When the supply of water from a well becomes difficult due to its depth, an ejector for a pumping station comes to the rescue. Adaptation can be internal or external. Read to the end and you will understand how they differ from each other and what service they provide to the surface pump. And also what is the difference between an ejector and an injector.

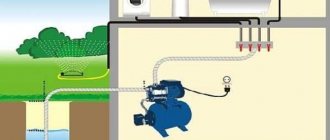

External ejector in the pump Source ytimg.com

Device Features

When arranging an individual water supply in a house, they often encounter a problem when the drinking water pool is located far from ground level. The surface pump is already starting to work intermittently, pumping it from a depth of 8-9 meters. But if you equip the pumping station with a simple ejector, water is drawn in more efficiently.

The device becomes necessary in several cases:

- If you need to lift water from great depths.

- When the source silts up. This happens during dry periods and the water level drops.

- In cases where water intake occurs intensively. For example, when watering a garden.

Let's look at how an ejector for a pump works. The movement of fluid in a system obeys Bernoulli's law. When there is a certain flow, its speed can be increased. To do this, it is enough to direct the flow of water through the nozzle. The passage of a bottleneck entails the formation of a field around the flow. The pressure in this zone decreases and is accompanied by a vacuum effect.

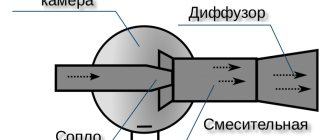

Water jet ejector Source ytimg.com

A chamber is assembled with a suction pipe attached to one side, directed towards the water source. On its other side, a diffuser is installed in the form of a Venturi tube, which ends with a pipeline connected to a surface pump. A pipe with a fixed nozzle at the end cuts into the side of the chamber.

When a stream of water released along a side branch creates a vacuum in the chamber, it sucks in a fresh portion of liquid from the source. And the accelerated jet from the nozzle directs it into the diffuser, in which the low pressure returns to normal.

The water rushes upward and is picked up by a surface pump at a depth at which there are no difficulties with suction. But some of the liquid on the surface is immediately redirected to a second pipeline, which is called the recirculation line. It ends with a nozzle in the chamber. By gravity, the water reaches the last one, and the process is repeated again. And while the pump remains in active mode, it continues indefinitely.

Ejector drawing Source truboproduct.ru

The recirculation line contains a valve that regulates the amount of liquid returned. This allows you to configure the entire system to operate more efficiently. And the productivity of an ejector pumping station is determined by the excess water reaching the consumer.

The mechanism makes it easier to start the pump. A small amount of water passed through the system is sufficient to make the first intake. Therefore, the pump does not run idle for a second. And for work you can use a much lower power engine. All this significantly saves energy.

Surface ejector pump Source prom.st

See also: Catalog of companies that specialize in the design and installation of sewerage and water supply

Ejector pumps

The procedure for connecting an ejector as an independent device consists of two stages:

- An additional pipe is laid according to all the rules that were taken as the basis when installing the water supply pipeline. An additional pipe is needed to supply the injection medium.

- Connecting the pipe to the suction unit. It is necessary to install a coarse filter and a return pipe. It is recommended to install a valve to regulate the operation of the system.

The valve is necessary if the water level in the pit is higher than that for which the pump is designed. In this case, you can adjust the discharge flow.

Types of ejectors

Pumping stations are equipped with ejectors in two different ways. Usually the device acts as part of the pump itself and is then considered internal. But there are situations when it is more profitable to install the water ejector as a separate external unit. Although this is accompanied by a loss of productivity.

Built-in ejector

This design feature allows you to significantly reduce the dimensions of the installation. The pump itself creates primary pressure in the ejector mechanism and takes in liquid for recirculation. The device is not afraid of silt and sand that may be present in the stream. And if liquid is needed for irrigation, then you don’t even have to filter the water coming from the well.

Used when the depth is no more than 10 meters. But this is the maximum value and for operation you will need a very powerful motor for the pump. The location of the water at a distance of 7-8 meters allows the use of a conventional surface pump, which creates sufficient pressure for running a large household.

But the noise level created by the ejector is very high. Therefore, there is a need to leave the pump outside the house. It is best when a small technical room is installed above the well, in which a surface pump with an ejector is located.

Internal ejector Source oboiman.ru

Using cooling towers to cool water

The type of cooling tower is selected depending on the total volume of the circulation cycle, the required temperature difference, and operating features.

For large volumes of cooled water, reaching several tens of thousands of cubic meters per hour, tower cooling towers are most often used. These structures can be seen at most thermal power plants and nuclear power plants.

In industrial enterprises they are used much less frequently - the total volume of water in the system is divided into smaller local cycles with their own operating parameters, different from others. Therefore, in such circulating systems, fan or ejection cooling towers are more often used.

An ejection cooling system differs from a classic fan cooling system in that the excess air flow is created due to the ejection effect, which is where the corresponding name comes from. Ejection is the process of mixing two media (steam and water, water and sand, etc.), in which one medium, under pressure, affects the other and, dragging it along with it, pushes it in the required direction. Using special nozzles, water is broken into very small droplets and sprayed under high pressure inside the installation. The flow of droplets carries with it an air mass with lower pressure. The remaining processes are similar to any other evaporative cooling tower.

Ejection systems have their obvious pros and cons. The positive aspects include the simplicity of the design: there are no fan units and no irrigation device is required. Such cooling towers are easier to maintain. However, from the advantages, there are also disadvantages: lower cooling capacity, high requirements for water quality, a significant decrease in efficiency when the nozzles become clogged or the pressure in the system decreases, and additional costs for powerful pumps.

Models for different states of the transported medium

There are ejectors for specific purposes:

- The name of steam jets speaks for itself. In this case, a stream of steam enters the mixing chamber from the nozzle. It is created at the beginning of the recirculation line on the surface. The hot jet carries a portion of liquid upward. Most often used for pumping water from the bilge of a ship.

- The gas industry uses an ejector to pump out gas that accumulates in a confined space.

- There is an air ejector that uses the Venturi effect. The air passing through the nozzle increases the dynamic pressure, but at the same time reduces the static pressure. A vacuum is created, which supplies the pumped air out.

Steam jet ejector Source bullion.ru

Contacts

Chistocom online store - chistocom.ru Phones: 8 495-592-33-40, 8 966-096-00-66 Address: Vidnoye, Belokamenny highway, 1A Office hours: Mon-Thu from 09:00 to 18:00; Fri from 09:00 to 17:00; Sat and Sun - closed e-mail:

- Review

- Characteristics

Ejectors are used to supply chemicals. Installed after the pressure regulator. The ejector is used in self-service car washes to apply chemicals.

The operation of the injector is determined by:

1 Select a model (nozzle) depending on the performance of the high-pressure apparatus.

2 The difference in water pressure allows you to mix chemicals thanks to the “Venturi” nozzle effect. This effect occurs when water passes through the diameter of a larger low pressure nozzle that is mounted on the lance (for example when using a double lance)

3 HP hose length. This hose should not be longer than 20 m.

4 Inner diameter of the high pressure hose. The longer the hose, the larger its diameter should be. Lengthening the hose affects the performance of the injector.

Difference from injector

Although both devices work in a jet manner, their operating principle is strikingly different. The purpose of the mechanisms is the same. Pour liquid or gas to the top.

But a pump with an ejector for sucking water from the source supplies it with an active recirculation flow with enormous energy. Mixing liquids rush upward, simultaneously creating a self-suction effect.

The injector for the pumping station operates differently. It compresses gases or liquids. And the upward flow occurs simply due to pressure.

Content

There are low and high pressure ejectors

Low pressure ejectors

Low-pressure ejectors, driven by fans with a capacity of 1000-12000 m 3 /h, with hydraulic losses in the suction networks of 49-294 Pa and coefficient β = 1, are typed and centrifugal fans are selected for them, produced by industry complete with an electric motor and a vibration-isolating base.

High pressure ejectors

High-pressure ejection devices are classified according to the degree of compression (the ratio of the final pressure of the mixture p to the initial ejected pH) and the degree of expansion of the working flow (the ratio of the initial pressure in front of the nozzle pp to the final pressure behind the nozzle pH and are divided into three groups:

- gas jet compressors with a high expansion ratio and a moderate compression ratio;

- gas (steam) jet ejectors having a high degree of compression with a high degree of expansion;

- gas (steam) jet injectors with a high degree of expansion and a low degree of compression.

The second group of devices is used to maintain a deep vacuum; with a compression ratio pс/pн>2.5, they are used in condensing units of steam turbines and in steam ejector refrigeration units. Optimal for them is a conical mixing chamber.

Briefly about the main thing

When planning to set up a pumping station on the site to supply household water, you need to check at what depth the water lies. After all, if it is located further from the surface than 10 meters, you will have to drill a large diameter well. This is necessary to immerse the remote ejector into it. Otherwise, the surface pump simply won’t cope.

But if the water depth is within 7 meters, then you can use a pumping station with a built-in ejector. In this case, the cost of system equipment will be significantly reduced. And the productivity of the system will allow uninterrupted provision of water to the entire household.

Recommendations

- Goldfinch and Semmens (2000). How steam locomotives actually work

. Oxford University Press. pp. 94–98. ISBN 978-0-19-860782-3. - Strickland L. Kness (1894). Practice and theory of the injector

. John Wiley & Sons (reprinted by Kessinger Publications, 2007). ISBN 978-0-548-47587-4. - ^ a b

Strickland Landis Kness (1910).

Practice and theory of the injector

. John Wiley & Sons (reprinted by Wentworth Press, 2019). ISBN 978-0469047891. - "STEAM INJECTOR". By: Mr. F. T. BURWELL, GWR MECHANICAL INSTITUTE. SWINDON ENGINEERING SOCIETY. TRANSACTIONS 1929-30 REGULAR MEETING. — JANUARY 21, 1930

- ^ a b

Goldfinch and Semmens (2000).

How steam locomotives actually work

. Oxford University Press. pp. 92–97. ISBN 978-0-19-860782-3. - Perry, R. H., & Green, D. W. (eds.) (2007). Perry Chemical Engineers Handbook

(8th ed.). McGraw Hill. ISBN 978-0-07-142294-9 .CS1 maint: multiple names: list of authors (link) CS1 maint: additional text: list of authors (link) - Power, Robert B. (1993). Steam jet ejectors for the manufacturing industry

(First ed.). McGraw-Hill. ISBN 978-0-07-050618-3. - Pullen, William Wade Fitzherbert (1900). Injectors: Their Theory, Design and Operation

(Second ed.). London: Technical Publishing Company Limited. paragraph 51. - Anderson, David N.; O'Day, Russell M. H. (July 17, 2013). Cab-Forward celebrates Southern Pacific Railroad's signature locomotive

(Revision 1st ed.). Sacramento, CA: Gerald Rood. paragraph 66. - Injector Model, Ted Crawford, Tee Publishing

- "Steam jet pump". General Electric. Received March 17, 2011. US Patent 4847043 ... coolant recirculation in a nuclear reactor.