Stages of processing metal products

Rusty metal product

The main causes of rust are interaction with oxygen contained in the air and constant contact with moisture.

This process goes very quickly, sometimes a few days are enough for a new product to become covered with rusty spots.

Regular inspection and painting of such objects can promptly prevent the spread of rust over the metal surface.

Preparation for applying paint is a rather labor-intensive process, consisting of several stages:

- removing old paint

- rust removal

- degreasing the area to be painted

- applying primer

- selection and application of suitable paint

If preparation is carried out in violation of technology and ignoring basic requirements, then this will significantly affect the final result. To get the maximum effect, it is also important to consider:

- size of area damaged by corrosion

- degree of damage

- location of the item that needs processing

- how complex is the shape of this object?

- financial opportunities to purchase the necessary tools and materials

Rusting of metals

Metal structures are subject to rust, and these processes occur in stages, chemical reactions flow into one another. Prerequisites and conditions for the start of the rusting process: the metal contains certain impurities (carbon and sulfur), oxygen and water have access to the surface. Carbon and sulfur, which are included in the composition of steels as additives, act as corrosion enhancers - the layer of formed rust is destroyed, a new layer of metal is exposed, and the process continues.

If there is an acidic environment and/or salts are present, the rusting process will accelerate even more. Acidity is increased by substances contained in atmospheric water - sulfurous and carbonate acid. Water causes corrosion of unprotected metal surfaces, regardless of their state of aggregation - in the form of vapor, liquid phase or ice.

When metals rust, the resulting layer of rust does not protect the surface, as in the case of passivation (creating a protective film on metals) and cannot prevent subsequent corrosion. Rust has a loose and hygroscopic structure, instantly accumulates moisture from the air and retains it. As a consequence, if rusting has begun, the growth of rusty layers accelerates oxidative processes for two reasons: the relative thickness of the metal decreases and the duration of contact with moisture and oxygen increases.

In ordinary cases, painting metals over a layer of rust makes no sense. Moisture and air have accumulated in the pores of the loose structure, which are sufficient to continue the processes of destruction of metals under the paint layer. In addition, rust cannot be compared to steel in terms of density; it is a weak and loose layer, and as a result, a stress zone forms under the paint layer - expansion of the corroded metal. As a result, the paint layer is covered with through craquelure cracks, and the paint quickly breaks down and flies off the surface even if the paint coating is locally damaged.

Removing old paint and rust

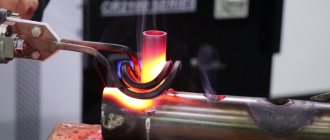

To remove old paintwork, you can use a scraper, a wire brush, or sandpaper. If it doesn't hold well, then even a metal sponge for cleaning pans will do. When these methods do not give the desired result, high temperatures should be used.

To create them, a hair dryer or a gas torch is suitable. After this, it will be easy to get rid of the swollen and burst paint.

Removing rust is not that easy. This can be done both by mechanical action on the surface and by using chemical compounds. Here are some ways:

- Metal brush, spatula, sandpaper - an old, well-known method. It is practical only in places where it is easy to penetrate and where the layer affected by corrosion can be easily removed.

- A special drill attachment will greatly simplify the work.

- A core brush and a petal wheel for an angle grinder are an effective method when the area of damaged metal is small and has a flat shape.

- The sandblasting installation allows you to remove rust even 15 years ago. Using this unit, you can clean a large area of metal surface in a matter of minutes and without much effort, even in the most difficult to reach places.

- Citric acid is used if the product has not been painted and can be immersed in citric acid for 24 hours. There is another option for working with this compound: treat the surface with it, and then cover it with plastic film and secure it so that it does not slip. This method helps even with a thick layer of rust and in places where mechanical methods do not help.

If you apply table vinegar with a sponge to the treated area and rinse, you can easily remove a thin layer of rust.

- To get rid of a thick layer of rusty deposits, phosphoric acid is applied to the metal structure with a brush or spray. It is left for 12 hours, then washed off with soapy water. Extreme care must be taken to ensure that acidic agents do not get on the face, hands, or eyes when working in rubber gloves and safety glasses.

- Rust converters have appeared relatively recently. They usually take the form of an emulsion or suspension, which is applied for several hours after removing the exfoliated layer. It reacts with rust to form insoluble iron phosphate. Then the iron salts are washed off with plenty of water.

It is especially important to thoroughly clean those places where rust forms several layers and falls off in pieces.

Work algorithm

Before painting a rusty metal structure, it must be prepared. The entire cycle of work operations can be arranged in the form of separate stages:

- Manipulations aimed at mechanical cleaning of the surface. Before painting a corrosive surface, it must be cleaned, otherwise the durability of the applied paintwork will be very low. A metal brush or a special drill attachment is suitable for the job;

- Smoothing the cleaned base with a sandblasting machine or any grinding device. Automation of the process speeds it up; manually grinding a structure is a tedious and time-consuming task;

- Rust can be removed with chemical compounds that dissolve it. These are many types of strong acids and alkalis.

Important: when working with chemical reagents, the master must follow safety precautions.

- Another option is to transform rust into a durable film. For this purpose, chemical converters are used, produced in the form of suspensions and emulsions. The drugs in this series have a significant disadvantage - the ability to change the color of the metal finish;

- After cleaning the surface, it should be degreased. If this step is omitted, the adhesion of the metal base will be low. It is good to wash rust with detergents containing citrus extracts. Sometimes wet cleaning causes rust stains that can be easily removed with a regular solvent;

- Priming a metal product. For this purpose, an inhibitor primer with iron oxide or zinc chromate is used. The product is applied strictly according to the instructions that come with the bottle. Advice: many users do not recommend using a sprayer for these purposes; manual application guarantees 100% filling of the metal pores;

- Final painting. Matte or glossy paint is applied in two layers. A roller or wide brush is used. Manual painting is of higher quality, since all areas are guaranteed to be covered with a protective composition.

As can be seen from the procedure described above, even a non-professional craftsman can paint rusty metal. Consistent implementation of key steps will inevitably lead to the desired result - the metal structure will be reliably protected from corrosion for some time.

Do you have a car and need money? Work as a courier using the Yandex.Pro application and earn up to 2,800 rubles per day! More details at the link.

- Convenient schedule.

Work a few hours a day or work a full shift. - Fast start.

You can start placing orders on the same day that the documents are completed. - Fixed salary.

The average courier earnings are 2800 ₽ per day before deducting the partner’s commission - Clear terms.

Parcels are insured and limited in weight: up to 10 kg for pedestrians and up to 20 kg for auto couriers. No work experience or special license required.

Degreasing and priming

Primer for metal

Degreasing is carried out using gasoline, acetone, and turpentine.

Using a brush, roller or spray, they treat the metal surface.

Then wash it off using a piece of rag.

A concentrated soap solution or diluted detergent will also work.

After this, you need to wait until the surface is completely dry.

The primer is used to close pores and cracks and make the surface smoother.

It also ensures good paint adhesion to the metal.

When choosing a primer, you should take into account that some of its types are highly specialized, intended for use only with certain types of paints, while others are universal and suitable for almost all types of paint.

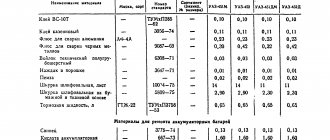

The following discusses several types of primers and their features:

- GF-021 is a gray liquid. It is diluted with a solvent. Its main function is to remove traces of corrosion. It can be used without subsequent treatment with any paint. It takes 12 hours to dry completely. It is characterized by low heat resistance - can withstand temperatures up to 60 degrees.

- Primer GF-031 ideally protects against corrosion. She is not afraid of high temperatures (up to 200 degrees). It is based on glypthal varnish. It has a yellow color. For dilution, it is recommended to use xylene and solvents (for example, RS-2, RKB-1). This primer is of such high quality that it is used in the aircraft industry for coating surfaces. It is sold at retail; the price is affordable.

- The VL-02 primer mixture contains orthophosphoric acid, which, by destroying metal particles, creates a continuous film. Its basis is polyvinbutyral. For dilution immediately before use, solvents R-6, 648 and RFG are used. It dries in record time - in just 20 minutes at a temperature of + 22° C. It is compatible with almost all enamels and organic solvent paints. It is especially good for processing galvanized metal, aluminum, and stainless steel.

- The composition of the AU-1417R primer suspension includes pigments, urethane and a rust converter. The presence of the latter allows you to process black steel without first cleaning the rusty metal. Urethane is a chemical widely used in the production of polyurethane foam. It ensures a high degree of adhesion of this primer to the metal. Thanks to the pigments, you can choose the appropriate color and use AU-1417R as the main paint. Then it is applied in several stages. It is important to wait until each layer is completely dry. This suspension also combines well with polyurethane enamels.

It is advisable to use a brush or roller when applying the primer. The sprayer does not always provide 100% closure of all grooves and cracks, especially if the surface of the object has a highly porous structure.

Preparing metal products for painting

In order to obtain an even and durable coating that will retain its properties and appearance for a long time, the surface of the product must be properly prepared. The technological process consists of the following stages:

- Cleaning.

Dirt, dust, remnants of the old paint layer and rust are carefully removed from the surface of the metal product. To do this, use coarse-grained abrasive materials, special brushes or a drill with an attachment. The choice of the right tool depends on the degree of contamination and the area of the corrosion area. Then use a clean paper napkin to wipe away any remaining dust. When processing large surfaces or difficult-to-remove remnants of old coating, a sandblasting machine is usually used.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

If the old layer of paint is “tightly” adhered to the surface of the workpiece, it does not need to be removed. To check its strength, notches are made in the form of a lattice with a sharp knife, and then adhesive tape is glued to this place and sharply torn off. If there are no traces of paint left on the tape, the coating does not need to be removed. If there are particles of old coating on the tape, it is completely cleaned.

- Priming and degreasing.

The stage of removing fatty contaminants is mandatory in the process of preparing for painting a metal product if polymer materials are selected or the next step is dipping. When applying other types of coatings, this stage can be skipped. But if there is visible fat deposits on the product, it must be removed.

For this, non-greasy solvents are used - acetone or xylene, which are applied to the part using a napkin or in the form of an aerosol. The latter type of spraying allows you to degrease even hard-to-reach places.

Be sure to wear protective gloves and breathing protection when working to avoid contact with these harsh chemical liquids. In the case of sandblasting, additional degreasing is not required, since grease deposits are removed along with other contaminants.

Primer - the application of the first layer of coating - is necessary for a higher degree of protection of the metal surface from adverse environmental conditions. It also makes the surface smoother, filling small defects.

VT-metall offers services:

Manufacturers offer a wide range of primers with anti-corrosion components. Universal primer-enamel paints are also offered, combining the properties of primer and paint at the same time. Such compositions reduce the cost of painting metal products and reduce repair time. But the traditional method of pre-priming is still used more often.

Usually two layers of primer are applied. This amount is enough to create a reliable and durable coating, even without applying a layer of paint. It is recommended to apply the primer using a roller, which covers noticeable surface defects well. The final coat of paint is used to give the part an attractive appearance, beautiful color and glossy shine.

Paint selection

After priming, painting is carried out in the main color. When choosing what to paint rusty metal on the street, it is important to consider the basis of the materials. It must be compatible with the previously applied primer layer.

If such a layer is missing, then choose such coloring agents that simultaneously solve the problem of rust and provide the required shade of the product. Such materials contain polymer components that neutralize the oxidative process.

Phosphoric acid, often used for this purpose, eats away rust. It acts where traces of corrosion could not be removed and protects the metal.

Under the influence of such paints, a continuous film is formed that does not allow air and moisture to pass through. This prevents rust from forming.

Paints offered on the market can be divided into ordinary enamels, acrylic (soluble and insoluble in water), created on the basis of epoxy resins, and alkyd.

Coating technology

Spray painting

If you are thinking, for example, about how to paint an iron garage or other metal structure, then you should definitely know that this procedure should consist of three main stages of work, the order of which must not be disturbed:

- Preparatory work;

- Application of primer;

- Coloring.

Types of paints

Acrylic paints are diluted only with water. They are considered combination paints because they combine three processes (surface stripping, priming and painting) into one. Apply them directly to rusty metal.

Their composition is unique in that it neutralizes rust, protects the metal from future corrosion and gives a beautiful appearance. The cost of these paints is quite high.

Their advantages include:

- No need to clean off rust.

- Long service life of painted surfaces subject to all technological requirements.

- No microcracks under mechanical loads.

- Dilution with water does not cause significant environmental damage.

- Easy to use.

- Can be used for both external and internal work, including in rooms with high humidity.

A distinctive feature of such paints is their good adhesion to the metal, even if there are remnants of a previously applied layer. They are mixed and applied to a degreased metal surface.

Any device for painting work can be used as a tool. They are based on water, so they must also be diluted with water.

Paints created on the basis of epoxy resins are called organo-thinned and two-component. They can also remove rust. As the name suggests, they have two components: a base and a hardener.

Epoxy resins create a strong insulating film. Hardener is sold separately.

The quality of painting depends on the proportion in which these two components are mixed. Usually the hardener is no more than 10%. More precise instructions are provided on the packaging of each product.

If necessary, these paints and varnishes are diluted with special active thinners. Drying time ranges from 4 to 10 hours. These paints offer a wide range of colors and are attractively priced.

Alkyd paints and enamels are sold ready-to-use. They are based on artificial alkyd resins and organic solvents. After complete drying, the surface becomes glossy. If the paint is a bit thick, you can use white spirit or turpentine to thin it.

It is easy to use and makes it possible to paint large areas in a short time. After drying, it forms a hard film of fairly significant thickness, which prevents the influence of environmental factors. It provides a variety of colors. Its disadvantage is severe toxicity.

Water-dispersed compositions save money. Paints with anti-corrosion additives and rust converters are more expensive, but they save effort and time on cleaning the surface. In addition, they create a durable, elastic coating that remains unchanged over time.

Surface preparation

We have gradually come to the conclusion that rusty steel products require minimal treatment before painting. How to prepare products depends on their condition.

Surfaces covered with rust in small spots or a uniform thin layer require dust removal and degreasing. It is enough to wipe them with a rag soaked generously in solvent. Another good option is to use aerosol degreasers: they contain corrosion inhibitors that reduce the chemical activity under the protective layer to zero.

Heavily rusty surfaces must be cleaned by hand: chop off large peelings, peel off with a scraper, then treat potholes and small shells with a wire brush. There is no need to polish to a shine: the surface may be covered with rust, but the last layer should be dense, durable and, if possible, uniform.

A prerequisite before painting for rust is to thoroughly dry the part. If possible, keep the product in room conditions at a humidity of 40–50% and a temperature of 20–25 °C. If the product is permanently fixed outdoors, schedule painting after 3-4 days of exposure in warm sunny weather. The more moisture has time to evaporate from the rusty layer, the lower the risk of premature damage to the coating.

Painting process

How to paint a metal fence

When painting metal products, you need to take into account that the temperature of such a surface, heated by the sun, can be much higher than the ambient temperature.

Painting heated products can lead to unwanted defects.

In summer, it is recommended to carry out such work in the morning.

On the other hand, painting wet, damp or condensation-covered surfaces is unacceptable.

Fog also creates excess humidity. The weather during the painting process of metal products located outdoors should be dry.

To apply paint you can use the following tools:

- Using paint brushes (care must be taken to ensure that streaks, streaks and drops do not form; a good method for products with complex shapes).

- Using rollers (preferably 30 cm in length; moving the roller from top to bottom, you need to overlap the strips).

- Spray paint sprayer (the most economical option).

One-time painting rarely gives the expected result. Usually it is necessary to make 2-3 layers, sometimes four or more. Allow at least 3 hours for the paint to cure before applying the next coat.

When is it possible to paint metal without stripping?

The general complex of preparing metal products for painting includes stripping, grinding, coating with primer and a layer of protective enamel. However, stripping is not always possible; in some cases it is easier to apply a coating with special characteristics. Let's try to figure it out.

We discussed above the first criterion that influences the possibility of painting against rust - the density of the rusty layer. More precisely, the product’s ability to accumulate corrosion activators. Over time, the variety and content of active chemical compounds increases, which is why, even in the absence of oxygen and moisture, reactions will still occur inside. It is impossible to predict how paintwork materials will behave under such operating conditions.

Another important factor is surface quality. A small, uniform layer of rust, similar to powder, allows the paint to penetrate to the surface of the metal and firmly contact the “body” of the product. But the presence of swellings and peelings on the rusty layer is almost guaranteed to lead to the destruction of the protective coating. Oil residues have a negative impact: if the rolled product has not been degreased, oil impurities can have an unpredictable effect on the protective layer.

Painting rusty surfaces in a cellar

When deciding how to paint rusty metal in a cellar, you need to be guided by the same principles as for the street, and choose from the same materials. The following must be taken into account:

What kind of ventilation is there in the cellar?

Converter dyes contain concentrated acid. When inhaled, it damages the mucous membranes of the respiratory tract. These chemical burns are difficult to treat. To avoid harm to health, you need to create good ventilation.

In those cellars where this is not possible, a respirator should be worn when working with chemicals. This creates inconvenience during work, but protects the respiratory system.

There is another way: choose paints and varnishes without a rust converter in their composition. Then it is necessary to reduce the painting time as much as possible due to the toxicity of such materials and the lack of protection for the mouth and nose.

How dry is the surface?

The question is not out of place, since the humidity in the cellar is usually significantly increased. It is not recommended to use special rust converters here, because they are washed off with water and the surface then has to be dried for a long time.

It is better to resort to mechanical cleaning methods if the shape and size of the object allows.

How to paint metal - applying primer

There are about a dozen ways to apply paint without removing rust. Most of this group of technologies involves factory methods of processing and preparing products; as a rule, we are talking about protective processing of heavy metal structures for construction. In private, you can use two options:

- Coat with expensive two-component paint, having previously treated the surface with a passivating composition, usually containing orthophosphoric acid.

- Coating with a universal primer suitable for application against rust, followed by painting with alkyd or polyurethane enamel.

The practical difference between these two methods lies in the cost of materials and the durability of the protective coating. Two-component paints are applied in a thicker layer and form a durable film. Unlike conventional enamels, this coating does not allow even minimal gas exchange; air and water vapor do not penetrate the rust. In addition, the paint has a higher hardness and at the same time retains elasticity; it can withstand even very significant swelling of rust. In this case, the layer of corroded iron is constantly compacted, and the reaction subsides.

How to paint metal, a budget type of coating in the form of primer and enamel ensures the safety of the product for no more than 2-3 years and requires regular updating. The latter consists of cleaning and degreasing the enamel layer and then applying another one. The essence is the same: over time, the thickness of the paint layer becomes large enough to ensure complete isolation of the product from atmospheric influences.

Description of materials

Many compounds that can be used to treat corroded metal are included in the group of water-dispersed (water-diluted) primers and primer paints. The latter include phosphoric acid, which is known to bind corrosion. Painting with these solutions allows you to create a polymer film on the structure - an excellent barrier from the aggressive influence of the external environment.

Also in demand are 2-pack solvent-based formulations (a mixture of base and hardener). Such mixtures, which lie directly on the rust, may contain the following components:

- Corrosion inhibitors;

- Epoxy resins based on targeted additives (EP-0199);

- Primer enamel type “Gramirust”;

- An organic solution containing a copolymer of vinyl chloride and vinyl acetate (XC-500).

Painting metal with a composition diluted with water is possible only in the absence of aggressive external factors. Such solutions are environmentally friendly, inexpensive and do not look flashy. Water-dispersed coatings can be applied to rust with a brush or spray, depending on the scale of the work. The resulting coating is matte and porous.

Most often, water-dispersed compositions are applied to rusty metal before painting solvent-based protective agents.

Which is better: heated floors or radiators?

Warm floorBatteries

In order not to apply 2 layers of different compositions to the rust, you can purchase a new generation combined product - 2-pack solvent-based products with epoxy resins.

It is necessary to quickly paint over rust with a two-pack paintwork material, because the individual components of the composition, after mixing, have a short period of viability. Before carrying out large-scale repair work, this factor must be taken into account.