Bone glue in most variations is an appropriate base based on organic components. They allow you to effectively connect elements made of wood, cardboard, hardboard and other similar materials. The connection itself is characterized by maximum strength; even if the structure is destroyed, you can notice that it is not the adhesive layer that is deformed, but the adjacent layers of wood or analogues. The mixture in question includes safe organic components that are approved for use in educational institutions and children's rooms.

Types of bone glue

To prepare the base composition, several main types are used, differing in the main components:

- Flesh option.

- Fish composition.

- Pure bone glue.

The latest version is the most common, the composition is obtained from animal bone waste. The most valuable specimens are considered to be pellets obtained from horns. The set includes collagen, gelatin and cysteine, which have excellent viscosity and are capable of firmly gluing products made of wood and similar materials.

The leather analogue is made from waste from the leather industry. In fact, the main part of the material consists of subcutaneous tissue, cut off during the tanning of hides. Oligopeptides and natural leather trimmings are often added to the composition of this glue. Output – scales, tiles, powder.

Fish bone glue is prepared from bones, heads, scales, entrails, and fins. This substance is the most expensive, but it was often used for icon painting and other works that required maximum care and accuracy. A composition is produced for fastening dissimilar parts, produced in the form of granules or flakes. Let's consider the features of all variations, as well as the features of their operation.

Description and use of wood glue

Wood glue is a solution made from various components, which can be of organic and inorganic origin. Designed for connecting products from different materials - wood, fabric, glass, paper, plastic.

The connection occurs due to adhesive bonds formed with the surface of the product. The substance is used to create reliable adhesion of fabric, plastic and paper products. But most adhesives are used for wood - antiques, furniture, musical instruments, dishes, cutting boards.

Types of wood glue and features of its use

The composition of wood glue affects the properties of the resulting substance.

The main components of organic origin are protein, remains of skin, skins, bones of animals and fish, fins and tails, which ensure reliable adhesion and environmental friendliness of the product used.

Environmental friendliness is one of the factors that you need to pay attention to when choosing a glue brand. It affects the safety of people living at home.

Below we will discuss the main types of wood glue used during repairs, construction or in household chores. What is natural wood glue made from? From parts, bones and remains of animals, fish. Synthetic compounds are distinguished by their non-plasticity, but the reliability of the seam and the ductility of the glue. Does not stick to metal surfaces; hardened glue can be easily removed from products if necessary.

Environmental friendliness is one of the factors that you need to pay attention to when choosing a glue brand.

Mezdrovy

The composition is based on waste that remains after processing animal skins. As the name implies, wood glue is mainly used in wood glue. This is the layer of subcutaneous tissue that remains when animal skin is processed. Skin trimmings containing oligopeptides are added to the flesh.

The elements form adhesive bonds between the bonded surfaces. Thanks to them, the products are glued together. This substance can be sold in the form of powder, flakes or tiles. To use, the composition is mixed with water in a ratio of 1 to 2 or 3. The solution is infused for 12 hours, gradually swelling. After half a day, the finished solution is heated in a water bath.

The operating temperature of hide glue is from 50 to 70 degrees.

The composition is based on waste that remains after processing animal skins.

Bone

Bone glue is used most often for repairs. As the name suggests, bone wood glue is made from the bones and waste of dead animals.

Bones contain gelatin, cysteine and collagen, which provide adhesive bonds. This wood glue is available in granules or tiles.

Unlike the previous type, this one needs to be mixed with water one to one and left to infuse for 4-6 hours. The working temperature of the solution is from 40 to 60 degrees.

The bone adhesive composition has high absorbent properties. When gluing materials in damp rooms, the substance absorbs moisture and deteriorates the quality of adhesion.

You can make bone glue yourself, but it will take 2-3 days.

The bone adhesive composition has high absorbent properties.

Fish composition

Fish composition includes bones, scales, fins and bones - all fish remains. The most expensive of the substances described in the article has a good price-quality ratio. Used in the form of elastic flakes.

Fish composition includes bones, scales, fins and bones - all fish remains.

Casein

Milk proteins are the basis of the composition, which is highly reliable. Heat-resistant, the quality of gluing is not affected by temperature changes. The disadvantages are that when used, wooden surfaces shrink and the color of the glued product changes. The prepared solution is used within an hour after preparation.

The prepared solution is used within an hour after preparation.

PVA

PVA is used in kindergartens, schools, workshops. It can be found in any home or apartment on the stationery shelf. Sold immediately as a ready-made solution, which can be used after opening the container.

It is transparent and elastic, the adhesive seam does not spread, gluing occurs quickly and is durable. It is possible to add additives to change characteristics.

A mixture of PVA and borax adds antifungal properties to the product.

Bonding occurs quickly and is durable.

Modern synthetic based adhesives

Recently, wood glues have been made from inorganic substances. This reduces the cost of the mass production process. Popular means:

- Moment Joiner;

- Titanium;

- Titebond.

All adhesives reliably glue wooden products. Moment is highly water and moisture resistant and is used in rooms with high humidity.

Titanium is suitable not only for joining wooden products, but also plastic, paper and glass. Dries within two hours, used during repairs and finishing work.

Moment is highly water and moisture resistant and is used in rooms with high humidity.

How to choose wood glue

The choice of glue depends on the purposes for which it is required. Highly specialized substances work only with wood and wooden products, universal ones - with any kind. What you should pay attention to when choosing:

- Purpose. Universal adhesives are applied to dry or wet surfaces. To increase the reliability of the seams, a high-quality fit of the products to each other may be required, or you can do without it. In this case, the liquid fills the cavities on the surface and does not lose strength;

- Technical properties. Reliability, moisture and water resistance, heat resistance, resistance to sunlight. To repair a stool, it is enough to use inexpensive PVA; there is no need to look for an expensive foreign synthetic composition;

- Environmental Safety. The release of harmful substances during the gluing process, the danger after contact with the epithelium, the effect on food products upon contact affect human health;

- Price. Low cost of a product does not mean poor quality. Before purchasing, you need to make a list based on the first three points, then study the opinions of people who have used it and look at the composition on the packaging, select an option that is suitable for the price and purchase.

The choice of glue depends on the purposes for which it is required.

Features of preparing wood glue yourself

There are four main types of compositions. In each of them, bones, remains of fish or animals, and proteins are softened to a jelly state, and then boiled to the required state. There are two options for making wood glue yourself.

First option:

- The raw materials are crushed, placed in a dense material and tapped with a hammer or chisel to get rid of large pieces. Small pieces will be ready for use faster.

- After the first stage, the powder is placed in a container and diluted with water. After 2-3 hours (if the particles are small) the solution will become jelly-like.

- In the final stage, the jelly-like solution is heated in a water bath for 15 minutes. Operating temperature – 70 degrees. The solution should be used when ready.

Second option:

- The second option is cheaper than the first; the substance can be stored until needed;

- The crushed particles are mixed with water in equal proportions, boiled for 20 minutes and cooled. The cold product is in the form of a paste;

- Before use, the glue must be diluted with water and heated.

Before use, the glue must be diluted with water and heated.

Terms of use

Products are glued together using wood glue, observing important features:

- First you need to clean the surface of the product until it is smooth and clean.

- The adhesive composition is heated to 50 degrees. Higher temperatures will spoil the glue and the seam will turn out to be of poor quality.

- Heated glue is applied to the surfaces of the parts, the products are connected to each other and left to dry.

- Two layers of glue are applied to the ends of the product, and one to other parts. Drying of the products lasts from one to two days.

If necessary, additives are added to the glue to change the properties of the adhesive substance. A list of additives and their features can be found on the Internet.

Two layers of glue are applied to the ends of the product, and one to other parts.

It is necessary to choose wood glue based on the material of the products that need to be joined and financial capabilities. If necessary, you can make wood glue at home.

: Wood glue comparison

Preparation

Carpenter's bone glue is mainly sold in dry form. The mass is small brown or yellow granules, sometimes this material is presented in the form of small slabs. Can the quality of the composition be determined visually? The purer and lighter the material, the better the product. The cooking process is also extremely important. For example, a tile needs to be crushed into crumbs, and then used for its intended purpose. The preparation of bone glue is divided into the following stages:

- Soak. Powder or granules are poured with cold, pre-boiled water. Tap liquid can negatively affect the quality of the finished mass. Fill the container so that all elements of the adhesive composition are covered. Soaking is considered correct if the substance becomes soft and gelatinous. The soaking process takes from 4 to 12 hours, depending on the amount of product being processed.

- Cooking. The swollen glue should be boiled for about 15 minutes in a steam bath. Maintain the temperature at about 60-80 degrees. The result should be a homogeneous liquid mixture without lumps. It is important not to heat the mass over an open fire and not to bring it to a boil. Otherwise, the protein from which the granules are made will begin to deform, and the adhesive ability will decrease. After a thin film has formed on the surface, the adhesive mixture is ready.

How to make high-quality wood glue

Greetings reader. In this article I want to talk about preparing wood glue, the one that old carpentry masters consider the best.

This glue is used for strong adhesion of parts made of wood and other materials that have a wood base (cardboard, plywood or hardboard). The main component of wood glue is a protein substance. It ensures reliable adhesion. Woodworkers divide glue into hide, bone and fish glue; everything will depend on the material that underlies it.

Components for making medron, bone and fish glue

Hide glue is created from waste from tanneries, leather trimmings and subcutaneous tissue, which is obtained by butchering animal skins.

Bone glue is obtained by boiling the bones and waste from them. This type is considered very popular. Fish glue is made from fish giblets and scales.

It is used in the case of restoration, as well as for heavy work that requires accuracy and quality.

Wood glue is considered to have high strength and remains on the surface even after the wood coating is destroyed. On the counters you can see them in the form of tiles or lumps of yellow or brown color. They say that the lighter and more transparent the lumps (tiles), the better the quality of the paste.

photo from Yandex.ru website

Method of preparing glue

If you decide to use dry paste, you must first prepare it.

The tile is wrapped in a piece of cloth and crushed with a hammer into small pieces, and the granules are drowned in cool water and kept until they become like a soft substance.

It may take about 12 hours for the glue to soak. It is recommended to use only boiled water, since salts in tap water negatively affect the strength of the paste.

After swelling, the glue is boiled in a water bath for about 20 minutes, stirring regularly. The temperature regime should not exceed 80° C. After this procedure, it turns into a uniform, lump-free, liquid mass. It is prohibited to heat wood glue over regular heat, as the solution may burn and boil, which will reduce the adhesive properties.

For cooking, it is better to use a “cleaner”, which consists of 2 metal containers.

Hot liquid is poured into a large container, a smaller container with glue, which has swelled, is inserted on top, then the “glue bottle” is set on low heat.

When boiling, the water in the outer container should not enter the inner container where the glue is located. Copper is considered the best option for “kleyanka”.

If necessary, such a device can be made independently from available materials. To obtain the required glue consistency, add hot boiled water when cooking or increase the time to evaporate as much moisture as possible. To glue the ends and tenon joints, it is better to use thick wood glue.

The readiness of this glue is determined by the presence of a small film on the surface, and it will begin to flow in a continuous stream from the stick with which the liquid was stirred. If the glue falls in separate drops, it means it is not ready.

Wood glue is used hot until it begins to thicken; the temperature should not be lower than 70° C. Basically, the “kleyanka” allows you to maintain the desired temperature regime of wood glue in room conditions, without auxiliary heating, for about 2 hours.

Tips for using glue

It is necessary to prepare glue in such quantity as you can use at a time. Even if you get clever and add all sorts of additives, over time it will lose its properties, and after 3 days it will generally begin to rot and become covered with a small layer of mold.

Apply wood glue to the areas of intended gluing with a small brush and a small amount. To prevent the freshly prepared product from being squeezed out too much, the applied layer is allowed to dry for about 5 minutes.

Then the sections are connected and the parts are ground together, squeezing with a clamp, or tied with twine. The product is left alone for 6 hours until the wood glue has completely dried.

The adhesive joint should not exceed a thickness of 0.2 mm. In order for the sizing to be high-quality and the parts not to fall apart after time, it is necessary to use only high-quality and dried material.

The moisture content of wood should not be higher than 11%, and veneer - 4.5%.

To obtain a more versatile and suitable wood glue, a variety of additives can be added to the finished product. For example, natural drying oil (or flax oil) - 10 g per 40 g of dry product. This combination increases the moisture resistance of joints.

To glue leather products, glycerin is added to the glue. Proportion: 1 teaspoon per 0.5 liter of glue.

To obtain high-quality putty paste, you need to add sifted wood ash or dried chalk powder to the hot glue.

If foam forms on the surface during the preparation of the glue, it means that the water has not been properly purified from salt and impurities. In this situation, the cooking temperature increases.

Subscribe

to the channel, like it. Good luck.

Peculiarities

The readiness of bone glue for wood can be checked in another way. The stick used to stir the substance is raised above the composition. If the product drips down in drops, the process is not completed; complete readiness is indicated by the flow of the mass in a monotonous stream.

To cook natural glue, a special device is used - a glue gun. It consists of two vessels of different sizes, one of which is inserted into the other. A large container is filled with water, and the second reservoir contains the resulting glue. At the next stage, a small vessel is placed in a large tank and placed on fire. The optimal manufacturing material for the glue is copper.

Production of hide glue

The production itself occurs as follows. Bone flesh glue is made from animal bones. Mostly these are cows. The bones are manually cleaned and then placed in a crushing machine where they are crushed into small pieces. Then, using a special solution, the bones go through the stage of degreasing and treatment with a solution of sulfurous acid. This is done in order to remove all the mineral salts contained in the bones of the animal.

Next, the bones are sent to special devices where they are cooked. In these machines they are first boiled in water and then steamed for some time. As a result, the output we get is glutin, which is formed due to the breakdown of collagen during cooking. This substance is the glue, but it is not yet ready for use.

When the drying process is complete, wood glue is not yet ready for use. Then it must again go through the cooking stage. After the glue comes out of the gluten production machine and the drying process, the glue is dry tiles, or an already crushed mixture, which is also called scaly hide glue.

In the first case, the tiles are sent to a crushing machine, and the result is a dry adhesive mass. After about one day, it is placed in cold water and soaked there. Then it is filtered and cooked in a steam bath at approximately 65 degrees, while constantly stirring. After all these processes, the hide glue is ready for use. It is sold under the name flesh glue GOST 3252-80. Where is it used? Let's figure it out.

Recommendations

You can prepare glutinous glue yourself. To do this, you will need to take two containers of different sizes. The outer shell could well be a tin can. Insert a tin can attached to a wire inside it.

The quality of the adhesive composition can be improved by adding various fixing substances. This will allow you to use glue for fastening not only wooden surfaces, but also other analogues.

Among the components used, the most popular, along with efficiency, are the following materials:

- Drying oil. About 10 grams of linseed oil or 40 granules of natural drying oil are added to the composition. This component allows you to increase the resistance of the working seam to moisture.

- Glycerol. An equally effective component makes it possible to use glue when processing leather surfaces. Added at the rate of two teaspoons per liter of finished substance.

- Chalk powder combined with wood ash. After sifting this mixture, add it in small quantities. The paste improves putty properties,

- Phenol, ammonia, borax. These components are an excellent antiseptic that prevents the formation of fungus and mold.

"Moment Joiner"

Professional wood glue made in Russia. The composition is easily applied to wooden surfaces; if necessary, you can immediately begin processing with varnish or paint. It is supplied to the market in different containers - from 200 ml to 30 liters.

Characteristics of “Moment” wood glue:

- water resistance class D2;

- preservation of properties when heated to 70°C;

- bonding strength – above 8 N/mm²;

- gluing time – 15 minutes;

- normal consumption is 150 g/m².

Most often, Moment Joiner glue is used for gluing decorative elements, small parts, plastic and veneer. Complete drying of the joints occurs 2 hours after applying the composition to the surface.

Storage

Natural protein-based adhesives have their own characteristics. Users who use such formulations for the first time should take into account some features.

Among them:

- Adding boiled water. This is necessary if you want to make the mass thinner or extend the cooking time of the composition.

- The optimal operating temperature varies from 30 to 70 degrees Celsius. After this, the finished adhesive mass retains its properties for two hours (provided the ambient temperature is 20-25 degrees). Then the composition begins to cool, and its properties are lost.

- Ready-made wood glue cannot be stored for long periods of time. Within a day it loses its properties. In this regard, to use it, it is necessary to use as many granules as required for a specific operation. On the third day, the composition begins to decompose and smell unpleasant, which is due to its protein base. The glue is applied in layers no thicker than 0.2 millimeters. A thicker layer simply will not set properly.

ACCEPTANCE RULES

3.1. Hide glue is taken in batches. A batch is considered to be a quantity of glue of the same type and brand, documented in one quality document. The quality document must contain the results of the physical and chemical tests specified in clause 2.10.

3.2. Hide glue is taken according to the standard mass, calculated at a moisture content of 17%.

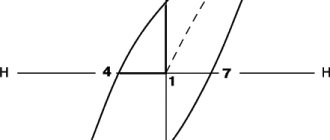

The actual mass of the glue is converted to the standard mass () in kilograms in accordance with the requirements of GOST 4680-49 according to the formula

,

where is the actual mass of glue, kg;

— actual moisture content of the glue, %.

3.3. To check the quality of the glue, 10% of the batch packaging units are selected from the batch, but not less than three.

3.4. If unsatisfactory test results are obtained, samples taken from the same sample are re-analyzed.

The results of the re-analysis apply to the entire batch.

Exploitation

Casein glue can serve as an analogue for gluing wooden furniture. It consists of sodium fluoride, kerosene, copper sulfate and slaked lime. This composition is not used very often because it has a short shelf life and is prone to drying out, changing color and decreasing in volume.

Working with wood glue is somewhat different from using synthetic analogues (for example, PVA (polyvinyl chloride analogue), which is also used for gluing cardboard and wood).

"Titebond" - modern glue

A one-component adhesive, similar in composition to PVA, but characterized by higher adhesion performance. Produced in the USA, it is supplied to the Russian market in containers ranging from 250 ml to 20 liters.

Characteristics of Titebond glue:

- operation at temperatures from -30 to 50°C;

- water resistance class D3;

- hardening time – 5-10 minutes;

- complete drying time – 2-3 hours;

- strong adhesive seam.

The scope of application of this brand of glue is extensive: gluing soft and hard wood, including butt joints. It is also possible to attach veneer, plastic, paper, laminate and other materials to wood.

It is advisable to use Titebond wood glue in the production of furniture of medium and high price categories, railings, stairs, complex and expensive wooden elements. When using this composition, you can significantly reduce the pressing time and obtain a more durable seam. According to the manufacturer, Titebond is non-toxic and does not damage the surface of cutting blades.

Preparation

The operating algorithm can be derived as follows:

- The glue is prepared according to the above method, with precise control of the cooking temperature.

- All bonding surfaces must be dry and clean. The maximum moisture content for wood is no more than 10 percent (veneer - half that).

- The adhesive mass is applied with a bast or bristle brush to both surfaces, the thickness of the seam is 0.1-0.2 mm.

- You need to wait three minutes. This will allow the adhesives to grip securely and not be squeezed out when connecting the parts.

- After fixing the elements, you will need to grind them together.

- It is advisable to tie the parts to be processed with twine or compress them with a clamp.

- Full use of the product is allowed no earlier than after six hours of exposure.

TECHNICAL REQUIREMENTS

2.1. Hide glue must be manufactured in accordance with the technological regulations approved in the prescribed manner and comply with the requirements of this standard.

2.2. All types of glue must be mold-free.

2.3. Tile adhesive should be light yellow to dark brown in color with a smooth or corrugated shiny surface. Small air bubbles inside the tiles are allowed. In thin places, the tiles should be translucent.

2.4. Glue tiles must be up to 250 mm long, up to 90 mm wide, and up to 10 mm thick. It is allowed to produce tiles in the form of scrap.

Gluing of tiles and the presence of hard lumps larger than 20 mm in flake and chip adhesive are not allowed. The sizes of the scales are not standardized.

2.5. Crushed glue should consist of pieces passing through a mesh with a side size of square cells in the light of 20 mm according to GOST 2715-75.

2.6. Granular adhesive must consist of granules passing through a mesh with a clear square cell size of 10 mm in accordance with GOST 2715-75.

2.7. The hot glue solution should not have a putrid odor.

2.8. The presence of salt deposits in tile adhesive is allowed only for the KM-3 brand.

2.9. The presence of foreign impurities and objects in the glue is not allowed.

2.10. In terms of physical and chemical parameters, the hide glue must comply with the standards specified in the table.

| Indicator name | Standard for glue brands | ||||

| KME | CMS | KM-1 | KM-2 | KM-3 | |

| Mass fraction of moisture, %, no more (except for galleries) | 17 | ||||

| Mass fraction of moisture in galert, %, no more | 68 | ||||

| Conditional viscosity of the glue solution (concentration 14.82% of anhydrous and ashless glue) in conventional degrees, not less | 6 | 5 | 4 | 3 | 2 |

| Mass fraction of ash in terms of absolutely dry matter, %, no more | 2,0 | 3 | 3,5 | ||

| Decay, 24 hours, not earlier | 5 | 4 | 3 | ||

| Adhesive ability, N/m, not less | 1570 | 1370 | 1080 | ||

| Mass fraction of fat, in terms of absolutely dry matter, %, no more | 0,3 | 0,5 | 0,8 | ||

| pH of 1% glue solution | 5,5-7,5 | ||||

| Foaming of the glue solution (concentration 14.82% of anhydrous and ashless glue), cm, no more | 15 | 20 | 20 | 25 | 40 |

| Foaming of the adhesive solution during mechanical shaking, mm, no more | 100 | ||||

Notes:

1. It is allowed to increase the ash content for grades KM-1, KM-2 and KM-3 by 0.5% for enterprises operating on sea water.

2. Norms for foaminess of glue during mechanical agitation were optional until 01/01/83.

conclusions

All of these types of wood glue are environmentally safe. It is better to carry out construction operations with the hide version or PVA. These substances have excellent setting parameters and are affordable. For restoration and gluing of delicate and thin surfaces, glue made from fish raw materials is suitable.

Basic criteria for choosing wood glue:

- The lighter and more transparent the granules or tiles, the better the quality of the raw materials used.

- The most expensive and best glue is made from fish waste. It meets the highest standards. Used for restoration work and joining delicate surfaces.

- Bone and flesh composition is used for routine repair work.