- To the wooden steps. As a rule, such installation does not cause any difficulties. Detailed installation plan:

The accuracy of installation mainly depends on the experience of the contractor and compliance with the requirements for railings, which are regulated by the GOST standard 25772-83 “Steel railings for stairs, balconies and roofs.

General technical conditions": When installing railings with elements of artistic forging, it is necessary to take into account the load that is imposed on the upper and lower support posts, as well as the fact that the fence must withstand a leaning person with different weights (100 kg or more). You also need to take responsibility when installing balusters. There are three main options for attaching wrought iron railings:

- To the wooden steps. As a rule, such installation does not cause any difficulties. Detailed installation plan:

- To the walls. This fastening option is carried out using decorative clamps, brackets and special holders, which are secured with anchor bolts.

- To the concrete steps. This fastening is performed when the width of the flight of stairs is sufficiently large. Anchor bolts are installed in the holes and then filled with liquid mortar. This design guarantees high fastening strength. If the width of the flight of stairs is not enough, then chemical anchors are used to install handrails to the concrete stairs.

According to safety requirements, an external staircase with more than three steps, and an internal one - two, must have a fence. Working with metal is more difficult than working with wood, but welded railings are no less popular. Since the design of metal stair railings is simple, welding of railings can be performed by craftsmen with little experience.

Advantages and disadvantages of metal welded railings

The popularity of welded stair railings is due to their advantages:

- reliability, strength;

- long service life, up to 50 years;

- wear resistance;

- resistance to moisture, temperature changes;

- fire safety;

- compatibility with parts made of wood, plastic, glass;

- ease of care;

- the possibility, due to the plasticity of the metal, of design in the form of ornaments or original figures.

Among the disadvantages, they note the high cost compared to wood. For ferrous metals, additional processing and application of an anti-corrosion coating are required.

Since forged stairs are heavy, they should be fixed to a solid base. It is possible to improve the characteristics of a product and extend its service life with the help of polymer coatings.

Structural elements

The design of any railing consists of the following elements:

- Support pillars on which the strength of the entire fence depends. They are placed at the lower and upper points of each flight of stairs, at the corners of the turning platforms.

- Intermediate posts (balusters), which increase rigidity and perform decorative functions.

- Handrails attached to support posts and the tops of intermediate posts. They rely on them when going up and down the stairs. Typically, handrails for internal stairs are made of wood, and external ones are made of metal or plastic.

Standard railing design

To decorate or increase safety, free spaces are filled with additional elements. Instead of the classic row of balusters, it is possible to install panels made of wood, plastic, or reinforced glass between the supporting posts. If there is a shortage of funds on welded stairs, to save money, the space is filled with horizontal handrails made of metal rods or strips.

Types of forging

With the help of artistic forging, stair railings are thin and elegant. Such metal structures include an initial pillar and a main part . Forged elements can be made in two ways:

It is possible to increase the degree of decorativeness of metal products with the help of bluing, patination or gilding. For modern trends, parts of the future fencing are painted with special compounds. These measures are necessary not only to increase the decorativeness of the products, but also to protect the material from corrosion.

Separately, we note that forged elements are perfectly combined with a variety of materials: wood, glass, artificial or natural stone. This makes it possible to create truly exclusive designs.

Aluminum option

Like most metals, aluminum has a number of important qualities that allow it to be used for the manufacture of stair railings. First of all, this:

- corrosion resistance;

- durability;

- strength;

- resistance to low and high temperatures, as well as temperature changes.

Aluminum railings with decorative elements.

It should be noted that aluminum is lightweight; it sets it apart from other metals. In many cases, softness can also be considered an advantage - aluminum parts can be easily given the desired shape.

The process of assembling and installing aluminum railings is not particularly difficult; everything is done using conventional fasteners. Even an untrained person can assemble and install stair railings from ready-made aluminum parts with his own hands.

Assembly diagram of aluminum handrails.

As for the appearance of aluminum fences, railings made of anodized aluminum are widely used today. This material is externally indistinguishable from stainless steel. Anodizing increases the wear resistance of aluminum and improves its appearance - you can give the material different shades: gold, silver, nickel and others.

Aluminum railings with a golden hue.

Cold bending technology can be used to decorate aluminum structures. In this way, you can create, for example, rounded elements to fill the space between racks.

Cold bending of metal

Stylistic recommendations

A wrought iron staircase can harmoniously “fit” into almost any interior. But before developing a project, you need to take into account the overall design of your home and coordinate the proposed design with it, taking into account the style features.

- Renaissance, Baroque and Empire style items can be combined into one group. A common feature of these styles is floral ornaments intertwined into an intricate pattern of figures and the insertion of monograms. Bronze and copper are preferable as materials for forged elements. A good move would be artificial aging of the metal.

- Ultra-modern styles - techno, hi-tech - require a minimum number of decorative elements and do not welcome smooth ornaments. They require geometric shapes and angular fragments of compositions. Very expressive for these styles is the combination of forging (usually black metal) with polymer and glass elements. Designs with transparent or almost transparent steps look impressive in the interior.

Often there is no typical style in home design - the design combines fragments of different stylistic trends. In this case, you need to select a product either to match the dominant style or to an inconspicuous option so that the design does not stray from the general direction.

* onto metal steps or through the metal base of steps by welding or using bolts.

This question is asked by almost all potential customers during their first conversation. And, as a rule, they do not receive a comprehensive answer, only general information. It's not our fault. To understand the optimal method of installing wrought iron railings, a site visit is required. Here we will try to describe the various installation options in relation to various designs of railings and stairs.

When installing forged railings the following are used:

- support pillars. Pillars (i.e., material that has a sufficient base area for reliable fastening of fences, and can serve as a rigid support) are made of round, square or rectangular pipes; they can also be stacked structures from forged or turned parts, be “smooth” or decorated texture, forging, casting.

- support posts. The cross-section of the posts is the same or not very different from the material of the frame or the design of the forged railings; they are made of solid rolled steel (sq. 16, sq. 20, F 20). They can be straight or curly, and also form part of the concept of the drawing. The racks do not attract attention, create a feeling of lightness, airiness, and are good for short sections of flights of stairs or terraces with turns, radii and corners.

- separate balusters. Separate balusters or blocks require installation into each step and assembly with a frame handrail in place. As a rule, these elements are not optimal in terms of product rigidity, unless we are talking about short sections. The exception is radius stairs and balconies, the shape of which “ties” the structure, spreading the attachment points to different horizons.

Wrought iron railings can be installed:

— On the steps of the stairs (from above).

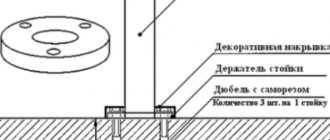

* by welding onto poles through a heel with a hole for an anchor or pin.

* using a chemical multicomponent composition on “recessed” racks.

* using self-tapping screws and wood grouse (more powerful self-tapping screws with a turnkey head) onto wooden steps through holes in the technical or decorative mounting heel.

* right through the wooden step onto the bolts.

* onto metal steps or through the metal base of steps by welding or using bolts.

When using a technical heel, the decorative element of the fastening unit is a special turned, stamped or cast plate on a pole or rack.

— On the string of the stairs at the end of the ceiling or formwork (on the side).

* on poles or racks with an overlay with 2 or more attachment points. If necessary, welding, pins, wood grouse, chemicals are used. compositions, bolted assembly. The method is possible when installing forged railings on concrete stairs and metal frames. This option allows you to maximize the usable space of stairs, balconies, and terraces.

* here it is implied that at the facility, most of the flights and spans of railings come into walls, partitions or columns. This method is used if the staircase has a closed shaft or the terrace has a colonnade. The set of fasteners and consumables is the same. Pillars and racks are used as necessary, as an intermediate support or support for the beginning (end) of a march.

Installation of forged railings is divided into:

— installation at an intermediate stage

- installation and finishing

In conclusion, a few words about installing forged products on existing pillars of completed objects. You can find on our website wooden, marble, plaster pillars, posts and columns with forged patterns attached. In these cases, our work plays the role of a protective screen in the railings and, of course, an original decoration of the staircase, balcony and the house as a whole.

If you have any questions about installing wrought iron railings, please call or write - we will be happy to answer you. For consultations and on-site measurements, our specialists travel free of charge.

- First of all, polish the finished product well using a grinder;

- Apply a layer of primer to the entire surface of the product. The soil will protect the railings from moisture, thereby saving your stairs from corrosion.

- You can then paint the fence any color you like. The most popular options are black, white and silver.

Finishing

The production of welded stair railings is completed by treating their surface. If stainless steel was used as the material, then you only need to clean the weld seams.

Sanded seam where the handrail bends.

Treatment of black steel and iron surfaces also includes the application of a primer and subsequent painting. This can be done after installing the railing on the stairs.

Advice!

But it is advisable to clean the welding seams before installation, since after installation some areas may become difficult to access.

Among modern technologies, polymer coatings should be noted. Their use makes the metal more resistant to wear and corrosion, and also increases the decorative value of the product.

Handrails with polymer coating.

How to make forged stair railings with your own hands

Nowadays, few people master the skill of blacksmithing. And of those who have mastered it, only a few are able to create a real masterpiece from a piece of metal. But how are stair railings created in the first place?

First of all, prepare all the necessary tools:

- Welding;

- Welding mask;

- Electrodes;

- Grinder saw;

- Levels;

- Tape measure, ruler and protractor.

Afterwards, you need to create a sketch model of the future railings. You can use 3D modeling programs to make everything detailed and faster, or you can simply draw a model on a piece of paper.

The classic stair railing is 950 millimeters in height.

Keep in mind that accuracy is extremely important in this matter - an error of a few millimeters on the diagram will cost several degrees of tilt in the future product, which is why you will have to start all over again.

The process of making fences is very interesting: each metal element must be given the desired shape using a hammer. After all, most likely you don’t have a blacksmith’s forge at home? Therefore, you will have to be patient and process cold metal with a hammer.

The frame is created using a welding machine; after creation, ready-made elements are attached to it. Assemble the fence, carefully following the intended drawing. Afterwards, all that remains is to complete the final finishing and you can install the railings on the stairs.

A spiral staircase looks great in any interior, regardless of its style. You can learn about the dimensions of such a staircase from the material: https://homeli.ru/remont-i-otdelka/lestnitsy/razmery-vintovoj-lestnitsy.

7. Coating the metal with paint or patina . Apply paint/patina with a brush or spray - the latter creates a better finish that covers any small imperfections. Railings for outdoor stairs need to be treated with a primer and an anti-corrosion compound. For stairs located inside the house, this operation is not necessary.

If you dream of having a staircase with wrought iron railings in your home, you don’t have to order them from a specialized workshop. If you wish and have some basic welding skills, you can assemble it yourself from ready-made elements. We suggest using simple step-by-step instructions, and the result will exceed all your expectations.

4. Layout of elements in accordance with the picture . Immediately after delivery of the finished forged elements, arrange them on the “floor” pattern in accordance with the specified location. You will immediately see if some parts do not fit - they can be returned for exchange, provided that the manufacturer has something to replace them with.

6. Cleaning the structure . This is done using metal brushes and a grinder. Clean all welded areas, level them so that at first glance the entire surface is uniform, remove rust (if any). Wear safety glasses when working.

7. Coating the metal with paint or patina . Apply paint/patina with a brush or spray - the latter creates a better finish that covers any small imperfections. Railings for outdoor stairs need to be treated with a primer and an anti-corrosion compound. For stairs located inside the house, this operation is not necessary.

That's it, the railings are ready and can be fastened into place. The fixation method is determined by the type of base. Concrete stairs provide reinforcement to which you can attach anything. For stairs made of natural stone, special fasteners are used to minimize the likelihood of damage to parts. A separate metal frame is created for wood and glass.

Based on SNiP, in cm.

How metal railings are made

Various technologies and design solutions can be used for the manufacture of metal railings:

- Prefabricated ones, the most common, can be made of stainless steel or aluminum. A protective coating is often applied during the manufacturing process.

- It is possible to purchase a set of individual elements for self-assembly.

- Welded stainless steel structures are first shaped by cold bending. Then the joints are bonded by welding, and the seams are cleaned and polished.

- Cast bronze or brass railings are rarely used due to the high price of the material. The manufacturing process goes through the stages of melting, forming, cooling, cleaning and finishing. Usually the products are individual, unique and aesthetically pleasing.

- Combined railings are a metal frame filled with glass, plastic or wooden elements.

Selecting material for railings

Cast iron

This design of railings is one of the most reliable, and it looks very “solid”. But using it in a private home is hardly advisable for two reasons. Firstly, significant weight will require the construction of more powerful spans - increasing the cost of work. Secondly, welding cast iron with your own hands is not an easy task. If you choose it, you will have to order injection molded elements and pay a lot of money for them. In fact, you can’t do much on your own.

Stainless steel

Aluminum

Light weight and ease of processing - all this makes this material for railings quite attractive. The only negative is that it cannot be painted, and few people are happy with the constant dim light of a metal fence in a residential building.

The technology of artificially coating such railings with a protective layer (anodizing) at home is difficult to implement. As a rule, lovers of aluminum structures purchase them ready-made, in parts, and assemble them locally with their own hands.

Steel

This option has many opponents, but the author considers it the most acceptable. Firstly, a skilled owner will be able to make railings of any configuration with his own hands. Either using a pipe bender or forging metal. Secondly, the superficial design of the hardware will also not cause much difficulty. There are several methods of chrome plating and nickel plating of metal parts that can be done with your own hands.

An alternative is to use polymer coating technology. So you don’t have to worry about the final appearance of such railings. You can see photos of wrought iron railings here.

It is not necessary to install the railings from one material with your own hands. In private homes, prefabricated structures are no less popular.

Wood

Cheapness and ease of processing are quite significant advantages when making handrails with your own hands. But there are also disadvantages - fragility, the need for systematic maintenance (and this means additional costs), the difficulty of attaching to flight spans made of other materials. If they are wooden, then you can choose such railings. In other cases, this is not the best solution. Perhaps just for the manufacture of some filling elements or handrails.

Plastic

In terms of price, it's a good choice. But besides fragility, there is a more pronounced drawback - susceptibility to mechanical stress. The polymer elements of the railings quickly become covered with scratches, and in most cases they have to be replaced, since only small, insignificant damage can be eliminated.

Copper alloys

It makes no sense to consider it for one reason - the high cost of metal railings. Such designs are not made by hand - only to order.

Rococo is perfectly complemented by asymmetrical and dynamic lines, in which there are almost no right angles. This includes staircase railings for a private house with wide “curls”.

Components of a stair railing

Knowing the terminology will make it easier to understand the design manufacturing process.

Handrails - the top of a railing. Simply put, that part of them that we usually grasp with our hands when going down or going up stairs.

Balusters are vertical posts that serve as supports for handrails.

Filling. These elements are mounted in the space between the railing posts. In some fencing schemes they may not be present. The owner decides whether to use them or not.

The criteria for assessing the feasibility of their use are as follows:

- distance between supports. If it is significant, then filling the railings is necessary. First of all, for the safety of the kids;

- How do such railings fit into the interior of the room? In some cases, padding elements may simply be superfluous;

- final cost of work. The use of these elements leads to increased consumption of materials, not to mention the total time for the manufacture of railings and their installation.

There are few filling options. Solid ones (in the form of sheet or panel fragments) are not so common. In a residential building, this is usually glass (for example, stained glass). The specifics of its attachment to metal, cutting into parts according to the diagram of the railing, will significantly complicate their manufacture with your own hands.

Much more often, filling is done using crossbars (from a pipe, strip iron, rod), which are usually attached parallel to the handrails. This is the simplest technique. Although installation can be carried out according to other patterns - diagonally, crosswise, in the form of a diamond, and so on. The most successful solution is shaped fillings made from rods. It’s not that difficult to do it with your own hands, if you wish.

The first rule of choice: safety

Stair railings like the one in the photo can be a source of problems. Wide open space between elements or no fencing at all can lead to injury, especially if there are small children in the house. Therefore, when choosing railings, first of all think about the safety of your family members.

There are certain standards that need to be taken into account:

- If the stairs go near the wall, in addition to the railings, you need to install handrails.

- If the width of the stairs is more than 1.25 meters, railings are installed on both sides.

- If the width of the staircase is more than 2.5 meters, railings are installed on both sides; additionally, handrails are placed in the center.

- The height of the railing must be more than 1.2 meters.

- The metal from which the railings are made must be fire-resistant and strong enough (load 30 kilograms per linear meter or more).

Remember: if there are small children in the house, it is better to purchase wrought iron railings for stairs without wide gaps between the elements so that the child cannot stick his head between them or fall down the stairs.

However, even with such significant advantages, they have their disadvantages:

Basic requirements for railings

It’s worth reminding, since when making them yourself you shouldn’t neglect them.

- Security.

- Ease of moving up the stairs.

- Compliance with the style in which the entire home is decorated.

The author strongly recommends that you familiarize yourself in detail with the current SNiP and GOST before making a final decision on the design of the railings, their layout, and materials. This will avoid many problems in the future. And if you consider that not all “homemade products”, the drawings of which are posted on the Internet, comply with regulatory documentation, the remark is more than relevant.

Optimal sizes of railings

Based on SNiP, in cm.

- Height. 95±5 is taken as standard. You can also install additional handrails for children, especially when the staircase is steep and the risers are high. It is advisable to install them at a level of 55±5. It is rare in private houses, but it happens that the marches are quite wide. If this parameter approaches 200, then another handrail (intermediate) is installed exactly in the middle of the stairs. Although this is not the rule, but the exception, it is worth paying attention to.

- Distance between posts. It is not recommended to place balusters more than 15 apart from each other. For support pillars, the maximum according to SNiP is 120. Firstly, you will have to think about filling, since the gap in the railing is significant, and a child can easily crawl into it. Secondly, the handrails will need to be installed thicker and stronger, otherwise their deflection cannot be avoided.

The parameters of the handrails should be specified separately. The author did not find such data, but common sense and some requirements for railings indicate that these elements should not be made wide. The hand should cover the handrails so that the hand does not slip off them. Even for the sake of originality, you should not forget about the safety (and convenience) of movement.

The secret of the popularity of forged railings

As a representative of the ancient profession of turning metal into a real work of art, I will reveal the secret of the popularity of forged railings.

When arranging a country house, you should take into account its comfort, style, functionality and safety. The last principle is decisive when choosing enclosing elements. As a result, the railings turn into reliable protection and a true decoration of a suburban area, building and premises.

A variety of forged elements, in which reliability and durability are combined with the imagination and skill of the author, allows you to turn a house into a medieval fortress, a fairy-tale castle, and even an ultra-modern building in the high-tech or minimalist style. No matter what purpose the railings are used for, they are doomed to become part of the exterior or interior. The ability to install functional, stylish and at the same time durable elements explains their great popularity.

With such an awkward design, the manufacture of a metal staircase with your own hands begins.

Prefabricated aluminum railings for concrete stairs

The parts from which aluminum railings are assembled can be purchased at a hardware store, and assembling it yourself will save some money. The following components will be needed:

- racks with a diameter of at least 4 cm;

- crossbars with a diameter of 16 mm;

- handrail, diameter – 5 cm;

- hinges for fixing the handrail;

- connecting parts and holders for crossbars;

- additional fasteners and accessories - anchors, glazing beads for racks, decorative plugs, filling, etc.

Elements of aluminum handrails.

The guardrails will be attached to the steps. To do this, markings are first made - it is necessary to determine the location of the racks on the stairs. It is recommended to place the racks in the middle of the steps with a distance of 35–50 mm from the edge. Then holes for anchors are drilled, depth - 10 cm.

Designations of rack fastening elements.

The resulting recess is first filled with a special adhesive. This is done in order to mix the glue with the dust remaining after drilling. The anchor is inserted, rotated and removed. The recess is again filled with glue and the anchor is inserted again.

Then the anchor needs to be drilled at the points above which the glazing beads will be located. This is done for mounting with self-tapping screws; the stand is also drilled in the appropriate places. Next, the stand is put on the anchor, but not secured - the height may need to be adjusted.

Rack mounting diagram.

A flange is put on it through the top of the rack; it serves as an additional fastening and should be located at the bottom. Hinges are attached to the upper ends of the posts. A handrail is mounted on them - it is placed on hinges, adjusted in height and fixed with self-tapping screws.

Advice!

If the staircase design includes several flights, then the handrails are connected to each other by rotating elements.

Do-it-yourself assembly and installation of aluminum railings.

How much will it cost to make metal stairs yourself?

Actually, it's not that expensive. Let's do the math based on the length of the staircase being 2.5 m.

Calculation of parameters of a metal staircase.

In total, if you decide to weld the stairs yourself, the price of such work will be approximately 27,000 rubles. Cheap? In general, yes. However, keep in mind that most companies selling rolled metal work only with wholesale buyers; Finding a company where the materials you need can be purchased in small quantities will be quite difficult, and as a result, the price of the ladder will increase by one and a half, or even double.

Let's summarize all of the above. So, now you know how to make a metal staircase with your own hands, and if you already have experience and all the necessary tools for working with metal, it’s really simple and significantly cheaper than buying a ready-made structure. Otherwise, a better decision would be to buy a ready-made metal staircase - and, by the way, not necessarily an ordinary marching staircase: beautiful and original screw designs are not much more expensive!

Preparation for installation

Regardless of the chosen railing option, to purchase and procure materials you need to measure the length of the staircase enclosing structure and determine the height and number of racks (balusters). Here it is necessary to take into account the following regulatory requirements regarding the safe operation of a flight of stairs:

- The minimum height of the fence above the level of the steps is 0.9 m.

- The racks should be attached to the surface of the steps or to the side of the string to make the passage wider.

- The maximum clearance between filling elements should not exceed 15 cm.

- The optimal diameter of a round handrail is 5 cm. A rectangular one should be selected that is close in cross-section.

To do the work yourself, you need to prepare the following set of tools:

- electric welding machine (if you plan to assemble a welded structure);

- grinder equipped with a metal circle;

- electric drill with perforation function;

- a regular set of plumbing tools;

- measuring devices - tape measure, square, ruler, building level.

If you have welding skills and plan to install railings from ordinary “black” pipes with subsequent painting, then a profile measuring 40x40 mm will be used for the posts, and a profile of 60x40 mm will be used for the handrail.

Round pipes with a diameter of 42 mm will also work. Stainless steel and chrome-plated pipes are sold in standard sizes - 50, 38 and 16 mm and are used for handrails, balusters and crossbars, respectively. Some manufacturers sell ready-made installation kits made of metal parts that can be quickly assembled on site.