Spot welding is quite popular and widely used, regardless of the industrial sector and other factors. Along with the spot procedure process, a fairly important question is how to remove it. Often, to cope with this problem, specialists use special drills to drill out spot welds. It can be used in mechanical engineering - to replace or repair a body, remove an element welded by spot technology, etc.

Design

The possibility of carrying out the work in question can be primarily associated with the design features of the drill used. These include the following points:

- The working end has a flat shape.

- Along the axis there are core protrusions, which are sharpened to a cone. When forming the cutting part, an angle of 90° is maintained. Due to this element, there is no need for alignment.

A drill bit for drilling spot welds can be purchased at a specialty store. Their cost is relatively low, but to work with difficult-to-process materials, versions made from special alloys are required.

Heavy-duty spot welding drill 8 x 50 mm

In some cases, a conventional drill is used for drilling spot welds. However, when using them, it is almost impossible to achieve the required result.

Bottom line

It is necessary to note that today plasma cutting is used for the drilled hole. With its help, you can burn through any thickness of a structural part made of iron.

This is a fairly expensive service, which is why it is used in rare and extremely necessary situations. Many craftsmen who work with bodies still use spot welding.

Thanks to the appropriate drills, the work becomes easy, not costly in terms of finances, time and effort, and pays off due to its properties and functions. In addition, it is necessary to emphasize that such drills require regular sharpening using a special design.

Spot welding bit

Spot welding can be processed using a special crown. It is also used for drilling. The features of such a proposal include the following points:

- The design includes a central spring-loaded rod.

- A cutting disc is placed on the rod, which has several end teeth on the sides. Due to their specific placement, metal is removed.

- The crown metal used is characterized by high wear resistance. That is why there are no problems with removing the alloy formed in the cutting zone.

The technology of using crowns for drilling spot welding is characterized by the following features:

- The roll is pressed into the metal. At the very beginning of drilling, the main thing is to eliminate the possibility of the rod moving relative to the surface being processed.

- As the tool is immersed in the metal, the alloy is drilled out. The main thing is that the working part only goes through the depth of the seam.

- In order to increase the rigidity of the structure, the tool is placed in a special frame.

Core drill for spot welding

It is worth considering that when making a drill for drilling a spot weld and a crown, almost the same cutting alloy is used. An example is high-speed steel P18, which can withstand prolonged exposure to high temperatures without changing the main operating parameters. It is worth considering that Chinese manufacturers use 45X alloy, which is characterized by less efficiency in use.

The crown is a fairly massive instrument. That is why when using it you need to press the working part tightly against the surface being treated. It is worth considering that when working with low-carbon steel during spot welding, the structure becomes more dense and durable. That is why more effort is required when working.

Another common problem is that the design of the crown determines the uneven cutting of the teeth into the surface being processed. This is due to the presence of various protrusions that are formed during spot welding. The result of such a problem can be called eccentric drilling of a hole, after which it is quite difficult to separate the fused elements.

Peculiarities

A spot welding drill bit is used to remove a permanent weld joint. Such a cutter allows you to accurately drill out the welding point without causing significant damage to the surface of the part. Often a tool with a diameter of 8 mm is used for drilling. You can find a similar drilling tool in specialized retail outlets, but its cost can be quite high. However, the purchased drill will recoup your costs by greatly facilitating the procedure for removing parts connected by spot welding.

The main advantages of the cutter for removing spot welding fasteners.

- It is possible to carry out work on drilling welding without first forming a recess at the welding point, that is, without punching. This feature of the drill is convenient, as it saves a lot of time and effort.

- You can work with a drill for a long time, sequentially drilling several welding points in a row. Even when heated, the drill does not lose its properties.

- The service life of the tool is quite long, since this product is made from high-strength steel grades and has the ability to undergo multiple sharpening cycles.

- After drilling out the weld points, the dismantled part remains preserved for reuse. In addition, the surface of the second workpiece, to which the dismantled part was attached, is not damaged, and it can again be used for its intended purpose.

The tool intended for dismantling welding points is made of alloy steel with the addition of titanium coating. There are 2 types of such tools available: with one working side or double-sided. The drill diameters are different - they can be 6, 8 and 10 mm. The choice of drill diameter depends on the size of the weld point that will have to be drilled. In this case, an additional 1.5 mm is added to the diameter of the drilled object.

According to its structure, the drilling tool has 3 main parts.

- Core area. The height of this part must be selected so that it exceeds the thickness of the part by 2 mm.

- Cutting part. To strengthen this area, titanium coating is applied to the metal, which significantly strengthens the drill, prolongs its wear resistance and allows the tool to work regardless of its heating.

- Mounting area. This part is designed to secure the drilling tool into the holder of an electric drill.

By visual signs, it is quite simple to distinguish a tool designed for dismantling welding points from other drilling analogues - the axis of the tool has a cone-shaped shape, with an angle of 90°, while the working end part of the drill is flat.

Advantages of a drill for drilling spot welding

The tool in question, which is designed to work with seams, has a fairly large number of advantages. These include:

- The processing procedure is simplified.

- Long-term drilling can be carried out.

- The tool is ideal for creating flat surfaces.

Drilling Spot Welding

As previously noted, you should only purchase products from well-known manufacturers. This is due to the fact that alloyed alloys are characterized by a lower degree of resistance to high temperatures.

general information

Drills for resistance welding differ from conventional construction drills. They have a special shape, thanks to which they can be used to drill out weld spots obtained by resistance welding. This type of drill can be used with most types of thin sheet metal: from copper to zinc. Products made of polymers can also be drilled.

As we indicated above, a drill for spot welding has a special shape, different from the usual drill. The spot welding drill has a flat end and a small cone-shaped protrusion. The protrusion is sharpened at an angle of 90 degrees and allows you to quickly center the drill relative to the weld point.

Professionals say that it is not necessary to use special drills for spot welding to drill out weld spots. Masters of their craft can sharpen their own drill bit for drilling spot welding, using a regular construction drill bit as a “base”. It really is possible. But sharpening a drill is a topic for a separate article. Because the process is very labor-intensive and requires experience. If you are interested in this topic, watch the video below.

How to work with spot welding drills?

The drilling technology carried out is characterized by quite a large number of features. Recommendations for its implementation are as follows:

- The selected drill is installed in a drill, which should be able to adjust the number of revolutions. In addition, attention is paid to the power indicator.

- It is not recommended to use the drill immediately. This is due to the fact that it is recommended to pre-mark the joints. The case where the pin pops out and breaks due to the applied load has become quite widespread.

- The drill used is set to minimum speed. After this, the drill or crown is installed strictly perpendicular to the surface being treated.

After drilling the connection points, in some cases it is necessary to apply force to separate the part from the base. A chisel and hammer can be used for this.

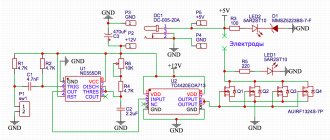

Diagram of a homemade welding machine

For everyday needs, there is no reason to buy a welding machine, especially since you can make it yourself.

The dimensions of such a device will directly depend on the needs. It is more convenient to assemble a medium-sized device. Below is a diagram of a spot welding machine.

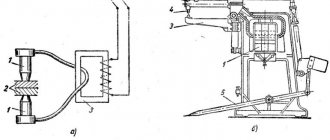

1 — modified OSM-1.0 transformer; 2 — conductor (duralumin rod with a diameter of 30, L300, 2 pcs.); 3 — liner (steel rod with a diameter of 10, L30, 2 pcs.); 4 — electrode (copper rod with a diameter of 12, L50, 2 pcs.); 5 — brass washer (2 pcs.); 6.12 — M6 screws; 7 handle; 8 - eccentric; 9 — cheek (2 pcs.); 10 - spring; 11 — output of half of the secondary winding (4 pcs.); 13 — textolite bushing (with a groove for the end loop of the spring); 14 — M8 bolt (6 pcs.); 15 — textolite washer (4 pcs.); 16 — insulating coating (varnished fabric or protective adhesive tape on a fabric basis, 2 pcs.); 17 — transformer casing.

The operation of the welding machine is based on the physical law of Lenz-Joule.

The meaning of the law is that the conductor begins to generate heat by passing electric current through itself, in an amount proportional to the resistance of the conductor material, the square value of the current and the time it takes for the current to “pass.”

Wires are selected taking into account this law.

Since resistance spot welding occurs due to an electric pulse, to create the device you will need a transformer, which is not recommended to be connected directly to the power source.

A rectifier bridge with a thyristor is required for proper connection.

The circuit of a homemade device involves the use of another power supply with a transformer and a rectifier bridge for more power.

The current is collected and the pulse is created using a capacitor.

The bridge of the first transformer is closed by a thyristor, which acts as a cathode.

It will remain open until the capacitor is completely discharged. “Impulse” is the beginning and end of the welding machine.

To create a more powerful device, the circuit changes slightly: it is necessary to add a semiconductor thyristor and a time relay.

Sharpening a drill bit for spot welding

It should be taken into account that if the drill is used frequently when drilling spot welds, the cutting part can become significantly dull. Sharpening a drill yourself is quite difficult. This is due to the following points:

- In manufacturing, metal that is resistant to temperature is used.

- The cutting part of the structure resembles a cone. In this case, the surfaces are located at an angle of 90°.

Drill sharpening

In some cases, a regular grinder is used for the job, in others a special sharpening mechanism is required. It is worth considering that if the technology is violated, the tool will simply fail.

Separating parts

Drilling is carried out in the places marked with a center punch until all metal is removed at the connection point.

You can drill over the paintwork or sand the metal with sandpaper to obtain a smooth surface. At the cored spots of spot welding, the metal element is bored using a drill.

Kits (steel processing tools) for this type of work are not specialized. All this can be purchased at stores that sell power tools.

Metal drilling kits come in a variety of diameters. You can always choose the appropriate version. There are also specialized products on sale, but they usually cost more.

It is necessary to drill spot welds at low and medium speeds. The sharpening angle of the drill is of particular importance. A point is made at the end, which will allow you to easily and quickly carry out the work process, removing the point connection. The power tool must be stopped periodically to allow some time to cool down.

Depending on the area of the contact point, it is necessary to select a drill; usually it can be 6-8 mm in diameter

If the welding point on the structure is difficult to reach, then such places require more careful handling

You can use a special drill attachment for this to drill the weld at a certain angle.

Auto body shops carry out such technological processes well and quickly using pneumatic drills, the air supply is carried out from an electric compressor.

The tool, powered from the mains supply, also has speed control functions. When carrying out work, you can always experimentally set the required spindle speed of the power tool.

Drilling out spot welding

The procedure in question is quite simple to perform. You can do it as follows:

- The most suitable tool is selected.

- The next step is to prepare the surface. To do this, mark the drilling point.

- After this, the minimum speed is set on the tool and direct drilling is carried out.

It is worth considering that in some cases the metal can be damaged. This is why you should work carefully.

Varieties

The working part of the tool can be used for any materials and surfaces, therefore there is also a classification according to the material being processed.

For metal. The type of drill is selected depending on the type of metal.

If during operation the tool works slowly and heats the metal, it is necessary to sharpen it. This is done manually if the diameter is up to 12 millimeters, and larger sizes are sharpened on a special machine.

How to prepare an area for drilling

When considering such a technology, it is worth considering that the final result largely depends on the quality of surface preparation. The features of this technology include the following points:

- It is recommended to core the drilling site. You can use a screwdriver for this.

- By cleaning the surface of various contaminants, you can significantly improve the quality of the work performed.

If you do not pre-prepare the surface, there is a possibility that the rod will pop out. If the load angle changes, the rod may break. In addition, with a fairly large contact area, the tool used can overheat greatly.

That is why it is possible to supply liquid to the cutting zone to cool the tool and the processed liquid.

Effective removal of spot welds

Spot welding is used to produce a wide variety of products. That is why the technology of its removal by drilling has become quite widespread. The resulting seam can be removed in a variety of ways.

You can achieve high efficiency when carrying out such work as follows:

- Prepare the surface correctly.

- Use only professional drills and crowns.

- Correctly choose the operating mode of the tool used.

If you choose the right drill, you can remove almost any spot weld. It should be borne in mind that quality depends on compliance with all recommendations.

Sheet element processing technology

Pneumatic drills or electric drills are suitable for these purposes. Each tool has its own pros and cons when working.

An electric tool, if drilled for a long time, becomes very hot. It also cannot be used in damp areas or in rainy weather. The pneumatic type drill is safe to use in the rain or in damp areas.

To drill spot welding joints, you can use drills of a suitable diameter or specialized crowns. The last type of metalworking tool has a design function of limiting the depth of metal cutting.

This is very convenient for long periods of work. The use of a crown will help reduce the numerical percentage of defects when separating parts.