemical corrosion and stress corrosion cracking.

Advantages and disadvantages

Unlike other methods of anti-corrosion protection, electric arc metallization has a number of positive characteristics:

- parts and structures subjected to metallization have a long service life (up to 30 years);

- the thermal spraying process occurs with a relatively low thermal effect on the base (heating temperature 70-100°C), which eliminates structural changes and deformation of the base metal;

- the applied spraying has high anti-corrosion resistance and wear resistance;

- the EDM technological process is characterized by high productivity (up to 100 kg/hour of sprayed metal) and economic efficiency (low energy and other production costs), and is not critical to the size of the structures being processed, their location and weather conditions;

- metal spraying can consist of various metals and alloys, and reach a significant thickness (up to 15 mm), has high adhesion (only increases over time), is highly ductile, does not peel off and does not collapse as when exposed to fairly low temperatures (up to -60 °C), so under conditions of mechanical deformation (bending);

- anti-corrosion coatings created using EDM have a self-healing protective property, which consists of clogging places of mechanical damage to the protective layer with coating metal oxides;

- EDM equipment is highly reliable, lightweight and easy to maintain;

- The EDM process has a high potential for automation, including through the creation of automatic lines.

The main disadvantages of electric arc metallization are:

- limited range of filler materials (due to requirements for their electrical conductivity and use in the form of wire electrodes);

- the presence of a significant proportion of oxides in the anti-corrosion coating, which affects its impact resistance (associated with overheating and oxidation of the sprayed material at a low feed rate of wire electrodes);

- there are cases of insufficient adhesion strength of the sprayed metal to the base (15–45 MPa);

- the presence of high porosity of anti-corrosion spraying limits the use of metallization in aggressive environments without the use of additional protection methods.