Currently, there are a huge number of ways to attach to walls, ceilings and other elements of building structures.

Often there is a need to attach a frame for paneling to a concrete wall or brickwork, install a lamp, etc. In all these and many other cases, an anchor bolt with a nut will help you, which will ensure reliable fastening in any conditions. Plastic fasteners are also in great demand, but they cannot provide such strength and reliability as anchor fastenings; in addition, they are not afraid of fire and exposure to aggressive environments.

An anchor bolt with a nut, the sizes of which are very diverse, is widely used for fastening elements of massive structures to a monolithic base. There are other fastening options, but it is the anchor bolt that provides the greatest reliability and durability.

The design of the fastening element and its features

Anchoring can be:

- With nut;

- Double spacer equipped with a nut;

An anchor bolt with a nut is the simplest type of fastener, with different sizes. It consists of a stud with a tapered shank, a sleeve with longitudinal grooves and a nut, thanks to which this structure is secured in the mounting hole. Fixation is carried out as follows: the fully assembled fastener is installed in a pre-drilled hole, the diameter of which corresponds to the outer diameter of the sleeve. When the nut is tightened, the pin begins to move in the axial direction and expands the slotted sleeve, thereby ensuring reliable fixation of the anchor in the mounting hole.

Double-expansion anchor bolts equipped with a nut differ from conventional ones in that their design provides for the presence of two bushings that deform when the stud moves in the axial direction. Fastening occurs as follows: when the screw is tightened, the first spacer sleeve moves inside the second, thereby opening it, while the first sleeve is also expanded by the conical shank. Thus, the surface area of contact between the anchor and the mounting hole is significantly increased, increasing the reliability of fixation.

Characteristics of steel 35x

Application of steel 35X

This steel has a very specific application environment, but it is of great importance, since it is from this steel that the most important parts of various mechanisms are most often made, including shafts of internal combustion engines, gear transmissions of rotational motion, as well as axles and, in some cases, rings. rails.

- The designation “steel” makes us understand that the steel falls under the “Quality” category. This means that the amount of harmful impurities in 35X steel is lower than that of ordinary quality steel.

- The number 35 refers to the percentage of carbon in the alloy - on average 0.35 percent.

- The letter “X” at the end of the abbreviation tells us about the increased content of an alloying element such as chromium in the steel.

Chemical composition

As in any other case, the characteristics of 35X steel are very dependent on the alloying elements included in its composition. It is they who endow steel with the basic properties necessary for certain conditions. For 35X, the composition of chemical additives is as follows:

- Carbon - significantly increases the strength and hardness of steel, reducing ductility - 0.35%.

- Silicon – slightly increases strength, without affecting the overall fragility – 0.22%.

- Manganese - adds strength to steel, resistance to impact loads, without reducing its ductility - 0.65%.

- Chromium – slightly increases the hardness of steel and protects it from corrosion by forming an oxide film – 0.95%.

- Copper also has a positive effect on the corrosion resistance of steel - up to 0.3%.

- Nickel - similarly increases oxidation resistance, as well as strength and flexibility - up to 0.3%.

The so-called “harmful impurities” contained in 35X steel, such as sulfur and phosphorus, adversely affect the structure, and, as a result, the quality of the resulting steel. However, their content is often negligible and in this case amounts to only 0.035% each.

Anchor bolt with nut: typical dimensions and technical characteristics

According to the technical characteristics, the use of an anchor bolt is possible in monolithic materials, such as concrete. During the installation process, you must always take into account that when you tighten the nut, the stud moves out. The minimum length of the anchor pin is 18 mm, and the longest can reach a size of 400 mm. Depending on the length of the stud, its diameter also changes and can vary from M 6.5 to M 24. Since the anchor fasteners are made of metal, it provides reliable fastening of structural elements in the event of a fire.

Typical dimensions of an anchor bolt with a nut, table

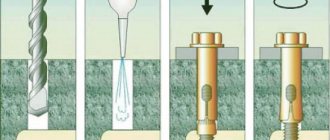

Installation

The most commonly used method of attaching anchors is using a spacer. To do this, a hole of the required diameter and required length is drilled using a hammer drill with a drill. It is cleaned and the anchor is hammered in so that the anchor sleeve is buried to the level of the surface (Fig. 10). Then the nut is tightened, which wedges the conical rod. The nut is tightened until it stops. After that, it is unscrewed and what is needed is hung on the rod. The next step is to screw the nut back and tighten it with a wrench.

READ ON THE TOPIC:

How to choose the most optimal hammer drill.

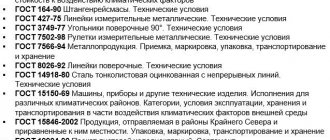

Requirements of the regulatory document (GOST)

Due to the fact that all fastening systems are critical structural units, all their parameters are strictly regulated by relevant documents. In particular, GOST also stipulates the load-bearing capacity of anchor fastenings. In some cases, human life depends on the strength and reliability of fastenings, therefore the requirements stipulated by GOST must be strictly observed. All threaded parts of anchor connections (bolts, nuts, studs) must also comply with GOST requirements.

STEEL GRADE 35

Quality medium carbon steel

This type of steel is used for parts that require high ductility and impact resistance.

High-quality carbon steels of type 35 are manufactured according to GOST 1050-88 and are marked with two-digit numbers that indicate the average carbon content in hundredths of a percent.

For example, steel 35 (0.35%). It has high strength (σв = 640...730 MPa, σ0.2 = 380...430 MPa) and relatively low ductility (δ = 9...14%, ψ = 40...50%).

In addition, this type of steel is not susceptible to medium stress, is resistant to deformation and wear, and is not subject to cracking and corrosion.

Therefore, steel 35 is used in the production of high-strength fasteners and flange connections. Temperature range: from - 40 to + 450 degrees Celsius.

Methods of welding RDS, ADS submerged arc and gas shield, ESW. We recommend heating and subsequent heat treatment. CTS without restrictions

Weldability of steel grade 35

Structural grade 35 has limited weldability.

With an increase in carbon in the steel, the heat-affected zone and the weld are hardened, hardness increases, and welded joints become more brittle and prone to cracking.

Satisfactory steels have a carbon content of 0.25 to 0.35%. They are less prone to cracking and, with the correct welding conditions, a high-quality seam is obtained. To improve the quality of welding, heating is often used.

Steel application temperature 35

The minimum application temperature (the temperature of the coldest five-day period in the region) is minus 40.

Maximum application temperature plus 425.

Rules for installing an anchor bolt with a nut

The quality of installation has a significant impact on the further operation and load-bearing capacity of the anchor. In essence, there is nothing complicated in installing these fasteners, and they are all installed according to the same principle, but there are a number of simple rules that must be followed to ensure that your fastening is reliable and durable. To ensure the required quality it is necessary that:

- The size, that is, the diameter of the fastening hole, does not exceed the outer diameter of the spacer sleeve, otherwise wedging the sleeve will not provide the necessary fastening strength. Pay special attention to the choice of drill, consider its wear. If the bushing does not fit into the drilled hole, you should not drill with a large drill, try repeating the drilling with the same drill, this will somewhat “break” the mounting hole and allow you to install the anchor in place;

- The mounting hole was free of concrete residue, dust and other construction debris that would prevent the anchor bolt from being installed in the desired position;

- When attaching structural elements to an already installed anchor, first tighten the lock until it stops so that the spacer sleeve takes the working position. After this, unscrew the nut and mount the required element on the rigidly installed rod.

Installation of an anchor bolt with a nut in concrete video

When carrying out repair and construction work, you can use various types of fastening systems, but it is the anchor fastening that provides the greatest strength.

Production time for curved bolts 1.2

The manufacturing time for a foundation bolt type 1.2 takes no more than 5 minutes.

First of all, this will be appreciated by our customers who are passing through Moscow and who require a small batch of foundation bolts.

Up to 50 sets will be produced within one hour right in front of the customer.

When ordering bulk quantities of anchor bolts, we give the best production times not only in Moscow, but throughout Russia. We provide a flexible system of discounts for regular wholesalers.

How to place an order for production

To quickly complete your application, log in to the website and use the order form through the online store cart in the upper right corner of the page.

If your order requires clarification, use the order form at the bottom of the page.

In order for us to respond to you faster, please provide your email and phone number.

If you wish to receive an invoice for payment immediately, you will need to indicate the name of the organization and payment details.

Indicate the desired date for receiving the finished order and the name of the transport company through which your order should be sent after production.

You can send your application directly to our email: [email protected]

You can discuss all the details with your manager on a single phone number.

Types of wall anchors depending on the fastening material

The metal anchor is designed for fastening massive structures and is made from durable materials:

- structural steel with low carbon content. This type of metal provides an increased margin of safety and allows the use of clamps for increased loads;

- corrosion-resistant steel, which contains alloying elements. Along with an increased margin of safety, the material is resistant to corrosion processes, which allows the fasteners to be used in wet conditions;

- aluminum-zinc alloys, which are known as brass. Fastening elements made of non-ferrous metals are used mainly for fastening structures in domestic conditions.

Certain types of fasteners may include a sleeve made of plastic or polyamide.

Bolt Load Calculation

The bolt head markings usually contain the following information:

- manufacturer's mark (JX, THE, L, WT, etc.);

- strength class;

- arrow “counterclockwise” (if left-hand thread).

The first number indicates the nominal tensile strength (tensile strength): 1/100 MPa (1/100 N/mm²; ~1/10 kg/mm²). Example: (strength class 9.8) 9*10=900 MPa (900 N/mm²; 91.71 kg/mm²).

The second number indicates the percentage of yield strength to tensile strength (tensile strength): 1/10%. Example: (strength class 9.8) 9*8=720 MPa (720 N/mm²; 73.37 kg/mm²).

The yield strength value is the maximum permissible working load of the bolt, above which irreversible deformation occurs. When calculating the load, 1/2 or 1/3 of the yield strength is used, with a double or triple safety margin, respectively.

According to the current international classification, high-strength bolts include products whose tensile strength is greater than or equal to 800 MPa (800 N/mm²; 81.52 kg/mm²). Accordingly, starting from 8.8 for bolts and 8 for nuts.

Examples of material flow

An example would be a common kitchen fork. By bending it in one direction, you can get a completely different object, which means its fluidity is disrupted, which leads to deformation. In this case, the material only deformed, but did not break, which indicates a high degree of elasticity of the steel. Conclusion: maximum strength is much higher than yield.

Other kitchen equipment, such as a knife, will break if you try to change its shape. Conclusion: the knife has the same fluidity and strength; such a product can be called fragile, despite the fact that it is made of steel.

A similar practical example would be screwing in a nut: the bolt itself increases in length only after a certain amount of action is applied to it. If the outcome of the experiment is unfavorable, the thread on the fastener may break.

The percentage of elongation is an average indicator that demonstrates the length of the deformed part before the onset of failure. Figuratively, we can call this kind of bolts flexible, meaning precisely the ability to elongate.

The technical terminology for this is quite simple: elongation is nothing more than the percentage of increase in a sample compared to its original size.

Advantages and disadvantages of anchor connections

The advantages of such connections are:

- have the best load capacity;

- supplied with a wide range of fixing elements;

- possibility of use in various environmental conditions;

- ease of use (there is no need to use specific equipment for installation);

- Possibility of application for static and dynamic structures.

The disadvantages of professionals include:

- the need for careful preparation of holes in durable structures;

- careful selection of anchor type;

- higher cost.

Correctly selected anchor fasteners will allow you to securely attach the structure to the wall, ceiling or floor. It will allow you to obtain a durable and reliable connection.