Methods of heat treatment of materials

Equipment for heat treatment of steel, cast iron, aluminum and other metals is intended for heating and subsequent cooling of raw materials. During these processes, its structure and properties change, while the chemical composition remains original. The main types of thermal effects are:

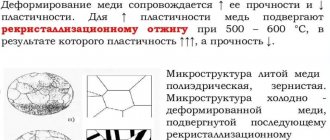

- Annealing . Metals heat up and then cool down. The temperature decrease occurs in the oven at a slow pace.

- Hardening . Processing occurs when the degrees rise to a critical level, followed by rapid cooling.

- Vacation . Carried out after hardening, it is designed to reduce brittleness and stress in steel, and increase its flexibility.

- Normalization . A process similar to annealing. The difference is that the metals are cooled in the open air.

The process of processing metal blanks in an industrial furnace

Weld processing - overview of methods

Welds are responsible for the integrity of the metal structure. In particular, the connection must be strong enough, resistant to rust and moisture. Weld seam processing is designed to ensure the fulfillment of these tasks.

Processing methods

There are three methods by which welded joints are protected:

- Heat treatment. Thanks to this method, it is possible to remove residual stresses in the material resulting from welding work. Heat treatment is carried out using one of two technologies: local, when only the connection itself is heated or cooled, or general - the entire part is subject to temperature treatment.

- Mechanical restoration. In this case, the task is to remove slag residues and check the reliability of the connection. A typical example of machining is tapping a seam with a hammer or sanding it. If the slag is not removed, corrosion may develop.

- Chemical treatment. Applying protective coatings to joints is one of the ways to combat corrosion processes. The most affordable option for chemical protection is treating the seam with a primer paint and varnish material.

Heat treatment

In addition to reducing residual stresses in the metal, heat treatment allows you to achieve the following goals:

- make the structure of the seam and heat-affected zones more adapted to external factors;

- optimize the physical and operational properties of the material, in particular, increase rust resistance, heat resistance, etc.

Heat treatment of welded joints involves heating the welded joint or the entire metal to a given temperature for a certain time. Next comes artificial cooling, which is also carried out according to a certain scenario.

Heat treatment equipment

Four types of technological equipment can be used for heat treatment of joints:

- Induction devices. Induction heating is often used during pipeline installation. The essence of this method is the use of copper inductors, including multi-core air-cooled copper cable. When installing the inductor on the pipeline, the distance between the pipe and the inductor must be taken into account. The general rule is: the larger the gap between objects, the worse the equipment's power is used.

- Flexible resistance heaters. This method is considered one of the most convenient and affordable methods for processing welds.

- Muffle furnaces. When working with this type of equipment, special attention must be paid to the uniform heating of the connection, which is achieved by non-centered installation of the part in the furnace.

- Heating using gas-flame equipment. When using gas flame heating, welding and special multi-flame gas burners are used. Gas heaters produce thermal energy resulting from the combustion of a mixture of combustible gas and oxygen.

Heating equipment is selected based on installation conditions, availability of a particular type of device and other circumstances. Heating equipment must meet certain requirements: be clearly connected to the welds, not have too much mass, and ensure uniform heating of the joint both in width and length.

To reduce heat loss, all kinds of heat insulators are used when heat treating welded joints.

Thermal insulation must be heat-resistant with low thermal conductivity, durable, but at the same time flexible, wear-resistant and safe to use.

Heat treatment methods

Several methods of heat treatment of welded joints are known:

- Preheating. It is used both before welding and during welding of parts. This type of heat treatment is used when welding structures made of low-carbon steel. The metal warms up to 150-200 degrees Celsius.

- High holiday. The technique consists of heating the material to 650-750 degrees Celsius (the specific temperature depends on the type of steel). The temperature is maintained for 5 hours. The technology makes it possible to reduce stress by 80%, as well as increase the material’s resistance to mechanical stress and increase its elasticity.

- Normalization. Applicable to carbon and low-alloy steel grades. Such heat treatment of the compound is carried out at temperatures from 950 degrees Celsius. At the end of heating, exposure and cooling are carried out under ambient conditions. Normalization makes it possible to reduce the grain size of the metal, reduce stress, and also increases the strength of the weld.

- Austenization. It is the hardening of a welded joint by heating it to a temperature of 1070 degrees and above. The part is heated for 60 minutes, and then rapid artificial cooling is performed. The technique is widely used for hardening austenitic steels. The result of austenitization is increased elasticity of the welded joint.

- Stabilization. Stabilizing annealing differs from austenitization by a lower temperature and a shorter period of holding the metal.

- Thermal rest. The technology consists of heating the weld to 250-300 degrees Celsius. Then the metal is kept in a heated state. As a result of the procedure, the level of diffuse hydrogen in the welded joint is reduced and internal stresses are reduced.

The choice of the method by which heat treatment of welded joints will be carried out depends on the physical and chemical characteristics of the steel (determined by its grade). Fulfillment of technological requirements is of particular importance, otherwise the quality of the welded joint will deteriorate.

Key parameters to consider when performing local heat treatment:

- width of the heated area;

- uniform heating across the wall thickness and width of the heated area;

- holding period;

- cooling intensity.

Mechanical restoration

Mechanical elimination of welding defects is carried out using a wire brush. You can greatly simplify the task and improve the quality of sanding if you use a portable sander or an angle grinder with a flap attachment. Instead of a nozzle, you can also use an abrasive wheel.

Mechanical cleaning allows you to remove the following weld defects:

- scale;

- burrs;

- oxides;

- consequences of discoloration.

Despite the simplicity and low cost of the technology, there are a number of nuances regarding the choice of nozzle, knowledge of which will allow you to perform the job better:

- First of all, you need to choose a grinding wheel from a suitable material. Aluminum zirconate circle is best suited for mechanical cleaning. The advantage of this material is that, firstly, it provokes corrosion processes, and secondly, aluminum zirconate is stronger than aluminum oxide, from which some types of nozzles are also made.

- The blades of the grinding wheel should be on the fabric component. The fabric is more reliable and more resistant to heavy loads compared to paper, which is sometimes used on petals as a base. However, such attachments cost much more than their paper-based counterparts. The higher cost of fabric attachments is completely justified and will pay off for work that is aggressive towards the material, such as sanding seams.

- The size of the abrasive grain depends on the type of work being performed. Very often, when cleaning joints, nozzles with different grain sizes may be needed. Therefore, it is recommended to purchase several types of attachments at once.

- If you need to properly clean a seam, then different grain sizes are simply necessary, since grinding is carried out with a gradual change of attachments to smaller grain sizes. For example, large scales are removed with coarse-grained nozzles, but fine grinding is done with fine-grained nozzles. Finishing penetration is carried out with the finest grains. Nozzles should be changed sequentially - no more than one size may be missed. However, when it comes to creating a mirror-like shine on a welded joint, no size can be skipped.

- To process seams located in hard-to-reach places (cavities, edges, holes), special devices are used - burrs installed in a grinding machine. Burrs come in a wide variety of sizes and shapes, so choosing the right configuration is easy.

Types of heat treatment equipment

Since heat treatment furnaces and equipment are designed for different purposes, they differ in:

- Loading hole location . Horizontal, vertical, tubular, under a hood, in the form of a well.

- Additional features . Work in vacuum, gas environment, etc.

- Temperature capabilities . Low, medium or high temperature.

This is how a vertical oven is loaded

Depending on the fuel used, equipment for heat treatment of metals and other materials can be divided into the following types:

Gas ovens

In order to reduce heat loss, chamber heat treatment furnaces are well insulated and made of refractory materials. The hearths of such devices are made of cast iron, steel, and can also be ceramic or silicon.

Thanks to the ability to set precise settings, the furnace can operate over a wide temperature range - from slight heating to complete melting of the material

Thermal chamber gas furnace at a new facility, ready for operation

Muffle structures

Muffle equipment for heat treatment, which can be purchased at, is distinguished by its special chamber capabilities. It serves several purposes simultaneously:

- Maintains the desired temperature.

- Provides even heating.

- Protects samples from contact with combustion products, air and fumes.

Materials for the manufacture of muffle furnaces can be ceramics, clay, mineral wool, asbestos, brick and others.

SNOL oven with a ceramic chamber and the chamber itself

Electric furnaces

Electrical equipment for the heat treatment of metals has the greatest variety of models and varieties. According to the method of influencing the material and converting energy, they are divided into:

- Induction . The crucible of such industrial furnaces includes metal parts. Heating occurs through the release of energy when an electric current passes through them. Mainly used for making alloys.

- Arc . Operate with direct or alternating current. Metals are processed in a vacuum or gas environment. The devices must be equipped with a cooling system. They are an option for inexpensive equipment for heat treatment, as they consume a small amount of electricity.

- Infrared . The heat source in such devices emits infrared radiation, which promotes rapid and uniform heating of parts.

Brand new electric oven with thermofiber chamber

Chamber electric furnaces for tempering with a rolling hearth type PVO

Chamber-type electric furnaces with horizontal loading are designed for heat treatment modes that require uniform heating of parts and maintaining temperature with high precision. Such processes include tempering of steel parts, which is the final operation of heat treatment and allows, after hardening, to reduce internal stresses and obtain a more balanced structure.

The working space of the heating chamber is formed by screens made of stainless steel sheets. At the bottom of the chamber there is a tray in the form of a lattice. Heaters made of superfechral alloy wire are located in the air channels between the screens and the furnace lining. Along the length of the heating chamber, air defense furnaces have several independent heating zones.

A centrifugal fan is installed on the top cover of the furnace in each zone. The fan ensures constant circulation of air flow, which allows you to set a uniform temperature throughout the entire volume of the furnace working space.

Electric furnaces PVO 30.40.25/7 and PVO 35.80.25/7 have a composite door. The lower part of the door is mounted on the hearth and moves with the hearth. On the PVO 30.40.25/7 electric furnace, the upper part of the door is equipped with an electromechanical lifting drive. The upper part of the air defense door 35.80.25/7 opens by rotating around a horizontal axis using hydraulic cylinders.

All electric furnaces of the PVO type are equipped with a mechanized hearth drive. The movement of the hearth and door is controlled from a remote push-button control station.

Electric furnaces are supplied assembled and lined.

All ovens have electronic heating control with digital temperature display. The use of high-precision temperature controllers allows you to set a uniform temperature throughout the entire volume of the furnace with an accuracy of ±5°C.

To record temperature conditions, an electronic temperature recorder is installed on the control cabinet.

The necessary power and control equipment is mounted in the control cabinet.

| TYPE | Opening/closing the door | Tmax, °С | Working space width×length×height, mm | Overall dimensions width×length*×height, mm | Power/voltage, kW/V | Furnace weight, kg |

| Air defense 8.16.8/7 | R | 700 | 800×1600×800 | 1430×4570×2295 | 60/380 | 2100 |

| Air defense 8.16.8/7 I1 | E | 700 | 800×1600×800 | 1430×4660×2785 | 60/380 | 2100 |

| Air defense 10.22.10/7 | R | 700 | 1000×2200×1000 | 1695×5445×2025 | 100/380 | 2500 |

| Air defense 10.22.10/7 I1 | E | 700 | 1000×2200×1000 | 1695×5715×2410 | 100/380 | 2500 |

| Air defense 17.15.16/7 | E | 700 | 1700×1500×1600 | 2500×3500×4100 | 160/380 | 3000 |

| Air defense 17.42.16/7 | E | 700 | 1700×4200×1600 | 2500×9800×3800 | 280/380 | 7500 |

| Air defense 30.40.20/7 | E | 700 | 3000×4000×2000 | 4600×10900×3700 | 300/380 | 15000 |

| Air defense 30.40.25/7 | WITH | 700 | 3000×4000×2500 | 4200×10000×5000 | 380/500 | 20000 |

| Air defense 35.80.25/7 | WITH | 700 | 3500×8000×2500 | 5100×20000×4800 | 700/380 | 25000 |

* - overall size with the hearth pumped out P - manual door opening, electromechanical drive of the hearth E - electromechanical drive of the hearth and door C - composite door: lower and upper parts of the door

Design of heat treatment equipment

Despite the differences in the way heat treatment equipment operates, they all have a similar design, which includes:

- Loading hole . A bucket, conveyor, winch, etc. can be used to load raw materials.

- Unloading block . It is a chamber where finished products are dosed.

- Smoke ducts . The latest models of appliances are equipped with automatic chimneys located on the back of the stoves.

- Camera . The main structural element into which the starting material is embedded.

Since the range of machines for processing metals, ceramics, porcelain, etc. is constantly updated, contact a specialist to correctly select the appropriate device! We will certainly help you choose the optimal equipment for your goals.

Additional mechanisms for providing heat treatment furnaces

Some types of production produce rolled products. This includes profiles, pipes, welded structures, etc. To give the required shape before or before the part enters the thermal oven, special temperature presses are used to straighten surfaces. There are dynamic impact devices and static units. The first option involves creating the desired geometry using pulsed impacts with the surface of a press for thick-walled or rolled pipes. Static presses make smooth and slow straightening of thin-walled pipes and profiles of various shapes. The editing procedure itself takes little time and includes the geometry control stage, the editing itself and final quality control. When highly critical products are processed on such a device, individual low-temperature tempering is used to relieve metal stress, carried out at a temperature of about 200 degrees.

After the product has undergone heat treatment, it must be tested to ensure the required quality. For these purposes, a stationary hardness tester is used, which provides operational control directly at the production site. If the object being processed has large dimensions that do not allow readings to be taken with a standard device, it is possible to use portable hardness testers, which differ in the direct method of measurement and the indirect option of reading mechanical properties. Some industries often use coercimeters, the main purpose of which is to control the chemical-thermal hardness, depth of the formed layer and other parameters on sample parts. In parallel with this device, portable microscopes with a dimensional grid printed on the lens can be used.

Treatment of the weld after welding

Welding is the most reliable, fastest and economical way to create permanent joints of metals and their alloys. During the welding process, the metal is heated to its melting point. This causes internal tension in him. In addition, slag remains on the surface of the weld. To remove slag and relieve internal stresses in the metal, various weld processing methods are used.

Basic methods of processing welded joints

The following weld processing methods have become the most common:

- Thermal. Used to eliminate internal residual stresses. It is carried out by local or general heating.

- Mechanical. Cleaning welds after welding removes slag and scale from the joint surface.

- Chemical. Consists of degreasing and coating with a protective layer. Prevents the formation of corrosion foci. The method is used to process materials susceptible to corrosion that will have to work in active environments.

The method of exposure is chosen based on the technical requirements for the structure and its operating conditions. Often all three methods are used sequentially.

Heat treatment

Heat treatment of welded joints must be carried out after welding thin-walled products that are especially susceptible to deformation under the influence of internal stresses. Such structures include pipelines, various containers, and pressure vessels.

Heat treatment of the weld

Heat treatment is also carried out for most critical structures, such as nuclear and chemical reactor vessels.

Heat treatment consists of heating the part and then cooling it according to a strictly specified temperature schedule.

Why is it needed?

During welding, a small area of the part near the seam is heated. Uneven heating leads to the emergence of internal stresses that can deform or even destroy the part. In addition, in the zone of uneven heating, the structure of the metal crystal lattice changes, which leads to a deterioration in its physical, mechanical and chemical properties.

Near the weld seam there is a hardening zone in which the strength is increased and the elasticity, on the contrary, is decreased. It is surrounded by a zone of softening, in which ductility is preserved, and the strength becomes lower than it was before welding.

Heat treatment of welded joints is designed to restore the internal structure of the metal and its properties, to restore the character

Chamber furnaces for heat treatment of metal surfaces

Chamber furnaces for heat treatment of metal are made of high-strength materials. Most often, the inside of the work box is protected with thermal fiber and fire-resistant bricks. Among the features of the models are:

- Operating temperature range from 50 to 1300°C.

- Heaters of open or closed type.

- Devices for removing excess moisture.

A chamber furnace for heat treatment may have reinforced walls and hearths. Additional equipment with shelves and baking trays, racks, hangers, rods and other devices is also allowed. To make it easier to monitor work processes, the door has a viewing window.

Industrial chamber electric furnace SNOL 144/1250 MS for metal processing

Basic set UINT-50-2.4

| № | Name | Quantity |

| 1 | Universal induction heating installation with power - 50 kW, frequency - 2.4 kHz. | 1 PC. |

| 2 | Input cable (connected to unit) | 12 m. |

| 3 | Output cable (connected to unit) | 20 m. |

| 4 | Wire for inductor | 22 m. |

| 5 | Compensating capacitor (mounted on the trolley) | 1 PC. |

| 6 | Recording single-channel device for measuring and recording the temperature of the heated part of the pipeline (built into the installation) | 1 PC. |

| 7 | Temperature rise and fall speed regulator (built into the unit) | 1 PC. |

| 8 | Thermocouple | 1 PC. |

| 9 | Compensation wire (connected to the installation) | 20 m. |

| 10 | Manual | 1 PC. |

The questionnaire can be downloaded here

SPECIFICATIONS

| Model | TIS 45/AC-PH | TIS 60/AC-PH | TIS 80/AC-PH | TIS 160/AC-PH | TIS 250/AC-PH |

| Power supply parameters | 380/220V, 50Hz | ||||

| Maximum power | 45 kW | 60 kW | 80 kW | 160 kW | 250 kW |

| Heat treatment parameters | |||||

| Maximum pipe diameter | 630 mmWith a wall thickness of 14 mm | 1020 mmWith a wall thickness of 22 mm | 1220 mmWith a wall thickness of 22 mm | 1420 mmWith a wall thickness of 40 mm | 1420 mmWith a wall thickness of 70 mm |

| Maximum wall thickness | 40 mm with diameter 325 mm | 50 mm with diameter 630 mm | 50 mm with diameter 820 mm | 60 mm with diameter 1020 mm | 70 mm with diameter 1420 mm |

| Maximum heating temperature | 620-830 °C | ||||

| Heating speed (adjustable) | 1-50 ºС/min | ||||

| Maximum duration of the heat treatment process | up to 24 hours | ||||

| Parameters of preliminary and accompanying (interlayer) heating | |||||

| Maximum pipe diameter | up to 1420 mm | ||||

| Maximum wall thickness | 70 mm | ||||

| Maximum heating temperature | 300 °C |

Equipment used

The following types of equipment are used for heat treatment of welds:

- Induction. The operating principle is based on heating the metal by eddy currents created by an induction coil (inductor) connected to a high-frequency generator. The heated area is preliminarily covered with asbestos. On top of it, coil turns are wound with a flexible wire in increments of 2.5 cm at a distance of 25 cm on both sides of the joint. Pads with wires located inside are also used as an inductor. The technology ensures fast, uniform heating of the joint area, regardless of the position of the parts.

- Radiation. Heating is carried out by heat from nichrome wires through which electric current passes. Flexible heating elements are convenient for processing complex shaped joints. Radiation equipment is more effective than induction equipment when working with metals with low electromagnetic characteristics.

- Gas is advantageous for use because it does not require electricity. However, it takes a long time to heat up. Therefore, the equipment is used on small structures. To ensure uniform heating of the joint, the work is performed with two multi-flame acetylene torches simultaneously on both sides.

- Muffle furnaces are used to work with small parts. They are also used on small diameter pipelines.

Types of chamber furnaces for solder reflow

A chamber solder reflow furnace manufactured by SNOL is necessary for soldering circuit boards that contain components for surface fastenings. Equipment is distinguished by the following features:

- Construction type.

- Warm-up method.

- Number of heating zones.

- Number of cooling sections.

When choosing equipment of this type, please note that it differs in the intensity and speed of heating. Just like chamber drying cabinets, they can have low, medium and high productivity.

Chamber electric furnace SNOL 4/1300 for solder reflow

Chamber kiln for firing ceramics

A chamber kiln for firing ceramics, porcelain or clay is used in educational and art centers, in pottery workshops and souvenir manufacturing enterprises. The type of equipment is selected depending on the needs and volume of production. Considering these factors, there may be different:

- Design features.

- Working chamber size.

- Temperature range.

Ovens are equipped with vertical or front loading. Pods can be either fixed or retractable. To ensure uniform temperature, fans are installed.

Electric furnace SNOL 80/1100 for firing ceramics and porcelain

The chambers are made of fire-resistant and heat-insulating materials. Tubular or wire high-resistance parts are used for heating elements

Classification of chamber thermal furnaces

For extremely precise operation, thermal chamber furnaces are equipped with hardening sections, microprocessor controllers and programmers. The devices automate equipment maintenance performed according to a given program. A properly selected oven with a fiber chamber not only speeds up the heating process, but also increases its efficiency.

Types of chamber furnaces can be divided into:

- Design features . The chambers are vertical, pit, bell-shaped, well-shaped.

- Energy source . The most popular are electric models; gas and oil models are also used.

- Like a pod . The choice depends on the volume of materials processed. There are retractable, roll-out and fixed slabs.

If we consider chamber firing furnaces in more detail, we can distinguish several main groups. They differ not only in purpose, but also in the volume of working boxes. There is also a wide choice of manufacturing materials, boundary temperatures, thermal gradients, types of convection and other factors.

Chamber firing furnace SNOL 7.2/1300 L

Vacuum ovens

Vacuum furnaces are the optimal means to produce high-quality tools, high-speed steels, titanium alloys, copper, refractory metals and structural steels. Vacuum furnaces carry out all processes with high technological precision parameters. The temperature in them cannot deviate by more than 5 degrees. They are used as components of heat treatment lines.

Vacuum furnaces can use nitrogen, helium, or air. Moreover, their operation does not require the use of water quenching tanks. This makes it difficult to harden low-carbon and low-alloy steels in them. To make the inner surface of a vacuum furnace, molybdenum sheets are used, heating elements are graphite, ceramics, and powder materials.

Installations that have high power are capable of creating a pressure in a vacuum furnace of 0.00005 mbar. The maximum ambient pressure level will be 20 mbar and the temperature will be 1350 degrees. Water is used as a coolant.

Vacuum chambers are equipped with various vacuum pumps, receivers with a gas cooling medium and installations that provide reverse water cooling. The degree of automation of this heat treatment equipment can vary between 0.7-0.9.

Vacuum furnaces are expensive because they require much more money to develop and manufacture. However, they have one drawback, which is due to the fact that the surface of the alloys is dealloyed if high temperatures are used in them.

Types of chamber furnaces by hearth type

In large industries, chamber furnaces with a sliding hearth are in demand, making the heat treatment process extremely effective. They provide fast and convenient loading and unloading. Retractable hearths reduce physical stress when servicing equipment. To unload such devices outside the furnace, forklifts are used.

A chamber furnace with a roll-out hearth allows you to avoid equipment downtime, since you can load several slabs. Thus, the efficiency level increases by 1.9-2.5 times, while energy consumption is reduced to 25%.

Chamber electric furnace SNOL 3500/1200 with sliding hearth

Unlike previous designs, a chamber furnace with a fixed hearth has minimal heat loss when metal blanks are placed on the stove. Loading and unloading is carried out using mechanical devices. If we consider compact electric ovens with a ceramic chamber, they do not need to use roll-out or pull-out trays.

Chamber electric furnace with loading at different levels on removable shelves

Furnace hearths are made of heat-resistant materials such as silicon carbide, cast iron, steel or ceramics. The plates can withstand high temperature and mechanical loads