Most popular brands:

GOST 20Х13 (AISI 420, DIN 1.4021)

– stainless steel with a martensitic structure, cannot be welded, is not prone to temper brittleness, and does not form internal defects during the production process. Used for the manufacture of measuring and cutting tools, springs, leaf springs.

GOST 12Х17 (AISI 430, DIN 1.4016)

– ferritic stainless steel heat-resistant grade, does not contain nickel. Characterized by good anti-corrosion resistance in moderately aggressive chemical environments and high temperatures.

GOST 12Х18Н9 (AISI 304, DIN 1.4301)

– a heat-resistant, corrosion-resistant alloy used in welded structures in contact with aggressive environments. It is used for sheet parts, welded equipment, heat exchangers, pressure devices.

GOST 08Х18H10 (AISI 304H, DIN 1.4948)

– an austenitic type of heat-resistant, corrosion-resistant alloy, used for the production of rolled pipes, components and assemblies for the chemical and engineering industries, heat exchangers, and industrial tanks.

GOST 03Х18H11 (AISI 304L, DIN 1.4306)

– chromium-nickel grade is used for the production of equipment, tanks and pipelines for the chemical industry, in the production of nitric acid and other aggressive substances.

GOST 08Х18H10Т (AISI 321, DIN 1.4541)

– a stainless, heat-resistant and heat-resistant alloy, non-magnetic, resistant to oxidation and has good weldability without preheating. It is used as food and technical stainless steel for the production of rolled sheets and pipes, welded equipment, the manufacture of containers, tanks, tanks and equipment in the chemical and oil and gas industries.

GOST 03Х17H14М2, 03Х17H14М3, (AISI 316, 316S, 316L)

– non-hardening austenitic grade, areas of application – welded parts, equipment for the pulp and paper and chemical industries, boiler bodies, tanks and installations for the coal industry.

GOST 08Х17H13М2Т (AISI 316Ti, DIN 1.4571)

– structural heat-resistant heat-resistant stainless alloy is used for fasteners and welded structures in various industries.

GOST 20Х23H18 (AISI 310S, DIN 1.4845)

– heat-resistant and heat-resistant austenitic stainless steel used for the manufacture of forgings, clamps, combustion chambers, fasteners and boiler elements, used pipes, couplings.

When choosing stainless steel, you should take into account the operating conditions of the metal, the expected load, and the necessary additional properties of the product. If you are in doubt about how to choose the right stainless steel, it is better to contact a specialist. Leave a request on the website, and our managers will give recommendations on selecting the optimal grades of stainless alloys for the given operating conditions.

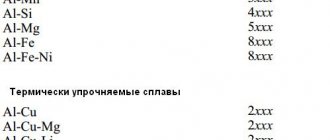

Duralumin – aluminum alloy

Duralumin was produced in 1909 in the city of Duren, Germany. The new chemical alloy, which was named after the city, quickly gained popularity throughout the planet. The approximate composition of duralumin is: 94% aluminum, 4% copper, 0.5% each of manganese, magnesium, iron and silicon. The alloy is heated to 500°C, then quenched in water and subjected to natural or artificial aging.

The most common aluminum alloy today is duralumin.

After hardening, duralumin acquires a special hardness and becomes approximately seven times stronger than pure aluminum. It, however, remains light - almost three times lighter than iron. The alloy has become much stronger, but has lost one of its most important properties—corrosion resistance. Again we had to use aluminum to combat corrosion. Items made of duralumin began to be clad, i.e. cover with the thinnest layer of pure aluminum.

Metal color

Another criterion that more or less clearly distinguishes stainless steel from aluminum is the shade of the product in question. If we have stainless steel in front of us, then its surface, as a rule, has a shiny, colorless tint. However, over time this condition persists.

If we consider an aluminum product, then the color of its surface is usually matte (this metal is difficult to polish to a glossy shine), gray or whitish. After processing with sandpaper, the sanded area will quickly become covered with an oxide film and become dull.

How to determine aluminum at home - Metalist's Handbook

We welcome everyone who, being a real owner, draws knowledge and experience from our site. This suggests that today for some reason you are interested in the question of how to distinguish aluminum from stainless steel. But really, it’s not that simple.

Features of aluminum

Why is aluminum so valuable? This is a pure metal classified as non-ferrous. It is lightweight, durable, has a good degree of deformation, and is resistant to aggressive environments and corrosion.

All of the listed advantages allow it to be used in a variety of areas from industry and construction (except for industries where high-strength structures are manufactured) to domestic use.

The demand for the valuable metal is great, so it is important to know how to accurately distinguish it from other similar metal alloys.

There are several ways to help you do simple research on your own at home. Find out how to distinguish aluminum from stainless steel - advice from forum members and experts.

- Using a magnet. Aluminum of any grade will not stick to a magnet. Stainless steel also has this property. But there is an exception to the rule. If it contains nickel in sufficient quantities, the tested products will have some attraction. If there is a lot of chromium or copper in a stainless metal, it will not have any effect on the magnet.

- Marking on stainless steel. Some stainless steel products have identification markings. This already gives a hint on how to distinguish aluminum from stainless steel. If there are markings, for example, “STAINLESS” and the like, this is not aluminum.

- Plain paper won't lie. The method is very simple. Experiment conditions: you need white, as thick paper as possible (printer paper will also work). Use a thick cloth to remove dirt from the edges of the products being tested. Move the cleaned areas one by one with some pressure across the sheet. There will be no traces left of the stainless steel. Aluminum will draw gray stripes.

- How to distinguish aluminum from stainless steel by the color of the metal? The surface of the object has a shiny, colorless hue that does not change over time - it is stainless steel. The matte surface of a product that has a grayish or whitish color is aluminum. It will not be polished with sandpaper to a high gloss finish. Check it out.

- Under mechanical load. Another simple way will help you understand how to distinguish aluminum from stainless steel. Hit the product against the surface of any hard metal in the dark. Aluminum will never spark, unlike stainless steel.

- Thermal conductivity, melting. Compare where the water heats up faster. Of course, in an aluminum container. This metal has much better thermal conductivity. But it is not used on the burner of a gas furnace; the melting point is 660 °C. Stainless steel cannot be melted in the usual way (melting index is above 1800 °C).

- Testing for copper sulfate. An option available to everyone. Copper sulfate, after exposure to aluminum, will leave cloudy stains and traces on it, but will not appear on stainless steel.

- Alkaline solutions. Any housewife knows that it is impossible to boil aluminum cookware in alkaline solutions. It will darken and lose its appearance. Conclusion: aluminum products are afraid of alkali, both sodium and potassium. The same cannot be said about stainless steel.

- Acid test. All acids, starting with the usual citric acid and ending with more aggressive ones, will leave marks when they get on the aluminum surface. You won’t see them on stainless steel; it doesn’t react with acids.

Duralumin – an alloy of aluminum with transition metals

The industry is not able to provide itself only with pure metal, and duralumin comes to the rescue here - various combinations of manganese, copper and magnesium in an alloy with aluminum.

In addition to all the above properties of its older brother, the transition metal has:

- high degree of strength;

- long service life;

- plasticity;

- high hardness.

It accumulates fatigue properties more slowly and is resistant to cracking.

The disadvantage of products made of duralumin is susceptibility to corrosion, which can be prevented by anodizing, applying a thin layer of paints and varnishes, aluminum.

The choice between the two metals depends on the end use. We pay tribute to their advantages, but also foresee their disadvantages. The domestic sector leaves the choice to aluminum, while the industrial sector votes for the strength that duralumin has.

Naturally, the question arises of how to distinguish aluminum from duralumin. It is almost impossible to determine by eye which metal is which. The chemical laboratory will give you the exact answer. But experts on the forums have their own opinion on this matter.

- Follow the markings.

- The color of the alloy is steel gray.

- Scratches leave clear marks.

- A ringing sound is heard from the impact.

- During processing, the chips will break without ductility.

- The structure of the alloy is fine-crystalline.

You can determine the type of material by conducting an experiment. Apply a drop of sodium hydroxide to duralumin and aluminum samples for 10 minutes. After removing the substance, we learn about the metal from the resulting stains: the dark one is duralumin.

If you place a piece of aluminum in an acid with added alkali, it will dissolve, forming a white powdery precipitate. In the experiment with duralumin, blue copper granules will be present.

Unlike aluminum, the main characteristics of the alloy are lack of ductility, brittleness and hardness.

Everything can be learned by comparison; examine the parts of two samples several times, pick them up and compare the weight. Such familiarity will help you subsequently simply recognize metals.

Silumin - a twofold relationship

Products made from silumin, an aluminum-based alloy with the addition of silicon, literally flooded the market. Why does it attract the buyer and how to distinguish aluminum from silumin?

Advantages of silumin

Of course, this alloy of two materials has its “fans”. They call the following positive features of silumin:

- light in weight;

- highly durable;

- resistant to wear and corrosion;

- cheap price.

Cons of silumin

Silumin products should be treated with caution, unlike aluminum ones. in silumin, aluminum production waste, silumin-containing alloys, and metal powder do not have an exact proportion. It cannot be called high quality, since the manufacturer produces cheap products under the name of some brand.

The disadvantages of the alloy include:

- design flaws;

- they are unsuitable for food products;

- dangerous to health.

You can distinguish silumin from aluminum visually. The products have a glossy smooth gray surface.

Today, public dissatisfaction with plumbing products continues to grow due to the heterogeneous structure of the material with numerous internal stresses and voids. After 3-5 months, the water tap turns into dust, and the rotary steel ball rusts.

When replacing heating radiators, many are faced with the choice of which material to choose for the new design. Cast iron batteries are a thing of the past; manufacturers offer aluminum, steel and bimetallic ones.

While steel is easily recognizable in appearance, the problem with aluminum and bimetallic structures is that you can’t tell the difference by eye. Moreover, the latter option is in greatest demand.

In the store there is a chance not to buy a fake, but how to distinguish bimetal from aluminum at the market?

Visual recognition will not provide accurate results to the consumer. Both the aluminum and bimetallic systems have external fins made of aluminum. And it’s impossible to visually determine the weight of one section.

For reference: the aluminum section weighs 1–1.6 kg, the bimetallic radiator “compartment” weighs 1.5–2 kg.

You can use the “old-fashioned” method and arm yourself with a neodymium magnet, which has greater power.

Preliminary test. Place the magnet first on the steel, then on the aluminum radiator. The magnetic tester will attract the first option to the surface. The effect will be weaker for a bimetallic radiator. Its steel tubes are located under a diamagnetic material - aluminum. With a powerful neodymium magnet, it is possible to catch the attraction.

It is more difficult when the coolant tubes are made of copper, which, like aluminum, is impervious to the magnetic field.

Difference from other non-ferrous metals

It is known that metals have largely identical properties. But each element has its own distinctive characteristics. They allow you to understand how to distinguish metal from aluminum:

- copper is recognized by its bright reddish hue;

- iron and its alloys have high magnetic properties;

- You can recognize gold by its yellow color;

- Lead has high fragility and density;

- silver has a bright shine;

- Tin has high ductility.

The above methods are only estimates and approximate. More reliable information is available on the pages of special reference literature.

How to distinguish aluminum from stainless steel

Plain paper

One of the easiest ways to determine the difference between aluminum and stainless steel. For the experiment you will need a sheet of plain paper. It must be white paper. The one used for printer printing is suitable. The denser it is, the better for the business.

The essence of the experiment is as follows. First, you need to clean the edge of the product under study from dirt, grease, oils and other deposits. Next, you need to move this place along a sheet of white paper. The pressing force should be as strong as possible. It is very easy to draw conclusions. Stainless steel on a white sheet will not leave any marks, while aluminum will show thin stripes of gray color.

Checking for density

This is exactly the case when school knowledge in physics, mathematics and chemistry will be useful in real life. Aluminum can indeed be defined by its density. How to do it:

- Take a graduated cylinder and fill it with water.

- We place a piece of the material being tested in it.

- We calculate the volume - the object will displace some of the water from the graduated cylinder, which will indicate the level on the scale when the material is removed.

- Weighs the piece being tested.

- Now we apply the formula: divide the mass by the volume.

If the result is close to 2.7 grams per milliliter, then we are definitely looking at aluminum.

How to check that it is silver?

Simply rub the silver item with chalk. If it darkens, it means

precious metal.

Can also be done using a lapis pencil. After you rub the product with it, your silver

will darken after some time in the place where they touched.

Interesting materials:

How much should you save? How many views do you need on Tik Tok? How much should I pay for a deed of gift? How much grain was threshed in Belarus 2022? How many peoples are there in China 2022? What is the population of Warsaw? How much is the population in Poland? How many nations are there in the world? How long does your work experience last? How many weeks are there in December 2020?

Mechanical loads

This is also a fairly simple method that can be done at home. Its essence lies in the fact that the product under study must be hit against a solid metal object. To obtain a more accurate and visual result, this should be done in the dark.

If the product is made of stainless steel, then we will see quite pronounced sparking upon impact. It can be seen even in dim lighting. In the case of aluminum, there will be no sparking, even if you look very carefully in complete darkness.

What is the difference between aluminum and duralumin?

An accurate result in identifying these materials can only be obtained in a chemical laboratory. But there are a number of simple methods that will help distinguish an aluminum product from a duralumin one.

- Aluminum produces a higher ringing sound when impacted, unlike duralumin.

- After removing the chips, the aluminum surface is shiny.

- When drilling an aluminum surface, the chips do not stick to the drill.

It is extremely difficult to confuse aluminum with silver, because silver is much heavier.

In general, all methods can be considered approximate, because only specialists from a special laboratory will give an accurate result regarding the chemical composition of scrap metal.

Thermal conductivity and melting

In the case of various containers, metal can be determined by heating. So, in an aluminum pan, ordinary water is brought to a boil quite quickly. Under the same conditions (volume of water, heating) in a stainless steel container, this process takes much longer. This is due to the fact that the thermal conductivity of aluminum is many times better than that of steel.

The melting point of aluminum is about 660°C, while for stainless steel this indicator is beyond 1800°C. When using a conventional gas burner, which is used as camping equipment, it is quite easy to reach a temperature of 700°C. This means that it is also possible to melt a small aluminum object on such a fire. Stainless steel cannot be melted under normal conditions (without pressurization and oxygen supply).