In industry and in everyday life, argon arc welding of metals is often used. With such welding, carried out in a protective atmosphere of argon, the metal is protected from the influence of the external oxygen environment. When carrying out this type of welding, non-consumable tungsten electrodes are used. Tungsten electrodes can withstand high temperatures for a long time and melt much more slowly than other metals.

To improve the quality of welding, oxides of rare earth elements are added to tungsten. Depending on their content, such electrodes are marked.

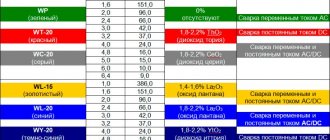

Marking tungsten electrodes by color

Argon arc welding with a non-consumable tungsten electrode is the optimal welding method for obtaining a high-quality weld. This method allows you to obtain a beautiful seam with high strength characteristics. This method allows welding of a wide range of materials - alloyed and unalloyed steels, cast iron, non-ferrous metals and their alloys, etc. Depending on the type of welding current and the material being welded, the type of tungsten electrode is selected.

Tungsten is the most refractory metal known to modern science, its melting point is 3410°C, and its boiling point is 5900°C. This results in insignificant consumption of electrodes during welding work. The cleanliness and accuracy of the final weld is another criterion, the presence of which influences the choice of argon arc welding with a tungsten electrode in a number of industries, for example, in the automotive industry. To enhance the stability and stability of the welding arc, special electrodes are created from tungsten with the addition of oxides of rare earth elements - lanthanum, zirconium, thorium, cerium.

Features of the use of a specific brand of tungsten electrodes depend on the chemical composition and the amount of alloying additive in it. Marking tungsten electrodes at one end with different colors makes it possible to navigate the product range and greatly simplifies the selection of the required type of product. An additional guide is the letter designations in the names of materials for welding - the second letter following the letter W (tungsten) in the name means the name of the additional element. The numerical designations in the marking of all tungsten electrodes are responsible for such characteristics of the material as the percentage of the alloying element (in tenths of a percent). In addition, you may find additional numerical values in the designation of a specific brand. They characterize the length of the non-consumable electrode, which can be 50, 75, 150 and 175 mm. The diameter of the products can also vary, the most common electrodes are the following diameters (in millimeters): 1.0, 1.6, 2.0, 2.4, 3.0, 3.2, 4.0, 4.8, 5, 0, 6.0, 6.4.

Physico-chemical composition

Most tungsten electrodes for overhead lines contain 97% tungsten and higher. Naturally, this parameter is individual for each brand, but in most cases it is pure metal. Tungsten electrodes for argon arc welding, which without additional elements contain 99.5% tungsten. In other cases, on average, it contains 1.5-3% of such additives as:

- Cerium oxide;

- Lanthanum oxide;

- Zirconium oxide;

- Thorium oxide.

Symbols and markings

Marking tungsten electrodes is quite simple, since their composition does not contain a lot of different elements, but there is only 1 additive, or there is none at all. The colors of the tungsten electrodes precisely correspond to the various additives. If you look at the designation, then the typical one here will be, for example, WL15, which will be deciphered as:

- W – tungsten electrode;

- L – presence of lanthanum oxide;

- 15 – presence of additive (in this case lanthanum oxide) 1.5%.

Thus, the second letter denotes the additive, and the numbers indicate its content in hundredths of a percent.

Selecting a tungsten electrode

The choice is made based on the conditions of use. If welding is carried out using alternating current, then it is better to choose purely tungsten ones. Zirconium additives increase arc stability and maximum operating temperature. The thorium oxide in the composition improves temperature resistance, so such electrodes can be given any shape. Yttriated tungsten tools provide better arc stabilization. Cerium in the composition ensures versatility of use in any mode.

Basic modes and nuances of application

The main feature of using these tools is the selection of the correct current mode, regarding its type and polarity, since the characteristics of the electrodes manifest themselves differently in each case.

| Diameter size, mm | Constant current, straight polarity, A | Constant current, reverse polarity, A | AC current, A |

| 1 | 15…60 | 15…20 | |

| 1,6-2 | 20…100 | 20…60 | |

| 3 | 80…250 | 25….40 | 60…150 |

| 4 | 200…360 | 40…50 | 120…200 |

| 5 | 350…550 | 50…80 | 180…300 |

| 6 | 500…700 | 80…125 | 250…340 |

Manufacturers

Due to their popularity, such electrodes are produced all over the world. The following brands can be found on the market:

- Tungstone (Poland);

- Abicor Binzel (Germany);

- Jasic (China).

Let's consider a list of the main brands of tungsten electrodes.

An electrode with a tungsten content that does not fall below 99.5% is also known as “pure tungsten.” Provides excellent arc stability when operating on alternating current. The priority area of use of the product is alternating current welding of metals such as aluminum, magnesium and their alloys. Suitable for use in argon and helium shielding environments. A distinctive feature of welding can also be considered that the electrode is not sharpened, as is the case with other electrodes, but a sphere is formed on the working side of the electrode. The spherical shape of the tungsten electrode is obtained under the influence of high temperatures during the welding process. This brand of tungsten electrode is characterized by a relatively short service life and safety for the health of the welder.

Electrode with 2% thorium dioxide additive. These are the most popular alloyed electrodes; they were the first to demonstrate the superiority of alloyed electrodes over classical products when operating under direct current conditions. The priority area of use of the product is considered to be welding of stainless, carbon, low-alloy steels, as well as copper, titanium and their alloys. When welding with a thoriated electrode, it is necessary to change the sharpening angle depending on the welding current in order to adapt to any task.

Universal electrode with 2% addition of cerium dioxide. This substance increases the permissible welding current range. But even at low current values, cerium electrodes are superior to products made from pure tungsten. Suitable for working with any types of steels and alloys (including molybdenum, nickel, titanium, bronze) under AC and DC conditions. They have a high service life. The most striking drawback of the material is the concentration of cerium oxide at the hot end of the electrode when welding with high current values.

An electrode with the addition of yttrium dioxide, the size of which can be 1.8-2.2%. Yitrated tungsten electrodes are the most stable non-consumable electrodes in use today. They are used for welding particularly critical joints using direct current of direct polarity. Suitable for welding carbon, low-alloy and stainless steels, titanium, copper and their alloys.

Electrode containing 0.8% zirconium oxide. Suitable for working with aluminum, magnesium and their alloys under alternating current conditions. An ideal solution for tasks where even minimal contamination of the weld pool is unacceptable. The products allow you to create the most stable arc.

Electrodes with the addition of 1.5% and 2% lanthanum oxide. The products provide extremely easy arc starting, arc stability throughout the work and excellent arc restart performance. Lanthanum oxide reduces wear on the working end of the product and increases the current load by 50% compared to a pure tungsten electrode of the same size. The uniform distribution of lanthanum oxide along the entire length of the product allows you to maintain the initial sharpening of the electrode during long-term work. The electrodes are completely safe for the health of the welder.

GlobalWeldingCompany offers to purchase tungsten electrodes with alloying additives and unified markings, the performance characteristics of which meet modern international standards. A huge range of professional welding materials directly from suppliers is always available in Moscow - so that you can make a choice in favor of a balance between price and quality. Here you will find both standard sizes of tungsten electrodes with the required markings, as well as rare ones that other suppliers do not offer or usually carry on order.

You can buy tungsten electrodes in our online store. Please check with our managers for wholesale prices.

Source

WT-20

Tungsten electrodes

W T - 20

(the composition, in addition to pure tungsten, includes 2.0% thorium oxide) are most widespread in Russia, as for decades they have shown high efficiency, stability and relative versatility.

These electrodes are suitable for welding all types of steel, as well as tantalum, molybdenum and many other materials with direct current .

Technically they are capable of operating on alternating current, but are not designed for this.

They have easy arc ignition and relative durability. But a significant disadvantage of WT-20

at the moment reduces their consumption - thorium is

a radioactive

chemical element.

Dust from an electrode during sharpening, inhaled into a person's lungs, can have a significant impact on his health. Poorly ventilated areas intended for working with WT-20 and the long-term nature of the work themselves are also dangerous. All of the above does not mean that you should immediately abandon thorium tungsten electrodes, but it is advisable to strictly observe safety precautions

when working with them.

Tungsten electrodes for argon arc welding

Among non-fusible electrodes, there are often unique models that are designed for functions that other varieties are not capable of. Tungsten electrodes for argon arc welding are used to create an electric arc of the required power and also to melt the base and filler metal, which is used as welding wire. Taking into account the fact that the protective medium here is argon gas, no coating is required for the wire. These products are characterized by high performance characteristics and good heat resistance.

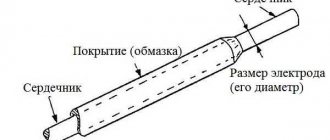

Appearance of tungsten electrodes

Tungsten electrodes for argon arc welding are thin rods that are made from pressed particles of this metal. The fact is that tungsten is very refractory, which is why these products are made from it. For electrodes, not solid metal is used, but pressed small particles that are subjected to high heat treatment. In appearance and properties they are not much different from cast metals. Products can be produced either with special coatings that contribute to arc stabilization, metal deoxidation, gas or slag formation, metal alloying, and so on, or without it. Non-consumable tungsten electrode is produced according to GOST 23949-80.

Welding with a tungsten electrode in an argon environment is much better than other types of this process. There is no excess residue from the coating. The tool itself is universal and does not give any negative complications. For home use, this method may seem somewhat expensive, but in production and when working with critical structures it becomes indispensable.

Marking tungsten electrodes by color

In this article we have listed all the main markings by which tungsten electrodes are classified .

They are best used for welding with alternating current, in which the working end is processed to give it a spherical shape. Also, even minimal contamination of the weld pool should not be allowed. Zirconium electrodes create a very strong and stable welding arc. Therefore, the current load on them can be much greater than on electrodes with cerium, lanthanum and thorium coatings.

The main metals to be welded are: aluminum and its alloys, bronze and its alloys, magnesium and its alloys, nickel and its alloys.

Used when welding with alternating sinusoidal current (with an oscillator). Such electrodes create and maintain a stable arc in any inert environment (preferably argon or helium). Due to the limited thermal load, the working end of the WP is formed into a ball.

The main metals to be welded are aluminum, magnesium and their alloys.

This rare earth metal enhances emissions to improve initial arc start-up and maintain arc stability even at low current levels. These are universal electrodes that are used for welding with alternating current and positive direct polarity current.

Cerium electrodes are used when welding pipelines, as well as thin-sheet steel products and when welding fixed joints using orbital machines.

The main metals to be welded are: metals with a high melting point (molybdenum, tantalum), niobium and its alloys, copper, silicon bronze, nickel and its alloys, titanium and its alloys. Suitable for all types of steels and alloys on AC and DC.

They have an easy initial start of the welding arc and a low tendency to burn through. A stable primary arc and excellent arc re-ignition make them a leader in industrial applications. Lanthanum oxide significantly increases operating current, produces less weld contamination and reduces wear by 50% compared to conventional tungsten electrodes.

Main metals to be welded: high-alloy steels, aluminum, copper, bronze. Suitable for all types of steels and alloys on AC and DC.

They are used when welding critical components and structures using direct current of direct polarity (DC). And they are considered the most stable of all non-consumable electrodes known today. Yitrated electrodes make the cathode spot at the tip more stable, so arc stability is greatly improved.

Main welded metals: carbon, low-alloy and stainless steels, titanium, copper and their alloys.

These are the most common electrodes, since they were the first to show the significant advantages of composite electrodes over purely tungsten electrodes when welding with direct current.

Thoriated electrodes work well when welding on direct current and with improved current sources, and depending on the task at hand, you can change the angle of sharpening of the electrode. They perfectly retain their shape even at high currents, unlike purely tungsten electrodes, which begin to melt.

The main metals to be welded are: stainless steels, metals with high melting points (molybdenum, tantalum), niobium and its alloys, copper, silicon bronze, nickel and its alloys, titanium and its alloys.

Source

Color change over time

If the ring begins to darken or show signs of rust, it is a piece of mediocre quality jewelry. Rings made of tungsten, titanium, thisten and stainless steel (without color coating) do not change the original shade, are not afraid of exposure to ultraviolet radiation, water (even sea water), are resistant to corrosion, and do not oxidize when interacting with the skin (unlike some silver jewelry) .

| Tungsten ring | Titanium ring | Thisten ring | 316L steel ring |

| Do not change color, do not darken, do not fade, do not rust. |

A change in the color of the tungsten ring, as well as models made of thisten or titanium, is a sign of an increased content of impurities in the metal alloy. As well as the darkening of the steel ring - the fact that its composition does not correspond to the proven grade of 316L steel.

Tungsten electrodes for argon arc welding

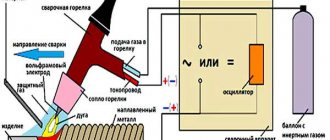

Argon welding is a modern welding using a non-consumable tungsten electrode in an inert gas environment.

Such welding protects the metal from interaction with an oxygen environment, which causes its oxidation and nitriding. The inert gas argon is most often used as protection during operation, but it is possible to use nitrogen, helium and various gas mixtures. In TIG welding, Ar (argon) is widely used, but He (helium) is used in rare cases to solve certain production problems. Gas components are constantly used in this welding. Indeed, argon does not form an explosive mixture with the atmosphere. It is slightly heavier than air and more practical for welding than helium. But the arc itself, when using helium, has 1.5–2 times more energy than when using the same argon. A mixture with the following components is widely used during welding: 35–40% pure argon plus 60–65% pure helium. Argon completely stabilizes the arc, and helium efficiently fuses the metal.

Tig welding has only two international names. TIG – welding with non-consumable special tungsten electrodes in an inert gas environment. MIG/MAG - welding with the electrode wire itself directly in an environment of inert argon or even carbon dioxide.

Marking of tungsten electrodes

Tungsten electrodes are used in argon arc welding. The use of tungsten in this case is justified, since it is refractory - able to withstand high temperatures without melting.

Currently, our industry produces electrodes with a length of 175 mm and the following diameters: 1 mm; 1.6 mm; 2 mm; 2.4 mm; 3.2 mm; 4 mm. The difference between sizes is due to the need to work with certain ranges of welding currents:

Tungsten electrodes for argon arc welding are made from pure tungsten, as well as calibrated and lanthanum, which help improve the quality and stability of the welding arc. The brand of electrodes is qualified based on the percentage of impurities and additives. Currently, there are only three categories of tungsten welding electrodes:

The consumption of the number of electrodes when using argon welding depends on the type of welding itself, the diameter of the rod used, the type of current and a number of additional indicators.

TIG welding with consumable electrode

The electrode in this case is a metal rod. It is covered with a layer of rutile. The welding arc is ignited by molten metal vapors, which give ionization in argon. The oscillator is not used in this case.

Prices for electrodes in these categories depend not only on the country of origin, but also on the pricing policy of the enterprises that produce them. Currently, tungsten electrodes have the following cost:

Which brands are the best?

Tungsten electrodes are presented by both foreign and domestic manufacturers.

The most popular were:

- products of the Swedish company ESAB, manufactured not only in Europe, but also at Russian factories;

- the high price of Fubag rods from Germany corresponds to their quality;

- the entire range of tungsten electrodes is in the catalog of the Italian brand BlueWeld;

- lanthanum wire EVL from Ecotek plant.

In addition to products from large factories, trading enterprises offer products from many Chinese manufacturers. The most popular were Shaanxi Yuheng Tungsten Molybdenum Industrial Co., Ltd, which has been producing tungsten electrodes for over 15 years, Hangzhou Linan Dayang Welding Material Co., Ltd, etc.

Application of tungsten electrodes

Argon welding is used in a wide variety of industries and agriculture. The ability of the TIG ac/dc device to connect various carbon, stainless, structural steels, as well as modern metal alloys, characterizes this technology as the most popular in production at the moment. The aerospace industry is typically the primary user of this type of welding.

In industry, tig welding is used to connect parts of various configurations. Argon welding is used to create transitions between pipes of different diameters. Aluminum welds after tig welding do not form cracks and have the chemical integrity of the metal, which allows this welding mode to be used for sealing containers with nuclear waste in connection with their disposal.

Due to the simple technology of argon welding of aluminum, it can be used in everyday life using TIG ac/dc home inverters. In domestic conditions, it is even possible to organize the welding process of stainless steel. The reliability of the resulting seam is beyond doubt, since the weld seam is a single whole with the metal being welded. Modern welding technologies place argon arc welding using tungsten electrodes in one of the first places in the world in terms of the quality of work performed.

Source

How to choose a tungsten electrode?

In this article we will tell you how to choose the right tungsten electrode for argon arc welding, what types of tungsten there are, their distinctive properties, and how the composition affects the quality of the weld.

But at the very beginning, we would like to draw your attention to the fact that tungsten electrodes of the WL-15, WL-20, WC-20, WY-20 and WZ-8 brands have appeared in the range of PTK branded products.

Our tungsten electrodes have undergone X-ray microanalysis of elemental composition at the National Research Institute. We conducted this paid study on our own initiative in order to demonstrate to dealers and consumers the highest quality of our products.

The analysis was carried out on a Tescan Vega II scanning electron microscope, which allows you to obtain SEM images and analyze the elemental composition in real time, which is necessary for quality control of products and materials.

You can familiarize yourself with the research protocols and the results of the elemental composition of tungsten electrodes produced by PTK in the reporting documents.

The essence of the welding process with TIG equipment

If you are already familiar with types of welding such as MMA and MIG-MAG, then you probably know that the former uses an electrode as the main consumable material, and the latter uses a moving wire.

TIG machines also use an electrode, but this time it is made of tungsten, a material that is refractory. Protection against oxidation is provided by argon gas, which is why the process is often called argon arc welding. The English abbreviation TIG means Tungsten (tungsten) Inert (inert) Gas (gas), which affects the most important elements in the work.

Why is there a filler rod here? It is fed manually to form the seam. Under the action of an arc, the metal melts while in a protected gas environment and creates a high-quality connection.

In this article we will not focus on how the device itself is selected. For this purpose, a separate material has been created that will help you understand how to choose an argon arc machine for TIG welding.

What is a tungsten electrode and where is it used?

A tungsten electrode is a round rod made of pure tungsten or tungsten with the addition of additives (alloying additives). Tungsten is used in TIG welding with a non-consumable electrode.

If you have a question, why “non-melting”, then the answer is very simple. Tungsten has the highest melting point among pure metals (3422°C). Therefore, argon arc welding is performed with straight polarity, because the temperature of the cathode spot (-) reaches 3000 °C, and the temperature of the anode spot (+) reaches 4000 °C. Because of this, the electrode is not consumed during welding, but burns out.

Electrodes can have a clean or polished surface. A distinctive feature of clean electrodes is that they are chemically cleaned, i.e. The workpieces are etched to remove oxides and contaminants from the surface.

This is the most labor-intensive and costly procedure, therefore it is used much less frequently in industrial production. The ground surface of the electrodes suggests that the electrodes may have been processed by forging, broaching, or centerless grinding. The latter method is the most popular; as a result of this manufacturing, the thermal conductivity of the electrodes improves.

The diameter and length of tungsten electrodes can vary. Standard electrodes have a length from 50 to 175 mm, and a nominal diameter from 0.5 to 10 mm. In Russia, electrodes are manufactured according to GOST 23949-80, TU 48-19-27-91, TU 48-19-39-85, 48-19-221-83 and TU 48-19-527-83 from pure tungsten and tungsten with activating alloying additives of rare earth metals.

Tungsten electrodes are used exclusively in TIG welding, due to the prevention of oxides on the surface of the connecting seam. Welding occurs in a shielding gas environment, which protects the welding zone from exposure to oxygen.

This type of welding uses a chemically inert gas (noble gas). These gases include helium, argon and special welding mixtures. A distinctive feature of these gases is that they have very low chemical reactivity, in other words, they do not interact with the metal of the weld. These gases are also colorless and odorless.

The influence of current polarity on the tig welding process

The polarity of the welding current significantly affects the nature of the process of arc welding in an inert gas with a tungsten electrode. Unlike welding with a consumable electrode (which includes MMA and MIG/MAG welding), when welding with a non-consumable electrode in a protective atmosphere of an inert gas, the differences in the nature of the welding process in reverse and direct polarity are of the opposite nature.

So, when using reverse polarity, the TIG welding process is characterized by the following features:

– reduced heat input into the product and increased heat input into the electrode (therefore, when welding with reverse polarity, the non-consumable electrode must be of a larger diameter at the same current; otherwise it will overheat and quickly collapse); – the melting zone of the base metal is wide but shallow; – the effect of cathodic cleaning of the surface of the base metal is observed, when, under the influence of a flow of positive ions, the oxide and nitride films are destroyed (the so-called cathode sputtering), which improves the fusion of the edges and the formation of the seam.

While when welding with straight polarity the following is observed:

– increased heat input into the product and reduced heat input into the electrode; – the melting zone of the base metal is narrow but deep.

As in the case of MMA and MIG/MAG welding, differences in arc properties for direct and reverse polarity in TIG welding are associated with the asymmetry of energy release at the cathode and anode. This asymmetry, in turn, is determined by the difference in the voltage drop in the anode and cathode regions of the arc. Under non-consumable electrode welding conditions, the cathode voltage drop is much lower than the anode voltage drop, so less heat is generated at the cathode than at the anode.

Below is the approximate amount of heat generated in different sections of the arc in relation to TIG welding at a welding current of 100 A and when using straight polarity (as the product of the voltage drop in the corresponding area of the arc and the welding current):

– in the cathode region: 4 V x 100 A = 0.4 kW at a length of ≈ 0.0001 mm – in the arc column: 5 V x 100 A = 0.5 kW at a length of ≈ 5 mm – in the anode region: 10 V x 100 A = 1.0 kW over a length of ≈ 0.001 mm.

Due to the fact that when welding with direct polarity there is an increased heat input into the product and a reduced heat input into the electrode, when welding with direct current, direct polarity is used. At the same time, due to the fact that heat is released mainly in the anode region, only those areas of the base metal to which the arc is directed melt, i.e. where the anode is located.

What are alloying additives and rare earth metals?

We have looked at the alphanumeric designations of tungsten electrodes, now it’s time to talk about the rare earth metals (elements) that are part of the electrodes, or rather, alloying additives (additives).

Rare earth metals are a group of 17 elements that include scandium, yttrium, lanthanum and lanthanides. All these metals are silvery-white in color, similar in chemical and physical properties, and form refractory oxides that are practically insoluble in water.

These metals received the name “rare earth” due to the fact that they are rarely found in the earth’s crust, and these metals are also difficult to mine and industrially produce.

The most commonly used additives in tungsten welding electrodes are lanthanum, cerium, yttrium, zirconium and thorium.