Ventilation units in forges have the task of combating smoke, dust, harmful gases (carbon monoxide and sulfur dioxide) and excess heat entering the room. In improved forges with furnaces for heating products, this task is greatly facilitated, but forges with open forges are widespread and ventilation is especially important in them. The forge ventilation device consists of the following parts: 1) a device for blowing to the forges - a fan, an air duct, a nozzle (the blowing tip of the air duct), 2) a suction device - a receiving umbrella (a cap over the forge), an exhaust pipe and a draft stimulator (deflector or fan) , 3) supply unit. To blow the furnaces, high-pressure fans described above are used, and air is taken both from outside and from inside the room. Air ducts from the blower fan to the furnaces are usually supplied in underground ducts, and since the air in them moves at high speed and the diameter of the pipes is relatively small, sometimes smoke pipes (heating pipes) are used for the blower air duct, which can be sealed under the floor without a device for them channels. At the hearth itself, a valve or valve with a long handle is placed on the air duct, which is brought to the front side of the hearth for convenient use. The blowing nozzle has one or more holes for air outlet; sometimes the air duct tip is cast iron with a slag collector at the bottom and a cleaning hole with a cover with a counterweight. The umbrella over the forge is arranged in such a way that the edge of the umbrella is at the same distance from the blow nozzle at which the umbrella is raised above the forge; The device of the forge is shown1 in Fig. 257, which shows a typical forge design with basic dimensions. The furnace cover should be as complete as possible; therefore, the non-working sides of it are closed tightly, and on the working sides of the umbrella there are folding aprons, which should be opened only when necessary.

The umbrella should move smoothly to the exhaust pipe, which is made straight; in a typical forge, the pipe diameter is 500 mm, the height is 4 - 5 m and at the top there is a “Shanar-Etoile” deflector. At a height of 0.5 - 1.0 m above the umbrella, a throttle valve is installed in the pipe, which can be fixed in any position. To better capture smoke, the umbrella is equipped with additional devices: 1) double activated umbrella (Fig. 258, a); in this case, the smoke escaping from under the first umbrella is picked up by a draft that forms in the gap between the walls of the umbrella; 2) double pipe (Fig. 258, b); in addition to the exhaust pipe, a second pipe about 1 m long is made, which can go down on blocks; lifting height 0.5 - 0.7 m; sometimes a bell is made at the bottom; the drain pipe is equipped with a counterweight, an iron box in the form of a ring around the pipe, into which sand is poured for the load.

When the exhaust pipe passes through the ceiling, fire prevention measures must be taken. The pipe should not touch the wooden parts of the building anywhere and have reliable insulation, for example, in the form of winding with asbestos cardboard, placing cases filled with sand, etc. The draft stimulator in forges is predominantly the “Shanar-Etoile” deflector; in the case of using a fan, the hood is usually arranged in one of two ways: 1) direct suction of smoke by a fan, which passes the smoke through itself and is in this case called a smoke exhauster; chimneys from the furnace to the fan can go both up and down into the underground channel (Fig. 259);

2) the use of ejection, i.e. creating thrust with a strong stream of air, dragging the surrounding air along with it; in this case, the fan operates as a blower. The tapering air duct (nozzle) is discharged into the exhaust pipe (Fig. 260). Ejection is turned on during ignition, and then it can be turned off, since it does not provide any particular advantages when natural draft is established; sometimes for ejection they use a blower fan, from which an air duct is branched into the exhaust pipe; After igniting the forge, the fan switches to blast.

Exhaust devices in forges work normally only if there is sufficient supply ventilation from a central installation or local units installed in the forge itself. The supply air is heated in winter and its volume is regulated depending on the number of simultaneously operating forges.

Step-by-step instructions for making a homemade blower for the forge

The forge is the main tool in the forge, but in order to create the required fuel temperature in it, you will need to blow the forge. There are many models of fans on sale, but they are very expensive, so we will consider the option of how to make a blower for the forge with your own hands. This option is more economical and requires a minimum of time.

Blacksmith chair vise: neighbors with an anvil

It is impossible to do without a vice in a forge, because workpieces have to be clamped in them. They must be adjacent to the anvil, so a wooden base for them is dug near it. This must be done so that the working plane of the anvil is at the same level as the jaws of the vice. If it is not possible to purchase a chair tool, you can temporarily replace it with ordinary ones, but you must “get it right” that ordinary cast iron is not able to withstand such hard work.

Parts and tools

To create it you will need the following parts:

- Electrical engine.

- Impeller (you can take it from a centrifugal fan or make it yourself).

- 2 plastic buckets.

- PVC pipe.

Tools you will need:

- Screwdriver or screwdriver.

- Drill.

- Knife or hacksaw for cutting holes.

Working wheel

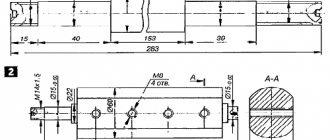

First we will make the impeller. The wheel itself consists of blades that are fastened together, and in the middle of the wheel there should be a hub for mounting the engine. A circle made of any material (wood, plastic, etc.) can be used as a wheel. The blades can be cut from stainless steel of the required diameter and attached to the circle in any convenient way. To simplify the manufacturing process, you may need a drawing with dimensions. Here is an approximate version of the drawing:

This is what a homemade fan looks like, although the number of blades and size may be different.

The impeller is ready, now let's move on to the housing. The fan will have the shape of a snail, so the blower is often called a snail for the forge.

Frame

This is what the snail-shaped blower looks like in the diagram. To make it, at the bottom of the bucket, in the center, we make a hole, which should be slightly larger than the diameter of the motor shaft. Then you need to make fastenings, as in the photo or any other fastenings that will securely fix the engine so that it does not rotate and does not touch the impeller.

After this, you need to cut the bucket so that it is wider than the impeller. Next, we cut off the lid, the same diameter as the bucket, and in it we make a circle in the center, which will be slightly smaller than the diameter inside the impeller.

Blower installation

We move on to the final stage - installation of the blower. We attach the first part with the pipe to the engine. Here you should pay attention to the fastening so that they are reliable. Next, install the impeller in this part and close it all with a lid. The latter is also secured with epoxy resin. For a more presentable look, you can paint the structure in a single color. As a result, the snail design should look like this:

Now the fan for the forge is ready and all that remains is to attach it to the forge itself and check the effectiveness of the product.

This type of blower for the ash pit is most preferable, since the air flow can be directed in the desired direction.

DIY gas forge

In today's article we will tell you how to make a small gas forge with your own hands - an excellent option for a home workshop.

If you are engaged (or plan to engage) in forging or smelting metal, then such a small forge will definitely come in handy.

The idea of making a “home version” of a gas forge belongs to the author of the YouTube channel Metal Extreme. Take note.

Necessary materials:

- sheet metal;

- fittings;

- steel strip;

- fireproof dry mixture for preparing concrete.

First of all, you need to make the base of the forge.

To do this, we weld a rectangular frame from a metal strip, and weld a bottom made of sheet metal from below.

To the bottom of the bottom you will need to weld two pieces of corner, between which there will be a profile pipe (support post).

After this we make the stand. We cut a piece of the required length from the corrugated pipe and process the edges so that there are no burrs. We weld a support mounting plate to the bottom of the rack - it will be attached to the floor using anchors.

We weld the upper part of the rack from below the base, installing corrugated pipes between the corners, which we previously welded to the lower part of the bottom.

We lay bricks inside the base. Then we weld a metal mesh with square cells - from reinforcement.

The next step will be to prepare fireproof concrete. Pour the prepared mixture into the base of the forge. Vibrate and align.

After this, we make the forge dome (upper part) from sheet metal.

At the ends of the dome it is necessary to weld U-shaped blanks cut from sheet metal. Next, we weld the reinforcement on the inside of the dome.

From sheet metal we bend a casing of the same shape as the dome, but smaller in size. We weld it to the inside.

The resulting cavity is filled with refractory concrete. Once the concrete has hardened, the casing can be removed.

Holes have already been pre-drilled in the upper part of the dome - we weld guide bushings for gas burners to them.

We install the dome on the base and weld it.

Next you will need to make the front and back doors. First, we make a mold of the required size from metal, then fill it with concrete.

The doors will operate in a vertical plane, so guides need to be welded for them.

On top of the doors there are mortgages, to which handles are welded.

Setting up a forge: particularly important points

First you need to decide what products you are going to create, because what your future workshop will look like will depend on their size. If there is no need to make fairly large “masterpieces,” then you can build a forge by spending quite modest funds.

- The premises are the first important point to stop at, because there are strict restrictions, and fire safety rules require compliance with them. The fact is that the blacksmith's workshop should be remote from both residential and commercial buildings. The required room area is at least 16 m2, and the door must open exclusively outward.

- The floor of the forge requires special attention, because flammable materials are strictly contraindicated here. If in ancient times in such workshops the role of floor covering was played by thoroughly compacted earth, now the best option will be concrete or something similar.

- Providing ventilation and soundproofing are also important. If it is simply impossible to work without the first one being forced, then the second one will make you a common enemy - both household members and neighbors.

If the necessary premises are not yet available, you can set up a forge either in the garage, or even in the open air, but in this case you will have to build a fire-resistant floor, a rain shelter and create when everyone around you has gone on business. When the question about the premises has found an appropriate answer, you can move on to a new “headache” - taking care of tools and equipment.

Fan device for forge

You will learn how a fan for a forge works, its types and how to make it yourself using improvised materials with detailed photos.

We will not reveal the secret if we say that interest in creating masterpieces from metal by forging it has not disappeared and will not disappear. To do this, the blacksmith's workshop must have a forge to create high temperatures due to the combustion of fuel. For the combustion process to be effective, the forge must be ventilated. In private forges, skilled craftsmen often make ventilation devices themselves. If you are also interested in how to make a fan for a forge, this article may be useful. From it you will learn how a fan works, its types and how to make it yourself using improvised materials.

fan for forge forge video Video watch

6 years ago

Fan for forge VT1-2 Blacksmith. It is used as a snail for a furnace providing air supply to a hospital...

1 years ago

Fans for forges, more details on the website: https://spbstanki.ru/kuznechnye-gorny.

3 months ago

We present to your attention a modern replacement for forge bellows - the BlackSmith forge fan...

2 years ago

Forge forge, dismountable forge, garage version of the forge, fan BLACKSMITH VT1-2.

6 years ago

Description – https://kovka-stanki.ru/tools/383/ Fans for forges of the VT1 Blacksmith series. Used as “snails” for…

2 years ago

second channel on YouTube – https://www.youtube.com/channel/UCedSQ_YEeQ8-3osEysAHh8Q group in contact for questions and comments, on…

2 years ago

This video was processed in the YouTube Video Editor (https://www.youtube.com/editor)

3 years ago

Not a great overview of a mini forge for working outdoors in the open air in your yard or on your property. Compact…

11 months ago

Designed to supply air to the combustion zone Country of origin: China Gross weight, kg: 3.75 Rotational speed…

3 years ago

Help the channel: donation https://yasobe.ru/na/dvokat https://www.paypal.me/advocatttt This video is about my homemade portable blacksmith...

10 months ago

There is a lot of debate and speculation about what to use as a blower for a gas furnace...

1 years ago

How to connect a 12V electric motor from a car stove through a computer power supply to blow the furnace!!!

10 months ago

In this video, continuation of the blacksmith theme, preparation and production of equipment and tools for home…

3 years ago

Fan for forge VT1-2 Blacksmith – https://www.smsm.ru/product/18961 Fan for forge VT1-2.5 Blacksmith…

4 years ago

Made, one might say, from garbage, except for the engine) In the video, when I turned it on, I muted the sound, just cameras...

1 years ago

Description and prices of fans for forges here https://sterbrust.com/catalog/ventilyatory-dlya-gornov/ Used as a snail for...

2 years ago

In this video you will know how to make a blower for a forge with your own hands, it will be a homemade fan like...

5 years ago

Inertial fan. It doesn't blow badly. But for now it's an experiment. I'll check what's what...

stab.su

Purpose of the fan for the forge

You can understand the role of the fan by studying the principle of the forge structure. It can be installed permanently or have a mobile design.

A classic stationary forge consists of a work table, in the center of which there is a recess (socket) intended for burning fuel.

Indoors, the forge must have a pipe with an exhaust hood to remove smoke.

A special feature of the forge is that the metal workpiece is placed in direct contact with the fuel.

This ensures that the workpieces are heated to a plastic state, in which the metal can be easily forged. The temperature in the working area of the forge should be at least 1000–1300 o C. It is achieved through fuel combustion. To maintain the combustion process in this area there must be good air exchange, which is provided by a fan. The air stream from it is directed into the forge socket through the nozzle.

The fan must provide a certain air pressure.

Important! The efficiency of the blowing and combustion process, which affects the temperature in the working area, depends on the fan power.

The combustion process is also affected by the type of fuel used. Fuel from coke, charcoal and gas is used as fuel. Liquid fuels made from petroleum products, such as gasoline or kerosene, are rarely used.

The anvil is the forge's faithful partner

Therefore, it should be located close to him. The best is its two-horned variety. The horizontal platform is called the “face”, so it must be protected from any flaws - only a perfectly polished surface guarantees the quality of the work.

On one side of the anvil there is a cone-shaped horn; here the rings are welded and rolled out. Not far from the base of the cone there is a round hole (15 mm), with the help of which the products are given a round shape. On the opposite side, where the “chin” of our face is located, closed rectangular parts are bent. There is also a hole here, but it is square, its dimensions are 30x30 mm.

At the bottom of the anvil there are 4 paws, which are intended for attaching it to the base. This is done with staples. This instrument also requires a special chair made of oak or birch, its diameter should be about 600 mm. In order to make something like a foundation for an anvil, the block of wood needs to be deepened into the ground by 50 mm, even deeper is better. This will avoid vibration of the tool.

Industrial fans design

A fan for a forge of this type often has a casing that is made in the shape of a snail. Its internal structure and principle of operation are shown in the figure, where a) is the appearance, b) is the structure and arrangement of internal parts.

The principle of operation of the “snail” is as follows:

- Inside the casing (3) of the fan housing, a rotation wheel (1) equipped with blades (2) is located on the axis.

- The shape of the blades and the direction of rotation of the wheel create the movement of air flow into the pipe (4) in the direction of the combustion zone.

- The direction of air flow is provided from the hole located in the central part of the volute body to its final turn, which has a narrowing. Due to this, the air pressure increases.

An example of an industrial product is a fan of the common brand VT1-2, produced under the Blacksmith brand.

It is designed for blowing both stationary and portable forges with a completely open top. The diameter for connecting the pipe of such a device is 50.8 mm, power is supplied from a 220 V network, power consumption is 150 W, the impeller rotates at a speed of 3000/3600 rpm.

The maximum pressure (pressure) of the air stream in the supply hole is 490 Pa. The fan has dimensions of 225x180x225 mm and weight of 2.65 kg.

The fan housing is made by casting and is highly durable. The device operates almost silently and is easily connected to the forge.

Fan for forge - device and manufacturing methods

We will not reveal the secret if we say that interest in creating masterpieces from metal by forging it has not disappeared and will not disappear. To do this, the blacksmith's workshop must have a forge to create high temperatures due to the combustion of fuel. For the combustion process to be effective, the forge must be ventilated. In private forges, skilled craftsmen often make ventilation devices themselves. If you are also interested in how to make a fan for a forge, this article may be useful. From it you will learn how a fan works, its types and how to make it yourself using improvised materials.

Purpose of the fan for the forge

You can understand the role of the fan by studying the principle of the forge structure. It can be installed permanently or have a mobile design.

A classic stationary forge consists of a work table, in the center of which there is a recess (socket) intended for burning fuel.

Indoors, the forge must have a pipe with an exhaust hood to remove smoke.

A special feature of the forge is that the metal workpiece is placed in direct contact with the fuel.

This ensures that the workpieces are heated to a plastic state, in which the metal can be easily forged. The temperature in the working area of the forge should be at least 1000–1300°C. It is achieved through the combustion of fuel. To maintain the combustion process in this area there must be good air exchange, which is provided by a fan. The air stream from it is directed into the forge socket through the nozzle.

The fan must provide a certain air pressure.

Important! The efficiency of the blowing and combustion process, which affects the temperature in the working area, depends on the fan power.

The combustion process is also affected by the type of fuel used. Fuel from coke, charcoal and gas is used as fuel. Liquid fuels made from petroleum products, such as gasoline or kerosene, are rarely used.

Industrial fans design

Industrially manufactured furnaces are mainly equipped with centrifugal (radial) fans for air blowing. They are simple to design and provide uniform blowing.

A fan for a forge of this type often has a casing that is made in the shape of a snail. Its internal structure and principle of operation are shown in the figure, where a) is the appearance, b) is the structure and arrangement of internal parts.

The principle of operation of the “snail” is as follows:

- Inside the casing (3) of the fan housing, a rotation wheel (1) equipped with blades (2) is located on the axis.

- The shape of the blades and the direction of rotation of the wheel create the movement of air flow into the pipe (4) in the direction of the combustion zone.

- The direction of air flow is provided from the hole located in the central part of the volute body to its final turn, which has a narrowing. Due to this, the air pressure increases.

An example of an industrial product is a fan of the common brand VT1-2, produced under the Blacksmith brand.

It is designed for blowing both stationary and portable forges with a completely open top. The diameter for connecting the pipe of such a device is 50.8 mm, power is supplied from a 220 V network, power consumption is 150 W, the impeller rotates at a speed of 3000/3600 rpm.

The maximum pressure (pressure) of the air stream in the supply hole is 490 Pa. The fan has dimensions of 225x180x225 mm and weight of 2.65 kg.

The fan housing is made by casting and is highly durable. The device operates almost silently and is easily connected to the forge.

Fan drive for forge

The rotation of the fan wheel with blades is carried out using a drive:

- electrically;

- by manual force;

- a combination of methods.

When using an electric drive, rotation is carried out using an electric motor that converts electrical energy into mechanical rotational energy.

The manual method involves simply rotating the handle of a glider-type gearbox.

This option is usually a backup and is used when there is a power outage and the installed electric motor cannot be used.

The figure shows the drives: a) - manually, b) - using an electric motor.

1—belt on pulley;

2 and 3 - transmission gears;

4 — rotation handle;

5 - electric motor.

What can a fan be made from for a private workshop?

In private workshops, both stationary and mobile types of forges can be used. Portable type forge devices are the simplest, which is why they are used more often. For homemade forges, you can construct a fan yourself from any suitable materials. The production of such devices is shown in the video:

Often devices that were previously used for other purposes are used as a fan.

- The figure shows one type of portable forge equipped with a pedal-type air supply drive. Traction is carried out with a blowtorch.

- The simplest option for ventilating the forge is a regular vacuum cleaner.

This figure shows a diagram of the design of a portable lightweight forge using a household vacuum cleaner.

It is connected by a hose to the ash pan pipe, welded 150–200 mm away from the ash pan.

The vacuum cleaner hose itself must be inserted into the reverse socket so that the air is not drawn into the vacuum cleaner, but is directed out of it towards the forge. The lower bowl with the filter is removed, and the vacuum cleaner is placed on the table stand.

- A good replacement for a household vacuum cleaner is a fan removed from the heating stove of an old car.

Having studied the principle of operation of the forge and the role of the fan in this process, as well as viewing photographs with diagrams of devices and videos on self-manufacturing of ventilation devices, you can safely begin to manufacture them.

And if you have experience in this area, you can share your knowledge with others in the comments to this article.

wikimetall.ru

Fan drive for forge

- electrically;

- by manual force;

- a combination of methods.

When using an electric drive, rotation is carried out using an electric motor that converts electrical energy into mechanical rotational energy.

The manual method involves simply rotating the handle of a glider-type gearbox.

This option is usually a backup and is used when there is a power outage and the installed electric motor cannot be used.

The figure shows the drives: a) - manually, b) - using an electric motor.

1—belt on pulley;

2 and 3 - transmission gears;

4 — rotation handle;

What can a fan be made from for a private workshop?

Often devices that were previously used for other purposes are used as a fan.

- The figure shows one type of portable forge equipped with a pedal-type air supply drive. Traction is carried out with a blowtorch.

- The simplest option for ventilating the forge is a regular vacuum cleaner.

It is connected by a hose to the ash pan pipe, welded 150–200 mm away from the ash pan.

The vacuum cleaner hose itself must be inserted into the reverse socket so that the air is not drawn into the vacuum cleaner, but is directed out of it towards the forge. The lower bowl with the filter is removed, and the vacuum cleaner is placed on the table stand.

- A good replacement for a household vacuum cleaner is a fan removed from the heating stove of an old car.

Having studied the principle of operation of the forge and the role of the fan in this process, as well as viewing photographs with diagrams of devices and videos on self-manufacturing of ventilation devices, you can safely begin to manufacture them.

And if you have experience in this area, you can share your knowledge with others in the comments to this article.

Fan for forge

The forge occupies a central place in the blacksmith's workshop. It is not just an integral, but the main element of any forge, which cannot be done without. In it, the workpieces are heated to the temperature required for processing (minimum T = 1300 °C). The following materials are used as fuel in the forge:

- coking coal grades OS, T and K (GOST 8180-75);

- coke;

- charcoal;

- gas (propane-butane), etc.

For efficient combustion of fuel (read: creation of maximum temperature), air must be blown into the furnace with an excess pressure of about 150...200 mm of water column. This air pressure is provided by the fan for the forge.

- The design of the fan for the forge and its principle of operation;

- Fan drive

- Technical parameters of the fan for the forge

- Delivery contents

- Advantages of a fan

The design of the fan for the forge and its principle of operation;

In industrial furnace designs, centrifugal (radial) fans in a snail-type housing are used. The basis of a centrifugal fan is a housing that looks like a snail. An impeller rotates inside this housing. The wheel has blades. The design of the blades (their shape) in combination with the direction of rotation of the wheel ensures air movement in a certain direction. The direction is chosen from the inlet hole (in) to the pressure hole (the “snail” turn ends with this hole).

Fan with universal drive.

When a wheel with blades rotates, a centrifugal force (acting from the center of rotation to the periphery) is created in the radial direction. Under its influence, air is sucked in through the inlet hole in the center of the fan and exits through a pressure hole directed tangentially to the circumference of the housing. The absence in this design of the possibility of a centripetal force (if present, it would act from the periphery to the center and interfere with the centrifugal force) contributes to the effective removal of air from the “snail”.

Fan drive

The fan drive, which creates rotational movement of the impeller, has different design solutions:

- electric. Its basis is an electric motor (three-phase is installed on powerful fans), which converts electrical energy into rotational energy;

- manual. Converts the muscular force of the person turning the handle through a cylindrical planar gearbox into rotational motion;

- combined. Hybrid of manual and electric drives. If there is a power outage (which is not uncommon in rural areas), the blacksmith can continue heating the workpieces by placing an assistant “on the handle.”

Technical parameters of the fan for the forge

To illustrate the operation of a fan for a forge, we present the main parameters of the very common model “VT1-2” from the Blacksmith brand. This fan is used to supply air to a portable or stationary open-type forge in which the top is completely open.

The fan has the following technical characteristics:

- pressure channel diameter, mm: Ø 50.8;

- maximum productivity, m3/hour: 240;

- power supply, V: 220;

- power consumption, W: 150;

- rotor (impeller) rotation speed, rpm: 3000/3600;

- maximum pressure in the pressure port, Pa: 490;

- weight, kg: 2.65;

- geometric dimensions of the package, mm: 225 x 180 x 225.

Delivery contents

The fan is supplied assembled, fully prepared for installation. The packaging is a cardboard box.

Advantages of a fan

The fan for the forge “VT1-2” of the Blacksmith brand has the following advantages:

- simple and convenient air flow adjustment;

- cast durable housing;

In addition, for intensive work over a long service life, the device is equipped with built-in thermal protection. It has a low noise level, installation and assembly are easy, and operation does not require special training of operating personnel.

Fan for forge “VT1-2” brand “BlackSmith”.

blower for forge

In this video you will know how to make a blower for a forge with your own hands, it will be a homemade fan like...

second channel on YouTube – https://www.youtube.com/channel/UCedSQ_YEeQ8-3osEysAHh8Q group in contact for questions and comments, on…

Making homemade bellows from plywood and dermantine Another bellows https://www.youtube.com/watch?v=pb-tXoQ5Ns8…

How to blow air into a homemade forge with your own hands at home.

Selecting from two fans using an empirical method and connecting via the computer power supply for the burner...

A productive hood for a fume hood, also known as a blower for a forge, which can be powered…

Made a powerful forge for melting metals...

Group on VK https://vk.com/99diy Hello everyone, friends! My name is Andrew! And today I will show you a simple and maximum...

Forge forge, dismountable forge, garage version of the forge, fan BLACKSMITH VT1-2.

Made, one might say, from garbage, except for the engine) In the video, when I turned it on, I muted the sound, just cameras...

A homemade sledgehammer with a round head. This is a test sledgehammer, in the future I will make exactly the same one only from wood...

There is a lot of debate and speculation about what to use as a blower for a gas furnace...

I am remaking the system for blowing and cleaning the ash pan in a homemade forge on coals. video partner: https://al...

A short video about the new coal forge, and tips on how and what to make it from. For blowing I use an old kitchen...

Robib good, but not for long,

Available option for supplying air to the furnace.

Who is interested, join groups on Odnoklassniki and VK https://vk.com/kovka.kurchatov https://ok.ru/kuznyakurchatova power supply from...

How to connect a 12V electric motor from a car stove through a computer power supply to blow the furnace!!!

We present to your attention a modern replacement for forge bellows - the BlackSmith forge fan...

Fan for forge VT1-2 Blacksmith – https://www.smsm.ru/product/18961 Fan for forge VT1-2.5 Blacksmith…

I made a forge with electric blower from an old barbecue, it turned out to be two in one.

Fan for forge VT1-2 Blacksmith. It is used as a snail for a furnace providing air supply to a hospital...

My second video on making a coal forge. This forge is much simpler to make than the first one, but...

I made a blower for the new forge, the new forge will follow the video) motor from the Volga stove.

How to make a HORN without any problems! A budget option. I'm on instagram https://www.instagram.com/aleksandrlopata I'm on facebook...

Help the channel: donation https://yasobe.ru/na/dvokat https://www.paypal.me/advocatttt This video is about my homemade portable blacksmith...

In this video, continuation of the blacksmith theme, preparation and production of equipment and tools for home…

Forge, #blowing, #forging.

In this video I will show you how to make a forge with your own hands. Enjoy watching. How to make a blower...

Help the author - https://www.donationalerts.ru/r/74pavlo More subscriptions to YOUR channel - https://vktarget.ru/?ref=2816489.

Made from junk parts Video available at https://www.youtube.com/watch?v=jCSM0E5fUFw Write questions and advice...

Inertial fan. It doesn't blow badly. But for now it's an experiment. I'll check what's what...

brskills loader firmware sm-j500m mod herobrine 1.5.2 ddtank apple transformar bravissimo em phantom diminuir voltagem com diodo modo de recuperacao iphone 5s fonte do gta san andreas receptor century midiabox shd7050 analogico digital hd 3d vitinho joga minecraft

debojj.net

Making a forge with your own hands

Forged products have long been used in industry and in everyday life. They are used to build beautiful fences, decorate indoor fireplaces, and canopies over the front door. Forged flower stands find their place in the rooms of the house. All of these things can be made in a home workshop with some equipment.

A forge can heat up to high temperatures, so its main purpose is forging decorative metal products.

To forge metal, the main thing is to heat it to the required temperature. This is done using a blacksmith's forge. If there is a barn on your summer cottage in which you can set up a home workshop with a forge, then it is recommended to make a forge with your own hands. Its different designs differ only in the type of fuel used. The remaining differences are not of fundamental importance.

Blacksmiths often use fuel in the form of coke; it gives a high temperature and produces little waste.

- How to make a forge for heating metal before forging?

- Let's compare an industrial forge with a homemade device

- Some useful tips

The rest of the blacksmith's assistants

Without a suitable tool, any blacksmith cannot be called such. Mandatory equipment includes:

- The war hammer can weigh up to 12 kg, so it requires both hands to operate it. The head is suitable for basic work, while the rear takes part in accelerating the steel along the axis.

- The sledgehammer is a heavyweight, its weight reaches 16 kg. Used when greater strength is needed.

- Handbrake. This is a small hammer (from 500 g to 2 kg) for basic work. Rowan is used for the handle, as this wood is able to neutralize the recoil from an impact.

- Pliers are a fascinating tool in every sense. Only with its help can you pull future products out of the forge and hold them during forging.

It is better to ask about how to make a forge at home on special forums, where they will answer you in detail and professionally. Or you can go the other way - watch the video and take action. The choice is yours.

How to make a forge for heating metal before forging?

Before making a forge, you need to choose the type of forge. The closed-type forge has a chamber for heating the workpiece. This design is the most economical in terms of fuel costs. But the size of the workpieces has limitations associated with the size of the heating chamber.

In an open-type forge, fuel is poured from above onto the grate, and an air flow is supplied from below. The heated workpiece is placed on the fuel. This makes it possible to heat large-sized workpieces.

Holes are drilled into the steel plate grid and then inserted into the center of the table.

The sequence of actions when making a forge can be as follows:

- The base of the forge is its table. This is where the construction of the structure begins. Its lid is made of metal 4-5 mm thick. The height of the table is 700-800 mm. Its surface is most often made in dimensions ranging from 80x80 to 100x150 cm. You can weld a frame from a corner into which to lay fire-resistant bricks and a grate. The grate is usually placed in the center of the table. It can be made from a cast iron frying pan or from a steel plate 8-10 mm thick, in which holes with a diameter of 10 mm are drilled.

- The grate is inserted into the hole in the table and lined with refractory bricks. The height of the table is made comfortable for the home craftsman, usually up to the level of his waist.

- The air blowing mechanism is installed. It can be foot operated, but it is better to use an electric fan. An old vacuum cleaner is often used for this purpose. Its power is quite enough to produce a jet of air of the required strength. It's good if there is a speed controller. If it is not there, you can install an additional valve to regulate the air supply. Instead of a vacuum cleaner, some craftsmen use a manual siren drive.

- The whole structure comes together. You can start testing.

- Fuel is poured onto the grate. First, wood chips and larger firewood are placed, then coke is added. The blower is turned on, the workpiece is placed on the coke. You can also add a little coke on top of the heated iron. Then a small arch with a huge temperature inside it forms in its thickness. Instead of coke, it is quite acceptable to use wood waste.

A homemade forge can be supplemented with various devices inherent in industrial installations. Sometimes these devices cost practically nothing, but add convenience to work.

Dream come true: building a forge

This working tool consists of a table, hearth, tuyere and umbrella.

The table is a reliable foundation

If you decide to make a solid stationary forge, then you need to start by building a table on which the hearth is located. Usually its height is 700-800 mm, but it depends more on the height of the master. The dimensions of such a tabletop are determined only by the dimensions of those products that will be forged: the working surface can be either a meter by one and a half, or 1.5x2 m. The tabletop can be made of reinforced concrete, brick or steel sheet 4 mm thick. The body is constructed from logs, brick or stone. Clay, sand or crushed stone is poured inside this “box”.

Let's compare an industrial forge with a homemade device

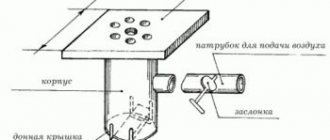

Industrial forges include (Image 1):

- Air supply nozzle. In our case, its functions are performed by a hose from a vacuum cleaner.

- Fireproof bricks that accumulate and maintain temperature. In a homemade forge, they can also be present on the desktop.

- The grate bars that hold the fuel. In the homemade version they are usually also present.

- Socket for loading solid fuel. This device can be equipped with a homemade forge if it is often used in the work of a home craftsman.

- The bricks that make up the frame. The homemade device does not have them.

- A fan that supplies air to the furnace. In the homemade version, its role is played by an old vacuum cleaner. But you can also install a separate fan.

- Metal frame holding the desktop. It is available in a homemade version.

- Air chamber. It can eventually be made for a home forge.

- Ash pit. A useful addition to a homemade forge for home use if the forge is used frequently.

- Air duct. To begin with, its functions in a homemade forge can be successfully performed by a vacuum cleaner hose.

- Casing.

Some useful tips

Now you can clearly see how you can complement your home blacksmith’s forge. In the meantime, you need to acquire a simple anvil and blacksmith pliers, without which it is impossible to work.

- Charcoal and stone coal, firewood and coke can be used as fuel. Coke is more expensive than coal, but its consumption is 5 times less. Combustion of coke produces less slag and soot. It's better to use coke. This is what professionals call coke of fine fractions, which does not need to be pre-cracked, wasting time on this.

- You can use mains or bottled gas as fuel. This fuel will allow us to eliminate the need for grate bars. The heating temperature can be adjusted. Fuel is quite cheap and available.

- It is recommended to install an exhaust hood made of sheet metal 4 mm thick on top. The joints of the parts are well welded to ensure the tightness of its internal volume.

- It is necessary to make a hole in the side wall of the forge for a gas burner. A smoke removal system is also needed. This is a pipeline with a cross-section of approximately 30x30 cm. Its height is about 5 m.

- Instead of a vacuum cleaner, you can use a fan from a car heater.

- A hole cut in the back wall of a homemade forge will significantly improve the ventilation of the installation. Using this hole, it will be possible to heat longer workpieces.

You can make a homemade forge for blacksmithing yourself in a small room at your summer cottage. This device will make it possible to produce unique forged parts to create canopies, fences, gates and other things to decorate the interior of the site and the house.