Carpentry work is a real mystery for a professional. Wooden masterpieces created by a talented “left-hander” are valued much more expensive than factory samples. It’s very disappointing when suddenly you don’t have the right tool at hand. At such moments, specialized equipment comes to the rescue of the master.

In this article we will talk about multifunctional household woodworking machines that are capable of solving several tasks at once: sawing, drilling, and milling. Today, together with the editors of the Agronom.guru portal, we will look at popular models of universal woodworking machines for the home, study their functionality and characteristics, and also provide current user reviews.

Universal household woodworking machine - a mini-factory in your garage or workshop

Sawing

They are used to cut workpieces and give them a certain shape. Divided into the following categories:

- sawmills for cross-cutting and longitudinal sawing with linear saws. Movements are reciprocating. Bulky units that require complex maintenance are now not as popular as the next two options;

- circular saws. Needed for performing transverse and longitudinal cutting with circular saws vertically and obliquely. They are used to shape primary lumber;

- belt based on a tape that rotates and moves along a linear path. Suitable for harvesting at the initial stages and sawing material later.

Safety rules when working on the machine

Any machine equipment has a class of increased danger to humans. These are the posters that hung in every factory and workshop.

Memo for a carpenter from the times of the USSR Our editors have also compiled their own list of rules, carefully re-read the following points (or better yet, print them out and hang them in your workshop):

- Operating the machine while intoxicated, under the influence of medications or other substances is strictly prohibited.

- Work in the workshop should be carried out in special protective clothing, which will prevent the possibility of being caught by rotating elements.

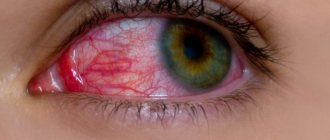

- The working area must be illuminated; the light should not “blind” the eyes of those working at the machine.

- Eyes must be protected with special glasses.

- During operation of the machine, the necessary fastening elements, as well as protective devices, must be tightly secured.

- Particles of abrasive materials must be removed from work surfaces and the floor after each stage of work.

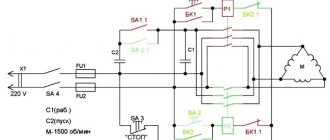

- Electrical sockets, extension cords, and any electrical equipment must be in good condition and insulated.

- It is necessary to provide the machine with reliable grounding. And the sockets themselves and the channels leading to the panel should be equipped with “automatic devices”.

Planing

Remove the top layer. The cutting tool goes deep and helps control the thickness of the workpiece, correctly creating the shape of the surface.

What types of thickness planing machines are there:

- one-sided - for processing the upper plane of massive workpieces;

- double-sided - for simultaneous work from above and below the workpiece;

- special - they immediately process the material from all sides, which simplifies the creation of the form.

There is also a jointer type for planing in one plane and chamfering at the desired angle.

Work table for the machine

The table or base for the machine is the most important structural element. The quality of the base assembly determines the safety and quality of work at all stages. Most often it is a welded or cast (which is better) structure made of cast iron and steel. Cast structures withstand greater vibrations than prefabricated ones. Cast iron is most often used in professional equipment, while “home” models are usually made of steel.

Main parts of the table: 1 – two parts of a split-type frame, 2 – movable table, 3 – fixed table, 4 – saw table, 5 – drum with knives, 6 – electric motor, 7 – sanding drum

To cut small elements, it is better to take a circular saw with sparser teeth. This will make the product look more neat.

The table can be adjusted to suit the height of the carpenter, and in some models this function directly affects the depth of cutting of wood: the lower the table, the higher the thickness of the cut.

Milling

Needed for processing wood using a milling cutter. You can work with flat surfaces with patterns, shaped variations, produce cylindrical and spherical parts, make grooves, splines, grooves, etc. Woodworking machines of this type are ideal for carrying out fine carpentry work.

Among them are:

- universal - for small and light parts. The rotation angle is adjustable in the horizontal plane;

- widely universal - equipped with a spindle head that rotates at any angle in mutually perpendicular planes;

- horizontal - there is no turning mechanism;

- vertical cantilever - the spindle is located vertically;

- non-cantilever - for working with vertical, horizontal and inclined planes;

- longitudinal - for dimensional workpieces. Massive units are used in large enterprises.

How to choose the right one

First of all, you need to think about why you are purchasing equipment: will it be one-time work on the machine, or do you plan to use it for permanent work. It is better to decide in advance on the list of tasks that you plan to perform on the machine. Study the lighting, the presence of sockets, measure the plane on which you plan to install the joinery product.

It’s better to imagine in advance where and how your machine will be located, and what kind of work you will entrust to it.

General recommendations for choosing a universal wood saw: when choosing a combined machine, it is better to pay attention to models with a circular saw. This “helper” is useful for almost all types of work: from preparing timber to cutting blanks for furniture. In addition, many machine models are equipped with a jigsaw. A stationary tool is much more convenient than a manual one, it does not block the master’s view of the material blade, and you don’t have to worry about the progress of the saw, because everything is provided for in advance by the device.

When working on the machine, use only dry wood. This will reduce the load on the machine and improve the quality of the product.

Additionally, woodworking machines are equipped with attachments for drilling, milling, edge processing, cutting quarters and grooves. There are models that combine up to five different functions, while others provide only two.

Turning

For the manufacture of elements in the form of bodies of revolution. They are created from straight blanks, from which a layer of material is removed in several stages.

The processed product is widely used in the construction industry and furniture production. These elements are used to make fasteners, body parts and decor.

Types of lathes:

- manual. The turner re-tunes the tool every time and constantly participates in the process;

- automated with a copying mechanism for carrying out template work. Managed;

- automatic. They work independently based on installed software and adjust the workflow based on logical algorithms.

Drilling

Needed to create holes of the required depth in wood. Suitable for working with high hardness rocks where precision is required. There are:

- vertical;

- horizontal;

- horizontal for recessed drilling. You can control runout and axis stabilization to make the process more precise;

- radial. You can quickly and accurately change the direction of drilling.

Device classification

Universal woodworking machines are suitable for most woodworking tasks.

By degree of versatility

Many devices use the principle of tool multitasking - when the same machine unit can perform several functions, it is enough to change the attachment. This technique is well suited for sequential processing of edges, cutting grooves, and other individual work operations.

Mini woodworking machine for sawing and drilling

All tools must be in stock, at least one at a time. This will reduce the number of downtimes due to the breakdown of one of them.

On average, such machines are capable of performing 5 or 6 functions. The main ones are: cutting wood using a cutter, sawing and planing using a cutting shaft, drilling, milling, grinding, and the last task can be solved using a disk or tape.

By type and power of equipment

Equipment power is one of the most important selection criteria. It determines how thick the workpiece can be processed and what sizes of grooves and holes can be made. With the proper dexterity and knowledge, very soon you will be able to create such a machine - already from wood cut by yourself.

Wood lathe

There is one more characteristic that will allow you to quickly and efficiently create such a masterpiece - the number of revolutions of the electric motor, which is often directly related to the power of the motor.

ATTENTION!

Basically, home machines have a power in the range of 0.9−3 kW. In this case, the shaft rotation speed varies from 2800 to 3600 rpm. That is, lower ones are not produced, and there is no point in purchasing higher ones.

By other criteria

It is very important to pay attention to the replaceability of parts and attachments. Even a multifunctional machine necessarily has its main function, and the rest can be provided by interchangeable attachments. In one, the manufacturer has provided a larger number of replaceable knives; in the other, it has improved the shaft or mounts for drilling.

Multifunctional machine configuration option

Some models may use others instead of these tools. For example, instead of a cutter there is a knife module, instead of a grinding wheel there is a belt. When choosing a machine, you need to pay attention to the size of the circular saw, the maximum dimensions of the drill, the working width of the planing, and the cutting depth. All these parameters must be indicated in the product data sheet.

The machine must be secured to the workbench only with special devices provided by the manufacturer. Self-activity will not lead to anything good here.

By choosing the maximum dimensions, you increase the capabilities of the machine in terms of processing different workpieces on it. But at the same time, the power of the electric motor increases, and hence the energy consumption and the dimensions of the machine itself.

Prices of woodworking machines for home depending on the type and power of equipment

Another important factor that needs to be taken into account when purchasing a machine is what maximum loads the equipment can withstand. And in this case, the determining factor is the power of the machine.

Price table for machines depending on type and power:

| Machine type | Scope of application and features | Power, W | price, rub. |

| Highly specialized |

| 2500-12000 | from 21000 |

| Universal |

| 450-3000 | from 16000 |

| Household |

| 1500-2000 | from 8000 |

Household machines are relevant for home use. Let's figure out which 220 V combined woodworking machine for home is best for you.

Comparative review of the most popular models and manufacturers

Today we have already mentioned one of the Belarusian brands. − a fairly strong enterprise that has been manufacturing machine tools for about 6 years. The company's office is located in Mogilev. The company's representative offices are located in almost all countries of the former CIS. Let's look at one more product in more detail.

Belmash SDM-2500 PRO, as its creators assure, is convenience, comfort, safety at the best price

This combined woodworking machine from Mogilev is designed to perform various technological operations.

Main functions:

- planing (jointing) along the plate or edges;

- planing (jointing) at an angle (along the edges);

- sawing along and across the fibers;

- sawing along the grain at an angle using

combined line;

- sawing across the grain at an angle using a rotating bracket;

- milling with disc cutters;

- milling with end mills, drilling.

Review of the combined woodworking machine "Belmash" SDM-2500 PRO

More details on Catalog.Onliner : Woodworking machines “Ant” are the brainchild of JSC “Algorithm” from the city of Rybinsk. The company's official website presents 5 new products of a fairly budget class.

Products of the Ant brand are a budget solution for a small workshop

In addition, here you can find out about the cost of consumables.

But the company offers these prices for related products and replacement parts

And one more manufacturer that needs to be mentioned in this review. Woodworking machines of Uni-Master LLC. One of the most popular models is the Master-Universal 2500E. This machine has been in great demand for many years.

The Master-Universal 2500E machine fully lives up to its name - it is truly universal

Appearance and characteristics of the Master-Universal 2500E machine

It can be used for sawing (longitudinal, transverse and at an angle), thicknessing, planing (horizontally and at an angle), drilling, milling. You can find out how effectively these functions work from the reviews.

Review of the combined woodworking machine “Master-Universal 2500E”

More details on Forum.Woodtools:

| Name | Peculiarities | Functions | Average price (as of April 2022), rub. |

| Designed for processing wood (plywood, particle boards, etc.) by sawing and jointing with manual feeding of the workpiece. | Planing on a plane and at an angle. Longitudinal sawing in different variations, including at an angle. Cross sawing. | 22 000 |

| The machine is equipped with an updated combined ruler, which includes parallel and angular stops. All scales are applied to it by inkjet followed by laser curing. | Planing (jointing) along the plate or edges, as well as at an angle. Sawing in different planes and at an angle. Sawing along the grain at an angle using a combination ruler. Sawing across the grain at an angle using a swivel bracket. Milling with disc cutters. Milling with end mills, drilling. | 35 000 |

| The machine has a combined line, similar to SDM series machines. Using carriages moving along the guides, you can adjust the required position of the parallel guide (for planing and sawing) and the rotary bracket (for sawing at an angle). | Planing (jointing) along a plate or edges. Planing (jointing) at an angle (along the edges). Thickening. Sawing along and across the fibers. Sawing along the grain at an angle using a combination ruler. Sawing across the grain at an angle using a swivel bracket. Milling with disc cutters. | 42 000 |

| A model with the ability to plan lumber to a given thickness (thicknessing). Available in two versions with different types of supply voltage. | Sawing. Jointing. Milling with a disk cutter. Milling with a shaped cutter. Thickening. Drilling. | 46 000 |

| A multifunctional woodworking machine is designed for processing wood blanks and its derivatives. | Thickening. Planing on a plane. Planing at an angle. Planing with a clamping device. Longitudinal sawing. Longitudinal sawing along the edge at an angle. Quarter selection. Cross sawing. Cross cutting at an angle. Milling. Drilling. | 35 000 |

| Connecting the motor using a belt drive reduces noise levels and prevents unnecessary loads. The table is made of cast iron. | Planing, sawing, drilling and milling operations. | 33 000 |