INFORMATION DATA

This standard applies to gaseous and liquid carbon dioxide (carbon dioxide, carbon dioxide) of high pressure and low temperature, obtained from waste gases from the production of ammonia, alcohol, as well as on the basis of special combustion of fuel and other industries. Carbon dioxide is available in low-temperature liquid, high-pressure liquid and gaseous forms.

Carbon dioxide of all types is used: to create a protective environment when welding metals; for food purposes in the production of carbonated drinks, dry ice, for cooling, freezing and storing food products in direct and indirect contact with them; for drying casting molds; for fire fighting and other purposes in all industries. Liquid carbon dioxide of the highest and first grades is used primarily for the needs of welding production.

Formula CO2

Molecular weight (according to international masses 1977) - 44.009.

In terms of physical and chemical indicators, gaseous and liquid carbon dioxide must comply with the standards specified in the table.

Notes:

1. For liquid carbon dioxide obtained from alcoholic and acetone-butyl fermentation, the presence of impurities specified in paragraphs 2, 5, 7 is not standardized.

2. For enterprises producing carbon dioxide from the expansion gas of coke oven gas purification, from the flue gases of calcination of petroleum coke in chamber furnaces and thermal cracking plants using high-sulfur fuel and other waste gases containing carbon monoxide, the release of carbon dioxide is allowed only for technical purposes, except for welding, with a volume fraction of CO not exceeding 0.05%.

3. Vanadium oxides in accordance with clause 12 should be determined only by enterprises that produce carbon dioxide for food purposes from waste gases from ammonia production, where vanadium oxide is used as an inhibitor in purification solutions.

PACKAGING, LABELING, TRANSPORTATION AND STORAGE

1. Gaseous carbon dioxide and high-pressure liquid are supplied through pipelines, the pressure in which must be agreed upon between the manufacturer and the consumer.

High pressure liquid carbon dioxide is supplied in pressure vessels:

cylinders in accordance with GOST 949-73 with a capacity of up to 50 dm3 with a working pressure of 200·102 kPa (200 kgf/cm2) at an ambient temperature of the working area not higher than plus 60 °C and a fill factor of 0.72 kg/dm3;

in cans for household siphons in accordance with GOST 19136-80 with a capacity of at least 0.01 dm3;

in other types of containers and special containers according to regulatory and technical documentation for vehicles.

When using cylinders with a different operating pressure, the filling factor should not exceed: at an operating pressure of 100·102 kPa (100 kgf/cm2) - 0.29 kg/l; 125·102 kPa (125 kgf/cm2) - 0.47 kg/l; 150·102 kPa (150 kgf/cm2) - 0.60 kg/l.

The permissible deviation of the net weight of filled cylinders should not exceed 2% of the nominal value.

Low temperature carbon dioxide is supplied by:

in isothermal tanks according to GOST 19662-89;

in tank containers of standard sizes IC and ICC in accordance with GOST 26380-84 and GOST 19663-90.

2. Cylinders and other high-pressure vessels supplied from consumers must have a residual carbon dioxide pressure of at least 4·102 kPa (4 kgf/cm2).

Each cylinder must be monitored for residual pressure.

3. After hydraulic tests, cylinders must be washed with hot water (60-80) °C and purged. To do this, the valve of the cylinder is turned out, the cylinder is turned upside down, the water is drained from the cylinder and blown through using a special pipe inserted through the neck into the cylinder to its entire height. The cylinder is placed in its normal position, the valve is screwed onto the neck of the cylinder and the symbol of the carbon dioxide manufacturer is stamped.

After washing, the cylinders are purged with dried carbon dioxide.

4. Transport marking - in accordance with GOST 14192-77 with the application of a handling sign “Afraid of heating” and a warning inscription “Do not throw”.

Marking characterizing the transport danger of the cargo - in accordance with GOST 19433-88 (class 2, subclass 2.1 (Fig. 2), classification code 2112 - for high-pressure liquid, 2115 - for low-temperature liquid), serial number 00N 2187.

Transport marking of the tank container is carried out in accordance with GOST 25290-82 and GOST 19433-88.

Each cylinder is labeled with the following symbols:

names of the manufacturer and its trademark;

names and varieties of product;

batch numbers and production dates;

symbols of this standard;

gross - net mass.

For carbon dioxide produced on the basis of expansion gas from coke oven gas purification, an additional warning notice is applied: “Use for food purposes is not allowed.”

5. Liquid carbon dioxide in cylinders is transported by all modes of transport in accordance with the rules for the carriage of goods in force for this type of transport.

By rail, filled cylinders are transported by carload in covered cars, including in baggage cars of a passenger train without transshipment along the route (no more than 20 cylinders in one car), as well as in universal containers on open rolling stock.

Transportation by road in special containers is allowed according to regulatory and technical documentation.

Transported cylinders must be in a horizontal position with gaskets between them or in a vertical position with protective rings and under tight loading conditions (necessarily with protection from possible falls).

Liquid low-temperature carbon dioxide in tank containers is transported by rail and road in accordance with the cargo transportation rules in force for this type of transport.

6. High-pressure liquid carbon dioxide in cylinders and cans for household siphons is stored in special warehouses or in open fenced areas under a canopy that protects the cylinders from precipitation and direct sunlight.

Liquid low-temperature carbon dioxide is stored in isothermal storage tanks (tanks).

SAFETY REQUIREMENTS

1. Safety requirements

1.1. Gaseous carbon dioxide is a colorless and odorless gas at a temperature of 20 ° C and a pressure of 101.3 kPa (760 mm Hg), density - 1.839 kg / m3.

Liquid carbon dioxide is a colorless, odorless liquid.

Liquid carbon dioxide is produced in two types: high pressure from 3482 to 7383 kPa (critical pressure) at a temperature from 0 to 31.05 ° C; low temperature - from 3482 to 518.6 kPa (triple point) at temperatures from 0 to minus 56.5 ° C.

Carbon dioxide is non-toxic and non-explosive.

1.2. The maximum permissible concentration of carbon dioxide in the air of a working area has not been established; when assessing this concentration, one can rely on the standards for coal and ozokerite mines, set within 0.5% (vol.) or 9.2 g/m3.

In terms of the degree of impact on the human body, carbon dioxide belongs to the 4th hazard class according to GOST 12.1.007-76.

At concentrations of more than 5% (92 g/m3), carbon dioxide has a harmful effect on human health, since it is one and a half times heavier than air and can accumulate in poorly ventilated areas near the floor and in pits, as well as in the internal volumes of equipment for receiving and storing and transportation of gaseous, liquid and solid carbon dioxide. This reduces the volume fraction of oxygen in the air, which can cause oxygen deficiency and suffocation.

1.3. When the pressure drops to atmospheric, liquid carbon dioxide turns into gas and snow at a temperature of minus 78.5 °C, which cause frostbite of the skin and damage to the mucous membrane of the eyes.

1.4. When sampling liquid carbon dioxide, you must wear safety glasses and gloves.

When inspecting the inner vessel of a used tank for transportation and storage of liquid carbon dioxide, the tank must be warmed to ambient temperature, the inner vessel must be ventilated or purged with air. Work must be carried out in a hose gas mask.

Working without a gas mask is allowed only after the volume fraction of carbon dioxide inside the equipment is below 0.5%.

1.5. Premises for the production of carbon dioxide must be equipped with general supply and exhaust and emergency ventilation.

1.6. To determine and record the concentration of carbon dioxide in the air of industrial premises, stationary automatic or portable gas analyzers are used.

MAIN PARAMETERS AND DIMENSIONS

1. Cylinders must be manufactured for a working pressure of 9.8; 14.7; 19.6 MPa (100, 150, 200 kgf/cm2) from carbon steel and for working pressure 14.7 and 19.6 MPa (150 and 200 kgf/cm2) from alloy steel.

The steel grade is selected by the cylinder manufacturer in accordance with the list of grades given in the Rules for the Design and Safe Operation of Pressure Vessels.

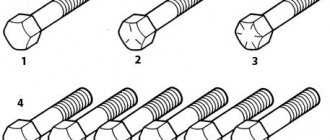

2. The main parameters and dimensions of the cylinders must correspond to those indicated in the drawing and in Table 1. The size of the neck chamfer is 1.5x45°. By agreement between the consumer and the manufacturer, it is allowed to manufacture cylinders with a concave bottom.

Main parameters and sizes of cylinders

1 - support shoe; 2

— cylinder body;

3

— neck ring;

4

- valve;

5

- safety cap

Dimensions in mm

Notes:

1. The weight of the cylinders is indicated without valves, caps, rings and shoes and is a reference value and a nominal value for the manufacture of cylinders with a weight limit.

2. The lengths of the cylinders are indicated as reference and are accepted as nominal when manufacturing cylinders with a limited length.

3. The approximate weight of the metal cap is 1.8 kg; from fiberglass - 0.5 kg; rings - 0.3 kg, shoes - 5.2 kg.

DOMOSTROYPlumbing and construction

Coloring of cylinders

- Nitrogen Black Yellow Brown

- Ammonia Yellow Black

- Argon raw Black White White

- Argon pure Gray Green Green

- Acetylene White Red

- Butane Red White

- Butylene Red Yellow Black

- Hydrogen Dark green Red

- Air Black White

- Helium Brown White

- Nitrous oxide Gray Black

- Oxygen Blue Black

- Neftegaz Gray Red

- Hydrogen sulfide White Red Red

- Carbon dioxide Black Yellow

- Phosgene Protective – Red

- Freon Silver Black Blue

- Chlorine Protective - Green

- Cyclopropane Orange Black

- All other flammable gases Red White

- All other non-flammable gases Black Yellow

Cylinder device

- Protective cap

- Valve

- Neck thread

- Passport details

- Porous mass

- 6. Backing rings

- Support shoe

- Protective cap

- Valve

- Passport details

- Backing rings

It is allowed to release gas from the cylinder only through a reducer designed for this gas and painted in the appropriate color!

Information on the cylinder

The information about the cylinder must be clearly stamped on the top spherical part of the cylinder:

- Cylinder number

- Test point stamp (diameter 12 mm)

- Manufacturer's trademark

- Working pressure (kgf/cm2)

- Actual weight of an empty cylinder, kg

- Quality control department stamp of the manufacturer (diameter 10 mm)

- Capacity, l

- Test hydraulic pressure, (kgf/cm2)

- Month and year of manufacture (IV-1999) and year of the next (2004) survey

- Month and year of the survey conducted (IV-2004) and year of the subsequent (2009) survey

On acetylene cylinders, in addition, the following must be indicated: M III-99 - date (month and year) of filling the cylinder with porous mass III-01 - month and year of testing the porous mass - stamp of the filling station

— a stamp with a diameter of 12 mm, certifying the verification of the porous mass

Rejection of cylinders

External damage to the cylinder due to which it should be rejected:

- Valve fault

- Neck thread wear

- Not all data has been knocked out or the inspection period has expired

- Severe external corrosion

- Cracks

- The coloring and lettering are not up to standard.

- Dents

- Bulges

- Sinks and grooves with a depth of more than 10% of the nominal wall thickness

- A misaligned or damaged shoe

Also, cylinders are not allowed for use if:

GEARBOX:

- when the adjusting screw is fully turned out, the gas passes into the working chamber

- The thread of the union nut is damaged

- one or both pressure gauges are faulty

- the pressure in the working chamber increased after the gas supply was stopped

- safety valve is faulty

PRESSURE GAUGE:

- there is no seal or stamp with an inspection mark

- verification period has expired

- When the pressure gauge is turned off, the needle does not return to zero by more than half the permissible error

- glass is broken or there is other damage that may affect the accuracy of the readings

VALVE:

- no fitting plug

- presence of traces of oil, grease, dust

- flywheel does not turn

- there is a gas leak

It is forbidden to completely consume the gas from the cylinder! The residual pressure must be at least 0.05 MPa (0.5 kgf/cm2)

The residual pressure in acetylene cylinders must not be lower than the following values: Ambient temperature 0C below 0 0-15 16-25 26-35 Minimum residual pressure MPa 0.05 0.1 0.2 0.3 kgf/cm2 0.5 1 .0 2.0 3.0

Carbon steel cylinders according to GOST 949-73 volume 1, 2, 5, 10, 40 and 50 dm³

Gas cylinders are steel cylindrical vessels, in the neck of which there is a conical hole with a thread into which a shut-off valve is installed. Each gas has its own valve designs, which excludes the installation of oxygen valves on an acetylene cylinder, and vice versa. A ring with an external thread is tightly fitted onto the neck, which serves to screw on a safety cap, which serves to protect the cylinder valve from possible shocks during transportation. The bottom of the cylinders, at the customer’s request, can be round, flat or on a shoe.

Cylinders for compressed, liquefied and dissolved gases are manufactured in accordance with GOST 949-73 from seamless carbon and alloy steel pipes. For liquefied gases at an operating pressure of not more than 30 kgf/cm², the use of welded cylinders is allowed. Requirements for cylinders are regulated by the rules of the State Technical Supervision Authority of Russia.

Depending on the type of gas contained in the cylinder, the cylinders are painted on the outside in conventional colors, and the name of the gas is also applied with paint corresponding to each gas.

Marking of oxygen cylinders

All information is applied in the valve area and is typed in four lines.

First line: Information about the manufacturer and its trademark. Cylinder number.

Second line: Release date and next required cylinder inspection.

Third line: Hydraulic and working pressure in kgf/cm2.

Fourth line: Volume of oxygen in Liters. Cylinder weight (without valve and cap) in kg.

Marking of carbon dioxide cylinder and acetylene

On these cylinders, information is printed in the valve area. All information is typed into four lines.

First line: Information about the manufacturer and its trademark. Cylinder number.

Second line: Release date and next required cylinder inspection.

Third line: Hydraulic and working pressure in kgf/cm2.

Selection and maintenance of storage containers. Equipment

The choice of container volume is determined by the needs of the customer. Cylinders with low values are used for domestic needs and simple short-term construction. Large containers are designed specifically for stationary use in factories and enterprises, and are not intended for frequent movements and transportation. Small containers are not equipped with valves. Medium-sized cylinders can be equipped and completed with:

At the customer's request, containers for storing and transporting liquefied substances are made with neck dimensions different from the current GOST 949-73. New equipment, at the buyer's request, may not be painted by the manufacturer.

The completeness is indicated by the customer in a specific questionnaire. Equipment with additional parts is indicated in notes with justification. Standardly supplied with the cylinder:

- Neck ring

- shoe

- Flow valve

- Safety cap

The outer wall must be painted with black paint with the yellow inscription “Carbon Dioxide”. Every 5 years all equipment is subject to technical inspection.

Maintenance of equipment for the transportation and storage of carbon dioxide is carried out by organizations that have permission for this type of activity. Before putting into operation, all cylinders must be painted with enamel, oil or nitro paint. After the procedure, containers for carbon dioxide are marked according to the rules of the current GOST.

Color coding of cylinders by gas type

| GAS | Body color, inscriptions, stripes |

| Black, yellow, brown | |

| Yellow, black | |

| Black, white, white | |

| Black, blue, blue | |

| Grey, green, green | |

| White Red | |

| Red, yellow, black | |

| Dark green, red | |

| Brown, white | |

| GREY-black | |

| Blue, black | |

| Blue, black | |

| Grey, red | |

| Black, white, yellow | |

| White, red, red | |

| Black White | |

| Black, yellow | |

| Protective, black, red | |

| Silver, black, blue | |

| Silver, black | |

| Silver, black, 2 red | |

| Silver, black, 3 yellow | |

| Protective, black, green | |

| Orange, black | |

| Purple, red | |

| Red, white - other flammable gases | |

| Black, yellow - other non-flammable gases |

Descriptions of gases - see on the page Technical gases

Mechanical properties

| steel grade | Time resistance, N/mm² | Flow limit, N/mm² | Relates. elongation, % | Relates. narrowing, % | Impact strength KCU, J/cm² | Brinell hardness, HB, no more |

| minimum | ||||||

| carbon | 638 | 373 | 15 | 29.4 (+20 °C) | ||

| alloyed | 883 | 687 | 10 | 98.1 (+20 °C) | ||

Main technical characteristics

| Small volume cylinders with neck W 19.2 | |||||

| Volume, l | Working pressure (kg/cm²) | Size, mm | Weight, kg | ||

| Steel 45D | Steel 30HGSA | Ø Cylinder parts | Case length | ||

| 1 | 150 | 89 | 250 | 2,0 | |

| 200 | 260 | 2,5 | |||

| 2 | 200 | 108 | 325 | 3,0 | |

| 150 | 330 | 4,0 | |||

| 5 | 150 | 140 | 480 | 8,5 | |

| 150 | 475 | 5,8 | |||

| 8 | 200 | 140 | 715 | 12 | |

| 10 | 150 | 140 | 830 | 11 | |

| 150 | 870 | 15 | |||

| Small volume cylinders with neck W 27.8 | |||||

| 40 | 150 | 219 | 1400 | 65 | |

| 200 | 1460 | 77 | |||

| 50 | 150 | 1700 | 77 | ||

| 200 | 1800 | 95 | |||

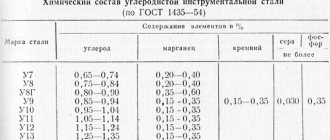

Chemical composition (%, maximum)

| steel grade | C | Si | Mn | Cr | Ni | Mo | S | P | Cu | N |

| 45 | 0,42. 0,45 | 0,17. 0,37 | 0,50. 0,80 | 0,25 | ||||||

| 30ХГСА | 0,28. 0,34 | 0,90. 1,20 | 0,80. 1,10 | 0,80. 1,10 | 0,30 | 0,005 | 0,025 |

For reliable fixation in a vertical position and for traumatic-free operation, special clamps are used for tables, racks and cages.

To heat the cylinders, special belts and heaters are used.

At the customer's request, cylinders are shipped in protective nets or covers.

Source of the article: https://granat-e.ru/ballon_cs.html

Types and characteristics

Cylinders for transporting and storing carbon dioxide are made of seamless pipes (alloy or carbon steel). The maximum operating pressure is 19.6 MPa. Manufacturers produce cylinders with volumes from 0.4 to 50 liters with a wide range of intermediate values. Depending on the scope of application, carbon dioxide cylinders are produced with standard and high precision. The weight limit is specified by the customer in the equipment design specification. The tare weight is indicated taking into account all additional parts (valve, shoe).

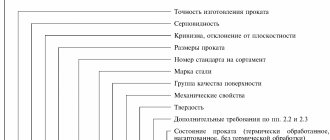

Marking of gas cylinders

High-quality marking of compressed gas cylinders is the success of your production.

According to established standards and GOSTs, informing the buyer about the product, its composition, shelf life and instructions for use occurs by applying the relevant information to its packaging. In addition to markings, additional security elements (holograms, hidden symbols, etc.) also serve as an indicator that the product is licensed and not fake (counterfeit). These requirements apply to both food and non-food (industrial) products.