Cast iron is an alloy of carbon and iron, which also contains alloying additives and impurities.

Cast iron parts are widely used not only in industrial and production areas, but also in everyday life. Cast iron products for private use: plumbing elements, fence structures, car parts and much more. The active use of this alloy leads to the need for welding work. The main difficulties in welding cast iron that home craftsmen encounter:

- due to the fluidity of the alloy, it is recommended to carry out welding in the lower spatial position;

- non-compliance with temperature conditions leads to overheating of cast iron, which can cause the formation of pores and stress in welds;

- cast iron in a molten state can release gases , which will negatively affect the quality of the connection;

- Accelerated or uneven heating or cooling can promote cracking .

In order to obtain a high-quality connection of cast iron products at home, it is necessary to take into account these specific characteristics, as well as correctly prepare the working surface, select the correct welding mode and electrode.

Preparation for welding

Preparatory operations must be carried out carefully and carefully, as this is one of the fundamental principles of obtaining a high-quality connection:

- the structure is cleaned of dirt, debris and dust;

- then you should degrease the parts with a solvent, for example, acetone;

- when working with thin cast iron, you need to use pads to remove heat ;

- edge cutting should be done before welding thick-walled products; for this, a file or grinder is used;

- cracks need to be drilled out along the edges and cut along the entire length; alternative method - cut out cracks, ends round off;

- depending on the chosen welding method (hot or cold), the product is heated or not. heated using various equipment: ovens, gas burners, or using improvised means: a blowtorch.

What to cut with?

Oxygen gas cutting is effective for iron, but does not work on cast iron for a number of reasons.

In particular, due to the formation of refractory oxide films. The easiest way is to use conventional mechanical devices, like an angle grinder, but their performance leaves much to be desired. They are usually used in domestic conditions.

The best results are obtained by air-arc and plasma-arc cutting methods . Today, these methods are most often used in production.

Welding methods

Experts distinguish 3 methods of welding cast iron:

- Hot is carried out by heating the cast iron parts before making the connection, the temperature is 600-650°C. This method cannot be used at home.

- Semi-hot is practically no different from the previous method, the difference is only in the heating temperature, the product is heated to 300-350°C.

- Cold implies the absence of heating of work products. Welding cast iron with an electrode at home is carried out using this technology.

[ads-pc-2][ads-mob-2]

Types of cast iron and features of welding products

To figure out how to weld cast iron and solve the difficulties that arise, you need to know what it is and how it differs from steel.

There are two main types of this metal:

- white;

- grey.

The first is distinguished by its fragility, which is given to it by inclusions of cementite - iron carbide (Fe3C) . He also gave this type of cast iron its name, painting the broken metal white or light gray.

They are used for conversion to steel (conversion), producing malleable cast iron.

Gray gets its name from the break in the dark gray color, with sparkles, that graphite imparts . The ability to obtain material of varying degrees of strength and ductility, as well as high casting qualities, has made it the main raw material for industrial products.

At the same time, fluidity complicates the welding of cast iron parts. The metal tends to pour out without forming a seam. In addition, the arc temperature leads to the appearance of refractory oxides. The graphite at the junction burns out, forming pores.

The problems of how to weld cast iron with electric welding do not end there.

When the temperature decreases from 750ºC, graphite combines with iron, forming cementite. In this case, the seam turns from gray to white and brittle.

How to cook cast iron with an inverter and a consumable electrode

Welding cast iron using an inverter and a consumable electrode is most often carried out using the cold method. Important components of successful work are: the correct choice of electrode and optimal welding modes.

Electrodes OZCH-3

The performer must make the connection with special electrodes containing nickel and/or copper:

- OZZHN-1;

- OZCh-2;

- OZCh-3;

- OZCh-4;

- OZCh-6;

- MNC-2;

- TsCh-4.

Recommended welding modes for some of the listed brands:

| Electrode brand | Current strength for an electrode with a diameter of 3 mm. | Current strength for an electrode with a diameter of 4 mm. | Current strength for an electrode with a diameter of 5 mm. | Current strength for an electrode with a diameter of 6 mm. |

| TsCh-4 | 65-80 | 90-120 | 130-150 | – |

| OZCH-2 | 90-110 | 120-140 | 160-190 | 220-250 |

| OZZHN-1 | 100-120 | 130-150 | 160-180 | – |

| MNC-2 | 90-110 | 120-140 | 160-190 | 210-230 |

The following technological features should also be highlighted:

- the length of one continuous seam should not be 30-50 mm;

- frequent breaks in the welding process will help eliminate the possibility of overheating; temperatures above 80°C are unacceptable;

- polarity is reversed.

This welding method can be performed in two ways: using studs and in layers.

1. The studs are equipped with threads, which allows them to be screwed into the edges of the product being welded. The studs should be staggered/staggered to prevent overheating during welding. The dimensions of the studs depend on the thickness of the workpiece; when selecting them, you should rely on the following recommendations:

- diameter – 0.3-0.4 product thickness, but not more than 12 mm;

- screwing depth – 1.5 times the diameter of the stud, but not more than half the thickness of the product;

- the height of the protruding part of the pin is 0.75-1.2 times the diameter.

After installing the studs, you can start welding. Metal is deposited around each pin, layer by layer. Then the performer needs to weld the space between the studs, which remains untouched, and make one or more connecting seams.

2. Multi-layer welding is performed after cutting the edges. The presence of sharp corners is not allowed. Surfacing should be done from the edges. The first layer is the main one, so during its deposition you need to carefully monitor the welding mode. Each subsequent layer, except the first and facing ones, must be forged with a hammer, without cooling.

Video

The following video demonstrates the Zeller 855 cast iron electrode, but from the video you can see how welding is done.

This information will help the contractor learn how to cook cast iron with an inverter using electrodes on cast iron, and easily carry out the connection work.

Welding with conventional electrodes

In order to save money, you can use ordinary (steel) consumables instead of special ones. General purpose electrodes have a more affordable price. The technology of multilayer welding with conventional rods is practically no different from the method discussed above, which uses special rods coated with non-ferrous metals. The stages of work are similar. The only difference is that the layers following the first are deposited not with a special electrode, but with a regular one.

Attention! Welding cast iron with electrodes not intended for this purpose is possible, but we do not recommend using it in any critical connections! This information is provided only for welding for experimental purposes.

Welding with cast iron electrodes

This welding method can be carried out using a cold or semi-hot method. A little preheating will improve the structure of the weld metal.

Cast iron electrodes are cast rods coated with coating, used to correct defects in cast iron. This type of consumables includes the following brands: MNCh-1; OZCh-1; OZB-2M.

Welding is carried out using direct and alternating current. The current value is determined as follows: 50-60 A per 1 mm. electrode rod. [ads-pc-3][ads-mob-3]

Specific qualities of cast iron

Compared to conventional metals, such a structure requires a special approach and special preparatory work. Otherwise, the material overheats and becomes more brittle. Cast iron as a special metal has several varieties, determined primarily by its structure. Experienced welders can easily determine how and in what way to weld a particular sample, based on just one section.

With a fine-grained structure and a color close to a gray tint, welding cast iron with an inverter is much easier than similar parts with large grains of a dark color. There are other factors to consider as well. For example, cast iron workpieces that have been in oil for a long time or are subject to constant oxidation in wet soils, water and other similar environments are completely unsuitable for welding.

Thus, the possibilities for welding this material are quite limited due to its physical properties and specific features:

- Cast iron has increased fluidity, so all parts made of this material can only be welded in a horizontal position.

- If the temperature regime is not observed, in most cases overheating occurs. As a result of carbon burnout, voids appear in the internal structure of the metal.

- In places of welding seams, metal stresses often form due to its low ductility and under the influence of too high or low ambient temperatures.

- When molten cast iron comes into contact with the environment, oxides may appear whose melting point exceeds that of the original material.

- As the part cools, cracks may form in the area of the weld, which indicates non-compliance with the work technology.

Welding with non-consumable electrodes

Welding cast iron using this technology is carried out in a protective environment of argon or fluxes, the main component of which is borax. Cast iron or special rods containing nickel, aluminum and copper are used as filler materials. Welding cast iron is carried out using tungsten, carbon and graphite electrodes.

The most common method is argon arc welding (AC TIG). In order for the work to be successful, you should adhere to several rules:

- Thorough cleaning of the surface from debris and dirt;

- the workpiece must be fixed at several points;

- It is recommended to use slight preheating of the product; for this you can use improvised means. It should be remembered that the presence or absence of heating depends on the type of cast iron being welded;

- the additive is supplied at an angle of 20-30 degrees;

- it is necessary to use small amounts of current;

- the connection should be carried out in stages : the performer welds a small section of 2-3 cm and forges the deposited metal so that

- avoid residual stress. Forging is done with a small hammer, the weight of which does not exceed 1.2 kg, the hammer is of a rounded type.

- Cooling of the part after welding is carried out gradually .

This method is not the main one when connecting cast iron products. This is due to certain difficulties that arise during the work process, as well as an increased level of labor and financial costs.

Process

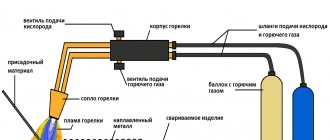

After everything for welding cast iron is ready, begin the welding itself. Work using both hot and cold technology is carried out by:

- gas welding;

- fusible electrodes, rod or wire (inverter or semi-automatic with carbon dioxide);

- welding with a non-fusible electrode, with filler rods, including in an inert gas environment (argon, helium).

The seam zone, or fusion of parts, is the most “capricious” part of the connection . A common defect in this case is peeling of the deposited material. The stud welding technique helps to avoid it.

They are screwed into holes with cut metric threads. The quantity depends on the size of the parts. The correct diameter is taken according to special tables.

Welding is carried out using inverter machines, including semi-automatic ones. The latter, due to the cooling effect of carbon dioxide, provide a high-quality compound

When welding, each pin is first scalded, then the space between them is filled.

In this way, it is possible to cope even with such a complex task as welding a cast-iron engine block using electric welding.

The cutting width when cutting a crack, and therefore the future seam, is kept within 3-5 mm. A smaller gap will give high-quality penetration. On the other hand, the thicker the seam, the higher the “whitening” of the welded edges, increasing their fragility.

DIY electrodes for cast iron

In the absence of special electrodes for welding cast iron, you can independently make consumables that are similar in characteristics to the OZCH-2 and OZCH-6 grades. Next, we will look at two ways to make electrodes for cast iron with your own hands.

- The production of electrodes for cast iron is carried out using the following technology:

Warning! We have not yet tried this method in practice, it was found in open sources, we are not responsible for the result. If you do, it is at your own peril and risk. Please share your results in the comments to this article. The next method is more traditional and has been tested by many, as shown in the video below.

- It is necessary to take copper wire with a diameter of 2-5 mm, sand it with sandpaper, degrease it and cover it with homemade coating; The easiest way is to prepare a coating from the coating of conventional electrodes (ANO-4, UONI-13/55).

- The coating of general purpose consumables is scraped off the rod, crushed and mixed with steel filings or iron powder in a 1:1 ratio. Then silicate glue is added to the resulting mixture, after which all components are thoroughly mixed.

- The wire is lowered into a homemade coating until the applied coating thickness is 1.5-2.0 mm. Then you need to wait until the excess mixture drains.

- The next stage is drying, which is carried out in the open air; the electrodes are dried in a vertical position.

- The final procedure - calcination is performed in the oven or on the stove at a temperature of 200-250°C.

- Homemade electrodes for cast iron are ready for welding. The welding mode with self-made electrodes does not differ from the operating mode with branded consumables.

2. There is another way to make a cast iron electrode. The welder will need a drill, a steel electrode (ANO-4, UONI-13/45) and copper wire with a diameter of 2 mm.

To make an electrode for cast iron with your own hands using this technology, you should perform the following steps: the wire is wound onto the steel base of a conventional electrode by rotating it clamped in the drill parton. To visually familiarize yourself with the production process, we recommend watching the video.

Do-it-yourself cast iron electrodes will allow you to save money and also perform welding work without downtime. But the quality will be lower than from using special electrodes for cast iron.

Making electrodes at home using cast iron can be done by a performer of any level.

How to make a seam?

The welding process of cast iron, due to its high fluidity, is usually carried out in the lower position of the parts being welded . An exception is the use of special electrodes.

Therefore, if it is necessary to perform work on several sides, the product must be turned over. To prevent the already completed seam from being destroyed, the parts are placed in a common frame that prevents them from moving.

With significant thickness of the products, it is impossible to connect them or weld the crack in one go. In such cases, the first suture is placed directly along the incision. Then, stepping back to the right and left, two more seams are laid at intervals. Then the distance between them is filled.

If the joint is not filled, the operation is repeated, applying another layer, and so on.

To reduce overheating of parts, the seam on cast iron is made in separate sections.

Security measures

Carrying out welding work at home requires careful and precise adherence to safety precautions. The most important points:

- the room in which welding work is carried out must be illuminated and ventilated ;

- It is mandatory to use means for grounding ;

- Cast iron does not respond well to rapid cooling, so its surface must be protected from moisture ;

- personal protective equipment when working .

Sequencing

The method of joining cast iron parts depends on their size, weight, and shape. Sometimes you have to use a stud system, multi-layer welding, etc. However, the general sequence of work is approximately the same.

We secure the elements prepared for welding using clamps or another method.

arc

We carry out welding in separate sections of 2.5-3 cm. While the seam is still warm, we hammer it with a rounded head and hammer it. We strike accurately, not too hard. The signal of readiness is the “release” of the seam: it stops flowing, and the sound of the blow becomes louder.

Having completed one pass, we immediately begin to fill the gaps, then (if necessary) to the next layer of surfacing. Work is carried out continuously until the joint is completely welded.

When working with a non-fusible electrode, the arc is ignited on a separate carbon (graphite) plate. This is done to avoid contamination of the base metal with tungsten electrode, as well as to protect the electrode itself from melting its tip.

Semi-automatic welding of cast iron is carried out according to a similar algorithm. The difference is the absence of a filler rod, since it is replaced by a special wire. Of course, a carbon dioxide cylinder replaces a container with argon.

Methods

Welding cast iron with argon can be carried out in several ways. Since all this is carried out in the same protective environment, the main difference is which tool will need to be used. Here, infusible electrodes and filler wire are distinguished, which can have a different composition, depending on the purpose for which the seam is created.

Weld

Using a non-fusible tungsten electrode is not as convenient as using a fusible filler material and cannot carry out the welding process if there is a gap between the parts. Welding, in this case, should occur only at the joint. But this method allows you to create a weld pool of sufficient temperature to weld the required depth of metal.

Tungsten electrodes for cast iron

Other types and methods of welding metal with argon involve the use of filler wire. It can fill gaps and weld at an angle, make ceiling and vertical seams.

Technology of welding cast iron with argon

Choosing a method

The most common option is using filler wire. It is more expensive because it requires spending money on consumables. At the same time, this is a more universal method that can be used in almost any position. If it is necessary to reduce the cost of the welding process, then cheaper wire can be used if the composition of the cast iron allows. For thick layers of metal, this method is not always convenient.

Welding with a non-consumable electrode is used when it is possible to create a large pool, which is feasible with a high metal thickness. Tungsten does not melt during welding, so you can use the same tool over and over again. But here it is necessary to use additional flux to improve weldability, as well as to enrich the metal with carbon.

Required material

When welding cast iron with argon, the additive is selected from certain options that are mass-produced. The most common material that meets quality requirements is nickel wire. It is great for almost any type of cast iron. An additional material here will be flux, which should contain carbon to enrich the seam during welding.

Filler material for welding cast iron

For a cheaper option, aluminum-bronze rods are used. They provide a more cost-effective weld, but it is then undesirable to use it at high temperatures, since its melting point will be lower than that of the base metal. Infusible, tungsten or carbon electrodes can also be used, the thickness of which is selected according to the thickness of the metal.

Carbon electrode for welding cast iron

Modes

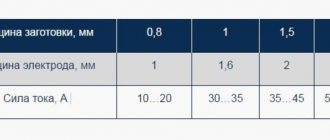

Welding cast iron with argon requires strict adherence to the instructions so that the quality of the connection is as high as possible. After all, to avoid difficulties when welding, you need to act according to proven modes. For welding with a non-fusible electrode it should be like this:

| Gas tank thickness, mm | Electrode thickness, mm | Current strength, A |

| 6-10 | 8-10 | 280- 350 |

| 10-20 | 10-12 | 300- 400 |

| 20-30 | 12-16 | 350- 500 |

| 30 and above | 16-18 | 350-600 |

Welding cast iron with argon technology

Welding cast iron with argon begins with preparing the surface, which must be thoroughly cleaned of rust and dust, and all existing deposits and oxidative films must be removed from it. After this, you can lay out the flux and heat the part before welding until the surface begins to change color. Welding should be carried out in small sections with periodic breaks to avoid cracks and other deformations. When everything is finished, you should heat the seam for some more time and gradually lower the temperature so that due to the rapid cooling of the cast iron there is no defect.