One type of final metal surface treatment is grinding. It involves removing the surface layer using various tools using abrasive materials. Metal grinding allows you to solve the following problems:

- remove all remaining irregularities after preliminary finishing;

- achieve high accuracy of the required dimensions of the part (geometric dimensions, internal and external diameters, compliance with the given shape of the surface of higher orders: parabola, ellipsoid, and so on);

- giving the detail aesthetic appeal.

Surface grinding work on metal in Moscow

Metal grinding in Moscow is actively developing.

In modern production facilities you practically no longer see old machine tools from the USSR era: they are being replaced by compact modern equipment. It not only allows you to perform metal grinding with better quality, but also has low energy consumption. The possibilities of metal grinding on machines are also changing for the better. If a couple of decades ago machines could only process flat surfaces, today metal profile grinding also works on the surfaces of shaped workpieces.

Gear grinding

Gears are part of a wide variety of mechanisms. The complexity of the shape of the working part determines that special grinding equipment has to be used. Among the features of this technology, we note the following points:

- The profile of the ring gear is processed.

- The circle changes to the size of the tooth involute.

- Special machines are suitable for working with gears.

Gear grinding

Often the tooth surface is hardened, which makes the machining process significantly more complicated.

Advertisements for the request “grinding work in Moscow”

You can find out a lot about grinding metal surfaces in Moscow and the price of this service on the Internet.

For example, on message boards for services and vacancies. Thematic catalogs offer information about metal grinding services. But accessing these resources is like playing the lottery, where the winning cry is “bingo!” doesn't always sound like that. If you require complex work, for example, grinding small metal parts, it is better to contact a company that has a personal website with clear information and prices for services.

Creation proportions

A paste is most often applied to a metal polishing cloth. Most pastes contain 60% abrasive, 40% binder and 2% process activating additive.

Various compounds are used in chemical processing:

- 2/3 hydrochloric acid, 1/3 sulfuric acid and dye;

- 30 parts of phosphoric acid, 5 parts each of hydrochloric and nitric acid, 0.5 parts each of disodium acetic acid and sulfosalicylic acid, 1 part glycerin, 0.1 part benzyl alcohol;

- 20-30% phosphoric acid, 4% hydrochloric and 4-5% nitric acid, 1.5% methyl orange, the rest is water.

The first solution is heated to 70°C; three minutes are enough for processing. The temperature of the second mixture is 80°C, the processing time is 3 minutes. The third solution is heated to 25°C, the part is kept in it for 5-10 minutes.

Solutions for electrochemical polishing:

- 730 g phosphoric and 700 g sulfuric acid, 4-6 g triethanolamine, 1 g catapine;

- orthophosphoric and sulfuric acid in a ratio of 65% to 15%, 12% glycerin, 5% chromic anhydride, water.

Services for grinding and polishing metal products

Along with grinding work on metal, the capital's workshops also perform polishing work, after which the products acquire a pleasant metallic shine and even gloss. Polishing of small metal parts is carried out in cases where there is no need to apply coatings to its surface. For example, along with aluminum grinding, polishing services can be ordered as ancillary services. Along with grinding and polishing of metal, its satin finish stands out - a treatment after which the material acquires a satin shine.

How not to make a mistake with speed

The main parameter on which the selected speed mode depends is the material. Let's look at the table:

| Processed material | Linear speed of circles, m/s | |

| grinding | polishing | |

| Gold, aluminum, lead, tin and their alloys | 10 — 20 | 18 — 25 |

| Copper, brass, silver, bronze | 13 — 18 | 20 — 30 |

| Stainless steel | 15 — 25 | 25 — 35 |

Surface grinding methods

Metal grinding - services are quite diverse.

The effective tool for performing this type of work can be the periphery or the end of the circle. When circularly grinding metal, high productivity of the equipment is guaranteed, however, during contact with the metal, significant heating occurs, which can affect the accuracy of the operation. According to the method of performing flat metal grinding with a machine, single-pass and double-pass processing are distinguished. In the first case, the machine operates vertically along the entire length of the workpiece and performs the operation in one go. In the second, both ends of the part are processed synchronously, and one pass of the tool is not enough for this.

There is also deep-feed grinding of metal parts with a minimum feed speed. With this method, the allowance is removed with each stroke of the tool, so its replacement is required quite often.

In addition to dry metal grinding, there is wet grinding, which uses water and waterproof sanding paper. But this technology is not so popular, since there is a risk of corrosion on the metal surface.

Abrasives used

The basis of any metal grinding tool is an abrasive material. It consists of grains of a certain size, held together with a special adhesive. Depending on the size of the crumb, an abrasive tool is used for processing with a given precision. Abrasive tools are manufactured in the form of:

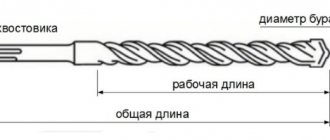

- circle (the range of diameters is quite wide);

- shaft (for internal processing);

- tape or circular tape;

- sheets (paper or special fabric can be used as a backing).

Natural (natural) and artificial stone are used as abrasive chips. At industrial enterprises and processing shops, abrasive tools with artificial material are used. It has improved physical and mechanical characteristics.

Did you like the article? Be sure to share your opinion in the comments section!

Surface grinding work in neighboring regions

Flat grinding services are also offered in regions adjacent to the Moscow region, and at a lower price.

Many customers, attracted by the opportunity to save money, try to entrust them to enterprises located in other regions, but inevitably lose. The reason is simple: gasoline and freight prices continue to rise steadily. To order cheap metal polishing, you don’t have to go anywhere. The equipment of our workshop, work on “native” and not on rented premises allows us to offer very comfortable prices.

Sanding flat surfaces

Flat grinding is one of the simplest technologies, since it is carried out only by the movement of abrasive nozzles, without rotation of other elements. This method is used for the manufacture of presses and other flat products. The technology used has its own characteristics:

- the metal workpiece is placed on a special table and securely fastened to it mechanically or using a magnet;

- the workpiece is mounted on an electromagnetic table or using machine tools;

- The main movement is taken over by abrasive attachments.

Thanks to this technology, it is possible to grind the most complex shapes. During operation, to increase efficiency, you can pour coolant into the contact point between the tool and the metal product.

Application area

The operating principle of laser metal polishing has maximum effect and industrial application when:

- Cleaning pipes in nuclear power facilities, oil and gas complex, housing and communal services;

- Laser cleaning of large building structures. Currently, the ineffective sandblasting method is used for such work;

- Cleaning the internal walls of heat exchanger pipes. Nowadays, human resources are used for these purposes at nuclear power plants, and laser grinding units will minimize human participation in such actions.

- Cleaning the surfaces of turbine blades. Now, for such work, the blades have to be dismantled. Mobile laser units will allow cleaning on site, without dismantling;

- Cleaning elements of shut-off and control valves. The laser method allows you to selectively get rid of the old coating of the ball and preserve its geometric parameters;

- Cleaning threaded connections. Additional cleaning is often required after threading. The laser easily copes with the task.

IMA Information

The Italian Machinery Association offers machines that combine devices that perform both cleaning and grinding, deburring, deburring, scale and surface polishing. You can choose such a device based on your production processes and the parameters of the material used, as well as the surface quality requirements of the client. Check out the offer of Costa Levigatrici devices in our catalogue.

The catalog presents Costa Levigatrici cleaning equipment of the MD (standard and universal devices), MB (one-pass cleaning) and WD (wet cleaning) series. It can be effectively used in any sheet metal processing plant, significantly increasing productivity and eliminating time-consuming manual labor.

Such devices quickly and efficiently perform polishing, grinding and deburring, as well as rounding edges up to 2 mm and removing the black layer. The equipment is designed both for processing cut parts and sheets, as well as for coil-to-coil, sheet-to-coil, coil-to-sheet technologies.

If you are interested in other engineering materials on the selection of equipment and technologies, we bring to your attention the following articles:

Do you have other questions or needs? Contact us immediately by phone or email, or visit any of our locations.

Do you need repair, installation, machine restart services or operator training for your equipment? IMA's customer service has the extensive experience and knowledge to solve any problem.

Nozzle selection

Concrete, which has high strength and excellent abrasive resistance, cannot be cut with nozzles equipped with corundum and carbide compounds. This tool can be used to process metals and other materials that are softer than concrete. For cutting concrete, diamond chips obtained artificially are used, which have a very high hardness.

Layers of fine technical diamond applied along the edge of the hardened disk are processed sequentially one after another, which increases the service life of the diamond disk. There are several types of diamond blades for cutting concrete:

- continuous, where the layer of diamond chips is continuously distributed over the entire edge;

- segmented, having a solid base, but an edge consisting of separate segments;

- turbo - diamond disk (combined) - the principle of operation is similar to the segment one, but has a more durable reinforced diamond edge capable of cutting reinforced concrete.

Diamond turbo disc for reinforced concrete Extra Max (230x22.2 mm.). Photo VseInstruments.ru

Diamond chips are attached to the segments and the edge of the disk in the following basic ways.

- Soldering with silver solder. This fastening method allows the diamond blade and grinder to work effectively when cutting concrete using the wet method (cooling with water).

- Laser welding. This welding method allows for high-quality fastening of the smallest particles of diamond chips. The diamond blade, after forming a cutting edge in this way, is used for the dry method (without cooling with water) of cutting concrete.

A solid edge diamond blade is best used on stationary equipment that has its own water cooling system.

The existing radial clearances in the segment disks allow better heat removal from the cutting zone, which makes it possible to perform dry cutting with them. The formation of a diamond edge on segmented wheels is usually done by laser welding, without a bonding alloy such as silver solder. This limits their use for cutting reinforced concrete due to the occurrence of hard (without damping) impact loads leading to edge breakage.

Turbo diamond discs are versatile in use. They are used in different technologies for cutting concrete, both wet and dry.

The wavy cutting edge provides additional heat removal from the working area, which is important for dry cutting. Unlike segmented turbos, diamond blades have a softer cutting action, which allows them to react less critically to the reinforcement in concrete and to obtain a cutting edge without chipping