Machine tools and tools in finished form are available in a wide range in specialized stores. However, their price is not affordable for everyone, especially a novice master. Homemade machines are a way out of a situation with a limited budget. Let's consider the features of their use and manufacture. Let's talk about the most popular devices. The information will help you decide on the choice of necessary equipment for organizing work in the workshop.

Using a non-factory electric grinder Source notperfect.ru

Using homemade machines in the workshop

The work that is performed in the workshop affects the equipment of the room with special devices. Typically, equipment is placed if the free area is at least 3 m2.

Workshops are often set up in small rooms, outbuildings, and garages. The best place is a separate building. In this case, the noise from the work being performed will not disturb other residents of the house.

Universal workshops are often set up to perform various jobs. If a person is engaged in the production of any products, then specific homemade tools and devices are made. Often workshops are equipped with machines for carpentry and processing of metal blanks. Often, premises for the repair of wheeled vehicles are also set up.

Basically the workshop is equipped with:

- devices that allow you to prepare tools, facilitate labor and mechanize operations;

- homemade products for processing metal parts;

- workbenches.

A workbench made of wooden elements Source skilljob.ru

It is also necessary to install shelves in the room where various tools will be stored. At the same time, they ensure unhindered access to them and compliance with fire safety rules.

Do-it-yourself knife sharpening device: drawings and nuances

To make a sharpener from a washing machine engine with your own hands, you can take parts from old Soviet appliances. To build a sharpening machine you will need the following parts:

- tube for turning flanges;

- grindstone;

- special nuts;

- steel elements for the construction of protective casings;

- cable cord;

- launching device;

- a block of wood or a metal corner.

Homemade unit for sharpening knives.

The flange section must match the dimensions of the sleeve. A sharpening stone will also be placed on this element. This part will also have a special thread. In this case, the flange is pressed onto the motor shaft. Fastening is carried out by welding or bolting.

The working winding is fixed to the cable. Moreover, it has a resistance of 12 ohms, which can be calculated using a multimeter. A frame is also made, for which a metal corner is taken.

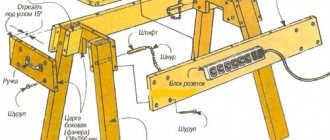

Workbench for a carpenter

This type of equipment is a table. It is distinguished by its high strength and the presence of 2 vices on the tabletop. The table is also equipped with clamps that clamp the workpieces during planing. In addition, the workbench may still have places where other homemade devices, such as a router, will be attached.

A special table must have a comfortable height. She matches the height of the master. The minimum length of the workbench is 1000 mm. Often it is equal to 1700 mm or even 2000 mm. The standard width is 800 mm.

Before making a workbench for carpentry, get acquainted with its main parts Source infourok.ru

A workbench table is created as follows:

- The table surface is created - this is a shield, which is made from oak, beech or hornbeam boards with a minimum thickness of 55 mm. They are tightly fitted to each other. The boards used are impregnated with drying oil before joining. To create a rigid structure, a 50 mm block is used. It is fixed around the perimeter of the working surface.

- The supporting elements of the workbench are made. To do this, use linden or pine timber. Its size is 120*120 mm or 150*150 mm, and its length is approximately 1200 mm. The supports are connected by jumpers in the horizontal plane. To do this, take boards that are fixed at a distance of 300 mm from the floor.

- Make homemade devices to accommodate the tool. These are shelves located under the countertop. When they are open, they are often replaced with bedside tables.

- Attach a vice.

If a stationary workbench is created, its supporting elements are fixed to the floor. Depending on the specifics of the work being performed, mobile and collapsible tables are also manufactured.

Mobile workbench on wheels Source foamin.ru

Carpenter's workbench vice

This homemade tool is made using a screw rod. Its thread length must be at least 160 mm. In this case, the diameter of the rod itself must be 20 mm. For the vice you will also need wooden blocks and metal pins. The manufacturing sequence is as follows:

- Prepare a block of 200*300 mm. Its minimum thickness should be 50 mm. This will be one of the sponges. A hole for a screw is drilled in the center of the workpiece. On the sides of it, two more holes are made for the studs.

- A second movable jaw 200*180 mm is cut out and similar holes are drilled in it.

- A threaded pin is inserted into the workpiece. A handle is installed at one end. To prevent the jaws from moving, pins with a cross section of 10 mm are passed through other holes.

Wooden vice for a carpenter Source infradom.ru

Hammer upgrade

A common occurrence is a wooden handle falling out of the hammer socket. One of the ways to create a reliable handle fastening is to make a cut in the upper end of the handle. The holder is inserted into the hammer socket. The cut is filled with Moment glue. A wooden wedge is driven into the groove.

In order not to look for nails while working, and especially not to hold them with your teeth, a round magnet is glued into the bottom of the hammer handle. Magnetic nails will always be at hand for the worker. It is dangerous for the hammer to accidentally fall out of your hand at height. To prevent this from happening, a hole is drilled in the handle through which the cord is threaded. The worker's belt is threaded through the loop.

Metal workbench for a mechanic

All useful homemade products and devices simplify the processing of workpieces. Such devices include a workbench for a mechanic. Its minimum dimensions are:

- length – 1800 mm;

- width – 700 mm;

- height – 900 mm.

The table is created in the following sequence:

- frame assembly;

- installation of 2 cabinets, covered with metal;

- securing a working surface consisting of a wooden base in the form of a shield, on which a sheet of metal of a suitable size is placed on top;

- assembly and installation of a rack at the back of the workbench to strengthen the entire structure and accommodate tools.

When assembling a bench, use:

- beams as racks - four corrugated pipes 40*60 mm with a wall thickness of at least 2 mm;

- three beams 50*40 mm to connect the racks and ensure longitudinal rigidity of the structure;

- corrugated pipe 40*30 mm with a wall of at least 1 mm in the amount of 9 pieces to create the frame of the cabinets;

- metal corner 50*50 mm for the manufacture of shelving racks, the height of which will be a maximum of 2000 mm;

- board 50 mm thick for the tabletop panel;

- a sheet of metal no thinner than 6 mm to cover the top surface of the workbench.

Sheet metal Source glavmetall.com

See also: Catalog of construction companies that have their own production of materials and components for the construction of houses

Stool

Making a stool with your own hands is quite simple:

- 4 supports, 50 cm long, are made from timber 40 x 40 mm.

- The legs in the middle of the length are fastened with crossbars.

- Grooves are made in the supports using a chisel.

- At the ends of the transverse planks, protrusions are cut out using a chisel to fit the grooves.

- The protrusions are lubricated with wood glue and inserted into the grooves.

- While the glue dries, the supports are tightened with a belt.

- The seat is cut out with a circular saw from a wide board 30 mm thick.

- A seat measuring 300 x 300 mm is nailed or screwed to the legs of the stool.

Wood lathe for lathe

There are various homemade machines and machines for the workshop. They all make the job easier. These include a lathe. Its structural elements are:

- Durable frame made of metal angle or pipe. Sometimes it is created from wooden blocks. The bed is fixed to the floor, and its lower part is weighted.

- A support, which is a supporting element for the cutters. This part of the machine must provide reliable fixation and allow the workpiece to move to the side. For this purpose, the design provides a screw rod.

- The clamping spindle, also called the headstock. The head of a powerful electric drill is often used as it.

The head of an electric drill is often used as a headstock. Source woodtoolsimg.ru

- Tailstock used for longitudinal movement of the workpiece. It is recommended to use the factory spindle, which has four cams.

- Electric drive providing rotation of 1500 rpm. Its power should be from 250 to 400 W. Often a washing machine motor is used as an electric motor. The design also includes a belt drive. This is a transmission, for the operation of which it is necessary to install pulleys on the shafts.

The electric motor of washing machines is often used as a drive for a lathe. Source dobro-teh.ru

Cutters for the machine

It is recommended to equip homemade devices with factory cutters. After all, they are sharpened with high quality using special equipment. As a last resort, for production use:

- old files without significant defects;

- steel square reinforcement is the optimal material for making cutters;

- square or rectangular spring from the car.

Subsequently, the existing workpieces are sharpened. Creates a semi-circular cutting edge for roughing wood parts. Finish turning work is carried out with a cutter that has a straight blade.

After sharpening, the cutting elements are hardened. During this process, the cutters are first heated and then placed in machine oil.

Wood boring tools for a lathe Source 24aul.ru

Choosing a location for a workshop: good advice

Place for building a workshop

When determining a location for a future carpentry workshop, it is necessary to take into account some axioms of its placement:

- As far as possible from residential areas and buildings with domestic animals, if any. The noise produced by work equipment will have an adverse effect on the nervous system of your household.

- It is advisable to choose an open space. The absence of shadows will allow you to save a little on heating the workshop in winter and on lighting throughout the year. Solar radiation will heat and illuminate the room.

- To avoid flooding of the building during rains and snowmelt, there is no need to build it in places with a low general level. This can lead to problems with the building itself and even to emergency situations, such as electrical short circuits.

- It is advisable to ensure ease of access in all weather conditions in order to avoid constant snow clearing in winter, and to prevent flooding of the building during spring snowmelt.

- A plot of soil not suitable for farming will be an excellent place for a future builder

Stationary circulation saw

The stationary circular saw is placed on a sturdy table. Its working surface is usually made of metal sheet. It is reinforced with stiffening ribs. For their manufacture, a steel angle is used.

On the working surface there are usually:

- stops;

- guides;

- elements for adjustment;

- cutting disc.

On a note! The circular saw is powered by an electric motor. Its power should be approximately 800 W, and its rotation should be 1700 rpm. The electric motor of the angle grinder corresponds to these characteristics.

Angle grinder for a stationary circular saw Source tdrim.ru

Before making a device for sawing wooden parts, prepare a working angle grinder with the necessary characteristics. Further actions are performed in the following order:

- Assembling the frame.

- Prepare a worktop in which a slot is made for the cutting disc.

- Two wooden blocks are fastened in parallel. They will be used as stops.

- Set the scale necessary to control the cutting of wooden parts.

- Clamps are installed so that workpieces and guides can be fixed.

- The grinder is secured by first installing the disk into the previously created slot in the table top. The power tool is fixed from below the working surface.

Useful hammer upgrade

When working with a hammer in an inconvenient place, you often have to take nails with you in your pocket or even in your teeth. Agree, this is not very pleasant.

By installing a small but powerful magnet on the hammer handle, you can at least partially solve this problem. The upgraded hammer will carry the nails itself and you can safely work without holding the next nail in your teeth. It's convenient, and your teeth don't get damaged.

Drilling machine

Interesting homemade products and devices often help craftsmen out when making various products in the workshop. One such device is a drilling machine. Its main parts include:

- electric drill;

- base made of metal parts with the ability to secure the workpiece;

- a stand for fixing an electric drill, which is created using chipboard with a thickness of 20 to 25 mm or an old photographic enlarger;

- a unit that supplies the drilling tool.

The drill press stand must have guide rails. They are necessary for the electric drill to move strictly in a vertical direction. There are different options for feeding an electric tool, but the most common design is a lever with a spring. It is manually controlled by simply pressing. The design of the machine also includes stops. They are needed to adjust the depth of the hole created in the part.

Pipe bender

A device for bending metal pipes is a metal rod welded to the frame. I make the rod from a piece of reinforcement. The pipe is placed on a pin, and on the other side a long piece of reinforcement is inserted into the pipe. By pressing the lever, the pipe is bent at the desired angle. The device is suitable for small sections of round pipes.

Making a pipe bender with your own hands

- Two axles are welded to a metal frame from pieces of smooth reinforcement, onto which old car hubs are placed.

- Protruding chamfers are removed from the hubs so that the side surfaces of the rollers are smooth.

- The channel is placed in the opening between the hubs with the shelves facing up.

- The same profile, smaller in width, with the flanges down, is placed into the channel.

- An axle is welded to the top of the inner profile, onto which the third hub is placed.

- A vertical shelf made of steel sheet is welded to the frame.

- A hole is cut in the vertical bar and the bearing is pressed into it.

- A nut is secured to the middle channel by welding.

- One end of the screw rod is screwed into the nut.

- The screw shank is threaded through a bearing in a vertical bar.

- A rotary handle is welded to the shank on the back side of the bar.

- A swing arm is welded to the axis of the drive hub.

The machine is ready for use. A profile pipe is inserted between the rollers and clamped with a screw. The rotary lever drives the rollers, which pull the pipe, bending it. The bending radius is set using the rotary handle of the screw.

A pipe bender made from car hubs is one of the device options. There are many designs of bending devices. In some models, the drive roller is coaxially connected to the motor shaft.

CNC router

There are homemade machines and devices of complex design. Such devices include a CNC router. It is made for processing metal and wooden parts.

Work with a CNC router is carried out to a higher quality. This machine has advanced capabilities. When creating it, an LPT port is used, and numerical control is also provided. The copying unit is created from printer carriages with a matrix of needles.

The milling device is assembled as follows:

- The tabletop is made using a plywood sheet. Instead, chipboard with a thickness of at least 15 mm is used.

- A cutout is created to accommodate the cutter.

- The milling unit is installed.

- The electric drive is located.

- The transmission is secured.

- The spindle is mounted.

- The stops are fixed.

The process of creating a wood router Source tmklazer.rf

A CNC milling machine for processing metal workpieces is made with a more durable frame. The device is created in the following sequence:

- The column and frame are mounted when using a channel. From them a structure in the shape of the letter “P” is created. In it, the bridge between two supporting elements is formed by a part that is the base of the milling unit.

- Guides are made from angle iron. They are fixed with bolts on the column.

- Guide consoles are created from a pipe with a rectangular cross-section. To move them to a height of maximum 150 mm, the design provides a car jack.

- A threaded pin is inserted into the console.

- A working surface is created.

- A vice, fixing elements and guides are installed.

- The rotating unit is mounted. In this case, they strictly ensure that the shaft is in a vertical plane.

Designing a press for a garage with your own hands

The design of a homemade garage press is intended for straightening, pressing, bending sheet materials and for compression. Devices for plumbing work are characterized by a compact and simple design. The forces from such a press can vary between 5-100 tons. For garage work, 10-20 tons is quite enough. To make a similar design, a manual drive is used. The hydraulic device contains two chambers with pistons.

Homemade design

Do-it-yourself press from a jack drawings

You can see how to make a simple device on a special video of a press made from a jack with your own hands:

https://www.youtube.com/watch?v=7Yf_ApwwJgs

A simple option is a hydraulic one, which can be constructed from a bottle jack. An important element is the frame, inside of which the jack is placed. The platform is used as a reliable base. The upper surface is used to support the elements being processed. The table should move freely up and down on the frame. In this case, rigid springs are attached to the base on one side, and to the working surface on the other.

Using a jack

Here is a simple assembly diagram:

- the necessary elements are cut out according to the drawings;

- The base is mounted by welding. In this case, the steel structure should resemble the letter P;

- a mobile table is made from a pipe and channel;

- Finally, the springs are fixed.

Thicknesser

Crafts for the workshop are often created to perform woodworking. The material always has to be planed. It is to solve this problem that a surface planer is made. The machine consists of the following parts:

- The frame consists of two frame structures, which are welded from 40*40 mm corners. The frames are fastened with studs.

- Tabletop made of metal or lumber, pre-impregnated with drying oil. The working surface is bolted to the frame.

Bed with a steel tabletop for thickness planer Source prostanki.com

- A broach consisting of rubber rollers. They are taken from a broken washing machine. The rollers are provided with smooth rotation by sliding them onto bearings.

- A casing that protects rotating parts. It is made of sheet metal about 5 mm thick and fixed to a frame made of corners measuring 20*20 mm.

- Electric motor with a power of 6 kW, which can rotate at a speed of at least 3000 rpm.

Clamps are used to secure the thickness planer. The device is fixed on the working surface. Do not forget about the required gap, when setting it, take into account the thickness of the workpiece.

Impact screwdriver from starter

There are situations when it is impossible to unscrew a rusted bolt or screw with a conventional tool. An impact screwdriver does this job perfectly. The tool is made by hand from parts of a car starter:

- The shaft and bushing are removed from the starter housing.

- Part of the shaft is cut off, leaving a splined rod.

- A piece of pipe of suitable size is placed on the sleeve.

- A piece of bolt of equal diameter is welded to the end of the pipe.

- The end of the shaft is ground into a tetrahedron shape, onto which heads of the required size are placed. For screws, a bit is inserted into the head.

When you hit the head of the bolt with a hammer, the shaft slides with beveled splines inside the sleeve, performing a rotational movement. The stronger the blow, the more force the shaft rotates.

Wood sanding machine

The design of such a machine has a cylinder on which sandpaper is placed. This unit rotates while processing the part. The assembly of a homemade machine is often performed for grinding cylindrical workpieces. A device is also made to create a flat surface of the workpiece.

When fixing the sanding paper, follow these rules:

- the width of the abrasive cloth should be approximately 250 mm;

- the sanding belt is connected without a gap exclusively end-to-end;

- The sandpaper is attached using a high-quality adhesive;

- at the edges of the shaft for the abrasive cloth there must be a side, the protrusion of which is from 2.5 to 4 mm;

- a rubber backing should be placed under the tape.

The shaft of the device is rotated by an electric motor. These two parts of the machine are connected by a belt drive. The design of the frame itself can have different designs. The option is chosen depending on the size of the workpieces being processed.

Device for polishing wooden parts Source notperfect.ru

How to sharpen a drill for metal: do-it-yourself device

You can make a simple metal drill sharpening machine from ordinary tools. An abrasive block is suitable for this.

At home you can use the following equipment:

- You can use an electric sharpener to sharpen the drill. In this case, sharpening is performed from the edge. When using a sharpener, you need to pay attention to the sharpening angle and the fixation of the drill on the axis of rotation. Excess metal should be removed gradually. Finally, the edges are shaped into a cone;

- A grinder is used as a do-it-yourself sharpening machine. For sharpening, the cutting tool is secured in a vice. To do this, the mounting angle is selected, and the disk is mounted.

Varieties of devices for sharpening drills

It is worth considering that the grinder is mounted on a flat surface. In this case, the disk should be located downwards. If the grinding device is not secured securely, it can damage the drill. Sharpening with a grinder can only be done for products with a small diameter. It is not possible to finish using a grinding device. The edge of the shield is used to support the cutting tool.

You can also use a drill attachment, which should be equipped with a grinding disc with sandpaper. To grind elements with a drill, you need to find two flat surfaces.

Briefly about the main thing

Typically, craftsmen assemble machines for their workshops if the area of the room is at least 3 m2. Universal devices are manufactured or to perform a specific type of work. In addition to shelves and racks, in the workshop you can often find a workbench for carpentry work made of boards and bars, which is equipped with a vice.

Craftsmen also make a metal workbench from corrugated steel pipes, angles, and sheet metal. They also assemble a lathe on a metal frame, with a clamping spindle in the form of a drill head and an electric drive. Also popular in the workshop are a stationary circular saw based on a grinder, a drilling machine made from an electric drill, a surface planer made from an electric planer, and a CNC router.

Homemade folding stand

A very original idea for a folding stand for hand tools. Everyone is in their place. It doesn't take up much space. The design is based on furniture guides. The clamp holds the stand in the upper position. Neodymium magnets prevent instruments from falling out of their stocks. A great idea for DIYers who love to do everything with their own hands.

Veneering

Previously, this term was used to describe the procedure of gluing carpentry products with plywood - thin sheets of wood of other, more valuable varieties.

Nowadays we understand “plywood” as multi-layer laminated boards, and we call thin wood sheets “veneer”. Accordingly, instead of “veneering” today many people say “veneering”. Using veneer, you can give a beautiful, even sophisticated look to products made from “simple” types of wood that grow in our latitudes. For example, oak veneer can be used to cover birch furniture. By the way, today many examples of furniture, including “elite” foreign ones, are actually covered with veneer of more valuable species and are sold as made from solid wood, at much higher prices. I don’t recommend that beginners start gluing veneer right away, since this is a non-trivial task that requires skill, patience, and in the case of large parts, also serious equipment in the form of powerful presses or vacuum bags for uniform gluing of veneer.

Handle holder for hacksaw

In the practice of workers, there are often cases when it is necessary to cut down something located in a hard-to-reach place . In such cases, beginners wrap the hacksaw blade with some kind of rag so as not to get hurt, and begin to saw. This is extremely inconvenient, so it is better to make a special handle. Of course, its creation will take some time, but the result is worth it. To create a holder you need to do the following:

- Collect the necessary materials (a small board no more than twenty millimeters thick, an M6 bolt 80 mm long and a wing nut, epoxy resin).

- A pen is drawn on the board and then cut out. Using a round file, special recesses are made into which the fingers will fit for a stronger grip.

- Using a hacksaw, a gap is created on top, into which it will then be inserted.

- There, using a drill, a hole is created for the bolt.

- The handle is sanded.

- The bolt is placed in a vise and a slot is then created for the hacksaw blade. The gap should not exceed more than three centimeters in depth.

- The bolt is cut and rounded.

- Using resin, glue the bolt into the drilled hole.

- Testing is carried out, namely: is the handle comfortable to hold and how tightly does the blade hold.

History and evolution

Further in the text you will come across technical solutions that are effective, but little known to amateur craftsmen, because... in industry, for one reason or another, they are not used or are used to a limited extent. However, they can simplify and facilitate the manufacture of a homemade lathe for processing wood so much that in some cases it will be possible to limit the use of a power tool to a hand drill. The machine tool industry of the millennium is developing under the sign of solving the problem: how to make machine parts with an accuracy of, say, 1 conventional unit of length on a machine with an accuracy of, say, 0.2 of the same units? Etc. To understand how technology came to such a life, it will be useful to briefly turn to history.

The ancestor of all machines for processing materials by rotation is a device with which Neolithic people made fire and drilled horn, bone, stone, etc. 1 per rice; in the latter cases, an abrasive of wet quartz sand was added under a drill made of wood or bone. The primitive Celts, using the same principle, invented a foot-operated lathe, pos. 2; the centers were made from sharpened, burnt stakes of hard wood. In England, this unit is still used by furniture makers. The forest is not cut down there block by block. Having bought a couple of scaffoldings for felling, the master then carries armfuls of finished legs, balusters, etc. to the track. In a craft of this type, the machine survived for approx. until the beginning of the 18th century, pos. 3, although the workpiece rotates back and forth in it and the master has to be additionally distracted in order to turn the cutter over.

Stages of evolution of the wood lathe

In Ancient Egypt, already in the era of the Middle Kingdom, a lathe with a bow drive was well known, pos. 4. The “motor” was, naturally, the slave. In the Russian village community (in the world), with its strong traditions of mutual assistance and mutual assistance, the bow lathe survived in the outback until... the 80s of the last century! Mass individual wooden construction was in no way included in the five-year plans, but the Soviet leadership in the provinces turned a blind eye to unauthorized logging in limited quantities for their own needs or to unauthorized purchases of wild logs from timber industry enterprises for the universal Soviet currency of 40 volume. and a capacity of half a liter.

Read also: The screwdriver button does not work

For fine and/or small work, a foot machine with a string and a bow machine were not suitable: there are always inhomogeneities in wood, and the workpiece itself was the flywheel - the damper of torsional vibrations. Radical improvements to the lathe were introduced by the master Theodore in Ancient Greece approx. in 400 BC uh, pos. 6. He supplemented the foot drive, firstly, with a crank - now the workpiece rotated in one direction. Secondly, I made the centers rotating and equipped one of them with a grip to hold the workpiece. Thirdly, he introduced a heavy flywheel into the kinematic scheme. Individual machines of this design were in operation at industrial enterprises before the start of electrification of industry, pos. 7 – given the complete absence of social guarantees at that time, the labor of an unskilled helper was cheaper than the cost of maintaining a steam engine.

The electrified wood lathe (item 8 in the previous figure) has remained virtually unchanged since the end of the 19th century (see also figure below):

- a – motor rotor and other massive drive parts do not require the use of a separate flywheel;

- b – the clamping chuck can accommodate various tips for different types of workpieces (see below) or a drill;

- c – a tool rest with a rotating shelf-support for the cutter, mounted on a movable carriage, makes it possible to carry out a wide variety of working operations;

- d – tailstock with a rotating center allows you to bring the processing accuracy to the maximum possible on wood;

- d – the tailstock quill feed screw (see below) makes it possible to carry out complex processing of a workpiece into a part in one installation. During processing, the wood yields under the pressure of the holder and the center. If the tailstock is fixed rigidly, the workpiece becomes loose during processing. The machine has to be stopped and the blanks reinstalled, which in no way contributes to the quality of the work.

Design and kinematic diagram of a modern wood lathe

What if there is no motor?

A non-volatile wood lathe can still be useful today; say, at a dacha or an unequipped construction site. The muscular strength of a normally developed person is sufficient to turn pieces of ordinary timber with a diameter of approx. up to 150 mm. In such a case, 2 options are possible (see next figure): a good old machine with a foot drive (the dimensions of its most important unit, the crank, are given at the top right); For more details about it, see below, and processing on trestles with manually driven tow rope (bottom right in the figure). You can’t round timber to the girth in this way, but it is possible to grind the support pillars of a porch, gazebo or canopy over a barbecue.

Construction of energy-independent wood lathes

If you love wood and want to work with it, then you have probably thought about whether this can be done at home, so to speak, in your usual environment. To answer this question, you should study this article, where we will talk about all the features of work processes and operating conditions of the tool.

Do-it-yourselfers - make your own processing equipment

Peculiarities

Experienced specialists have long known that homemade CNC machines made from plywood are in some cases not inferior to full-fledged factory-made metal analogues. Such structures are used, of course, only where there are no significant mechanical stresses, strong vibrations, heating and the need to remove heat with water.

The technical qualities of plywood devices may well be at a decent level. At the same time, the cost of such equipment is reasonable.

Attention: such systems are designed for private use only. A plywood machine is not useful as a full-fledged production workplace. Before doing it, you need to soberly assess your abilities and knowledge in the field of carpentry. In the absence of special skills and the ability to work with power tools, you will have to forget about making machines yourself.

In addition, you will have to carefully select the main construction material.

Direct drive or belt drive

There are several ways to transfer rotation to the workpiece. The simplest is direct drive. In this case, the workpiece is attached directly to the motor shaft. A distinctive feature of this design is its simplicity. With all this, direct drive has a number of significant disadvantages.

First of all, a direct drive machine does not allow you to adjust the rotation speed, which is critical when working with hard material. It is also worth considering the load on the electric motor, especially when working with large workpieces. No matter how well it is centered, it cannot do without vibration. Motor bearings are not designed to withstand longitudinal loads and will often fail.

To protect the engine from damage and provide the ability to adjust the speed of rotation of the workpiece, it is worth considering a belt drive. In this case, the engine is located away from the axis of rotation of the workpiece, and torque is transmitted through pulleys. Using pulley blocks of different diameters, it is easy to change the speed within a fairly wide range.

It is advisable to equip a machine for your home with pulleys with three or more grooves, which will allow you to process wood of any species with equal success, and, if necessary, work with soft alloys.