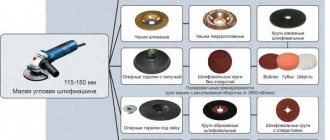

Angle grinder (angle grinder)

A wide selection of power tools on the Russian market is designed to facilitate various types of manual work. If in the professional sphere the purchase of specialized equipment is simply necessary, then in everyday life it is not always rational to spend money on an expensive tool, which after completing a certain job may not be useful at all. The most popular power tool is the angle grinder (angle grinder). Its scope of application is not limited to metal processing - grinding wood with a grinder is done using special attachments.

Attachment for grinder for sanding wood - types and application

The most popular tool for sanding wood is the grinder.

This device has many advantages compared to other equipment designed for wood processing.

The grinder is characterized by high productivity, provides high speed and excellent grinding quality.

Using an angle grinder, you can perform the entire range of wood sanding operations: from roughing to surface polishing.

The required effect can be achieved by attaching an attachment to a grinder for sanding wood. There are a lot of attachments, and those uninitiated in the intricacies of the work can make a mistake in their choice, which will inevitably affect the quality of grinding. What attachments exist for wood processing, how to choose them and use them correctly, we’ll talk about this.

What you need to pay attention to when choosing an attachment for an angle grinder

When choosing a grinding disc, you need to take into account the power and size of the grinder.

For devices of different sizes, circles are selected that are designed for a certain rotation speed.

The main rule when choosing attachments for an angle grinder is that the wheel for sanding wood must have a certain thickness; the use of wheels of small thickness is not allowed.

What parameters are decisive when choosing a disk:

- External diameter. The larger the size, the higher the processing speed and the longer the service life.

- Landing diameter. To attach a larger circle, use a special adapter for an angle grinder, which has a mounting hole of the required size.

- Disc thickness. The larger it is, the longer the nozzle will last.

- Grain. The size of the fractions is selected in accordance with the type of processing.

When working with an angle grinder, you must take precautions; inept and improper handling of the tool can lead to injury.

High rotation speed and heavy load on the device can cause the disc to break into pieces, which can injure a person. Before work, you need to check the correct position of the circle and the strength of its fastening.

All movements of the grinder should be made smoothly and softly without vibration.

The processing of a wooden house takes place in stages: first, rough surface treatment is carried out, then finishing, and at the final stage, finishing sanding is performed. Accordingly, the nozzles presented on the market today are divided into varieties that differ in purpose, shape and material of manufacture.

Coarse attachments

There are several types of attachments used for roughing wood. Their main purpose is to remove large inclusions, bark and knots from the wood surface.

- Grinding wheels structurally consist of a disk with soldered metal wires. The steel bristles can be positioned parallel or perpendicular to the tool. The wheels do an excellent job not only with rough processing, but also with peeling off old paint or varnish.

- Cord brushes are a disk with metal fibers, horizontal. An abrasive brush is suitable for rough sanding and surface leveling.

- End discs are used for processing bevel cuts and leveling the ends of logs.

- Metal brushes consist of bristles made of stiff wire, which are positioned perpendicular to the tool. Used for initial treatment and removal of old paintwork.

Attachments for gentle grinding and polishing

- Flap attachments for angle grinders are the most common. They consist of many trapezoidal petals made of abrasive material, which overlap each other. Thanks to this design, the nozzle wears out slowly. Depending on the degree of processing, you can choose discs with different grain sizes.

- Grinding wheels are made from sandpaper, felt, sponge, thick fabric and are usually sold in a set.

The discs are equipped with Velcro, with which they are secured to the plate attachment. The set for sanding wood consists of five circles made of the same material. They are very convenient to use; the worn disk is easily removed from the main nozzle, and another abrasive is placed in its place. Velcro wheels are used for fine and finishing sanding. You can polish wood with soft fabric and felt discs by applying a special wax-based polishing paste to the surface. - The cup attachments are a nylon brush consisting of many bristles of abrasive nylon. Used for fine sanding of wood.

Grinding machines

In addition to the grinder, other equipment is used for abrasive grinding. Today there is a wide range of different grinding machines:

- Belt machine for sanding timber. The machine performs grinding using an abrasive belt that constantly rotates on two rollers. The rotation speed depends on the power of the device. The machine has high productivity and copes well with large volumes of sanding flat surfaces. Great for roughing and removing old paint.

- Eccentric sander for rounded logs. The machine can work on both flat and curved surfaces. It is equipped with a round sole on which the abrasive is attached with Velcro. Used for fine sanding and polishing of wood.

- The vibrating machine for grinding log frames has a rectangular base. The machine can work on a flat surface, and it is also convenient to process the corners of a log house. Features high quality grinding.

Drill for sanding wood

To sand a wooden house, you can use a regular drill. With this tool you can quite easily and efficiently perform a small amount of grinding work.

However, it is not recommended to use a drill for large areas. The drill is also equipped with grinding wheels, in the center of which there is a pin for installation in the chuck.

There are several types of drill attachments for grinding:

- Flat, made in the form of a circle on which sanding paper is glued. The attachments are either rigid with Velcro or flexible with a rubber base.

- Petal type, consisting of abrasive petals, similar to attachments on a grinder. You need to be careful when working with them. If handled carelessly, petal attachments can leave transverse lines on the wood that will appear through the varnish coating.

- Drum nozzles are cylindrical in shape. The sanding belt is attached to the nozzle using a bolt. The drum is mainly used for grinding the ends of wooden workpieces.

Other grinding accessories

Another tool used for sanding wood is a Dremel. This is a mini universal device.

With its help, you can perform a wide variety of woodworking tasks with high precision: grinding, polishing, engraving, milling, drilling.

It is used extremely rarely for grinding large parts, but if you need to apply a drawing or engraving on a wooden surface, then it has no equal in this work.

When sanding wood with a grinder or drill, marks from the sanding discs often remain on the surface in the form of lines, grooves, and depressions.

Very often this happens due to inept handling of the tool and when working at high speeds.

It is quite difficult to get rid of these marks; you have to sand the surface again by hand.

For manual grinding, you can use a simple device that our ancestors used to grind - a sanding block.

It can be made from a rectangular wooden plank.

The board must be wrapped in sandpaper and secured with nails or screws.

During grinding, a lot of dust is generated, which settles not only on the surface, but also enters the respiratory system.

A log sanding mask, which is made from a special fabric that does not allow dust particles to pass through, will help protect your nose and mouth from dust.

Self-grinding mistakes

Most home craftsmen sand a wooden house with a household-grade grinder, which is not easy to use, has little power, and overheats quickly. A household appliance is not capable of sanding wood at a good quality level.

Professional equipment is expensive, so not everyone can afford it.

But even if you buy such a model, you need to know how to use it, otherwise, if handled ineptly, high-quality grinding will still not work.

Many people make the mistake of working at high speeds, pressing hard on the tool, which leads to damage to the surface.

The wrong choice of nozzles also does not lead to anything good. In the best case, the surface will simply be poorly polished, and in the worst case, cases of injury cannot be ruled out.

Types of attachments for working with wood and grinding wheels for angle grinders (angle grinders)

An angle grinder (angle grinder) or grinder is a tool necessary in every home. It is used not only for cutting and grinding wood and metal, but also for other work. To do this, use a variety of auxiliary tools . Let's look at what types of attachments there are for angle grinders and what they are used for.

Attachments for grinding wood on an angle grinder come in different shapes, purposes and materials. The wooden surface must first be roughened . And only after this the final processing is carried out.

The grinder attachments for grinding are as follows:

- Peeling circle. It is used if it is necessary to remove a layer of old paint. Can also be used on varnished surfaces. The disc itself is covered with metal bristles made of elastic wire. In structures, the location of steel bristles can be different.

- A cord brush is also a wire attachment. Used for rough grinding and removing irregularities. You can also work with metal, removing rust and old paintwork from it.

- End disc - an attachment for leveling a product from the end. This type of processing will be needed for bevel cuts and the edges of the workpiece. The technique is similar to working with a file.

Using a grinder and special accessories for it, you can restore furniture coated with varnish or paint. Thanks to this cleaning, the thickness of the wooden surface remains virtually unchanged . But if you paint the furniture again, the furniture will take on a beautiful and impressive look.

Milling

Milling attachments are produced in various designs; a distinctive feature is the size of the abrasive grains. According to their intended purpose during work, such attachments are similar to rasps; the use of an angle grinder allows you to increase the speed of processing the material. Craftsmen use these devices for final processing of wood.

Milling cutter for grinder

Special cutters are produced, there is an abundance of assortment on the market, each tool differs in purpose and features. Main areas of application:

- preliminary alignment of edges;

- sawing or cutting out a bowl from small-section blanks;

- groove sampling.

When working with milling and grinding attachments with a grinder, it is prohibited to remove the protective device - the tool casing. Each tool has a technical purpose and instructions, which clearly describe the materials suitable for use and the operating modes of the tool.

Grinding

The main purpose of the grinder is grinding. For materials processing work, there are grinding wheels, cord brushes, end and flap devices. Cord brushes are used for sanding rough wood, removing irregularities, and giving the workpiece the required dimensions. Processing of the ends of lumber is carried out by using end discs.

Sanding attachment

Giving a perfectly smooth surface and shine to wooden workpieces is done by the polishing process.

When polishing or grinding with an angle grinder, a varying number of attachments are used, such as felt, fine-grit sandpaper or a sponge.

Such designs are widely used in the form of Velcro, on which the base for the grinder is attached. During the process, the used part can be easily changed without using a special key to replace the disk.

Sandpaper

The most universal tools for working with wood are sandpaper or a sanding wheel. Main areas of application:

- parquet cycling;

- processing of ends and edges of wood;

- grinding;

- cleaning the wooden surface before painting.

Sandpaper attachment for an angle grinder

The design of the attachment for the grinder is a support that is attached to the grinder; the sandpaper is attached with Velcro on top of the tool. This fastening method allows you to easily replace the used element and select the grain size.

Velcro attachment

The main repurpose of easy-to-remove kits is to polish various materials. The tool can be used when working with stone, metal, wood and other materials. Main parameters, characteristics of the Velcro attachment:

- The basis is taken on a platform, the diameter of which is generally 125 mm, fastening occurs using special Velcro;

- fastening occurs on the mounting platform, which is fixed to the angle grinder;

- The grain size of sandpaper for an angle grinder varies, from coarse, marked p40, to fine, p220.

Velcro attachment

There are varieties with holes, they are adapted for vibratory grinding devices. Before purchasing, you need to pay attention to the diameter and grain size.

Petal nozzle

Wooden surfaces can be easily sanded using flap attachments. The component part has sandpaper superimposed on each other over the entire area of the tool. Due to the dense design and proper use, it is possible to use the kit for a long time, unlike its analogues.

The petal attachment on the grinder is used in an increasing manner. At the first stage of processing, a set of coarse abrasive is used, then medium and fine sections.

Metal brushes

Many craftsmen believe that metal brushes are used to remove rust and oxides only from steel products. In refutation of this fact, products made from brass wire are popular in wood processing. The relatively low price and increased service life make the brush a direct competitor to abrasive attachments.

The main purpose is to remove paint and varnish from the surface of the material.

It should be understood that the top layer of paint can be removed by exposure to temperature; a brush is used when working in hard-to-reach places. It is also possible to brush wood using a grinder with a brush.

The process involves artificial aging of surfaces in the production of unique interior products. The surface is processed with soft particles of wood, irregularities and temporary rings stand out against the general background.

Recommendations for selection

When choosing a polishing wheel for an angle grinder, you should consider several factors:

- outer diameter (larger sizes speed up the processing process and increase service life);

- landing diameter;

- thickness (the larger it is, the longer the circle will last);

- grain size (it must be selected taking into account the type of processing: for rough work - coarse abrasive, for soft work - fine).

Important aspects when working with an angle grinder

The appropriate attachments must be selected for each tool model . Before starting work, you must ensure that the disk is properly secured. The movement of the tool along the surface should be smooth. In this case there should be no vibration.

When sanding wood with an angle grinder, you should use thick discs. Due to the high rotation speed and the resulting load, the circle may break, which, in turn, leads to injury.

There are various types of assistive devices. Each specialist will be able to choose the tool that is right for him. Thanks to this, the work will be done efficiently, quickly, without using much effort.

Recommendations for selection

When choosing a polishing wheel for an angle grinder, you should consider several factors:

- outer diameter (larger sizes speed up the processing process and increase service life);

- landing diameter;

- thickness (the larger it is, the longer the circle will last);

- grain size (it must be selected taking into account the type of processing: for rough work - coarse abrasive, for soft work - fine).

When choosing a wheel, you also need to consider the size of the tool. The circle is secured with a special nut. When working with an angle grinder, it is important to strictly follow safety precautions. Circles should be chosen from the factory.

What kind of circles are there for cutting wood?

Processing wood with a grinder is a safe process, unlike cutting. The process is very dangerous; the tool is not intended for cutting wood. Soft woods are processed with an angle grinder attachment with extreme caution, because the tool may jam and be torn out of your hands. The cutting process at high speeds implies a high temperature effect on the disc material, as a result of which it can simply shatter into small pieces.

Despite the fact that the grinder is not suitable for cutting wood products, manufacturers offer various cutting discs for use. It is recommended to use the grinder as a stationary station when sawing wood.

Circular saws

Circular saw attachments are dangerous when using an angle grinder. The diameter of the circle must be selected based on the parameters and dimensions of the tool in order to be able to use a protective casing.

Circular saw attachment

There are more expensive modifications of circular nozzles; they have anti-jamming protection. The design has teeth set in different directions, smaller in size, the price of such a device is different, but you should not save on your health.

Chainsaws

The chain type of nozzles has a safer design. The sawing disc, which uses a chain from a chainsaw, eliminates jamming of the tool and reduces the risk of injury during work. The design has a system that allows the main element, which is attached to the angle grinder, to continue rotating, and the chain can remain stationary.

Chain disks come in many different modifications, with the help of which it is possible to carry out gardening work or use it for collecting small firewood. A disk of a chain design can be used instead of a peeling disk for cutting out cups in a log or removing a layer of bark.

Saws with few teeth

Increased safety when working with wood is achieved by using discs with a small number of teeth. Small discs usually have 3 teeth, those with a diameter of more than 180 mm - 4 teeth. This type of cutting disc is used for cutting both along and across the grain of wood. The saw wheel makes it possible to cut grooves and make tenons of various shapes.

Four tooth disc

It should be understood that when working with an angle grinder, you must adhere to technical regulations. There is no need to install larger diameter discs bypassing the protective casing; smaller discs can be used without loss of cutting properties.

Tungsten carbide discs

Tungsten carbide cutting discs have been produced relatively recently and are popular when working with an angle grinder. The universal tool is not equipped with teeth; instead of cutting elements, there are cutouts in the disk. The operation of the tool is most safe when cutting wood; it eliminates jamming when nails or thick rods of wood hit. The appearance is similar to a diamond blade for cutting concrete, the purpose is indicated on the packaging or instructions.

Tungsten Carbide Disc

The price of such a disk is high, but it is justified. It is worth overpaying for a modified tool rather than going broke on the sad consequences of using a regular saw blade.

How to use?

The grinder has a simple technical device. It is equipped with an electric motor connected to an angular gearbox. It ensures shaft rotation at high speeds of up to 1000 rpm (when working with wood, this speed is optimal). Powerful models require a three-phase power source; for household use, a standard power source with a voltage of 220 V is suitable. You have to work with the tool with a single point of support, holding the angle grinder suspended. Misalignment can lead to jerking, so a novice master needs to acquire serious skills for work.

Compliance with safety precautions will allow you to work correctly with the machine, namely:

- inattention in this matter is unacceptable;

- in order to prevent injuries when using an angle grinder, the protective casing is not removed from the disk;

- do not work with wood using strong feed;

- Before starting operations, be sure to wear goggles and thick gloves; protect hands with long sleeves; clothing should not be light, as sparks may fall on the body;

- It is important to take breaks during work so that your hands do not get tired and the machine does not slip.

It is convenient to work with a tool that has a support handle. The safest are those grinders that are equipped with a chainsaw chain. If the machine suddenly jams, the disc continues to rotate, which minimizes the risk of injury. It is also important to move the machine smoothly across the floor surface, avoiding vibration. Before starting work, you should once again make sure that the circle is securely and accurately attached to the axis.

It is better to start mastering the tool with cutters with small teeth. The smaller the teeth, the easier and safer the operations. During operation, any disk wears out, the diameter of the circle changes, and replacement is necessary. Change discs when switching from one type of processing to another during the grinding process.

It also happens that the disk is cracked or the casing is broken. It is imperative to remove and replace such a disk; further work is dangerous.

You should follow the following step-by-step instructions:

- disconnect the tool from the network, stop rotating the shaft by pressing the locking button, only after this is it possible to unscrew the disk and remove it;

- unscrew the retaining nut - the stopper is removed using a wrench; if the nut is tightened too tightly on the disk, you will need a gas wrench, which is heated and cooled before use, and the remaining part of the disk is cut out with a hacksaw;

- remove the unusable disc;

- put on a new one and secure it with a lock nut, firmly fix the thread on the accurately installed disk, after which you can continue working.

For details on the intricacies of sanding wood with a grinder, watch the video below.

Sanding wooden floors: tools and work progress

Wood flooring is a great way to create a warm and cozy atmosphere in your home. Especially if parquet or tongue and groove hardwood boards are laid. But in order for the wood fibers to acquire a characteristic pattern and become very smooth, you need to work hard with the tool after laying a new or restoring an old coating.

We will talk about how to sand a wooden floor and then apply varnish. We’ll also tell you what tools are used for processing, whether you can do it yourself, and what to pay attention to when carrying out the work.

Preparatory work

First, you need to carry out a number of preparatory measures so that nothing distracts you during the work:

- if the old floor is being restored, then it will be necessary to remove the worn-out coating using special means;

- prepare the room. Even if only part of the floor is being renovated, all the furniture will still need to be removed. If possible, protect windows and doors from dust by covering them with film;

- Inspect the floor covering for protruding nails, screws and other foreign objects. If any, recess the protruding fasteners into the floor surface;

- Next you need to check if there are any deep cracks, dents or holes in the surface. Any defects found must be covered with a special wood putty. Start sanding only after the material has completely dried!

Selecting a tool

Several types of tools are used for wood processing, and each of them has its own characteristics. It is worth noting that to get an ideal result you cannot limit yourself to one device. This is due to the fact that there are always hard-to-reach places in the rooms into which a large tool cannot fit. In such cases, manual finishing is carried out using sandpaper.

Angle grinder (angle grinder)

The popular name for this instrument is grinder. This multi-purpose device is used for various purposes, including grinding. And if you put on a petal attachment, you can easily remove old varnish or paint. To perform floor sanding yourself, an angle grinder is a universal machine, but it also has disadvantages.

When working with an angle grinder, a huge amount of dust is generated that flies in all directions. For small areas or outdoor work, this is a good option, but for large amounts of work indoors, we advise you to take a closer look at other options.

It is advisable that the grinder has a rotation speed regulator, otherwise the wood may burn at maximum speed.

Belt sander

It is a small combine with a moving sanding belt. That is, the device itself moves forward along the board, and the user only needs to move it back in time. The grinder is much heavier than an angle grinder, so working with it is not as comfortable. But such devices are equipped with dust collectors, which significantly reduce room pollution.

When you connect a construction vacuum cleaner, there is practically no debris left behind.

Considering that the working surface of this unit is long and straight, when processing an uneven floor, the recessed part of the board will remain unaffected. This means that the tape machine is more focused on perfectly flat floors. When working with it, you need to monitor the filling of the dust collector, otherwise the tool will begin to heat up and the speed will decrease.

Random orbital sander

The device received its name due to the peculiarity of the rotation of the working surface. Unlike a grinder, the moving part of an eccentric machine rotates with an amplitude of vibration of the disk of several millimeters, writing out a certain orbit. For this, people call it an orbital sander.

Don't buy cheap sanding discs and attachments. If overheated or hit, they can fall off and fly off at breakneck speed!

This feature of rotation allows you to obtain a more even and smooth surface. Such devices have an interesting mechanism for suctioning wood dust.

Several holes are made in the working disk through which waste is sucked in by a vacuum cleaner. The only disadvantage of an orbital sander is the high cost of attachments for attaching discs.

But overall, it’s an excellent unit for home use with a minimum of drawbacks.

Drum type machine

This is already a class of professional equipment that is used on large construction sites. This machine looks like a lawn mower.

It also has control levers and wheels for moving around the floor. If necessary, you can rent the device from specialized companies.

Typically, drum machines are used for sanding parquet floors and tongue and groove boards where a perfectly flat surface is required.

Grinding process

So, you have decided on the tool, prepared the room and surface, purchased the necessary consumables, it’s time to get to work. But first you need to think about your own safety.

Don't forget to wear protective gloves, goggles, a respirator and, if possible, a painting overall, and then no dust will reach you.

The fine dust that is formed during work is very insidious, so the use of a mask is mandatory.

Whichever tool you choose, the principle of operation will be approximately the same. The grinding technology takes place in several stages:

- Rough processing. To do this, you will need a coarse sanding sheet, marked P36 or P40. If you are restoring an old plank floor, the surface of which is quite rough, then you can take a larger one - P20-24. Having installed a tape or disk with a coarse abrasive, you need to walk over the entire surface 2-4 times. To obtain a flat surface, it is necessary that each strip of passage slightly extends onto the sanded area. Watch the force of pressing on the tool. If the pressure is low, the treatment will be insufficient, and if the pressure is too high, the engine of the device will begin to overheat.

- The next step is to install a finer grit sandpaper, P60 or P80, and perform 1-2 passes. During work, monitor the wear of the working surface and replace the sanding sheets in a timely manner. Before treating a pine floor, it is recommended to remove drops of resin using alcohol, gasoline or white spirit.

- The third final stage is finishing sanding the wooden floor. Install the finest sandpaper, P100 or P120, and also go through it 1-2 times.

If a flat tongue-and-groove board is laid in the room, then the first stage can be skipped. After this, the floor boards are ready for application of a protective coating.

Surface belt sanders

The most productive are surface belt grinders. They use abrasive sandpaper glued into a tape (Fig. 11). All such tools are equipped with a small bag for collecting wood dust. During operation, more than 80% of the dust generated accumulates inside this bag.

Rice. 11 Belt sander

Manufacturers recommend intermittent operation: grind for 5...7 minutes, and then give the tool a break. Even the presence of a fan inside does not effectively cool the device. After a three-minute break, you can continue working.

Manufacturers supply the tool with auxiliary devices with which you can fix the grinding machine in space (Fig. 12).

Rice. 12 Installing the belt sander on the table

Craftsmen make special stands for belt sanders, with the help of which the scope of application of the devices is significantly expanded (Fig. 13). With the help of such options, it becomes possible to polish the ends of products with high quality. The underframe itself can be fixed at any angle, which will allow for high-quality processing.

Rice. 13 Stand for belt sander

The industry produces stationary belt sanders (Fig. 14). They are called grinders. With the help of such devices, it becomes possible to grind products by resting them on a special support table. A grinder is similar in many ways to a belt sander. In fact, it is a stationary machine where you can carry out quite complex wood finishing operations.

Rice. 14 Grinder

Sanding wood with an angle grinder

The modern market is flooded with various types of power tools, each designed for its own purpose. Purchasing expensive equipment is advisable in the professional field. In everyday life, you can use the same devices for different purposes and not spend extra money.

Thus, the so-called grinder is often used in sanding wood. Or an angle grinder, designated by the abbreviation angle grinder.

With the help of special attachments, a tool originally intended for metal processing is transformed into a wood grinder.

How to choose the right grinding wheel on an angle grinder for wood

There are various grinders, in different sizes. Accordingly, you need to select a disk according to its size. To secure the disk, the tool has a special nut. You shouldn’t take risks and buy “handicraft” disks. Buy factory wheels designed for a specific model of grinder.

Types of attachments for grinders for sanding wood

There are several types of disks, differing in shape, material and purpose.

The stages of sanding a wooden workpiece are

- Rough processing

- Finish grinding

- Final sanding

Cord brush

The initial stage of wood processing is rough sanding. For rough grinding, so-called cord brushes are used. Cord brush

Designed for removing unevenness from the surface of wood. And also, for performing rough grinding of the surface, as a result of which the wooden workpiece takes on its final shape

Roughing wheel

In order to remove old coating from the surface of wood, including coating that has been painted several times, a grinder attachment called a sanding wheel is suitable.

Roughing wheel

consists of a disc with steel bristles. The location of the metal wire on the disk may be different.

Depending on the desired effect, the metal bristles are placed along the entire perimeter of the disc parallel to the tool or perpendicular to the segment - as in a regular brush.

End disc

For processing the edges of wooden workpieces and bevel cuts, special end disks

. The processing technique is similar to filing, but much more effective than hand tools.

Finish sanding wood with an angle grinder

The most common type of attachment on an angle grinder for sanding wood is a flap disc

.

True to its name, the design of the disc surface consists of sandpaper petals, trapezoidal in shape. The petals overlap, covering three quarters of the previous row.

Using a petal attachment, a soft treatment of the wooden surface is performed.

The disc varies in grain size, depending on the desired degree of surface treatment.

Final sanding of wood with an angle grinder

Relatively recently, a universal attachment for angle grinders appeared on the market. The so-called sticky disc is highly functional.

Replaceable discs with the desired grain size are attached to the sticky base of the nozzle. Changing abrasives is quick and easy. There is no need to change or remove the main nozzle, secured with a nut. First, purchase a sticky attachment for grinding on an angle grinder and replace it with replaceable abrasive discs of various grain sizes.

The final result of grinding is achieved by sequential transition of abrasives, from coarse grains, sequentially, to smaller ones

When is the best time to sand?

There are a lot of possible answers to this question. Traditionally, the frame is sanded after at least the main shrinkage has passed. During this time, the log dries out and it becomes easier to work with. It is extremely difficult to remove even a thin layer from raw wood. If you need to level it, it will take a lot of time, money for disks and effort.

On the other hand, if you have a frame made of dried timber and logs, then you can sand and process it right away. In this case, having placed the frame under the roof, it is sanded, immediately treated with impregnations and left to shrink in this form. This is done infrequently, although no one forbids it. They usually act according to the usual scheme.

The log house is polished after it has settled