Metal drills are indispensable tools that are used in production and at home to drill holes in objects with increased strength. When choosing this type of tool, first of all, it is necessary to focus on its declared performance characteristics, material of manufacture, sharpening angles and coating. Experts first of all recommend paying attention to the sharpening angles of cutting steel. The best metal drills, the ratings of which are presented below, have proven themselves to be the best and have received the largest number of positive reviews from consumers.

Irwin TurboMax 10503992

Irwin TurboMax 10503992 opens the ranking of the best metal drills. The tool is designed for work such as drilling holes in metal objects, plastic, and wood. The drills are also suitable for drilling holes in stainless steel with the obligatory use of coolant. The tip of the tools included in the kit is distinguished by a special sharpening, which ensures high drilling speed. The set includes 15 drills of different diameters and are highly durable. The cost of the kit is approximately 3,000 rubles.

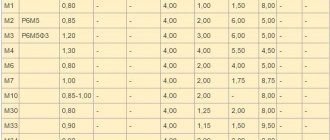

Marking of drills according to GOST

The marking of products for drilling is regulated by GOST 2034-80. This document stipulates that equipment whose diameter does not reach 2 mm is not applied to the drill. Information is indicated only on the packaging label.

Products with a diameter of 2-3 mm are marked on the shank indicating the diameter and steel grade. Encryption of equipment whose diameter exceeds 3 mm includes the following information:

- options;

- trademark;

- metal grade;

- strength class.

The metal grade is indicated in the domestic GOST version (for example, R6M7K6), or international (HSS). Information about additives (Co, Ni, Ti, etc.) can also be supplemented.

International standard color coding

| Color | Group | Processed materials |

| Golden | S | Heat-resistant alloys with the addition of titanium, cobalt, iron, nickel. |

| Green | N | Duroplasts, thermoplastics. Non-ferrous metals, alloys made from them. |

| Grey | H | Hard grades of hardened steel. |

| Red | K | Different grades of cast iron. |

| Blue | P | Steel for castings, some types of corrosion-resistant steel, carbon steel, tool steel. Alloyed. |

| Yellow | M | Austenitic steel is corrosion-resistant, some types of non-magnetic steel are wear-resistant. |

9.Hawera HSS-C SpiralBohrer GQ-32692

Hawera HSS – C SpiralBohrer GQ -32692 is included in the list of the best metal drills. The set contains 25 twist drills with diameters from d 1.0 mm – 13.0 mm x with diameter increments of 0.5 mm. The surface of the working tools is coated with titanium nitride, which gives them special hardness and heat resistance. The tools are made of high-quality high-speed steel and are fully ground. These drills boast a long service life and impeccable operation throughout the entire period of operation. GQ-32692 is excellent for steel, alloy and non-alloy castings, brass, bronze, cast iron and cast iron. You can buy such a kit for 6,000 rubles.

What types of equipment are there?

Metal drills

Depending on the type of work to be done and the material, one or another type of drill is selected.

Design

- Spiral type

The tool varies in length in the range of 40÷400 mm, and in diameter 1÷50 mm and is considered classic. The same diameter size is maintained along the entire length; along the circumference there is a cutting edge in the form of a screw with a twisted groove for removing the processed material, that is, chips. The cutting element is duplicated into a pair, which is positioned exactly 180°.

Such equipment is suitable for through holes in metals with great depth and for blind recesses. For a specific hole diameter, you should choose a drill rod that is 1 mm smaller in size, since the sides of the material are broken after drilling.

- Step type

The drilling element has a conical design. The edge increases in diameter towards the base and has an intermittent shape. A smooth rise and a sharp edge are present at the beginning of a new step; the drilling process can begin from any of the steps. Each tier has a diameter designation in mm, the number of tiers varies from 5 to 10. Such equipment allows you to make holes of various sizes on one sheet without changing cutting elements, which saves time. An existing hole can be drilled to a wider diameter by starting the process from a certain tier of the drill. Since each tier is included in a single structure, it does not allow for a recess depth of more than 3 mm, which is a significant limitation.

- Crown type

The structure, hollow on the inside of the mold, has many end teeth. The twisted cutting edge continues each tooth and can be in the range of 4÷16. The similarity of the design to a crown determined its name. Using such a drill, you can make large holes with a metal depth of 50 mm. In some cases, an alignment with fixed spiral elements or pins is used to ensure accurate operation.

- countersinks

The conical shape has no steps, the cutting edges are continued with grooves. The countersink is used for small recesses up to 5 mm. In addition to round holes, oval drillings can be made as the diameter increases. You can read more about countersinks here.

- Shank

The strength of the fastening affects the undesirable possibility:

- center shift;

- drill breakage;

- damage to workpiece material.

The type of attachment of the tail section must match the chuck.

- Cylindrical type

The shape of the cylinder follows the design of the cutting edge, but has a smaller diameter to simplify the rotational movement when immersed in metal. Three clamping tabs provide a secure fit when locked in place. A similar type is used in electric drills and small machines.

- Hex type

The hexagonal base smoothly transitions into a cylindrical shape and cutting waves. The type does not require additional fixation by twisting the cartridge and is installed in the receiving coupling of the mating faces. Quick changeover when creating wells of different diameters significantly saves time. All screwdrivers are compatible with hex shanks. Biting of the equipment or reciprocating movements can lead to unwanted falling out of the mounting chuck. This type is not suitable for wells in thick metal.

- Conical type

Reducing the diameter of the tail section at the end allows the element to be fastened with muscle force. The load during operation ensures its firm fit. Removal is carried out with a wedge driven into the slots of the cartridge. The species is widely used in drilling machines. It is allowed to use an intermediate cone with a large diameter of the cartridge.

Preparation method

The parameter determines the strength; lifetime; types of steels to be processed.

- One-piece look

Tooling is obtained by casting and this type is the most common. Made from high-speed steel, these can be countersinks, crowns, spirals and cones.

- Welded type

For hole diameters over 20 mm, welded equipment is used; carbon steel is used to make the shanks. The part has a low cost and a long service life.

- Carbide tips

Alloy BK8 is adapted for elevated drilling temperatures in durable metals. Unilateral sharpening of special technology guarantees an increase in shelf life. It is possible to replace the tip while maintaining the body of the element.

Marking

- H.S.S.

General purpose abbreviation for high-speed steel of high hardness and resistance to fracture, with impurities. Impurities determine the type, properties and cost: P – tungsten alloying; F – presence of vanadium; M – addition of molybdenum.

- HSS-E

Steel with the addition of cobalt from 5% to 8% makes the equipment suitable for working on stainless steel and a strength of 1200 N/mm². Often used in drilling processes in difficult materials with a binding effect when heated. The designation HSS-Co is also allowed.

- HSS-TiAIN

The abbreviation for three-layer coating of titanium, aluminum and nitride marks equipment with heat resistance up to 900°. Work on steel with a strength of 1100 N/mm² is allowed. HSS-TiAIN elements last a long time and outlast other types in service life by 5 times.

- HSS-TiN

Sodium nitride is used as a coating on the outer layer. Thermal resistance characteristics have been increased to a threshold of 600°. A drill with a similar marking is suitable for drilling materials with a strength of 1100 N/mm²:

- in cast iron;

- aluminum;

- alloy steel;

- carbon steel.

- HSS-G

Grinding with cubic boron nitride makes the cutting part resistant to abrasion and resistance to radial runout. The processed steel is only suitable with a strength of 900 N/mm² and is also used when drilling cast iron materials.

- HSS-R

Elements with conventional heat treatment and roller rolling are used in work on cast iron and mild steels.

Hard alloys

The material is used for tips and is suitable for high temperature loads. The equipment is highly resistant to wear. Can be used when drilling:

- in titanium alloys;

- stainless steel;

- heat-resistant steels.

Center drill

To produce holes in cast iron and steel products, metal and metal-ceramic alloys, combined centering elements are used. Such equipment is considered professional and provides high quality processing and accuracy. An important characteristic is also the elimination of errors and inaccuracies in work. Several surface roughnesses are distinguished in relation to the consumable tool used.

Wood drilling

Construction and repair, manufacturing of parts, many intermediate manipulations in any work require drilling in wood.

Design

The spiral type is common in universal sets that include working on wood, metal, and concrete.

- Forstner type

The twist drill is additionally equipped with cutting elements, and the process produces smooth hole walls and a flat bottom.

Also, the working part can take the form:

- centering;

- flat;

- single-sided for deep drilling.

- Shank

All tail parts can be divided into:

- cone type;

- cylindrical;

- 3,4,6 faceted;

- SDS.

Drilling in wooden material is specific in that it is enough to choose a drill that is harder in structure than the wood. Common high-strength steel, from which most drills are made, is suitable.

Formwork element

With the help of such a consumable element, a hole is drilled through the inner and outer skins of the boards in one operation. This is due to the length exceeding the usual, average size.

Concrete drilling

For such work, a core, screw and twist drill are used.

Ring elements

The type is necessary for drilling in plastic. You can also use spiral class elements.

Diamond equipment

Feather diamond elements are used for drilling on glass and ceramic tiles. For larger-scale work, such as drilling through reinforced concrete for wiring, there is a special tool and diamond bits for it.

DeWALT DT7926 Extreme2 HSS

DeWALT DT7926 Extreme2 HSS is one of the best metal drill bits that can be used both in production and at home when working with drills. They provide the cleanest and most accurate drilling possible, and are also characterized by high operating speed. The nanotechnology design of the tool prevents damage to the edges of the hole. The tip of the device has three flat edges that provide secure mounting in the chuck. The kit includes 29 drills with a diameter from 1 to 13 mm. The cost of a complete set is 5,000 rubles.

The best wood drills

Wood differs from metals in having lower density and tensile strength. Parts made of this material can be thick. Manufacturers of equipment intended for furniture makers and builders take this into account. For drilling, you can buy a long wood drill, or opt for a feather, spiral or screw tool. Our team recommends three brands of tools that are characterized by increased service life, good efficiency when processing wet and dry wood, and wear resistance.

Fit 36429

A model with a countersink, intended for furniture workshop craftsmen. With its help, you can make a hole for a standard confirm screw, 5x50 mm in size. Used in conjunction with a depth stop, which is adjusted with a hex wrench included in the kit.

The main drill is made of tool steel and works well with dry wood, chipboard, and plywood. The diameter of the countersink is 6.5 mm, the angle of the cutting edge allows you to quickly and accurately make a hole. Supplied in a blister that reliably protects from dirt.

Advantages:

- Universal cylindrical shank;

- Good quality metal;

- Increased resource;

- Low price;

- Proper sharpening.

Flaws:

- Not detected.

Stayer 2944

A universal wood drill that can replace a set of several tools. Designed to complete an electric drill. It has a “ballerina” type design with the ability to adjust the position of the incisors. Using the equipment, holes with a diameter of 30 to 130 mm are drilled. The position of the cutters is adjusted using the key included in the kit.

The product is made of chrome vanadium steel, which cuts well waterproof plywood, chipboard, dry and wet wood. The sharpening angle of the cutters ensures an even cut at high speed. The shank has a tetrahedral profile and effectively prevents rotation when working with high loads.

Advantages:

- Cheaper than a set of crowns of different diameters;

- Low runout;

- Convenient adjustment;

- Works well with plexiglass;

- Good sharpening.

Flaws:

- Setting up takes a lot of time if you lack experience.

Makita D-07107

A classic spiral model for wood with a centering tip, which allows you to make a hole in a precisely specified location. Made from high-speed steel and highly wear-resistant. The spiral and side cutters are precision ground. The cylindrical shank makes the tool easy to clamp into a three-jaw chuck.

Designed for drilling holes with a diameter of 12 mm. The total length is 155 mm with a working part of 125 mm. Copes well with any types of wood, chipboard, plywood. The sharpening angle makes the hole neat, without visible defects.

Advantages:

- Increased resource;

- Convenient to select the drilling point;

- Can operate at high speeds;

- Does not require additional sharpening.

Flaws:

- High price.

Bison MET-SH H19 R6M5

Bison MET-SH H19 R6M5 is a drill from a domestic manufacturer, included in the list of the best. Used for drilling both alloy and carbon steel. The tools are made of high-speed steel R6M5, have a cylindrical shank and are characterized by high accuracy and drilling speed. They are self-centering due to the cross-shaped point. The set contains 19 pieces of devices with a diameter from 1 to 10 mm. You can purchase MET-SH H19 in an eraser box for 1000 rubles.

Types of drills

Different types of drilling products are produced, the main difference of which is their purpose.

Spiral . Used for making blind and through holes. The diameter of the working part is uniform, so the product can make holes of only one size. Design differences: cylindrical shape, two helical cutting edges, grooves through which chips are discharged.

Stepped . The product can be identified by its cone-shaped shape, the surface of which is designed in the form of steps. Each of them corresponds to the diameter of the resulting hole. The closer to the shank, the larger the diameter of the cutting element. The peculiarity of the equipment is the ability to make holes of different diameters using one drill. Find out more...

Crowned . The design feature is a hollow cylinder, the lower end of which has serrations. The appearance determines the name of the type of product.

Equipment is used for making holes of large diameters (more than 30 mm). It cannot be fixed to the chuck of a conventional drill or screwdriver.

The throughput capacity of the crown structure is sheet metal up to 10 mm thick. Products can be diamond coated or carbide tipped. The equipment is also suitable for working on concrete.

Feathers . The design is distinguished by a flat shape, at the end of which there is a trident. This solution allows you to make large-diameter holes, while the equipment is easily fixed on the chuck of a conventional drill. When drilling a small groove, a depression from the main tooth remains in the center. You need to work with a feather drill at low speeds. It is often used with a hand crank.

Screw . When making deep holes, it becomes difficult to remove chips. You have to stop drilling and move the working part out to clean the groove. You can speed up the process by using an auger drill.

Its difference from the spiral one is the large angle of inclination of the helical grooves, as well as the increased thickness of the core. The core has the same diameter along the entire length of the equipment, whereas in conventional designs this indicator changes (it thickens closer to the shank).

AEG HSS-G 4932430416

AEG HSS-G 4932430416 are one of the best metal drills in an affordable price category. The devices are completely ground and made of high-strength and heat-resistant steel. The cutting head of the tool has a cross-shaped sharpening with an angle of 135 degrees, which ensures good alignment without the need for a core. 4932430416 are able to withstand high temperatures resulting from heating during drilling. Suitable for working with high-alloy steel and metal with a strength of more than 1000 N/mm². The set contains 19 pieces with a diameter from 2 to 10 mm. You can buy a set for 1500 rubles.

How to choose a drill

Not only the quality of the work performed, but also the possibility of drilling itself depends on the choice. For each material being processed, manufacturers produce equipment that takes into account the density and strength of the surface being processed. Alloys, the shape of the cutting edge and the angle of its sharpening are selected to suit the working conditions. When choosing, it is recommended to take into account not only the type of drill, but also its diameter, length, and shank design features. Our recommendations will help you understand these characteristics; based on them, you can choose a tool that will not let you down when working with any material.

Drill type

Classic spiral models continue to be in good demand. This is a good choice for a home workshop, for solving constantly recurring typical tasks. A simple design, effective removal of dust and chips, and simple installation make this tool convenient to use. Professionals prefer equipment of a more complex shape.

A core drill, which resembles a hollow cylinder in shape, is highly efficient. This tool makes it easy to cut large diameter holes in concrete and steel. Cone drills are distinguished by their stepped shape, each tier has a cutting edge. This allows you to drill holes of different sizes without changing equipment, which has a positive effect on productivity.

To work with wood, spiral models are used that effectively remove chips from the working area. “Ballerinas” help create holes of different diameters, and the feathers have a simple design and low price. Equipment for confirmants, equipped with an adjustable countersink, has been developed for furniture makers. Using a 35 mm Forstner drill, you can easily cut a blind hole for fittings without damaging the façade of the furniture panel or the front side of the workpiece.

Diameter

Diameter is one of the main characteristics. Products are produced with parameters from 1 to 55 mm. An electric drill is rarely equipped with accessories whose diameter is more than 10 mm - the power of the power tool may not be enough to complete the assigned tasks.

When choosing consumables for working with concrete, choose a diameter that matches the size of the dowels used. This allows you to carefully insert hardware into the prepared hole without breaking the shirt. The outer diameter of the dowel will expand after screwing in a screw or driving in an anchor, which will allow the fastener to be securely fixed in the wall.

When making a hole for a thread in metal, take into account the outer diameter of the bolt or screw. This operation has different accuracy requirements. For this reason, manufacturers produce products of different accuracy classes. Products of class B1 and B2 are standard tools, and category A1 are high-precision and are capable of drilling a hole with an accuracy of a fraction of a millimeter.

Length

The length of the drill depends on the type of work the master performs. When drilling sheet metal, no longer is required. This parameter is critical when working with brick, concrete, and wood. During the construction of houses, through holes are needed in the walls for laying utilities. The thickness of interior partitions is from 10 to 40 cm, depending on the level of sound insulation. The parameters of external walls and enclosing structures are from 40 to 60 cm. You can drill a hole using equipment of the appropriate length.

When choosing a tool, it is necessary to take into account that manufacturers indicate the total length in the markings. The working part is noticeably shorter, so it is recommended to check its dimensions when purchasing. For through drilling of concrete, you can purchase drills, the length of the working part of which reaches 90 cm.

Shank type and diameter

What should the shank be like? This part is clamped by a jaw chuck; its shape affects the reliability of the fixation. You can find products with square, cylindrical, triangular and hexagonal shanks. Square shanks have been used since the mid-19th century; they have proven themselves well, but they are difficult to fix in three-jaw chucks.

Cylindrical shanks are the most common. The advantages of this option are simple manufacturing and versatility. At high speeds, such a shank can scroll. This can be considered both an advantage and a disadvantage. Slipping protects against jamming, but does not allow large torque to be transmitted to it.

Hex shanks do not jam at high speeds; the design allows for the transmission of high torque. Work well in combination with jaw chucks. Spiral and feather versions of equipment and Forstner drills are produced with shanks of this type. In the 21st century, tools with SDS shanks, which have a complex shape, have become widespread.

Sharpening angle

The sharpening angle determines productivity, cutting mode and wear resistance. This parameter is selected taking into account the characteristics of the material being processed. For various types of steel, hard bronze and cast iron, the optimal sharpening angle is 116-116 degrees. For softer metals - standard bronze and brass - it is better to choose a cutting edge with an angle of 120-130 degrees. When working with copper, use a tool whose edges are sharpened at an angle of 125 degrees.

Concrete is a less demanding material in terms of sharpening angle. Pobedite tips are sharpened at an angle of 118-130 degrees. To work with plastic, it is recommended to use a tool with a sharpening angle of 90-100 degrees. It is easier to handle wood and aluminum equipment if the angle between the cutting edges is 140 degrees.

5. Metabo Bestell-Nr. 27,094 HSS-G

Metabo Bestell-Nr. 27 094 HSS – G – one of the best drills designed for metal work. Spiral type devices have a cylindrical shank with a 135 degree sharpening of the tip, which ensures fast and accurate drilling. In total, the set contains 25 pieces, the diameter of working tools varies from 1 to 13 mm. The cost of the set is approximately 1,700 rubles.

How to sharpen metal drills correctly

As the cutting edge of the drill becomes dull, it becomes necessary to sharpen it. This can be understood by the following signs: a characteristic squeal, rapid heating of the equipment, longer drilling, decreased accuracy, dullness is felt when touching the edge. To ensure quality work, it is recommended to take into account the following recommendations from experienced craftsmen.

An easy way to sharpen a drill

- Before sharpening, make sure that the sharpening tool/machine is in good working order and that it is in a stable position.

- Prepare a container with cold water to cool the metal.

- When passing the drill along the grinding wheel, you need to press the equipment tightly. Sharpening should begin from the back of the edge.

- When heating a metal, cool it in prepared water to avoid overheating.

- The sharpening angle is applied depending on the metal alloy used in the production of the drill.

| Processed material | Vertex angles, degrees | Relief angle, degrees |

| Tool steel | 118-150 | 7-15 |

| Magnesium alloys | 70-118 | 12 |

| Copper | 100-118 | 12-15 |

| Titanium alloy | 135-140 | 12 |

| Durali | 90-140 | 12-17 |

| Bronze | 119-150 | 12-16 |

The entire cutting surface, including the side passages, must be sharpened.

Anchor 25219

Enkor 25219 is included in the rating of the best metal drills. The set includes tools of various diameters (from 1 to 10 mm). There are 19 working items in total. The tip of the devices is made of high-strength hard alloy, which ensures high speed and long service life. Enkor 25219 belongs to the category of budget drills intended for metal. It is quite possible to purchase a set of 19 pieces from a Russian manufacturer for 1000 rubles.

About the manufacturers

The answer to the question of which metal drills are the best depends on the volume of work and on what material to be performed. The market is saturated with products from famous and unnamed companies, but if you are looking for a reliable tool that will not break after the first use, pay attention to what famous brands offer.

Among foreign manufacturers, the products of the German concern Bosch are famous. The company produces drills and sets for household and professional use. The products are characterized by high performance characteristics and a long service life. The professional tool is produced by the Japanese company Makita. Its products are resistant to damage and demonstrate high drilling speed.

Among domestic companies, the most notable brands are Zubr, Enkor, and Interskol, which specialize in inexpensive, high-quality tools. Metal-cutting tools from the GRIFF, Praktika, and Ataka brands have a good price-quality ratio.

Sets of drills of different types and purposes are popular Source amazon.com

3. Wurth Zebra Spiralbohrersatz HSS

Wurth Zebra Spiralbohrersatz HSS are one of the best drill bits designed for metal work. Made from high-speed steel HSS. The devices provide maximum accuracy and drilling speed, and are also characterized by increased strength. Ideal for drilling holes in structural steel with a strength of up to 1000 N/mm², cast iron and plastic. Suitable for use in vertical drilling machines and electric drills. It is recommended to use a special coolant during operation. The kit includes 13 drills with different diameters, which are supplied in a plastic case. The cost of such a kit is approximately 700 rubles.

The best drill bits for concrete

Concrete is a durable material that can be drilled using impact drills and hammer drills. During operation, the cutting tool experiences critical dynamic and vibration loads. A design feature of a concrete drill for a rotary hammer is the presence of a carbide tip, which crushes durable material. The tips are made from pobedit, an alloy based on tungsten and cobalt. This material is wear-resistant and can be used for working with granite. VyborExperta.ru suggests choosing two brands of equipment for production, which are distinguished by strength, reliability and durability.

Enkor 9365

The drill is designed to complete an electric impact drill or hammer drill. Drills well in concrete, brick, artificial stone. Made of high-speed steel and the tip is made of pobedite. A long drill can be used to drill through interior partitions and internal walls when laying communications. The developers have provided a universal cylindrical shank that is effectively clamped by any type of cartridge.

According to user reviews, when working with reinforced concrete, the tip is difficult to damage if it gets into the reinforcement. The manufacturer pays special attention to geometry, which is always ideal throughout its entire length. This eliminates damage when drilling to great depths.

Advantages:

- Good wear resistance;

- Lack of combat;

- High quality soldering tip;

- Reliable fixation in a three-jaw chuck.

- Convenient packaging;

- Low price.

Flaws:

- There are products with an offset tip.

Hurricane 901-22424-150-14

The body is made of alloy steel with a carbon content of 0.4%. The two-cutting tip is made of carbide steel with a cobalt content of 8%. Designed to work with rotary impact tools: rotary hammers and electric drills. Easily withstands vibration and shock loads and has high performance. A special feature of the equipment is the presence of a milled S-4 spiral, which effectively removes concrete dust from the hole.

Shank diameter 6.35 mm, tip shape hexagonal. This design ensures reliable fixation in the three-jaw chuck. With a total length of the cutting tool of 15 cm, the working part is 90 mm.

Advantages:

- Good wear resistance;

- Low price;

- Easily copes with B30 concrete;

- Strict geometry.

Flaws:

- Limited scope.

Attack N802-6

Attack N802-6 are not only one of the best, but also the most affordable metal drills. The tools included in the kit have excellent strength and provide good speed. There are 8 pieces in total in the set. The diameter of the drills varies from 3 to 10 mm. The hardness is 65.8 HRC. H802-6 not only provide high performance, but can last quite a long time. You can purchase a reliable tool kit from a Russian manufacturer for only 600 rubles.

Briefly about the main thing

Metal drills are one of the most popular tools in construction practice, but, unfortunately, they are not universal. In order not to spoil the work, it is important to choose the right drill, and for this you need to understand what criteria describe its characteristics.

The choice is based on the shape of the cutting part, not forgetting the shank and sharpening angle. The selection parameters are material, color, diameter and size; important information can be gleaned from the labeling. If you expect to work for a long time, pay attention to well-known brands that offer better sharpening, heat resistance, and wear resistance.

Bosch 2607017154

Bosch 2607017154 completes the list of the best metal drills. This set is designed for making both through and blind holes in sheets of alloyed and non-alloyed steel with an allowable tensile strength of 900 N/sq.mm., copper, bronze, plexiglass, etc. Bosch 2607017154 are made of high-strength, high-quality and high-speed steel coated with titanium nitride. Not suitable for drilling aluminum. When working with the product, it is recommended to use coolant to increase service life. The kit is sold in a special plastic, shock-resistant box. In total, the set includes 25 pieces, the diameter of the products varies from 1 to 13 mm. You can purchase a set for about 3,000 rubles.

18 29

The best Forstner drills for wood

Blind holes in wood for mounting hinges and various fittings are made using a Forstner wood drill with cutting edges on the side plane. The tool is designed for work that requires high precision. Forstner equipment does not heat up during drilling and can be used to solve professional problems. Experts recommend two brands, which have a good resource and can be used to perform important work in a furniture workshop.

Dewalt DT4590-QZ

The equipment is made of high quality high-speed steel. The centering drill simplifies the work, allows you to accurately select the location for drilling and securely fixes the tool, protecting it from displacement. The cutting edges have an effective sharpening angle, which ensures accurate drilling and the necessary accuracy.

The cutting tool works well with dry wood, chipboard and plywood. The cylindrical shank makes the equipment universal and allows use with any type of chuck. The working length of 87 mm makes it convenient to process workpieces of large thickness.

Advantages:

- Increased service life;

- Does not require additional sharpening;

- No runout;

- Good efficiency at high speed.

Flaws:

- Overcharge.

Metabo Forstner 627594000

The equipment of the German company is made of high-speed tool steel. The main purpose is to drill blind holes with even and smooth walls. The design has two ring and two main cutting edges, which ensure impeccable processing quality. A centering point is used for precise positioning on wood parts. The cylindrical shank is securely fixed in any type of chuck.

The tool is designed for processing hard and soft wood, chipboard and plywood. Gently handles laminated surfaces without chipping edges. A working length of 90 mm makes it easy to work with thick workpieces.

Advantages:

- No runout;

- Good sharpening quality;

- Competent design of the centering spike;

- Increased resource;

- Don't be dumb.

Flaws:

- High price.

Rating of the best drill manufacturers

| Nomination | Place | Manufacturer | Rating |

| Rating of the best drill manufacturers | 1 | Haisser | 5.0 |

| 2 | Metabo | 4.9 | |

| 3 | Bosch | 4.8 | |

| 4 | DeWALT | 4.7 | |

| 5 | AEG | 4.7 | |

| 6 | Ruko | 4.7 | |

| 7 | Makita | 4.6 | |

| 8 | Ryobi | 4.5 | |

| 9 | VIRA | 4.5 | |

| 10 | SIBRTECH | 4.5 | |

| 11 | Tulamash | 4.4 | |

| 12 | Interskol | 4.3 | |

| 13 | Zubr | 4.2 | |

| 14 | Anchor | 4.1 | |

| 15 | Attack | 4.0 | |

| 16 | Inforce | 4.0 |

Haisser

Rating: 5.0

Drills from the German company Haisser are very popular in different countries of the world. Experts highlight such advantages of cutting equipment as durable steel and sharp sharpening. The manufacturer offers a wide range of drills for metal, wood, concrete, glass, and ceramics. All of them are divided into two groups according to length. The “Medium TN” series consists of cutting equipment with a length of 3.4…15 cm; the “Long TM” line contains drills with a linear size of 5.6…20.5 cm. You can purchase both piece products and entire sets in domestic stores . The brand is the winner of our review.

Domestic craftsmen admire the sharp sharpening of the equipment, which does not become dull for a long time. The special design, where the shank is thicker than the working part, also deserves praise.

Advantages

- wear resistance;

- sharp sharpening;

- thoughtful design;

- a wide range of.

Flaws

- not detected.

Metabo

Rating: 4.9

The German brand Metabo has been operating on the European market since 1923. Having developed the first hand drill, the company’s employees had to start working on equipment for it. During this time, a wealth of experience in the production of drills has been accumulated, which helps the company to successfully compete in different countries of the world. Today there are 25 branches that operate using German technologies. Experts appreciated the precision of manufacturing, lack of runout, sharp and durable sharpening. The Russian representative offers cylindrical drills for wood, stone and concrete, metal and glass. Equipment is sold individually and in sets. Metabo drills get an honorable second place in the review.

Russian users managed to find very rare drills in the catalogs of the German manufacturer.

Advantages

- rich assortment;

- sharp and durable sharpening;

- exact dimensions;

- There are shanks for any tool.

Flaws

- there are fakes.

Bosch

Rating: 4.8

Bosch produces a wide range of products. There was also a place in the catalog for drills. The Russian consumer is offered universal equipment, drills for wood, metal, concrete, ceramics, as well as models for milling. Experts liked the ready-made sets, which consist of 10...156 cutting products. The quality boxes also deserve praise. Each drill is securely fixed in its seat. In the catalog you can select equipment both by thickness (1.0...13 mm) and length (3.4...13.3 cm). The role of the material is played by alloy steel grades, the shanks are cylindrical, hexagonal and for rotary hammers.

Domestic consumers speak highly of drills with pobedit tips; they help make holes in concrete and stone.

Advantages

- rich assortment;

- different types of shanks;

- quality boxes;

- high wear resistance.

Flaws

- high price.

DeWALT

Rating: 4.7

The American brand DeWALT failed to wedge itself into the purely German pedestal. The reason for this was the high prices for equipment. The company sells an impressive arsenal of drills on the Russian market; there are models made of tool steel, and there are products made from alloy materials. Experts liked the sharp cutting edge, which makes drilling fast, whether it's wood or steel. The manufacturer boasts a wide range of shanks. Home craftsmen liked the cylindrical designs with 3 edges at the end. They are securely fixed in the chuck and do not rotate in solid material.

Some craftsmen call it a pleasure to work with American equipment. They praise the drills for their excellent quality, but it is better to entrust the sharpening to professional sharpeners.

Advantages

- original designs;

- high quality;

- rich model range;

- sharp sharpening.

Flaws

- high price.

AEG

Rating: 4.7

The full production cycle at the plant in Germany was organized by AEG. The company's employees develop and manufacture high-quality drills. The experts liked the stone and concrete models the most. They demonstrate enviable performance and wear resistance. Metal drills are just as sharp as them. With their help you can drill holes even in hard grades of steel. But the range of equipment for wood processing leaves much to be desired. The manufacturer also deserves praise for the neat and practical boxes in which the drills are securely fixed in their sockets.

Domestic craftsmen liked the work of small metal drills, with the help of which they can quickly drill out rivets or broken bolts. Flattering reviews are received for products for hammer drills.

Advantages

- German quality;

- neat boxes;

- sharp sharpening;

- wear resistance.

Flaws

- a modest line of wood drills.

Ruko

Rating: 4.7

Professional precision tools have been produced by Ruko GmbH Precision Tools since 1974. The company, located in Germany, specializes in drilling and metalworking equipment. Experts consider high quality and reliability to be the main advantages of the brand. The manufacturer managed to achieve jewelry precision and endurance of drills through the introduction of innovative technologies and automated CNC equipment. The company's products have been certified in accordance with the requirements of the quality standard DIN EN ISO 9001: 2015. The production of equipment under the TERRAX brand has been launched in China. In total, the company's catalog contains more than 5,500 varieties of products.

Users have no complaints about the accuracy, sharpness, or wear resistance of German drills. Only the high price stops people from buying.

Advantages

- high quality;

- accuracy;

- endurance;

- sharp sharpening.

Flaws

- high price.

Makita

Rating: 4.6

Japan also knows how to make cool drills, as evidenced by Makita products. The company manages to compete with world leaders due to a competent pricing policy and good quality. The catalog widely presents a series of spiral models with a cylindrical shank. The manufacturer pays a lot of attention to the selection of steel grade for each type of equipment. There are innovative developments in the design of drills. For example, experts liked the series with a centering stop for precise formation of holes in wood. For household purposes, you can purchase ready-made sets with the most popular standard sizes.

Domestic users liked the universal kits, in which the manufacturer included 3 drills for metal, wood and concrete.

Advantages

- reasonable price;

- good quality;

- excellent sharpening;

- wear resistance.

Flaws

- poor selection of shanks.

Ryobi

Rating: 4.5

Ryobi's production site is also based in Japan. The brand produces a wide range of power tools, as well as accessories for them. The catalog contains a rich line of drills; here you can find modifications for working with wood, metal or concrete. There is a fairly wide choice of shanks, from cylindrical to special ones for the SDS chuck. The manufacturer is selective in the selection of metal grades; HSS steel successfully handles wood; for processing hard materials, alloy steel grades are used or those with HSS reinforced with titanium nitride.

Experts and home craftsmen consider the combination of cost and reliability to be successful. Factory sharpening lasts a long time, the sets are equipped with excellent organizing boxes.

Advantages

- affordable price;

- reliability;

- durable sharpening;

- convenient boxes.

Flaws

- The range of working parts is modestly presented.

VIRA

Rating: 4.5

The domestic brand VIRA was launched in 2004. The main activity today is the production of hand tools for work and home. The company boasts an extensive dealer network, so VIRA drills can be found in all corners of the country. The manufacturer offers sets for a specific type of material or combined sets, piece products for processing metal, wood, stone, concrete, glass and ceramics. Experts liked the series of drills for glass or ceramics, thanks to the peaked shape of the cutting edge, it creates a neat hole in fragile parts.

But equipment for metal or concrete is not wear-resistant. Such drills attract home craftsmen at an affordable price.

Advantages

- low price;

- successful series on glass and ceramics;

- variety of sets;

- wide dealer network.

Flaws

- Drills for metal and concrete quickly become dull.

SIBRTECH

Rating: 4.5

The Russian company SIBRTECH closes the TOP 10 best manufacturers of drills. Experts include affordable prices, wear resistance, and drilling accuracy as the advantages of the equipment. The base material for the manufacture of a wide range of drills is R4M4X2 steel. Thanks to the presence of alloying additives, equipment is obtained that is capable of processing hard steels, cast iron and non-ferrous metals. There is also a successful series for drilling wood, including Forstner drills. The stores offer different sets and individual products.

Russian users praise SIBRTECH drills for the accuracy of the holes, which does not exceed 0.1 mm from the declared size. At the same time, the high performance is pleasantly surprising. But the choice of shanks is limited only to the cylindrical design.

Advantages

- low price;

- accuracy;

- wear resistance;

- fracture strength.

Flaws

- one type of shank.

Tulamash

Rating: 4.4

The largest enterprise in the Russian mechanical engineering industry is Tulamashzavod. The production association includes 20 subsidiaries that actively work for both the civil and defense industries. Among diesel engines and diesel generator sets, there was also a place for equipment. Experts have no doubt about the quality of the drills, since all products have been certified in accordance with the requirements of the international standard ISO 9001. The discrete diameter reaches 0.2 mm. The catalog includes both household models with a cylindrical shank and industrial equipment with a conical shank.

Users praise Tula drills for their combination of price and quality, wide selection of standard sizes and wear resistance. But it’s difficult to find equipment for working with wood.

Advantages

- high quality;

- reasonable prices;

- wealth of standard sizes;

- different types of shanks.

Flaws

- few wood drills.

Interskol

Rating: 4.3

There is a high demand for power tools and equipment from Interskol in our country. The manufacturer successfully balances between price and quality, which attracts increased attention from potential buyers. Experts appreciated the presence of a magnetic holder in sets with drills, which securely fixes the equipment in the box. The brand's specialty is the production of drills with a shank for a screwdriver (1/4). The advantage of this design was immediately appreciated by installers working with drywall. When the drill jams, the shank does not rotate in the chuck.

The brand's assets should include a rich assortment of equipment for processing wood and metal, ceramics and glass. But the accuracy of the holes does not always please the craftsmen.

Advantages

- affordable price;

- large selection of drills for different purposes;

- original shanks;

- good quality.

Flaws

- There are drills with beating.

Zubr

Rating: 4.2

Another Russian brand is known to domestic users for its tools and equipment. The Zubr company produces products in accordance with GOST 10902-77, which inspires respect. The range of drills consists of modifications for metal, wood, glass and ceramics. There are even accessories with diamond tips. The manufacturer should include a cross-shaped point as an asset, which facilitates alignment. Many craftsmen also like the accuracy of the holes, which corresponds to the first class. However, the service life of the equipment is short, so the scope of application is limited to household work.

In the reviews, many flattering words are addressed to the Cobalt model (for metal). But the ZUBR 2994-H5 drill set is criticized for its short-lived sharpening. At the same time, all consumers are satisfied with the low price and beautiful packaging.

Advantages

- low price;

- variety of models;

- special sharpening;

- hole accuracy.

Flaws

- The cutting edge becomes dull quickly.

Anchor

Rating: 4.1

All types of drills are produced by Enkor. They attract the attention of potential buyers with an affordable price and a wide range. There are sets for different types of activities to choose from, as well as individual items. Each product has a marking that encodes the type of steel and the size of the equipment. Experts drew attention to the interesting design of the drills. Deep spiral grooves ensure efficient removal of chips, so the equipment does not get stuck in the material being processed. HSS plays the role of base steel; it does not imply professional use.

Users found quite rare drills in the catalog that allow them to perform the most complex operations. Tilers liked the products with diamond coating and hexagonal shank.

Advantages

- a wide range of;

- affordable prices;

- rare types of drills;

- hex shanks.

Flaws

- not very sharp sharpening.

Attack

Rating: 4.0

The Russian company Ataka has extensive experience in the manufacture of power tools and accessories. Consumables, among which drills occupy an important place, are suitable for any fit and type of fastening. Experts note a competent pricing policy and the desire to produce quality products. Metal drills occupy a central place in the manufacturer's catalog. The range of equipment for processing wood, concrete and glass looks more modest. Standard drills predominate over other types; there are also screw and stepped versions.

For experienced domestic craftsmen, the Ataka company's products in a good sense resemble USSR consumable tools. The drills are difficult to fit; they can be easily straightened. The kits are equipped with a compact plastic box.

Advantages

- quality steel;

- sharp sharpening;

- easy editing;

- affordable price.

Flaws

- modest assortment.

Inforce

Rating: 4.0

Inforce is trying to impose worthy competition on foreign brands. The domestic manufacturer has adopted modern technologies, thanks to which it is possible to create high-quality and durable drills. Experts especially note the perfect surface grinding, sharp sharpening and laser marking. The company sells most of its drills in sets, among which you can find both specialized and universal ones. The discrete diameter is 0.5 mm, which is enough to perform most tasks in everyday life. The series with a massive body looks the most durable and fracture-resistant.

Russian users praise Inforce drills for their good sharpening, lack of runout, and affordable price. The disadvantages include short-lived packaging and only cylindrical shanks.

Advantages

- sharp sharpening;

- drilling accuracy;

- wear resistance;

- reasonable price.

Which drill set to buy

When choosing a drilling consumable tool, you must be guided by the following criteria.

Drill type

To carry out work with a certain material. Products can be screw or feather, hollow conical or stepped conical.

Purpose

The user must know what material he will have to work with: glass or concrete, wood or metal. Based on this, choose the appropriate consumables.

Dial type

Store sellers offer customers specialized kits for working with specific materials or universal kits.

Manufacturer

An important factor is also the choice of the manufacturing company. The more reliable the company’s reputation, the longer the working life of their products, the higher the quality of the work performed.

Rules for storing drills

At workplaces of industrial enterprises, drills are stored in tool cabinets and bedside tables made of sheet metal, installed in the immediate vicinity of the machine, as well as on racks in special tool storage rooms. Drilling tools must be placed in a certain order (by type and diameter) in the appropriate compartments, cases or cases. Laying should ensure the safety of cutting edges, as well as working and seating surfaces. Before storing the drilling tool, clean it of metal dust and contaminants, and if not used for a long time, lubricate it with lithol or technical petroleum jelly. In order to prevent corrosion, it is prohibited to place acid-containing or other aggressive liquids near the tool storage areas. In home workshops, tools should be stored in compliance with the same rules. Only instead of bedside tables and cabinets, it is much more convenient to use plastic pencil cases and special stands (see video below).

When drilling deep holes in metal, it is recommended to pour a small amount of oil on the surface of the tool. I-20 is usually used in production, but not everyone has the opportunity to purchase this particular brand. What kind of oil can be used at home instead of industrial oil? Please share your thoughts and recommendations on this issue in the comments.

Criteria for correct selection

For initial orientation in a wide range of proposals, it is important to determine the upcoming scope of work. For home or country use, universal sets with blocks of elements for wood, metal and other materials are more suitable. If necessary, you can purchase additional drills for specific work. Next, select the type of working part, which is described in detail above.

Important things to consider:

- design;

- material of manufacture;

- alloys;

- diameters.

The shank requires the correct approach according to the available tool. You should be guided by:

- per cartridge;

- capture;

- drill removal method.

The cost of all equipment ranges from 9 rubles to 18,000 rubles.

Meaning:

- professional approach;

- specific work;

- required duration of operation.

Errors in selection

An amateur or a professional who constantly deals with tools is bound to face the problem of a shortage of one or another equipment. It is impossible to purchase a set that will meet all needs once and for all. The additional purchase of piece drills can be called a pattern. A specialized process will require universal support. However, having several sets and piece equipment in your arsenal, you can cope with any task. When forming a private workshop, you should not strive to buy a set with the maximum number of units. Also, it is considered unprofitable to purchase expensive instrumental elements in the hope of “someday coming in handy.” It is important to gain experience in drilling, the ability to distinguish between the features of the process and the ability to make the right choice of consumables.