Specifics of technology

Welding in a carbon dioxide atmosphere is a type of electric arc .

The constant discharge of the electric arc releases a large amount of thermal energy, which heats and melts the metal of the workpiece. The current flows through the workpiece, the air gap and the infusible tungsten electrode. The welding material in the form of wire is fed into the working area separately; it does not serve as a conductor. Feeding is carried out at a constant speed by a feed mechanism built into the semi-automatic welding machine.

In order to protect the weld pool from the effects of oxygen and hydrogen in the air, as well as water vapor, a protective atmosphere consisting of carbon dioxide is supplied to the working area. Its cloud displaces air and prevents unwanted chemical reactions

Equipment and materials for carbon dioxide welding

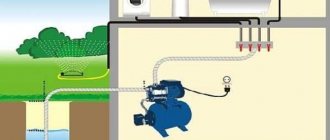

For carbon dioxide processing, inverter-type semi-automatic welding machines with several operating modes are used. The power of such semi-automatic devices is determined by the scope of their application: for professional use, high- or medium-power units are used; weaker models are suitable for domestic use. Semi-automatic machines operate without electrodes; instead, a special wire enters the welding area.

The device itself is supplied by the manufacturer as a set of the following elements:

- a power supply unit consisting of a transformer and a wire-feeding electrode;

- sleeves (hose);

- burner equipped with wire inside;

- conductive tip (nozzle);

- node from where gas is supplied.

To increase productivity and avoid overheating of the burner, cooling systems are additionally used. The quality of welding and its efficiency depend on what kind of machine is used. When purchasing a welding machine, you need to pay attention to some indicators and characteristics.

The power must be sufficient. High-power machines make it possible to cook thicker materials. It is advisable to choose models with a removable holder. The kit should be accompanied by detailed instructions to make understanding the operation of the inverter much easier.

What is carbon dioxide?

The CO2 carbon dioxide molecule consists of a carbon atom and two oxygen atoms. Under normal conditions, carbon monoxide is a gaseous substance, heavier than air, colorless and odorless.

Carbon monoxide has low chemical reactivity, making it an excellent candidate for creating a protective atmosphere around the welding zone . The same property is used when operating carbon dioxide fire extinguishers, which stop the access of air oxygen to the source of fire.

At atmospheric pressure it cannot exist in a liquid state. When cooled to -78°C, it hardens, forming a loose mass reminiscent of snow. This is the so-called “dry ice” used for cooling products in the food industry and trade.

The substance is released during the oxidation of organic substances - during combustion, decay, and respiration of living organisms.

Technical conditions for industrial CO2 are regulated by GOST 8050-85.

The substance is transported in a gaseous state, in containers under pressure.

Scope of application

Carbon dioxide is significantly cheaper to produce than argon, helium and others, but is inferior to them in its protective properties. Welding in a CO2 atmosphere is used for ordinary joints made of ordinary structural steels .

For more critical structures, special steels, and highly loaded components, more expensive inert gases are used, which are difficult to store and use.

In the mass production of standard metal structures, the use of carbon dioxide to protect the welding zone makes a noticeable difference in cost.

Organizing CO2 storage is also cheaper.

Features of the welding process

Semi-automatic carbon dioxide welding is practically the same process as submerged arc welding. The thing is that not all metals can be welded without a protective layer. But welding with carbon dioxide is, first of all, cheap, because other types of semi-automatic welding also have a high quality of the final result.

What is the essence of using carbon dioxide? It protects the welding area from ambient air, which contains moisture and oxygen. But under the influence of high temperatures, carbon dioxide breaks down into the same oxygen and carbon monoxide. So this oxygen begins to interact with the metal, oxidizing it. Which, of course, is not very good. This is why it is so important to neutralize the oxidizing chemical.

This can be done in one single way - by feeding metal containing deoxidizers into the welding zone. And this is silicon or manganese. Since these two metals are more active than iron, they are the first to react with oxygen. Therefore, for welding in carbon dioxide, steel wire is used, which contains these two elements. This is a very important point. It is believed that the optimal ratio of manganese to silicon in the filler wire should be 1.5-2.0. That is, there should be almost twice as much manganese.

The most important thing is that when oxygen interacts with manganese and silicon, oxides of these metals are formed. They do not dissolve in the liquid molten metal formed in the weld pool. But they interact well with each other, turning into slag, which is easily removed from the welding zone. Here are a few features of carbon dioxide welding.

Shut-off and control equipment for cylinders

When working with nitrogen oxide, special shut-off and distribution valves are used .

The reducer reduces the input pressure from 100 atm. up to a working value of 3 atm. It is equipped with two pressure gauges: at the outlet and at the inlet, by which the welder monitors the pressure value.

The gearbox is equipped with two filters that retain impurities.

The required operating pressure is set by rotating the regulator handle.

Using union nuts, the device is connected to the cylinder and to the hose supplying the consumer.

In the event of an emergency, the safety valve releases excess pressure into the atmosphere.

All devices associated with carbon dioxide - cylinders, reducers, hoses - are marked in black.

Refill features

A carbon dioxide cylinder for a semi-automatic machine is charged using two methods:

- bypassing from the storage tank through the reducer and flow meter into the refilled cylinder;

- pumping into a refillable cylinder using a compressor.

Regardless of the filling method, it is important to accurately determine the empty weight of the cylinder . By weighing the cylinder after filling, you can accurately determine the amount of CO2 injected.

Filling cylinders with carbon monoxide, unlike acetylene or oxygen, does not require extraordinary precautions. However, one cannot relax: in the event of a massive leak, carbon dioxide forms an atmosphere unsuitable for breathing. Therefore, it is necessary to carefully check the condition of cylinders, fittings and hoses for mechanical damage.

When refueling using the “cylinder to cylinder” method, it is recommended to turn the cylinder from which you refuel upside down and monitor its temperature.

Consumption

The carbon dioxide consumption for semi-automatic welding is determined by a combination of a number of factors.

- weather conditions (temperature, wind, humidity);

- quality of welding materials;

- qualification and experience of the welder.

It can vary from 3 to 60 liters per minute.

When calculating the planned consumption, such characteristics as the diameter of the welding wire and the thickness of the workpieces are taken into account. To the calculated value equal to the product of the specific consumption and the length of the seam, a margin of 10% is added for preparatory operations.

From a standard cylinder containing 25 kg of CO2, after reducing the pressure to working pressure, approximately 500-510 liters of gas are formed. At maximum consumption, this amount will be enough for 8 hours of operation of a semi-automatic carbon dioxide welding machine. On average, a bottle lasts for 15-20 hours.

CO2 welding technology

After the operator has set the required parameters on the equipment, carbon dioxide welding is performed:

- Before welding, the parts to be joined are prepared. The edge is chamfered and the surface is cleaned of dirt, oil stains, and paint and varnish substances. Metal brushes and sandpaper are used.

- The workpieces are installed in the desired position and secured.

- A test seam is made. To do this, a low-level direct current is installed on the equipment. Watch the metal. If a high current is applied, deformation of the parts being connected may occur.

- The parameters for the diameter of the wire used are adjusted and the workpieces are welded.

The connection is made in two ways:

- for metal of small thickness, the arc is led at an angle forward;

- for parts of large thickness, the arc is drawn at an angle backwards.

After completion of work, the supply of protective gas is not stopped. First of all, the filler wire drive is stopped, the power is turned off, and then the carbon dioxide is turned off. High-quality crystallization of the weld occurs. The slag film that appears on the surface is knocked down.

Carbon dioxide welding

Advantages and disadvantages

Working in a CO2 atmosphere has the following advantages over other types of welding:

- reliable protection of the welded zone from chemically active substances;

- cheapness;

- the ability to cook “by weight”, without the use of backing plates;

- stable arc on thin-walled workpieces;

- rational use of thermal energy of the electric arc.

In addition to its advantages, the method also has a number of disadvantages:

- low suitability for working with high-alloy alloys and non-ferrous metals;

- complexity of multilayer welding;

- danger of suffocation when working in unventilated areas.

The long preparation and startup time of the process makes it unsuitable for small volumes of welding work that need to be completed quickly.

Advantages

Semi-automatic welding with carbon dioxide has proven itself excellent when welding carbon steel of small thicknesses. In such cases, classic manual arc welding or gas welding is not effective enough, since these methods simply deform the metal, preventing the formation of a high-quality seam.

Also, semi-automatic welding with carbon dioxide is widely used in body repairs. In this case, it has several advantages at once. Firstly, the wire is fed automatically using a feed mechanism; the welder does not need to monitor this. Secondly, such welding is many times more efficient and faster than gas welding, for example. Thirdly, when working with thin steel, the speed of welding work also increases, since the wire melts quickly.

Do not forget that with this welding method, the metal around it practically does not heat up, which has a beneficial effect on the part. In this case, the welding joint is not only of high quality, but also beautiful. Also, this method can easily replace gas acetylene welding without loss of quality, also reducing the cost of work due to the low cost of carbon dioxide.

If we compare semi-automatic carbon dioxide welding with manual arc welding, it has many advantages here too. First of all, the welding zone is well protected from oxygen, which cannot be said about RDS; additional flux is required there. You can also cook in any spatial position, which is very convenient when working in hard-to-reach places. The welding process is also better visible and more convenient to observe.

Another advantage is the high welding speed. You will never be able to cook a huge amount of products using RDS, but you can with the help of carbon dioxide. Not to mention technology. Semi-automatic welding is simple, and the wire feeding is completely automated. This is not comparable in complexity to welding an RDS, where the welder does everything himself.

When welding with carbon dioxide, the arc ignites easily and burns stably; there is no need to frequently change electrodes and clean the welded joint from slag crust. If the welder does not need to move long distances while welding, then this method is simply irreplaceable, since it is extremely productive.

Also, a semi-automatic welding machine in combination with carbon dioxide will be an indispensable tool when welding various metal structures, where it is necessary to make many small seams. For example, if you need to weld gates, fences, gratings, etc. Therefore, in any repair shop you will find a semi-automatic machine. At the same time, the cost of repairs will be half as much as if you were cooking using RDS technology. Therefore, at many industrial enterprises, RDS welding has been replaced by semi-automatic welding in a shielding gas environment.

Safety precautions.

Carbon dioxide has two potentially dangerous exposure factors:

- balloon explosion when heated;

- suffocation when working in a closed, unventilated space when the concentration level exceeds 5%.

Based on these risks, safety requirements for carrying out work with CO2 are formed.

During the transportation:

- all cylinders must be transported in a special pallet, in a vertical position;

- Each cylinder must have rubber safety rings.

During storage and refueling:

- all premises must be equipped with gas analyzing equipment;

- when filling the cylinder, it is necessary to control its temperature;

- it is not allowed to refill the cylinder above the standard value;

- Do not touch pipelines, hoses and fittings without protective gloves.

During operation:

- when working in a confined space, organize constant monitoring of CO2 content in the air;

- provide ventilation or provide the welder with an insulating mask with an air supply;

- work together, and one person should be outside the volume and monitor the condition of the welder.

If safety requirements are met, carbon dioxide does not pose a health threat.

Danger of carbon monoxide CO.

Carbon monoxide is a highly toxic substance . If inhaled, it leads to a general depression of body functions and severe poisoning. Death is also possible. It is allowed to work in a carbon monoxide atmosphere only in self-contained breathing equipment.

Polarity

The polarity when welding semi-automatically in a carbon dioxide environment is reversed, that is, “plus” is connected to the workpiece, and “minus” is connected to the electrode. When working with straight polarity in a CO2 environment, it will be difficult to ensure the stability of the electric arc . An unstable arc with such a connection scheme leads to weld defects.

Features of welding in carbon dioxide

Welding of metals in a CO2 environment is performed with direct current of reverse polarity. If welding is carried out with direct current of direct polarity, this negatively affects the stability of the electric arc, as a result, a defect in the formation of the weld shape appears and the electrode metal is consumed in waste and spattering.

But if welding is not performed, but surfacing, then it is recommended to use the direct polarity of the current, since its deposition coefficient is 1.6-1.8 times higher than that of reverse polarity current.

Welding can also be performed using alternating current. In this case, an oscillator must be included in the welding circuit. Sources of direct welding current are current converters with a rigid characteristic.