We guarantee high quality services at a reasonable price.

We complete tasks in the shortest possible time with a guarantee of results.

DEAR CLIENTS!

Our specialists will be happy to provide you with comprehensive information about this service by phone or during a meeting at the site. You can leave a request and we will call you back, or contact us and arrange a meeting. Our contacts:

063-786-00-39

Kyiv, st. Lysogorskaya, 29A

In the construction of various objects, welding is used to firmly attach one part to another. Work can be carried out indoors, outdoors and underwater. It is very important for welders to consider what the weather conditions are like outside on a particular day. The safety of the specialist, compliance with safety regulations and the quality of the work performed depend on this.

Is it possible to cook in the rain with electric welding?

1.1. Personnel who are at least 18 years old, who have undergone special training, have a certificate for the right to work, including electrical safety group III, and who have no contraindications due to health conditions, are allowed to perform manual electric welding work.

1.2. Electric welders must undergo a mandatory medical examination upon entry to work and periodic medical examinations at least once every 12 months.

1.3. All new hires must undergo induction training at the labor safety service. The results are recorded in the logbook for introductory training on labor protection. After this, the HR department completes the final registration of the newly admitted employee and sends him to the place of work.

1.4. Every new hire must undergo initial training on labor safety in the workplace. All employees undergo repeated training at least twice every 6 months. The briefing is carried out by the head of the department. The results of the briefing are recorded in a journal.

1.5. Daily permission to work is issued in a work order - permission for hot work.

1.6. Upon entry to work and periodically at least once every 12 months, electric welders must undergo a knowledge test on occupational safety issues according to a program approved by the management of the enterprise.

1.7. In the process of performing work, electric welders are required to comply with the requirements of internal labor regulations, work and rest regimes.

1.8. In the course of daily production activities, an electric welder may be exposed to harmful and dangerous production factors:

- increased voltage in the electrical circuit, the closure of which can pass through the worker’s body;

- increased gas and dust levels in the air in the working area;

- increased levels of ultraviolet, visible and infrared radiation;

- increased air temperature in the working area and molten metal.

1.9. While working, electric welders must observe the rules of personal hygiene and wearing special clothing, special shoes, and using other personal protective equipment.

1.10. Overalls and other personal protective equipment are issued in accordance with Standard Industry Standards (see State Register of Inter-Galuzev and Galuzev regulations on the protection of goods).

1.11. Electric welders must not allow deviations from technological standards when carrying out work, know and comply with the requirements of this labor protection instruction, as well as the manufacturer’s instructions for the operation of equipment, accessories, and tools used in the work process.

1.12. The victim or an eyewitness to the accident must immediately notify the work manager of every production-related accident.

The work manager must organize first aid for the victim, transport him to a medical facility, and inform the owner and the labor protection service about this.

To investigate an accident, it is necessary to preserve the situation at the workplace and the condition of the equipment as they were at the time of the incident, unless this threatens the life and health of others and does not lead to an accident.

1.13. Electric welders must know how to provide first aid, how to transport a victim, know the location and contents of the first aid kit, and be able to use the equipment in the first aid kit.

1.14. Persons who violate labor safety instructions are subject to disciplinary and financial liability and an extraordinary test of knowledge about labor protection.

Safety requirements before starting work

2.1. Check the availability and serviceability of personal protective equipment, put them on, fasten the sleeve cuffs of the suit. In this case, the jacket should not be tucked into the trousers, and the trousers should be pulled out over the boots (felt boots).

2.2. Present to the work manager a certificate confirming knowledge of safe work methods.

2.3. Receive a task to perform the work from the manager and a work permit to carry out the work.

2.5. Inspect and prepare the workplace and approaches to it for compliance with safety requirements:

- remove all unnecessary items without cluttering the aisles;

- check the condition of the floor at the workplace, wipe off wet or slippery floors;

- prepare the tools, equipment and technological equipment necessary to perform the work;

- make sure that the welding equipment is in good condition, that the welding installation is grounded and properly grounded;

- arrange the welding wires so that they are not subject to mechanical damage and high temperature, and do not come into contact with moisture;

- make sure that fire and explosive substances and flammable materials are not stored near the workplace.

The work site, as well as downstream areas, must be freed from flammable materials within a radius of at least 5 m, and from explosive materials and installations - at least 10 m.

2.6.Check the serviceability of a portable lamp with a voltage not exceeding 12V.

2.7. When carrying out welding work in enclosed spaces or on the territory of an operating enterprise, check compliance with fire and explosion safety and ventilation requirements in the work area.

2.8. An electric welder should not start work if the following safety requirements are violated:

- absence or malfunction of the protective shield, welding wires, electrode holder, as well as personal protective equipment;

- absence or malfunction of grounding of the welding transformer housing, secondary winding, welded part and switch casing;

- insufficient lighting of workplaces and approaches to them;

- the absence of fences for workplaces located at a height of 1.3 m or more, and equipped access systems to them in fire and explosive working conditions;

- lack of exhaust ventilation when working in enclosed spaces.

2. 9. Detected violations of safety requirements must be eliminated before work begins, and if it is impossible to do this, the electric welder must report them to the manager.

3. Safety requirements during work

3.1. When performing electric welding work outdoors (during rain or snowfall), a canopy must be installed over the welder’s workplace and the location of the welding machine.

3.2. Electric welding work at height should be performed from scaffolding or scaffolding with guardrails. It is prohibited to carry out work from ladders.

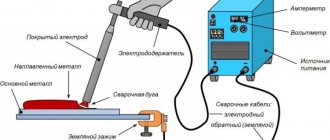

3.3. Welding must be carried out using two wires, one of which is connected to the electrode holder, and the other (reverse) to the part being welded. It is prohibited to use metal structures of buildings, technological equipment, sanitary pipes (water supply, electrical wire, etc.) as the return wire of the grounding network.

3.4. Welding wires must be connected by hot soldering, welding or using couplings with an insulating sheath. Connections must be insulated. Connecting welding wires by twisting is not allowed. Welding wires should be laid so that they cannot be damaged by machines and mechanisms.

3.5. Before welding, the electric welder must make sure that the edges of the product being welded and the adjacent area (20-30 mm) are cleaned of rust, slag, etc.

When cleaning, you must use safety glasses. The parts to be welded must be securely fastened before welding begins.

When cutting structural elements, the electric welder is obliged to take measures against accidental falling of the cut elements.

3.6. During breaks in work, the electric welder is prohibited from leaving an energized electrode holder at the workplace; the welding machine must be turned off and the electrode holder secured to a special stand or suspension.

3.7. Connection and disconnection of welding machines must be carried out by special personnel through an individual switch.

Welding safety

Containers in which flammable substances were stored before welding should be disconnected from the pipelines, and then cleaned and washed with hot water and caustic soda, steamed, dried and ventilated. In the process of preparing for welding work, the container must be ventilated at least 5-6 times with air changes. Immediately before welding work, check for the presence of explosive concentrations of gases or vapors using a gas analyzer.

During operation, you need to constantly monitor the condition of the air in the container, especially in its upper and lower parts. Air samples are taken with a hose, the end of which is lowered into a container no more than one meter from the floor level and 20 - 30 cm from its ceiling. If air samples indicate the presence of gases, welding work should be stopped and the container ventilated. During manual welding, it is recommended to supply clean air directly under the welder’s shield.

In the case of hot work using liquefied gases (propane, butane, etc.) and carbon dioxide, the exhaust ventilation must produce suction from the bottom of the container.

The worker located directly in the tank must be provided with a rescue harness and a safety rope. One end of the rescue belt is attached to the welder’s belt, and the other should be in the hands of the belaying worker.

The insurance worker is provided with the same protective equipment as those working inside the tank. He should not move away from the hatch as long as the welder is there.

During gas welding operations, explosions are possible during improper transportation, storage and use of compressed gas cylinders. During gas-flame processing processes, explosions of acetylene generators from the backlash of the flame are possible if the water seal does not operate. Explosions are caused by the presence of oil on the oxygen cylinder fitting or on the gearbox.

During operation, gas cylinders must be protected from sunlight and other heat sources. The room in which cylinders are stored must be located at a distance of at least 25 m from the place where gas-flame work is carried out. Only cylinders with homogeneous gases can be stored in one room; empty cylinders are stored separately from full ones.

During transportation, cylinders are placed with valves to one side and transported in a horizontal position with the obligatory use of gaskets. Cylinders are stacked only in one row. There should be no traces of oil, grease, or oily objects in the car body.

During loading and unloading operations, cylinders must not be removed from the vehicle with the caps facing down. It is not allowed to carry cylinders by hand. If a cylinder is found to be leaking, it must be taken to a safe place and, if possible, the gas must be carefully released from it. Within the production site, cylinders are transported on a special cart or stretcher.

Particular care should be taken when handling oxygen cylinders. Many substances, including metals, burn in a stream of oxygen, and flammable liquids (oils, fats, petroleum, etc.) burn explosively. Therefore, persons who come into contact with oxygen cylinders must work in clean clothes, and there should be no traces of oils and fats on their hands and tools.

| Correct movement of cylinders on carts: A - cart for one cylinder; B - trolley for two cylinders; B - stretcher for one cylinder. |

If during gas welding work the pressure in the cylinder turns out to be higher than permissible, you need to briefly open the valve to release some of the gas into the atmosphere or cool the cylinder with water. When releasing gas from the cylinder, the worker must be on the side opposite to the gas stream. In the event of a backfire, it is necessary to close the flammable gas valve on the burner first, and then the oxygen valve. The mouthpiece of the gas burner is cooled with water. When cooling the mouthpiece, you must ensure that the valves are completely closed, otherwise gas may accumulate on the surface of the water, creating an explosive mixture.

Empty cylinders should be handled in the same way as full ones. Empty cylinders are delivered to a warehouse or factory for filling with plugs and closed valves at residual gas pressure. The gas balance in acetylene cylinders must be no less than the values indicated in the table.

Permissible residual pressures in acetylene cylinders

| Temperature °C | Permissible residual pressure, MPa |

| Less than 0 | 0,049 |

| 0-15 | 0,098 |

| 16-25 | 0,196 |

| 26-35 | 0,294 |

Portable acetylene apparatus is installed outdoors under a canopy. To perform temporary work, it is allowed to install an acetylene apparatus in a room with a volume of at least 300 m3 for each apparatus, provided that this room is well ventilated. It is prohibited to install an acetylene generator closer than 10 m from hot work. The acetylene apparatus should be handled with care, as it can explode due to explosive mixtures of acetylene with air or oxygen, if the temperature or pressure of acetylene is unacceptable.

The safety valve must be checked annually with a hydraulic pressure of 6 MPa. The tight fit of the check valve to the seat must be checked after its installation and after each flame penetration into the valve.

It is forbidden to leave a working acetylene apparatus unattended, it is forbidden to work without a water seal and in cases of its malfunction, it is forbidden to work with faulty safety valves or install plugs in their place.

You cannot work with carbide dust, load carbide into wet containers, load the apparatus in excess of the established norm, and use carbide of excessive granulation. Do not push calcium carbide into the device's watering can with metal rods or other objects that can cause a spark.

build.novosibdom.ru

Welding at home. Means of protection

If you purchased a welding machine for welding at home, do not skimp on protective equipment. When welding indoors, do not forget about a properly equipped welding station.

How to protect yourself and the people around you from home welding? Let's try to figure it out in this article.

For those who want to cook in the apartment, it should immediately be noted that the apartment is not an industrial premises and such activities are prohibited in it. Why are we just banned? My property, I do what I want.

What are the dangers of carrying out welding work in an apartment?

- Fire. Still, there are many things and objects that are easily flammable. A fire extinguisher is required.

- They try to cook on the balcony, in the corridor, on the landing - a good idea until practice begins. Try to burn at least one electrode in a closed room without an exhaust hood, and you will understand how stupid the idea is. Even when welding on a balcony with open windows, the smoke dissipates after fifteen minutes, and the smell lasts for several days. In this case, maybe TIG welding can solve the problem with excessive smoke, but if only smoke was a problem.

- Spatters of metal from electrode welding fly in all directions. The welding area must be fenced.

- The welding machine heavily loads the electrical network, when the lights in the neighboring apartments start blinking, problems with the neighbors will begin. It is only possible to weld with electrodes up to 2 mm at currents of 30-50A. If an electric stove is installed in the apartment, welding at higher currents is possible.

The conclusion is clear: if you have just purchased a welding inverter and you are eager to cook with it and test it, you should not do this in an apartment or private house. At a minimum, you will be guaranteed problems with your neighbors, and at a maximum, you are thereby endangering the lives of people and the safety of property.

If you don't have a suitable space, purchase a garage or workshop.

The activity of an electric welder is associated with a certain health risk; this cannot be treated negligently. You must always think through your actions before starting work.

With regard to workwear, there is no point in establishing any strict limits (what material it should be made of - tarpaulin, split wood, other fire-resistant material). Because the intensity of welding at home is not at all the same as it can be in production.

The main requirement for workwear is that it must have a protective function: cover all exposed areas of the body and be made from natural materials, in no case synthetic.

It is also important to know that burns during welding can be obtained not only from splashes and drops of molten metal, but also from ultraviolet radiation emitted by the welding arc. And often the weakest points are:

- Face. It is not always possible to hold the welding shield (if anyone uses it) correctly during assembly and setting of tacks;

- Neck due to an unbuttoned collar;

- Wrists due to insufficient length of mittens or cuffs.

Unfortunately, for most home welders, such burns are commonplace. The need to close comes with bitter experience. If you are not confident that your workwear is protecting you as required, then this uncertainty will be reflected in the welding itself. Protect yourself in a way that does not hinder your movements.

What do experienced welders usually not think about, or what do experienced welders neglect?

- Exhaust or ventilation in the workplace;

- Respiratory protection;

- Hand protection. The use of gloves and mittens during preparatory work, marking, cutting, stripping metal, as well as during its assembly, tack welding, welding of finished structures;

- Eye protection

Ventilation of the workplace

During welding, harmful substances are released, but not all welders pay due attention to this, often becoming very interested in the process.

Therefore, the place in which you plan to cook must be equipped with ventilation or an exhaust hood, because the consequences of inhaling harmful substances may not appear immediately, but after many years.

Everyone should think about what can be done in their particular case. Don’t forget, you need to invest in your health too.

If you work outside in the open air, you will be at the mercy of weather conditions. Working in the rain, as well as after it, with wet metal is strictly prohibited! There is a high risk of electric shock.

If you work outside, but under a canopy, there is no point in thinking about a hood; natural air circulation in this case will be enough. However, if the place where your welding work is carried out is a garage or workshop, then simply opening the door or gate will not save you from harmful smoke.

Installing expensive exhaust equipment is not affordable for everyone, so the most budget-friendly and simplest solution would be to install an exhaust fan in one of the walls of your room.

Such fans will successfully cope with gas pollution in the room and will become reliable assistants in protecting the respiratory system.

Hand protection

Most DIYers don't think twice about what hand protection to use. They take either those that they have in stock, or those that are imposed by the stereotypes of the profession.

Let's figure this out.

The image of a Soviet welder appears before us in all canvas, including mittens. However, we are not only welders. We need to do a variety of work related to marking metal, preparing it for welding, and cutting. You can't do this kind of work with mittens.

You can’t work without protective equipment at all: your hands are susceptible to cuts due to sharp metal edges and burrs, as well as smeared hands from rusty metal or oiled metal, if it’s new, creating discomfort at work. Therefore, gloves are necessary for such work.

These can be cotton or rubber gloves.

The next stage in the work is assembly and tack. Here you need to find a middle ground so that you can work comfortably and at the same time have complete security.

Cotton gloves are not suitable for this, since due to their structure they have the ability to retain splashes and drops of metal that get on the hands, which are released even when using tacks. Mittens and leggings do not provide complete control when placing workpieces.

When using such protective equipment, the accuracy of installation, and sometimes the leggings or mittens themselves, suffer. Therefore, select for assembly something that gives you a feeling of comfort and control over the assembly process.

The best option for assembling and tack are gaiters or gloves made from suede leather, but the main thing is that they are unlined. Or gloves designed for argon workers, they have a lower density, which means the sensitivity of the hands is much higher, which will have a positive effect on the assembly process.

When scalding, use mittens and gloves that have a high degree of protection, wear resistance and an appropriate length that protects your hands from splashes and drops of molten metal.

Eye protection

When the question of protecting the organs of vision is raised, most people only think about a mask that protects the eyes from bright lights, the face from burns, and also allows you to see and control the process. But we will not talk about it, but about the use of such an accessory as safety glasses.

Unfortunately, our people have such a mentality that even when using a power tool such as an angle grinder, they put on glasses every other time. And those who work in a team and use protective equipment to the fullest, trying to protect themselves, often become the object of ridicule or barbs directed at them.

And mind you, because of the correct attitude towards your health.

But is it really worth wearing safety glasses and a mask while welding? If you pay attention to the welder’s working mask, then its inner part, as well as the light filter on the inside, is cut by splashes and drops of metal, regardless of what design the mask is. And if they fly there, then what prevents them from getting into your eyes?

The inside of the welding helmet. Metal splash marks

The welder also constantly has to knock slag off the seams and use a grinder. By wearing safety glasses you will protect yourself and your eyes during the entire period of work.

Try not to feel uncomfortable.

For example, if you wear tinted glasses while welding, or cheap, low-quality ones, the design of which prevents you from using a welding helmet, and the only desire you have is to take off such glasses.

High-quality branded glasses are a little more expensive, but the feeling of wearing them is much better. Try to use such means of protection with care, thereby showing how you feel about yourself.

There are some health hazards associated with being a welder, but when it comes to PPE, never settle for what you have and always try to improve your working conditions as best you can.

How to cook thin metal sheets with an inverter?

It is worth paying attention to the polarity of the electrodes. During DC welding, there will be a negative and a positive charge. First of all, you will need to determine which charge needs to be connected to which place. You need to proceed from the fact that a positive charge, holding the material that is being welded, will be able to heat up more. Most often, reverse polarity in the welding process is used when it is necessary to weld thin metal with a welding inverter, which can be easily burned. Therefore, it is important to ensure that the polarity is reversed and the amperage is correct. Electrodes for welding thin sheets of metal must be connected with the “plus” to the arc of the device, and the “minus” to the sheet of metal.

If you need to ensure that the weld seam on a sheet of metal is of the highest quality, and there are no holes on the sheets, you will need to ensure that the seam is visible during the welding process. This means that the angle of inclination of the electrode relative to the workpiece should be approximately 30°. The electrode will need to be placed as close as possible to the metal being welded. After this, you need to wait until a red spot begins to form, under which a drop of metal appears, capable of connecting the sheets to be welded together.

Is it possible to cook in the rain with electric welding?

If you purchased a welding machine for welding at home, do not skimp on protective equipment. When welding indoors, do not forget about a properly equipped welding station.

How to protect yourself and the people around you from home welding? Let's try to figure it out in this article.

For those who want to cook in the apartment, it should immediately be noted that the apartment is not an industrial premises and such activities are prohibited in it. Why are we just banned? My property, I do what I want.

What are the dangers of carrying out welding work in an apartment?

- Fire. Still, there are many things and objects that are easily flammable. A fire extinguisher is required.

- They try to cook on the balcony, in the corridor, on the landing - a good idea until practice begins. Try to burn at least one electrode in a closed room without an exhaust hood, and you will understand how stupid the idea is. Even when welding on a balcony with open windows, the smoke dissipates after fifteen minutes, and the smell lasts for several days. In this case, maybe TIG welding can solve the problem with excessive smoke, but if only smoke was a problem.

- Spatters of metal from electrode welding fly in all directions. The welding area must be fenced.

- The welding machine heavily loads the electrical network, when the lights in the neighboring apartments start blinking, problems with the neighbors will begin. It is only possible to weld with electrodes up to 2 mm at currents of 30-50A. If an electric stove is installed in the apartment, welding at higher currents is possible.

The conclusion is clear: if you have just purchased a welding inverter and you are eager to cook with it and test it, you should not do this in an apartment or private house. At a minimum, you will be guaranteed problems with your neighbors, and at a maximum, you are thereby endangering the lives of people and the safety of property.

If you don't have a suitable space, purchase a garage or workshop.

The activity of an electric welder is associated with a certain health risk; this cannot be treated negligently. You must always think through your actions before starting work.

With regard to workwear, there is no point in establishing any strict limits (what material it should be made of - tarpaulin, split wood, other fire-resistant material). Because the intensity of welding at home is not at all the same as it can be in production.

The main requirement for workwear is that it must have a protective function: cover all exposed areas of the body and be made from natural materials, in no case synthetic.

It is also important to know that burns during welding can be obtained not only from splashes and drops of molten metal, but also from ultraviolet radiation emitted by the welding arc. And often the weakest points are:

- Face. It is not always possible to hold the welding shield (if anyone uses it) correctly during assembly and setting of tacks;

- Neck due to an unbuttoned collar;

- Wrists due to insufficient length of mittens or cuffs.

Unfortunately, for most home welders, such burns are commonplace. The need to close comes with bitter experience. If you are not confident that your workwear is protecting you as required, then this uncertainty will be reflected in the welding itself. Protect yourself in a way that does not hinder your movements.

What do experienced welders usually not think about, or what do experienced welders neglect?

- Exhaust or ventilation in the workplace;

- Respiratory protection;

- Hand protection. The use of gloves and mittens during preparatory work, marking, cutting, stripping metal, as well as during its assembly, tack welding, welding of finished structures;

- Eye protection

Is it possible to weld by welding in the rain?

1 Is it possible to weld in the rain with electric welding - Metalworker's Handbook Ventilation of the workplace Hand protection Eye protection 2 Winter is not an obstacle to welding The influence of temperature on the process.

· Can I take a tripod on a plane? Many amateur photographers take on the plane not only a camera, but also a tripod. There may be some problems with its transportation. If its length when folded exceeds 60 cm, then.

1 Occupational safety instructions for electric welders 2. Safety requirements.

If you purchased a welding machine for welding at home, do not skimp on protective equipment. When welding indoors, do not forget about a properly equipped welding station.

How to protect yourself and the people around you from home welding? Let's try to figure it out in this article.

How to make smoked mackerel at home

For those who want to cook in the apartment, it should immediately be noted that the apartment is not an industrial premises and such activities are prohibited in it. Why are we just banned?

- How to make acetic anhydride at home

My property, I do what I want. The conclusion is clear: if you have just purchased a welding inverter and you are eager to cook with it and test it, you should not do this in an apartment or private house.

Welding in wet weather

At a minimum, you will be guaranteed problems with your neighbors, and at a maximum, you are thereby endangering the lives of people and the safety of property.

The activity of an electric welder is associated with a certain health risk; this cannot be treated negligently. You must always think through your actions before starting work.

With regard to workwear, there is no point in establishing any strict limits on what material it should be made of - tarpaulin, split wood, or other fire-resistant material.

Because the intensity of welding at home is not at all the same as it can be in production.

The main requirement for workwear is that it must have a protective function: cover all exposed areas of the body and be made from natural materials, in no case synthetic.

It is also important to know that burns during welding can be obtained not only from splashes and drops of molten metal, but also from ultraviolet radiation emitted by the welding arc.

And often the weakest points are:.

Is it possible to cook in the rain with electric welding?

Unfortunately, for most home welders, such burns are commonplace. The need to close comes with bitter experience. If you are not confident that your workwear is protecting you as required, then this uncertainty will be reflected in the welding itself. Protect yourself in a way that does not hinder your movements.

During welding, harmful substances are released, but not all welders pay due attention to this, often becoming very interested in the process.

How to learn to weld metal, what do you need to know before performing the welding process?

Table of correspondence between electrode diameter and welding current.

An inverter for welding is an economical device that is convenient to use. Even beginners can learn to weld metal with it. Before welding, it is important to learn about the operating principle of this device. The inverter is an electronic welding machine, so the main load will fall on the electrical network. When old welding machines are plugged in, there is a strong and maximum possible jolt of electrical energy. In connection with this, the power grid of the entire area is switched off. The inverter has storage capacitors that are capable of storing electrical energy, as a result of which uninterrupted operation of the electrical network can be ensured. In this case, the electric arc of the device will ignite softly.

Is it possible to weld a car using electric welding – Property protection

When purchasing a used vehicle, you need to carefully examine it for various deficiencies. In this matter, any minor nuances are important, since in the future they can result in big problems.

When choosing a car, many potential buyers pay attention only to the technical characteristics, condition of the engine, transmission, chassis and other related elements that set the car in motion.

Accordingly, due attention is not paid to checking the newness and integrity of the body, although the condition of this part of the vehicle is also of paramount importance.

Welding with a car inverter allows you to weld in hard-to-reach places.

Experts note that the body of cars produced by the domestic auto industry can have its original characteristics for up to 10 years of active use, after which it begins to wear out and rot. Imported cars are more durable in this regard; their body can last up to 15 years. This is due to the high quality of the metal used in the production of car bodies.

Main areas of body rot that require welding

Figure 1. Welding the body with an electrode is undesirable, as noticeable seams are formed.

At the end of its service life, the vehicle body enters a rotting phase, so it is necessary to identify the affected areas and repair them immediately. Of course, if you have the necessary material resources, you can replace the body completely.

But in other cases, they turn to welding for help. It successfully deals with corrosive areas. If you do not eliminate them in time, after a certain time they will completely affect the body, turning it into a sieve.

Despite the fact that a car is used for different purposes, corrosion damage to the body occurs in the same places. First of all, rotting begins in the lower part of the body and in areas where liquid, dirt and dust accumulate: under the wings, doors, in the front and rear parts.

Everything is clear under the wings and doors - these are the most contaminated areas of the car body.

The front part is affected mainly due to the human factor, that is, dirt from shoes gets inside the cabin and settles under the floors. The area in the back of the car where the spare tire is stored usually begins to rot.

Most motorists throw an uncleaned wheel there, so corrosion thoroughly affects this area.

This problem is widespread; it is difficult to do without major repairs. To solve this problem, special expensive welding equipment is often used, which is only available in automotive service centers.

If your financial capabilities do not allow you to go there, you can do welding yourself.

But to do this, you will need to understand the types of welding work and understand which ones are best suited for car body metal.

Is it possible to cook a car body with an inverter?

Figure 2. Welding inverters, despite their small dimensions, make it possible to obtain high-quality welds.

Often the welding process is carried out using electrodes, since this method is considered the most accessible and simple. But using them for welding areas of the body in a visible place is extremely undesirable, since the welded joints are too noticeable due to their sloppy appearance (Fig. 1).

Of course, in the luggage compartment and areas under the wings you can cook with an inverter. The main thing is to make sure that such equipment can easily reach difficult to reach areas.

In order to cook with an inverter, you must follow all safety regulations. Therefore, you should not take risks and climb into narrow, inconvenient crevices.

An inverter is often used to reliably weld bulky parts, such as body frames.

Today, both inverter and semi-automatic welding machines are used to create patches on the vehicle body.

Each method of creating welded joints has its pros and cons. Before working with such equipment, you must enlist the help of an experienced welder and follow safety regulations.

In addition, you need to take care of equipping the work area. If you're working in a garage, make sure you have plenty of open space. The room should be well lit.

Safety precautions when welding in bad weather

To avoid problems when welding in the rain, it is not recommended to deviate from the following rules:

In most cases, it is better to abandon the idea of welding in the rain altogether. No welding seam is worth losing your health. Always remember this and follow safety precautions when welding. In any case, we hope that these tips that were given in this article will help you stay safe when welding in bad weather.

on social networks

Method of welding body metal with an inverter

Figure 3. When performing welding work, special attention must be paid to safety precautions.

The main advantage of this method is its high speed, thanks to which you can complete all the work in the shortest possible time. The inverter has been used to create welds on car bodies since Soviet times.

It is used mainly for the domestic UAZ-469 SUV, the body of which is not so demanding in terms of aesthetic appearance.

For a domestic SUV, the first place is the reliability and strength of all components, which includes the body.

Today, owners of such SUVs most often turn to car repair shops to create additional frames, bull bars, rear and front winches, as well as fog lights located on the roof of the vehicle.

To increase the speed of work and increase the reliability of fastening with an inverter, it is these parts that need to be welded.

Inverter welding relies on the creation of high-frequency electric current. Most often, equipment of this type is quite bulky, but more expensive devices boast portability and small dimensions (Fig. 2).

At the same time, the quality of welds created by inverter machines practically does not depend on the person. Such equipment can be easily mastered in a few hours.

But this type of welding has its disadvantages:

- high price;

- inability to create welds on metal with a thickness of more than 3 mm;

- malfunctions due to moisture and dust entering the housing.

Experts recommend purchasing a device with a medium to high cost, since the cheapest models are considered unreliable. Another advantage of inverter welding is the ability to operate at low voltage in the electrical network. It should be remembered that when working with welding equipment of this type, it is necessary to follow safety rules (Fig. 3).

How to properly weld metal with an inverter?

The process of arc initiation and combustion pattern.

First of all, you will need to know what elements will be needed for protection when working with a welding inverter. You need to buy the following:

- Leather gloves.

- Helmet for protection.

- Jacket made of thick fabric.

- Metal brush.

You will need to adjust the welding current and select an electrode. In order to weld with a welding inverter, you will need to use electrodes from 2 to 6 mm.

The welding current is set depending on the thickness of the machine elements and the material being welded. In most cases, there is information on the device body about what current strength should be.

There is no need to bring the electrode to the welding base quickly. If you do this, sticking may occur.

Next, the ground terminal is connected to the base, which is welded.

The welding process must begin with ignition of the arc.

You should bring the electrode at a slight angle to the part that is being welded, and then touch it to the welding base several times so that you can use the electrode for welding.

The electrode is held several elements away from the workpiece that is being welded. In most cases, this distance is equal to the diameter of the existing electrode.

The result will be a weld seam. Scale (metal scale at the top of the weld) is removed with a small hammer. You can also use any other durable object that has a lot of weight.

How to control the arc gap?

Figure 1. An arc space of suitable dimensions will help form a good seam.

The arc gap is the gap that appears during welding between the metal workpiece and the electrode. It is important to continuously monitor and maintain the same value of this gap.

- If there is a small gap, this can lead to the seam being convex and not fused on the sides due to the fact that the base metal will not be able to warm up quickly.

- If there is a large gap, then it will not be possible to weld the part, and the arc will jump. As a result, the metal that is melting will fit crookedly.

- It is important to provide the required gap. This is necessary in order to be able to form a normal seam with good penetration. Visually, a gap of suitable dimensions can be seen in Fig. 1.

If you learn to control the arc length, you will be able to get the optimal result. The arc will pass through the gap and melt the base metal. As a result, a weld pool is formed. The arc will also be able to ensure the transfer of the metal that is being melted into the bath.

Tips for working with a welding inverter

So, you have finally decided to buy a welding inverter. Congratulations! Now you can fully experience the joy of welding without any hassle. If you have little experience in welding, then a welding inverter will allow you to smooth out all the mistakes of a beginner.

So, first, read the safety precautions. It is described in the instructions for use or the passport for the inverter welding machine. Carefully study the entire list and take into account its main points.

When working with the inverter, use special clothing and protective equipment (mask, gloves). Be sure to inspect the wires before starting work, make sure the quality of the connections, whether the holder and ground are securely fastened.

It is strictly forbidden to cook in rain and snow without a roof over your head. There should be no small metal shavings or other debris near the welding site and the apparatus. During the process, be sure to take breaks from work. Firstly, the device has an on-duration factor (DU). Its percentage value shows how long the inverter can continuously cook at maximum current. For example, the TSS Sai-160 welding inverter has a duty cycle value of 60%. This means that out of 10 minutes, only 6 minutes can be cooked at maximum current. The welding inverter should rest for the remaining time. Secondly, the substances released when the flux burns make breathing difficult.

If the electrode does not light up for a long time, try increasing the current. Usually it is chosen experimentally and selected individually for each case. The table shows the ranges in which the recommended value of welding current is found for electrodes of various thicknesses.

| Electrode diameter, mm | Welding current, A | |

| Minimum value | Maximum value | |

| 1,6 | 25 | 50 |

| 2 | 40 | 80 |

| 2,5 | 60 | 110 |

| 3,2 | 80 | 140 |

| 4 | 120 | 160 |

When you first try to light an arc, do not knock on the surface of the part. This can damage the electrode coating. A more effective solution would be to move the electrode similar to striking a match. This way the arc will flare up faster.

As we wrote above, the welding inverter prevents the electrode from sticking to the surface of the part. If the part is located on a car or similar equipment with independent power supply, be sure to de-energize it and secure the mass as close as possible to the point of contact.

Be sure to look at the temperature range in which the device operates. Thus, the manufacturer states that the TSS SAI-200 welding inverter operates in the range from -10 to +40. Remember that microcircuits are very afraid of condensation, and if God forbid the transistor unit fails, then its repair may cost as much as a new inverter.

Over time, you yourself will feel how your work skills become better and better, and the welding process becomes easier and easier.

We wish you pleasant use of inverter welding machines!

www.nvisota.ru