Plasma cutting of metal is a modern method of processing rolled metal and finished products, allowing in a short period of time to produce a high-quality cut with smooth edges, without deformation and with minimal waste. That is why this technology is widely in demand in many fields of activity: shipbuilding, utilities, mechanical engineering, enterprises producing steel structures and metal products, etc.

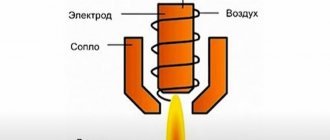

Plasma cutting technology is based on the interaction of electricity and working gas, when a stream of compressed air passing through an electric arc reaches a temperature of +30000°C and is ionized. Ionized gas is called plasma. A directed plasma jet is used to cut metal, alloy steel, and various alloys.

The components of plasma cutting are:

- Plasma unit (plasma torch)

- Compressor

- Power supply

- Ground clamps

- Hoses.

Figure 1. Equipment assembly for manual plasma cutting:

Let us dwell in more detail on the choice of a compressor unit for plasma cutting.

Plasma cutting of metal

metal plasma cutting services .

in detail »

To estimate the cost and timing of the work, you must send: sketches, sample photos, drawings in any format to the email: [email protected] or click on the banner “calculate the cost of the order” In the letter, be sure to indicate: 1. Number of parts. 2. Material.

The mail is being tracked promptly and a response will be given shortly.

FAQ.

1. Do you have the material?

- The material is varied, steel, from ordinary carbon to alloyed, brass, copper, bronze, textolite, caprolon, ebonite, etc. By agreement, we will find unique grades of steels and alloys.

2. Do you take single orders?

- We take orders from the 1st unit. Minimum order 2000 rub.

3. What are the prices and how much does it cost to make a part?

- Prices range from 300-800 rubles/hour of machine time, depending on the order volume and complexity. A correct assessment can be given after studying the drawing, sketch or provided sample of the product sent by email. For urgency, the extra charge is from 20 to 50%, depending on the volume and degree of urgency.

4. What are the production times?

- Production time is from 2 days depending on the volume of the order.

How to choose a plasma cutter

Before purchasing this device, evaluate the following characteristics:

- Versatility. Some devices are suitable for both metal cutting and stick electrode welding, argon arc welding. However, you need to understand that multifunctionality often has a negative impact on the quality of operations and productivity levels. Universal plasma cutting devices rarely cope with material whose thickness exceeds 11 mm.

- Current strength. With a higher current, the arc heats up more, which means cutting takes less time.

In addition, you can cut parts of greater thickness. Therefore, before purchasing, it is important to understand what you are going to do with this device, what parts to work with. For processing steel no thicker than 20 mm, a device with a current of 20 A is suitable. For thicker sheets, more power is needed - in the range of 40–60 A. For devices used in industry, this parameter is 200 A and higher. - Electrical network type. Household devices even operate on a 220 V network, but you need to be prepared for the fact that the current in them rarely exceeds 40 A. Industrial devices require a 380 V network.

- Duration of switching on (DS). This indicator is set as a percentage and records the time during which the plasma cutter can operate. A working cycle of 10 minutes is taken as a basis. That is, if the PV is 70%, it means that after 7 minutes of operation the device should cool down for 3 minutes. At 40%, the device can work for up to 4 minutes, and then it will need a 6-minute break. You can also find devices with a duty cycle of 100%; they are able to work without stopping, since they use water cooling.

- Compressor. This element of the system can be built-in or separately connected. For home use, devices with a built-in compressor are more convenient. However, they have a drawback - low power. For professional work you will have to purchase a separate compressor. Its task is to provide the plasmatron with constant pressure of dry air. Pulsations are not allowed, and the pressure level must be adjusted to the requirements of the device.

- Convenience. The sufficient length of the cable and hose package is responsible for this property. If the device will be used only at home, it is better to choose a small model to simplify the work.

Choosing a compressor for a plasma cutter

We offer to buy a compressor for plasma cutting on favorable terms. In the PNEUMO-ALLIANCE store you can buy a compressor for plasma cutting at a competitive price. The product is certified and meets the requirements of international standards and electrical safety regulations. Delivery within St. Petersburg is free. The electronic catalog presents models with various operating parameters. Each product item is accompanied by a photo and a brief technical description. When choosing a specific device, pay attention to the following characteristics:

- Design and principle of operation;

- Performance;

- Power;

- Operating pressure;

- Maximum pressure;

- Dimensions;

- Receiver volume;

- Noise level.

As an additional service, the PNEUMO-ALLIANCE company offers service and repair of supplied compressor equipment, as well as consultation with specialists on operating issues.

The best plasma cutters with a built-in compressor

The presence of a compressor eliminates the need to purchase it separately and allows you to use the device immediately after purchase. Such devices are easy to operate and do not require particularly complex maintenance.

Hypertherm Powermax 30 AIR

5

★★★★★

editorial assessment

100%

buyers recommend this product

Among the features of the model, it is worth highlighting the ability to connect to various power sources with a voltage of 120-240 volts. The innovative design of consumables guarantees stable operation of the cutter by optimizing air flow.

The dimensions of the unit are 420x195x333 mm. For ease of movement, two handles are provided.

Maximum power 3.8 kW. The always-on pilot arc makes it possible to quickly cut through grates or rusty metal. Resistance to overheating extends the life of the plasma cutter during intensive operation.

Advantages:

- convenient connection;

- light weight;

- high performance;

- overheat protection;

- quality cut

Flaws:

- high price.

Hypertherm Powermax 30 AIR is suitable for working with a variety of metals. An excellent choice for regular use.

Blueweld Prestige Plasma 54 Kompressor

4.9

★★★★★

editorial assessment

97%

buyers recommend this product

The torch control panel is equipped with a rotary potentiometer control, as well as indicators for torch voltage, phase presence and mains voltage. This provides ease of setup and monitoring of the device status. High cutting speed makes it easier to work with a large number of workpieces (their thickness should be no more than 10 mm).

The power of the device is 4.5 kW. The plasma cutter is protected from overload, overheating, voltage surges and can be operated in the most difficult conditions. Small dimensions and weight simplify installation in the chosen location and transportation.

Advantages:

- compactness;

- long service life;

- operator safety;

- convenient control;

- status indication;

- complex of protection

Flaws:

- short cable.

Blueweld Prestige Plasma 54 Kompressor is recommended for neat and precise processing of metals. Professional solution for shape cutting.

TCC Top CUT-50K

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

The device does not require the purchase of additional equipment or special settings. High cutting speed and accuracy make it possible to process a large number of workpieces in a short time without loss of quality.

With dimensions of 450x190x520 mm, it weighs 24 kilograms. The air cooling system reduces the risk of overheating of the plasma cutter when working in intensive mode. The device does not take up much space in the workshop and is easy to transport thanks to the presence of a special handle, although, of course, it weighs a lot.

Advantages:

- rich equipment;

- rapid cooling;

- ease of carrying;

- simple controls.

Flaws:

- heavy.

TCC Top CUT-50K is used for cutting various metals and conductive materials. Compact solution for use on a repair and installation site.

Telwin Technology Plasma 54 Compressor

4.8

★★★★★

editorial assessment

90%

buyers recommend this product

Small dimensions make it easier to place the device in the chosen location. In addition, the model is equipped with a shoulder strap for easy carrying. A large number of ventilation holes promotes rapid cooling during intensive use.

The maximum power of the unit is 4.5 kW, the duration of switching on at maximum current is 30%. Overvoltage and undervoltage protection ensures the stability of the machine during the cutting process. The current regulator and current status indicator help control the operation of the plasma cutter.

Advantages:

- compact and easy to carry;

- durability;

- easy setup;

- status indication;

- precise operation even with unstable network voltage.

Flaws:

- noisy.

Telwin Technology Plasma 54 Kompressor is worth purchasing for cutting steel, copper, brass, aluminum and other light metals. The right solution for a small workshop.

READ ALSO

11 best semi-automatic welding machines

The best plasma cutters with high-frequency ignition

Models of this type are characterized by ease of use and high cutting quality. They quickly start working, are suitable for long-term use, and are therefore recommended for professional tasks.

Aurora Airforce 80

4.9

★★★★★

editorial assessment

96%

buyers recommend this product

This model has high operating speed and high-quality cutting, which guarantee comfort during intensive use. The owner can adjust the burner blowing time (from 5 to 25 seconds). The maximum cutting thickness is 30 millimeters, the duration of activation at maximum current is 40%.

The durable case is not afraid of sharp impacts. The wide handle of the unit ensures ease of movement. Other features of Aurora Airforce include a built-in pressure gauge, small dimensions and convenient control of basic parameters.

Advantages:

- high performance;

- quick installation and commissioning;

- flexible setup;

- durable body;

- long service life.

Flaws:

- heavy weight.

Aurora Airforce can be used to cut any alloy and is intended for professional use.

Fubag Plasma 65 T

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

A conveniently located central connector allows you to quickly connect the torch to this cutter. The built-in filter and air dryer improve the quality of work and extend the service life of consumables. Round legs contribute to the stability of the device on the surface.

The power of the device is 9.5 kW, the maximum cutting thickness is 35 millimeters. The durable case reliably protects the internal elements from external influences and mechanical damage.

Advantages:

- high-quality cut;

- very high power;

- convenient control;

- long service life;

- reliable body.

Flaws:

- high energy consumption.

Fubag Plasma 65 T is good for cutting steel and aluminum workpieces. Useful in a professional workshop.

Svarog Real CUT 45 (L207)

4.8

★★★★★

editorial assessment

92%

buyers recommend this product

The plasma cutter has a simple and intuitive control panel, which makes it easy to operate even for an untrained user. A large number of ventilation holes on the case cover quickly remove heat, eliminating the risk of overheating of internal components.

The maximum power is 4.3 kW, the cutting thickness is 12 millimeters. Quick connection of the cable to special connectors simplifies the commissioning of the device. Small dimensions and weight facilitate comfortable movement and installation in the chosen location.

Advantages:

- light weight and compactness;

- ease of carrying;

- fast connection;

- simple controls.

Flaws:

- The cable is a bit short.

Svarog Real CUT 45 is recommended for professional use - when high-quality cutting is important.

Resanta IPR-40

4.8

★★★★★

editorial assessment

91%

buyers recommend this product

An easy-to-grip handle and a durable shoulder strap make the unit easy to transport. The case is not afraid of sharp impacts and reliably protects internal elements from damage.

The control panel contains an operating current regulator, a pressure gauge, and light indicators. This simplifies setup and makes it easier to monitor the current state.

The duration of switching on the cutter at maximum current is 35%, the metal thickness should not exceed 12 mm. The forced cooling system guarantees stable operation of the equipment during intensive use.

Advantages:

- long service life;

- durable body;

- convenient to carry;

- flexible setup;

- There is an indication of states.

Flaws:

- works noisily.

Resanta IPR-40 is suitable for cutting any metals and is used where precision work is required.

FoxWeld Varteg Plasma 70

4.8

★★★★★

editorial assessment

87%

buyers recommend this product

The FoxWeld plasma cutter has an emergency indicator that can operate in two modes, signaling when the compressed air pressure in the system is insufficient or the permissible temperature of the components is exceeded. This prevents damage and ensures high-quality work.

The maximum cutting thickness is 20 mm, the created pressure is 5 bar. The device is equipped with a ventilated front panel. A convenient control unit facilitates quick commissioning of the plasma cutter, and an ergonomic handle simplifies transportation.

Advantages:

- clear indication of states;

- rapid cooling;

- convenient control;

- ease of transportation;

- durable body.

Flaws:

- large dimensions.

FoxWeld Varteg Plasma 70 is worth purchasing for working with aluminum, copper, steel, etc. A universal choice for regular use.

Types and benefits

Based on their functions, there are two types of compressors for plasma cutting:

- Piston;

- Screw.

Models with a piston are more common due to their low cost and practicality, they are reliable, do not require special maintenance and high-cost repairs in case of unexpected breakdowns. But for industrial production, where metal cutting is a continuous process, it is worth choosing screw compressors, which are characterized by high efficiency and low power consumption.

For household use of a plasma cutter, it is enough to purchase an inexpensive oil-free compressor. Such a compressor will provide the minimum need for compressed air, which is necessary for low-intensity operation of the plasma cutter. Another advantage of oil-free compressors is the low noise level, which is an important factor when you are close to the compressor. Specialists will need a professional compressor for plasma cutting when working in production.